Suspender replacement method for tie bar type overpass bridge

A replacement method and a technology for overpass bridges, which are applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of suspender 2 corrosion, high risk, poor precision, etc., and achieve simple and convenient operation, reduce safety hazards, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

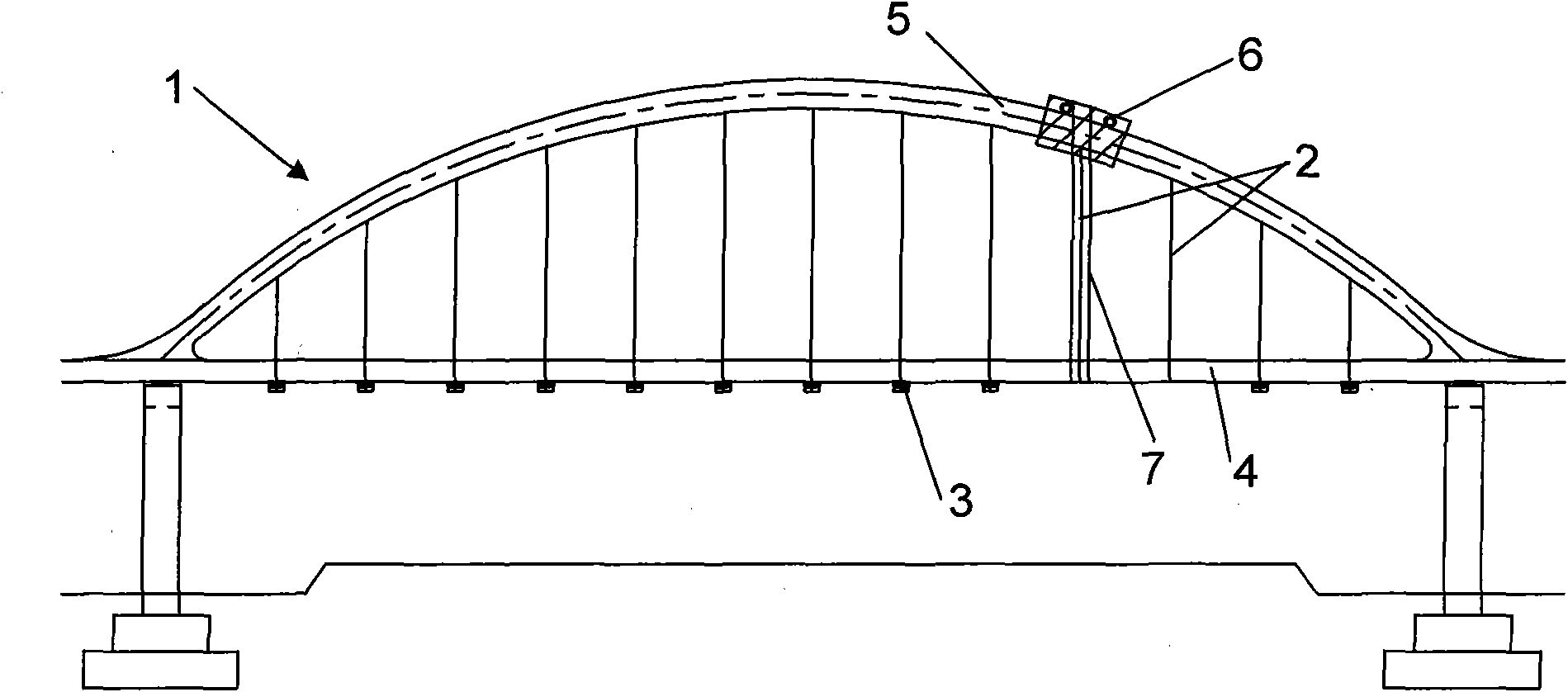

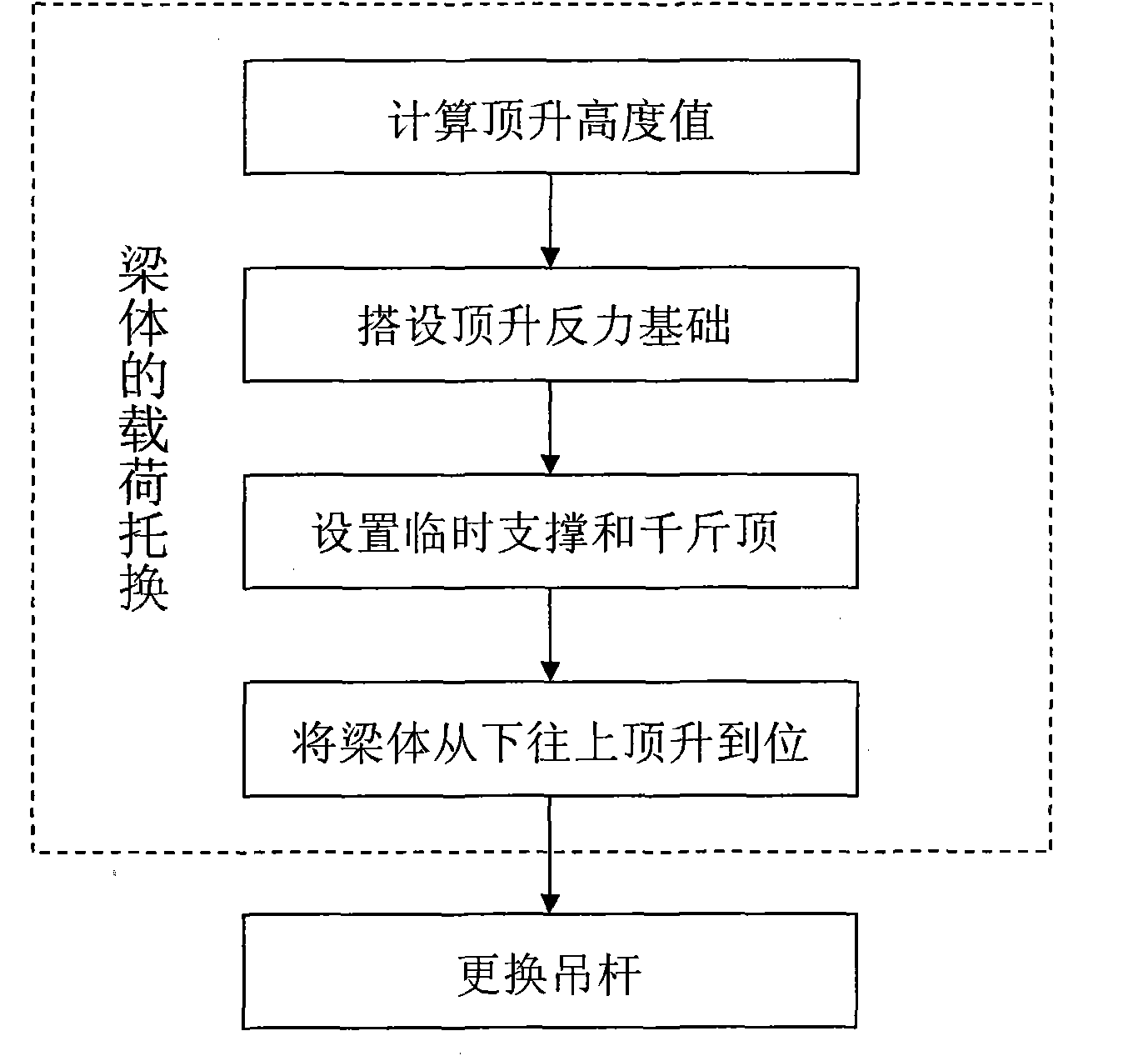

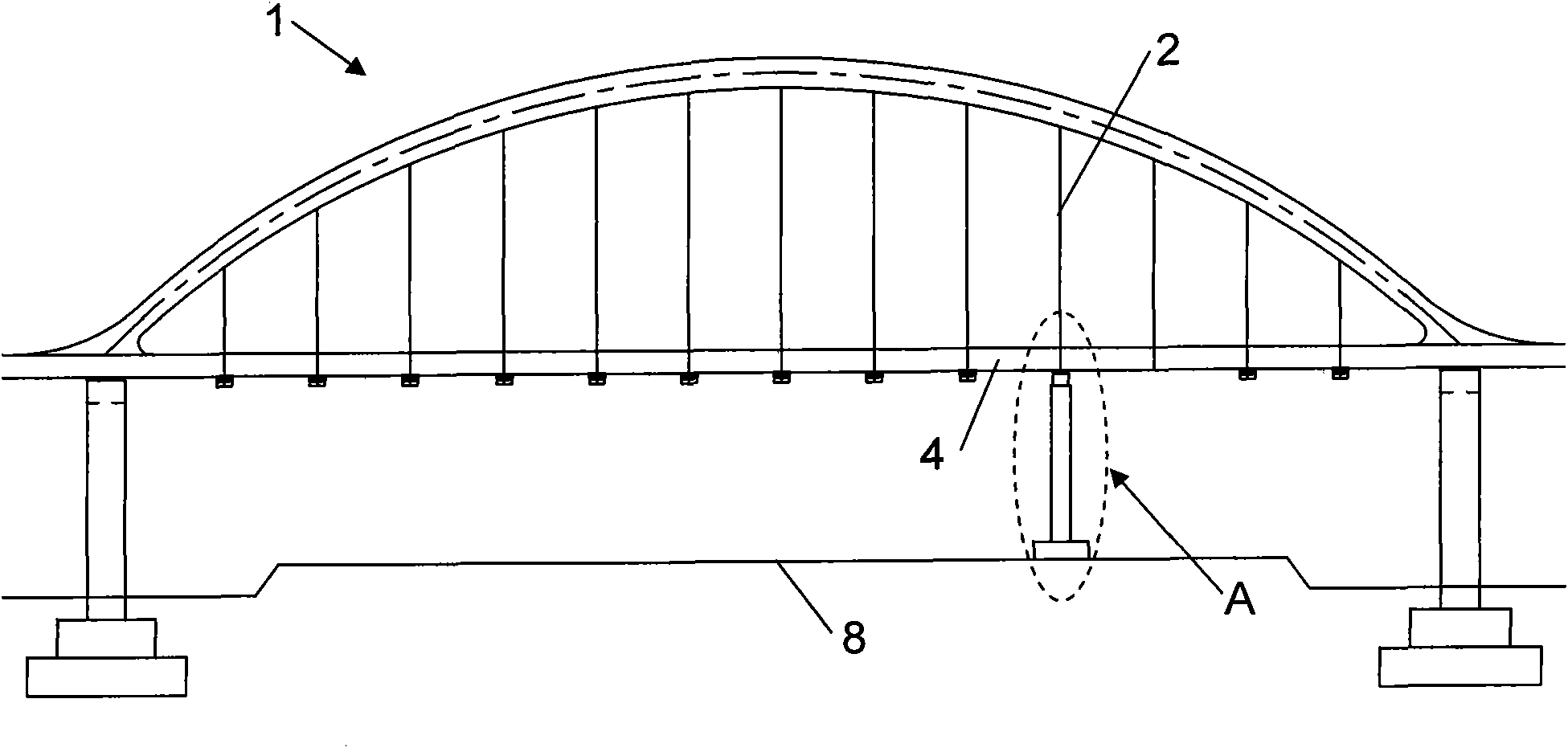

[0023] Please combine figure 2 , image 3 , Figure 4 As shown, the suspender replacement method of the tie-rod flyover bridge is the same as the prior art, and also includes the steps of underpinning the beam body 4 that needs to be replaced with the suspender 2 and replacing the suspender 2 . What is different from the prior art is that the specific steps of underpinning the load of the beam body 4 are as follows: First, according to factors such as the structure of the beam body 4 and the time when the suspender 2 is damaged, calculate the requirements for the parts of the beam body 4 that need to be replaced with the suspender 2. The height value of the jacking; then set up the jacking reaction foundation 8 at the corresponding bottom of the above-mentioned beam body 4 parts, and the jacking reaction foundation 8 can ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com