Automobile collision energy magnetic field absorber

A collision energy and absorber technology, applied in the direction of bumpers, etc., can solve the problems of complex structure, expensive price, large volume, etc., and achieve the effect of simple maintenance, low use cost and reduced economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

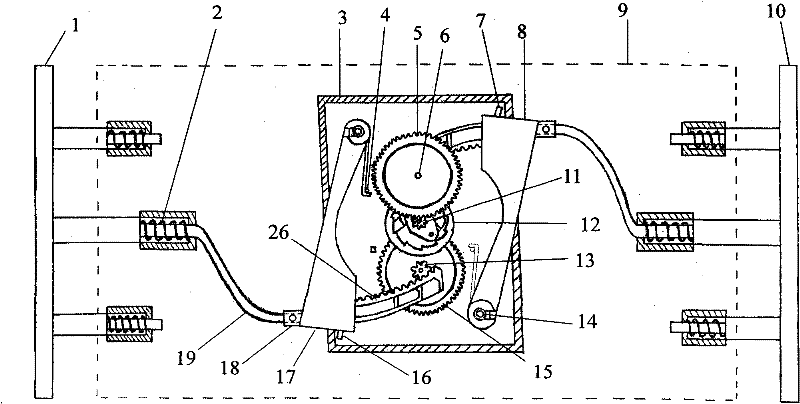

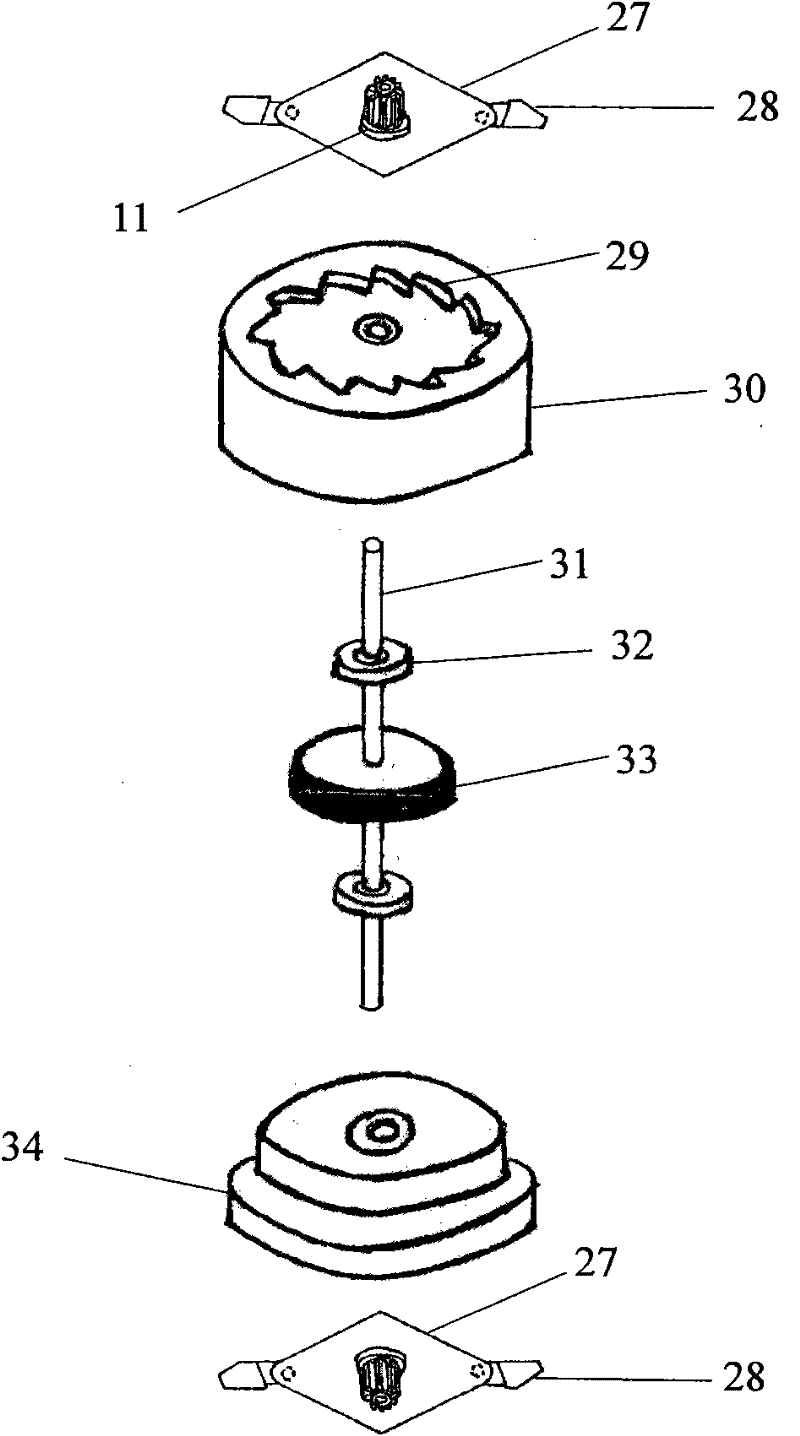

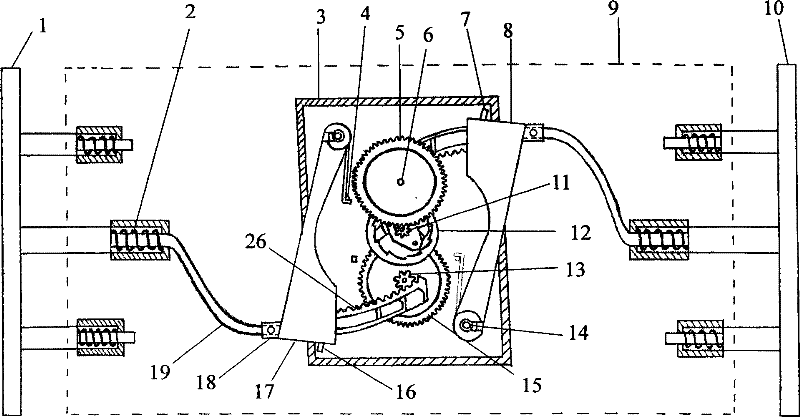

[0014] The present invention is installed under the automobile chassis, and its structural schematic diagram is as follows: figure 1 As shown, it is mainly composed of pressure handle, transmission gear, absorption wheel and so on.

[0015] When a car collides front and rear, the front and rear bumpers of the car will receive the collision energy, which will be damped and absorbed through the spring shock absorber, and the energy will be absorbed a little. The inner teeth of the pressing handle on the top are meshed with the passing wheels of the transmission gear, and the energy on the pressing handle is transmitted to the transmission gear through the transmission of the internal teeth of the pressing handle and the passing wheels of the transmission gear. The transmission gear shaft is fixed on the casing, and the transmission gear can rotate around the transmission gear shaft. During the gear transmission process, a little energy will be absorbed and consumed, but most of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com