Balanced excavation method for room and pillar mining method

A room-and-pillar and balanced technology, which is applied in ground mining, mining equipment, earth square drilling and mining, etc., can solve the problem that the capacity of the bolter is not fully utilized, the efficiency of the machine and personnel is not high, and the continuous coal miner does not fully utilize the equipment capacity. and other issues to achieve the effect of increasing coal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

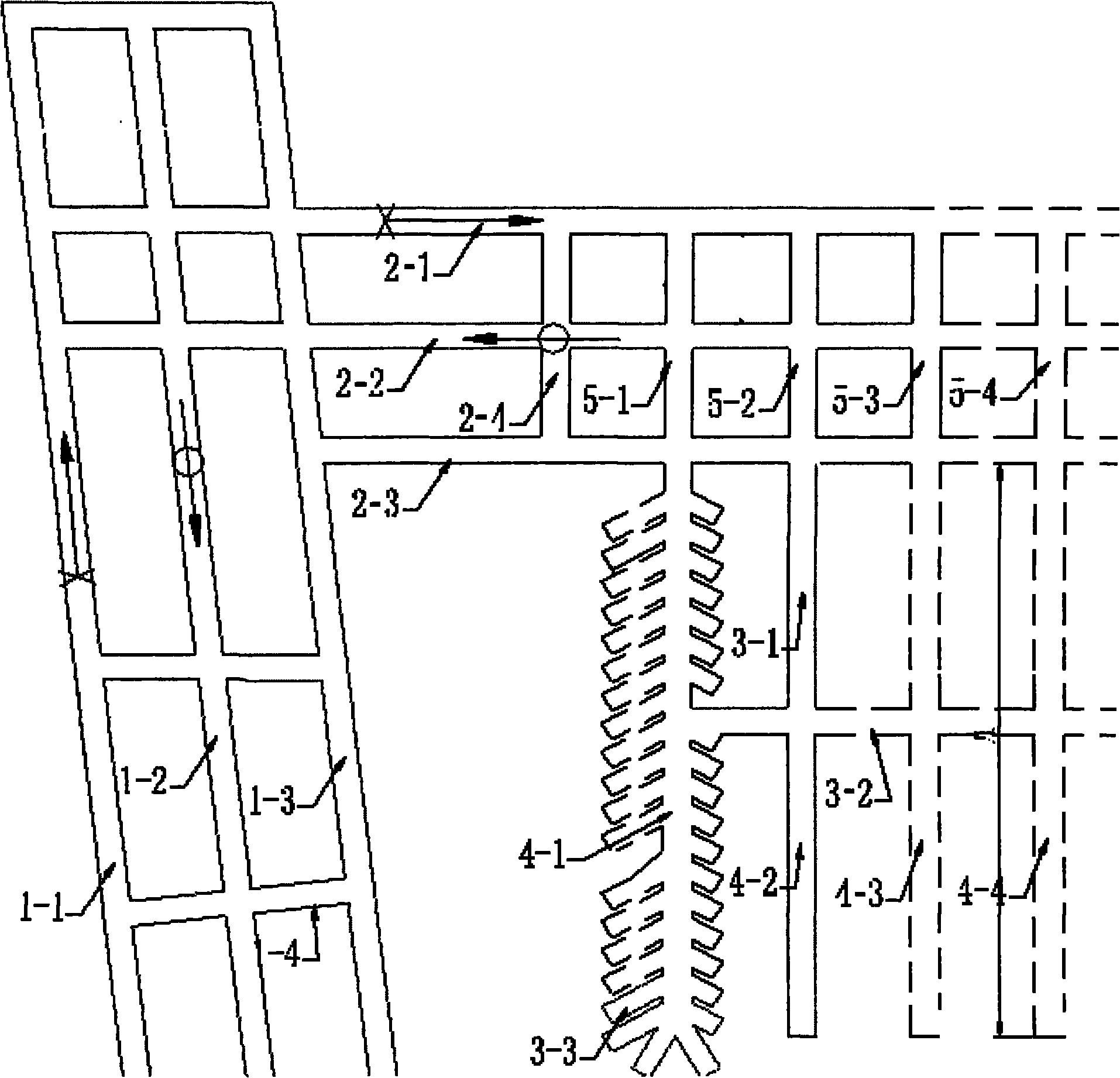

[0026] The idea of overall balanced mining of the present invention is: balance the time requirements of digging, mining and supporting. Calculate in detail the time required for continuous coal mining machine excavation and the time required for mining when each working face advances the distance of a connecting roadway, and check it with the time required for supporting the above roadway with a bolter machine. The support time should be less than or It is equal to the sum of excavation time and recovery time.

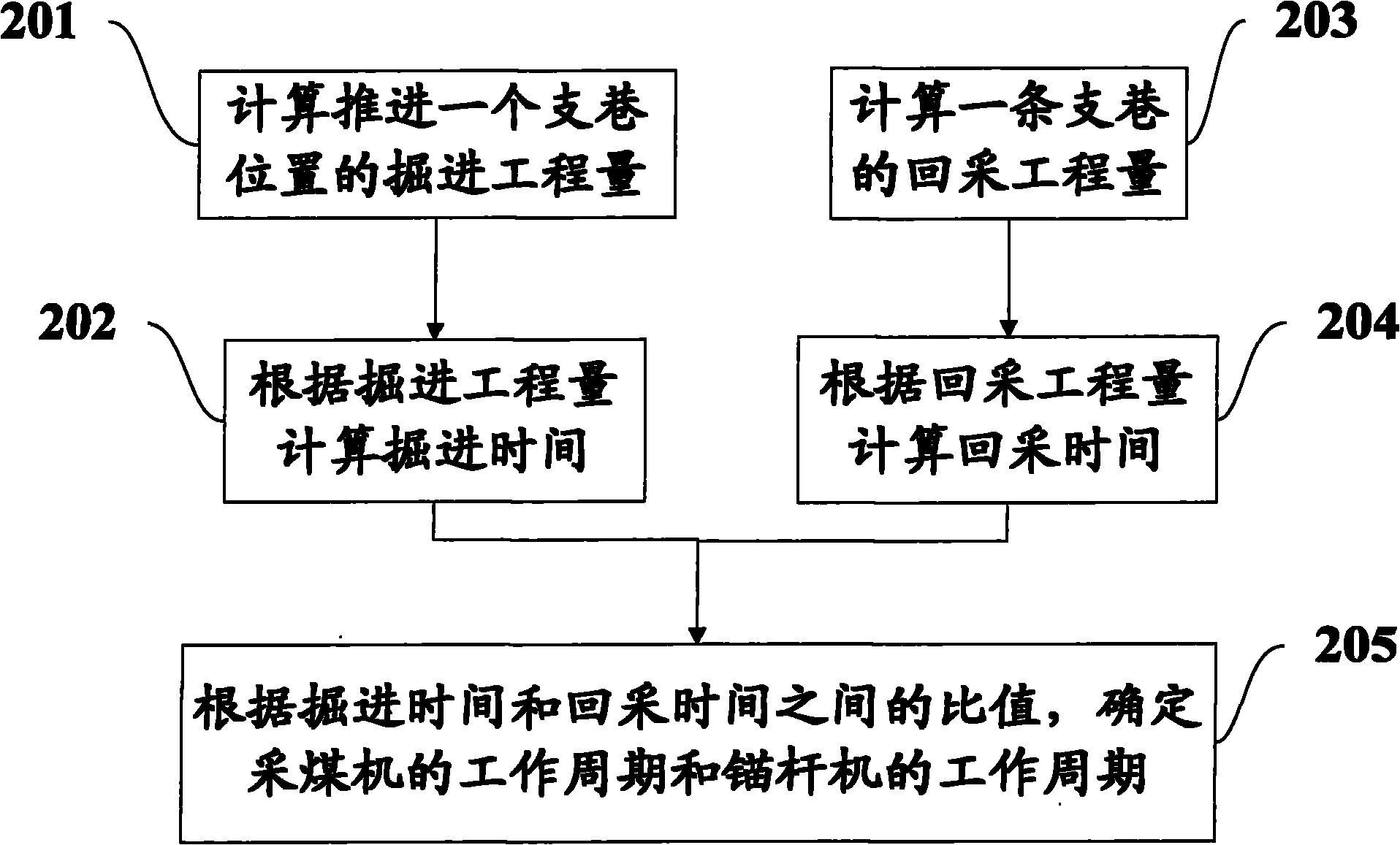

[0027] Such as figure 2 Shown, the balanced mining method that is used for the room-and-pillar coal mining method of a kind of embodiment of the present invention comprises:

[0028] In step 201, the excavation engineering quantity for advancing a branch roadway position is calculated. The excavation engineering amount may be an excavation length. Other measures are also possible, eg volume to be excavated and seam weight.

[0029] In step 202, the excavation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com