Vehicle seat slide device

A sliding device, vehicle technology, applied to vehicle seats, special positions of vehicles, movable seats, etc., can solve problems such as productivity problems, deformation, damage to operating handles, etc., to save space, reduce the number of parts, and simplify installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

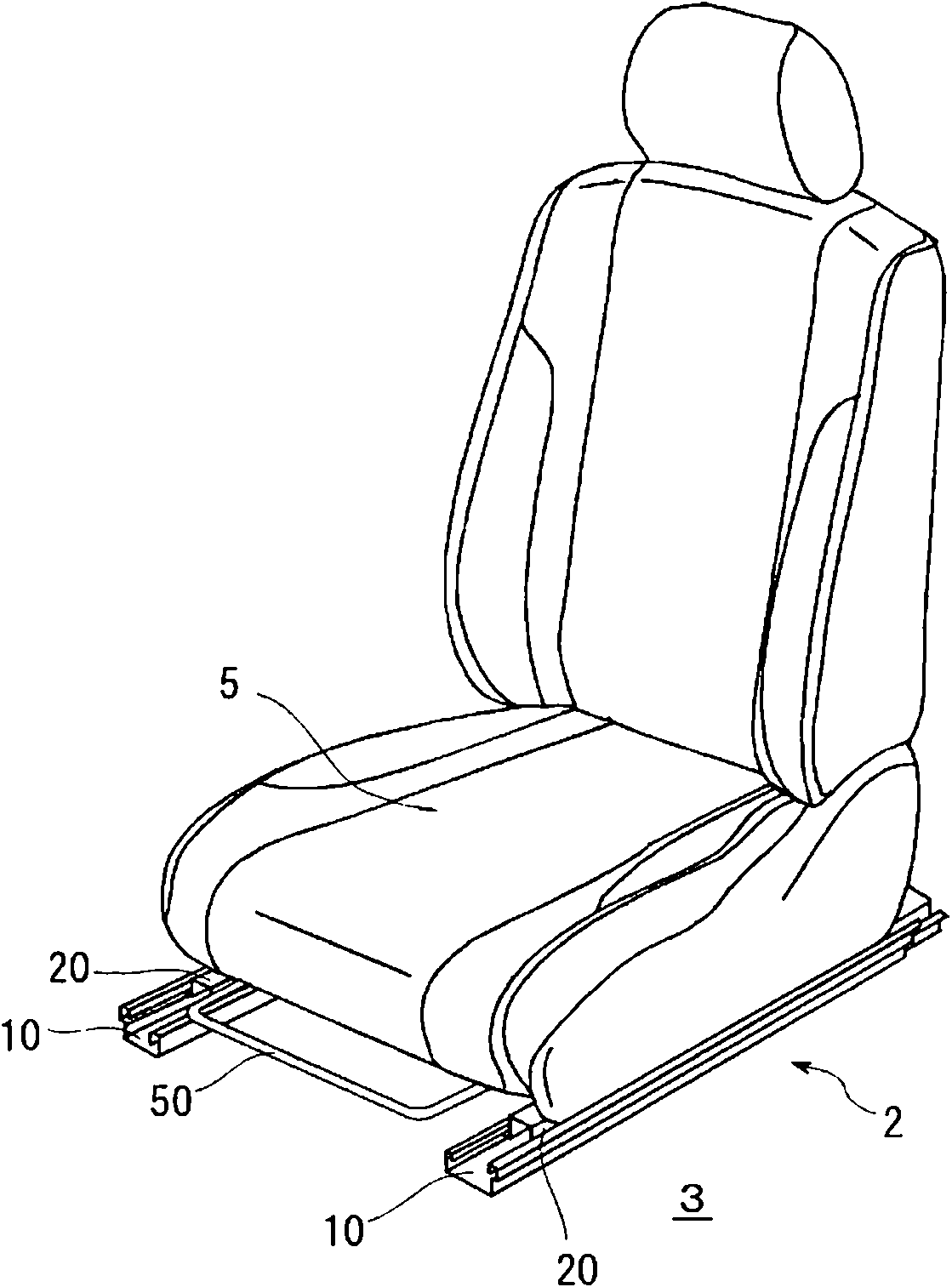

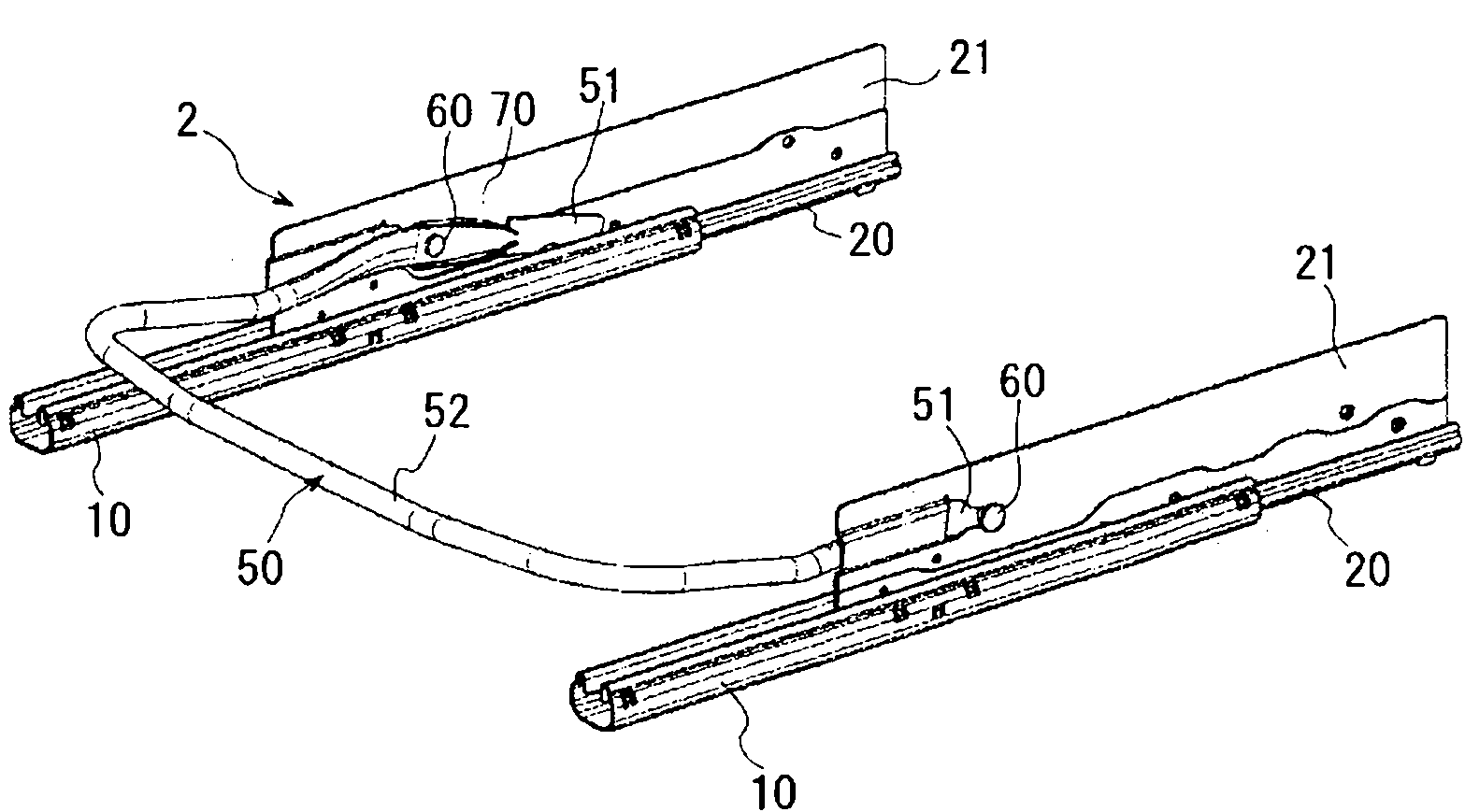

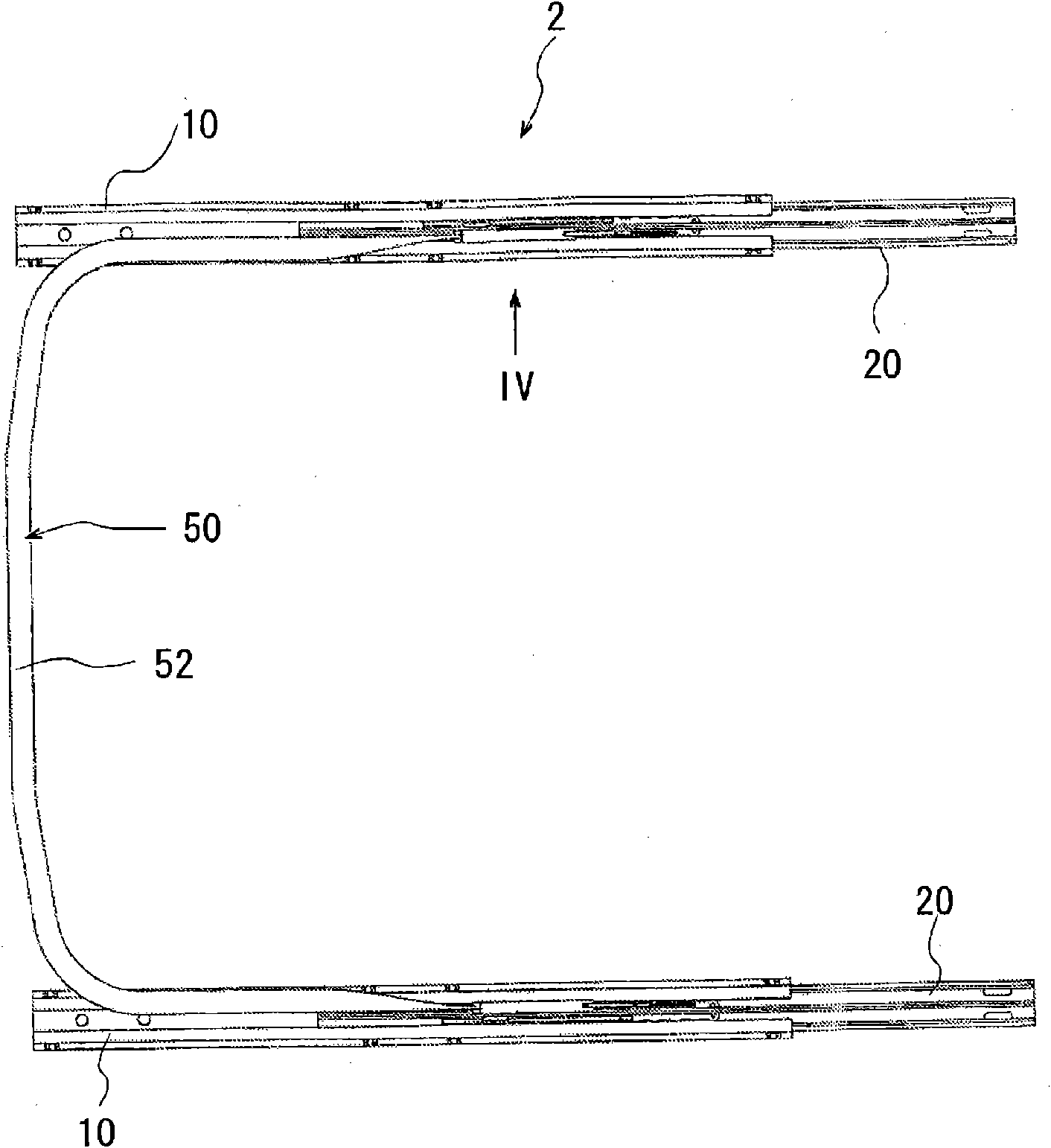

[0033] Hereinafter, embodiments of the vehicle seat sliding device according to the present invention will be described with reference to the drawings. figure 1 is a perspective view showing a vehicle seat sliding device assembled in a vehicle seat, figure 2 It is a perspective view showing the seat sliding device for a vehicle. The vehicle seat sliding device 2 is provided with: a pair of left and right lower rails 10 fixed to the vehicle floor 3; a pair of left and right upper rails 20 fixed to the vehicle seat 5; Handle 50.

[0034] Such as Figure 6 As shown, a pair of lower guide rails 10 has: a bottom wall portion 11; a pair of side wall portions 12 extending upward from both ends of the bottom wall portion 11; The lower flange wall portion 13. The lower rail 10 is formed by bending a single plate, and has a substantially U-shaped cross section.

[0035] The upper rail 20 has: a vertical wall portion 21 as a vertical wall; a pair of bottom wall portions 22 bent out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com