Reactive power compensation device for traction substation in electrified railway

A technology for traction substations and electrified railways, which is applied in reactive power compensation, circuit devices, reactive power adjustment/elimination/compensation, etc., and can solve problems such as inability to adapt to rapidly changing loads, inability to stabilize power supply voltage, and poor operational reliability, etc. problems, to achieve the effect of quickly adapting to load changes, fast construction speed, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

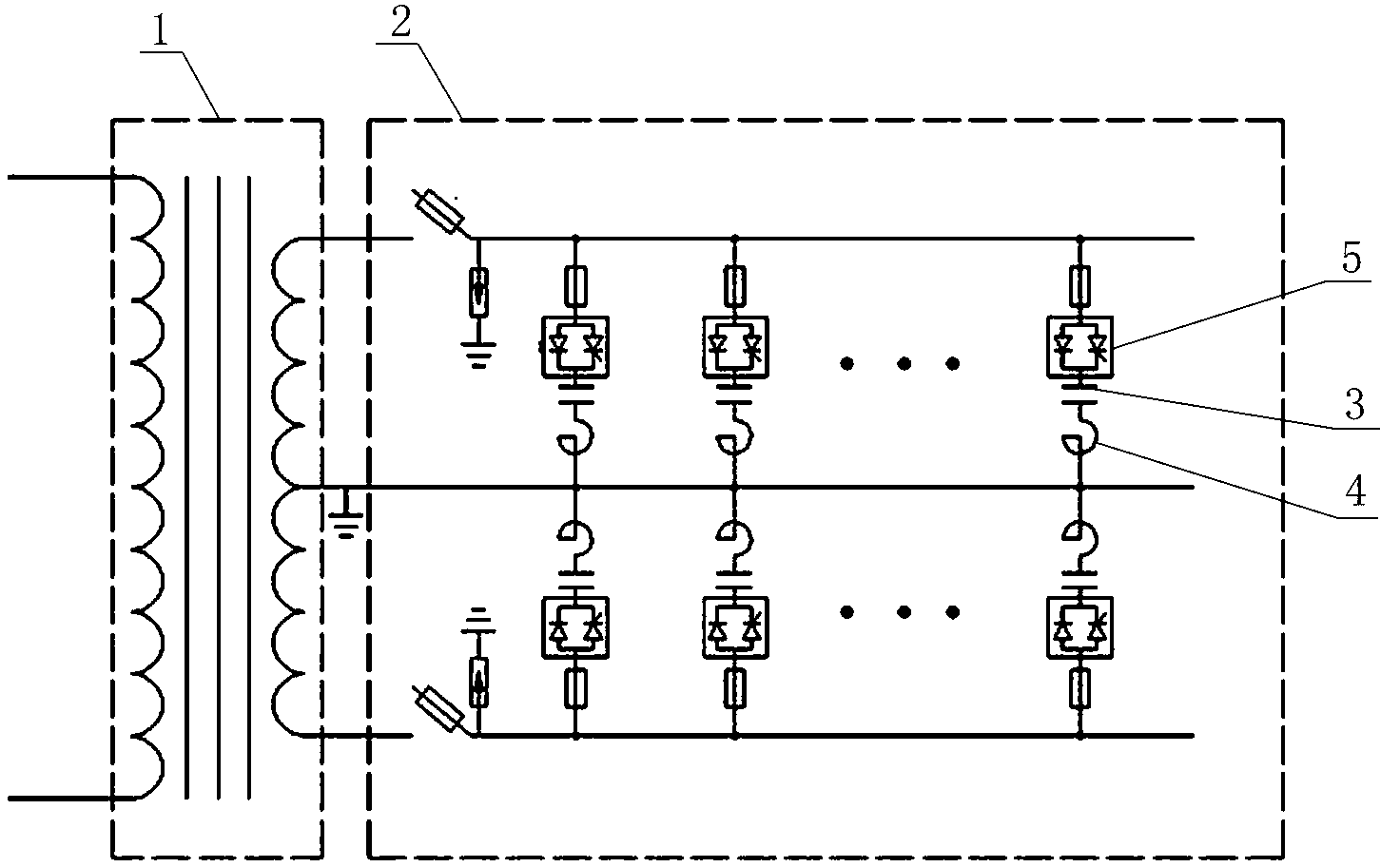

[0012] Such as figure 1 As shown, the reactive power compensation device of the electrified railway traction substation includes a special single-phase transformer 1 and a box power distribution device 2; several groups of contact devices, capacitors 3, and reactors 4 are installed in the box power distribution device 2 Reactive power compensation branches connected in series, both ends of each group of reactive power compensation branches are connected to the secondary side of the special single-phase transformer 1;

[0013] The secondary side of the special single-phase transformer 1 includes a set of windings with center taps; both ends of each set of reactive power compensation branches are connected to the windings with center taps;

[0014] The contact devices in each group of reactive power compensation branches are non-contact switches 5;

[0015] In specific implementation, a knife fuse switch (or circuit breaker), a zinc oxide arrester, and a fuse are connected in s...

Embodiment 2

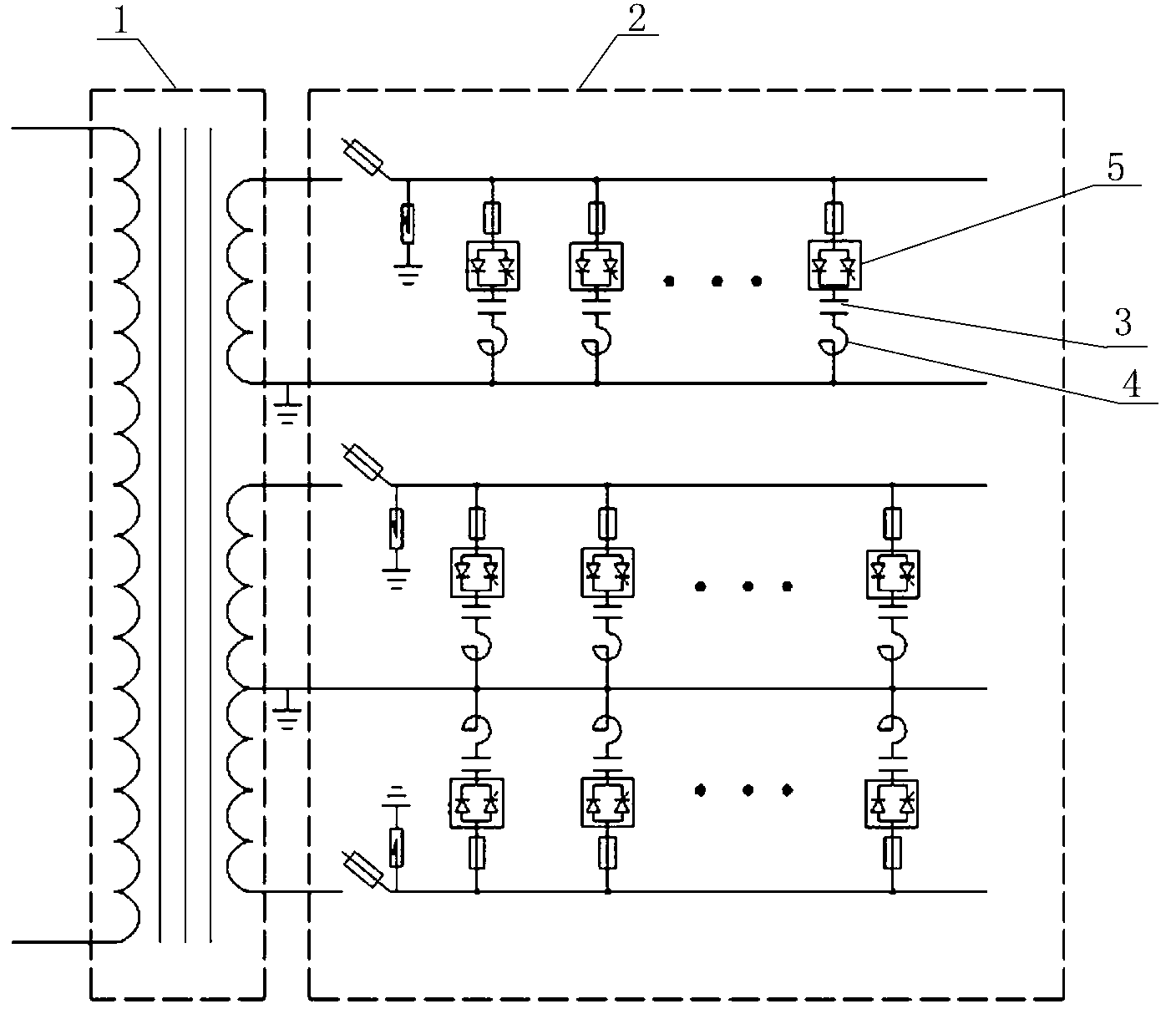

[0018] Such as figure 2 As shown, the reactive power compensation device of the electrified railway traction substation includes a special single-phase transformer 1 and a box power distribution device 2; several groups of contact devices, capacitors 3, and reactors 4 are installed in the box power distribution device 2 Reactive power compensation branches connected in series, both ends of each group of reactive power compensation branches are connected to the secondary side of the special single-phase transformer 1;

[0019] The secondary side of the special single-phase transformer 1 includes two sets of windings, one of which has a middle tap; the two ends of each set of reactive power compensation branches are respectively connected to the two sets of windings;

[0020] The contact devices in each group of reactive power compensation branches are non-contact switches 5;

[0021] In specific implementation, a knife fuse switch (or circuit breaker), a zinc oxide arrester, ...

Embodiment 3

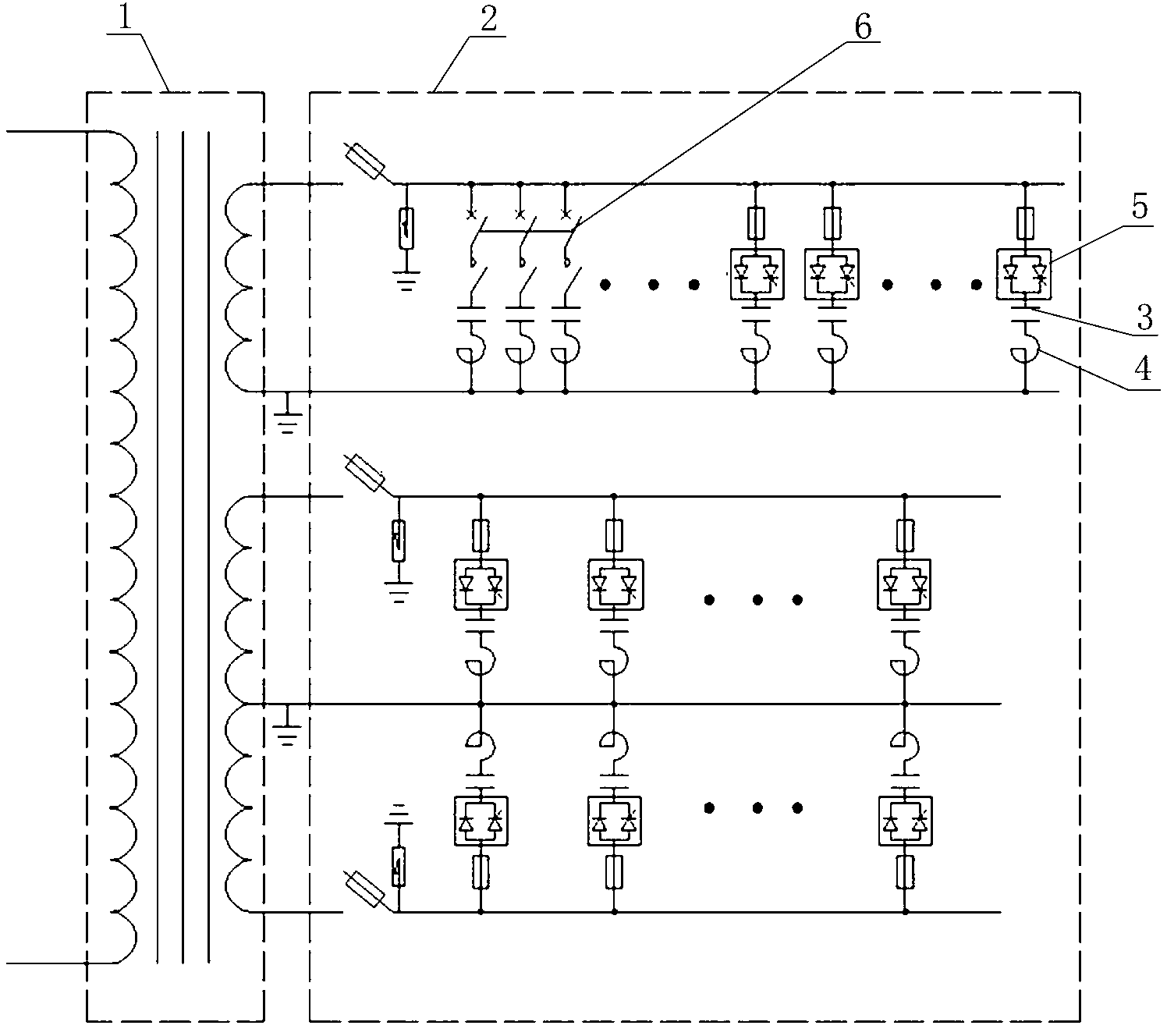

[0024] Such as image 3 As shown, the reactive power compensation device of the electrified railway traction substation includes a special single-phase transformer 1 and a box power distribution device 2; several groups of contact devices, capacitors 3, and reactors 4 are installed in the box power distribution device 2 Reactive power compensation branches connected in series, both ends of each group of reactive power compensation branches are connected to the secondary side of the special single-phase transformer 1;

[0025] The secondary side of the special single-phase transformer 1 includes two sets of windings, one of which has an intermediate tap; the two ends of each set of reactive power compensation branches are respectively connected to the two sets of windings;

[0026] The contact devices in several sets of reactive power compensation branches connected to the windings with intermediate taps are non-contact switches 5, and the contact devices in the remaining group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com