Curtain wall for green building decoration

A green building and curtain wall technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of inability to effectively fix the curtain wall, incapable of shock absorption and energy dissipation, broken connectors, etc. Service life, effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

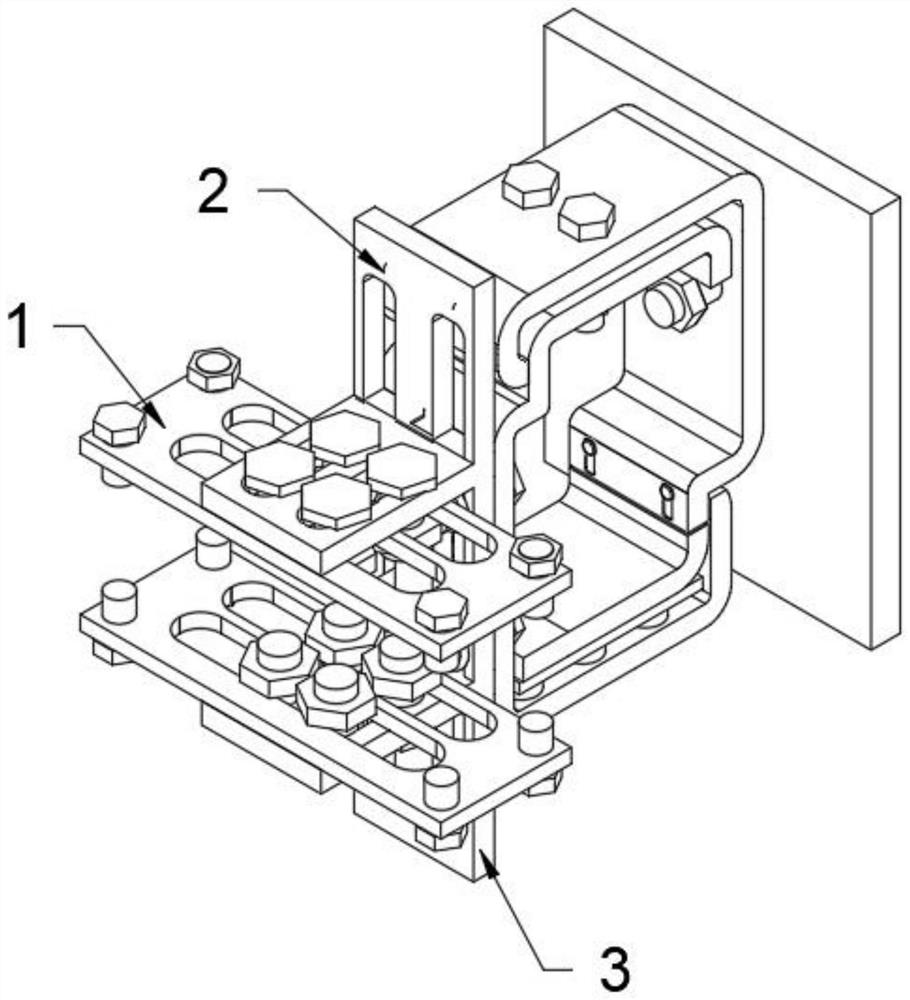

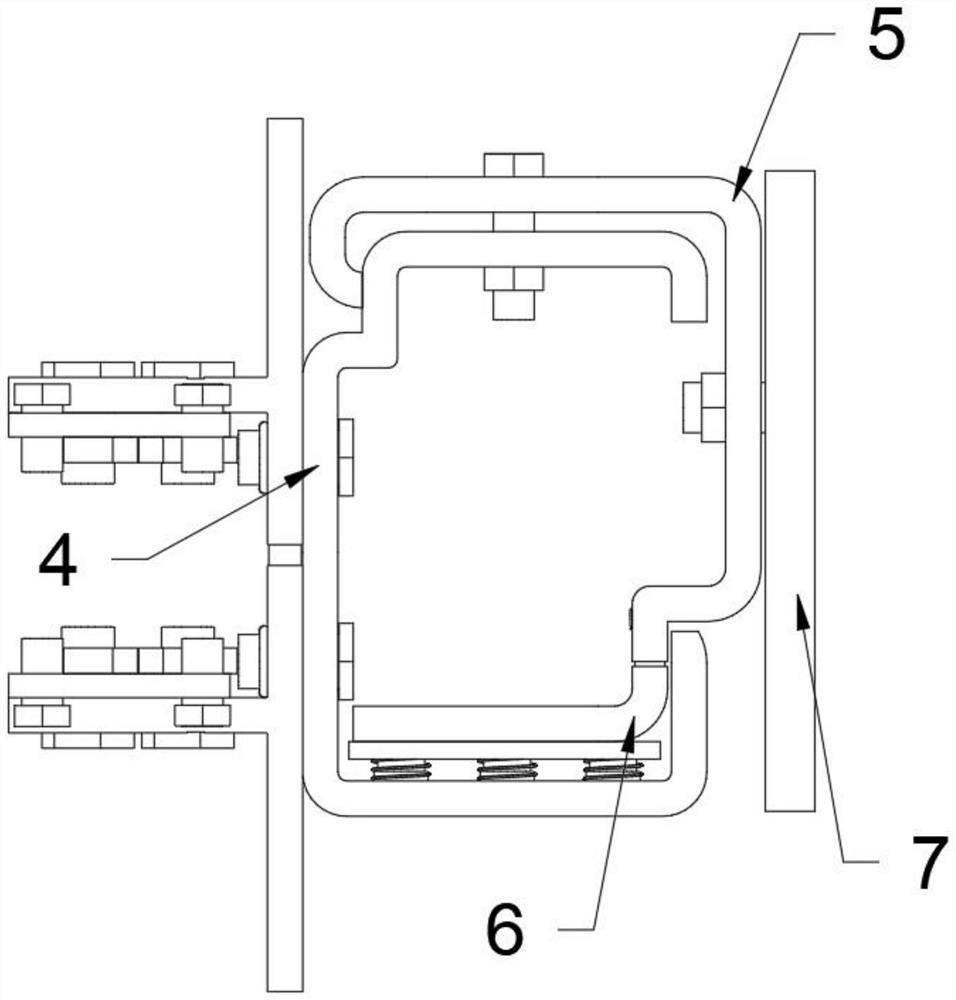

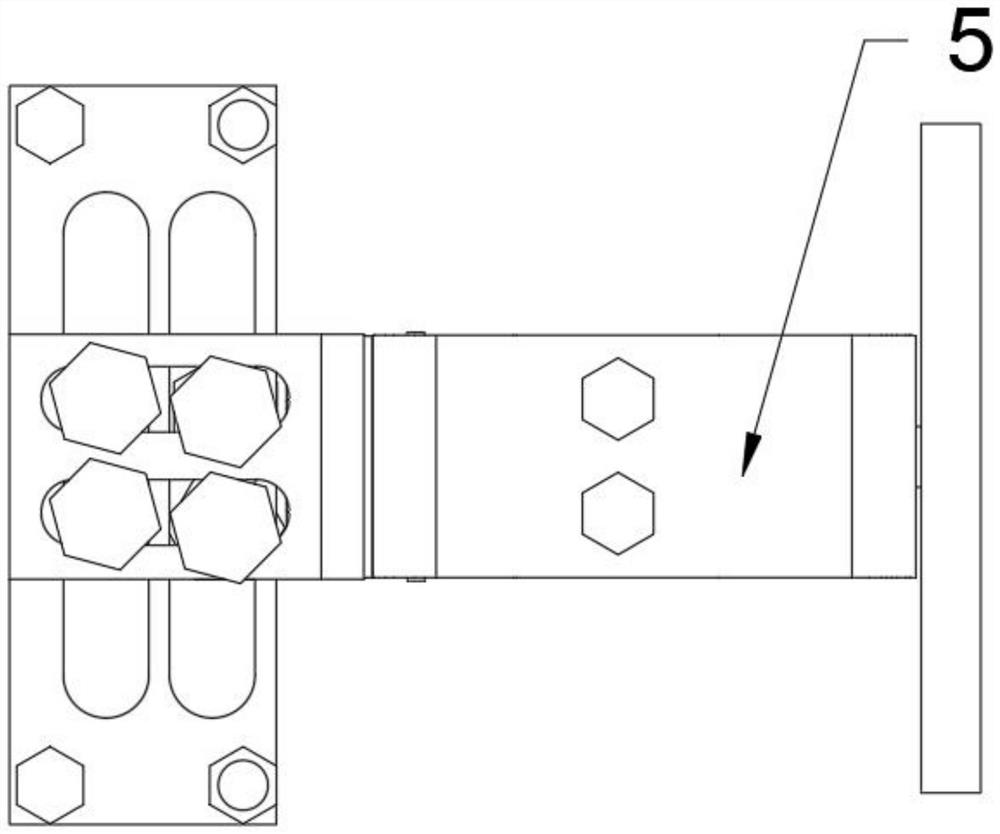

[0034] as attached figure 1 to attach Figure 10 Shown:

[0035] The present invention provides a curtain wall used for green building decoration, including: a back bolt slide plate 1, a main support plate 2, a sliding drag 4, a curtain wall drag 5, a dry-hanging curtain wall 7, and the main support plate 2 is inserted into the auxiliary support plate 3 at the inner top position; there are two backbolt slides 1, and the two backbolt slides 1 are respectively screwed to the inner positions of the main support plate 2 and the auxiliary support plate 3; the sliding drag 4 is screwed to the main support plate 2 and the right side of the auxiliary support plate 3; the main support plate 2 includes a main T-shaped plate 201, a T-plate chute 202, a support plate chute 203, a main board chute 204 and a main board slot 205, and the main T-shaped plate 201 There are two T-plate chute 202 of the same size inside the transverse plate of the main T-shaped plate 201, a main board chute 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com