Molding die, and molding die manufacturing method

A manufacturing method and a technology for forming a mold, which are applied in the manufacture of optical record carriers, recording/reproducing by optical methods, instruments, etc., and can solve the problems of deterioration, easy deformation and formability of molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

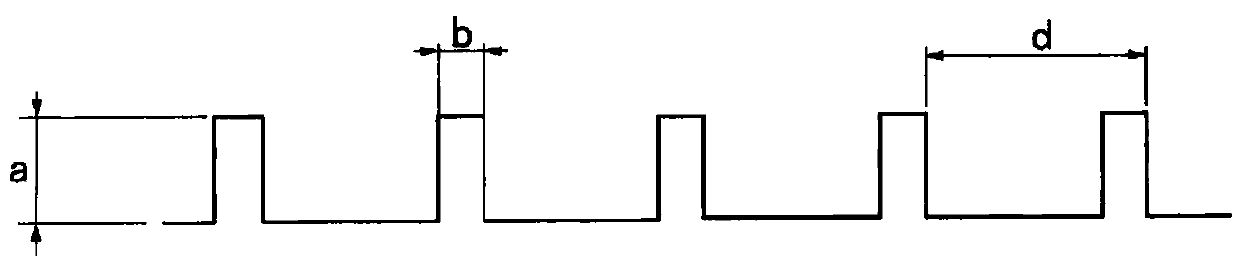

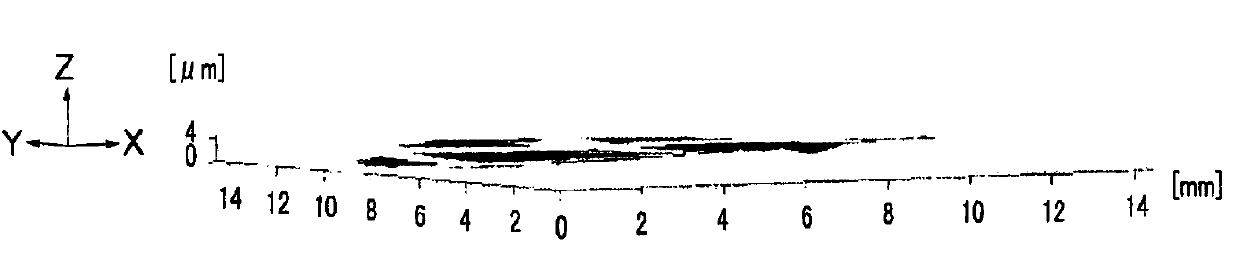

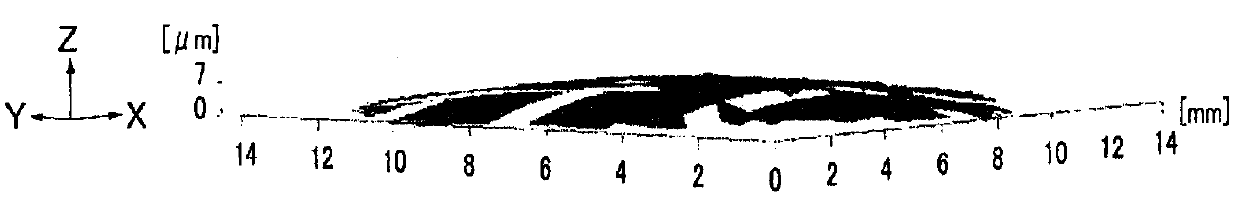

[0100] Produced on a 1mm thick flat SUS substrate by photolithography using near ultraviolet rays image 3 and Figure 4 For the resist structure 11 of the size shown, only 20 μm of Ni was deposited on the SUS substrate by Ni electroforming. Then, Ni was vacuum vapor-deposited to form a conductive film on the substrate formed in the second step, and then Ni electroforming was performed to deposit Ni to a thickness of 500 μm.

[0101] After the resist is removed, the forming die 10 is obtained. Oxygen plasma treatment is applied to the surface of the molding die to perform molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com