No-setting pump no-liquid idling preventing protector

An anti-idling and protector technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of reducing product specifications and varieties, false protection, no protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

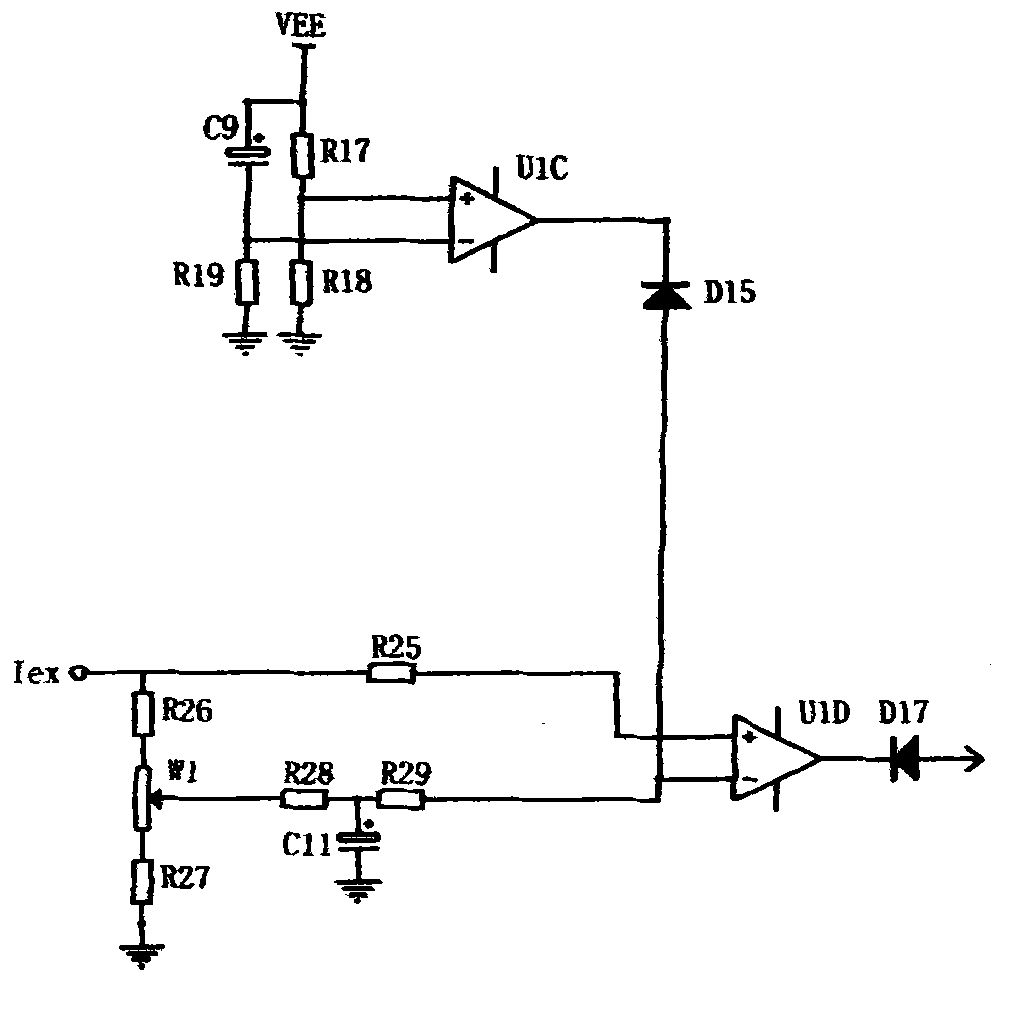

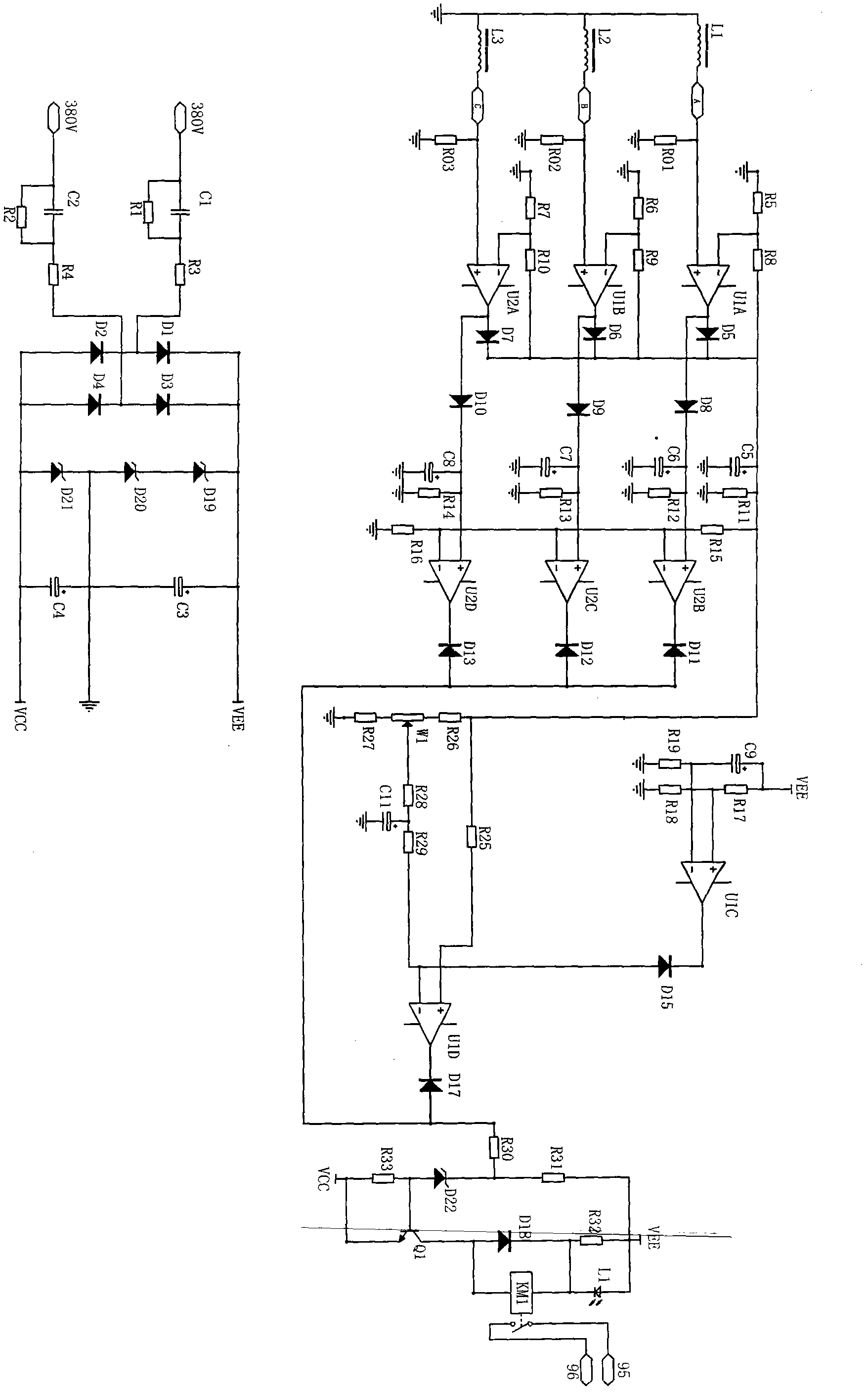

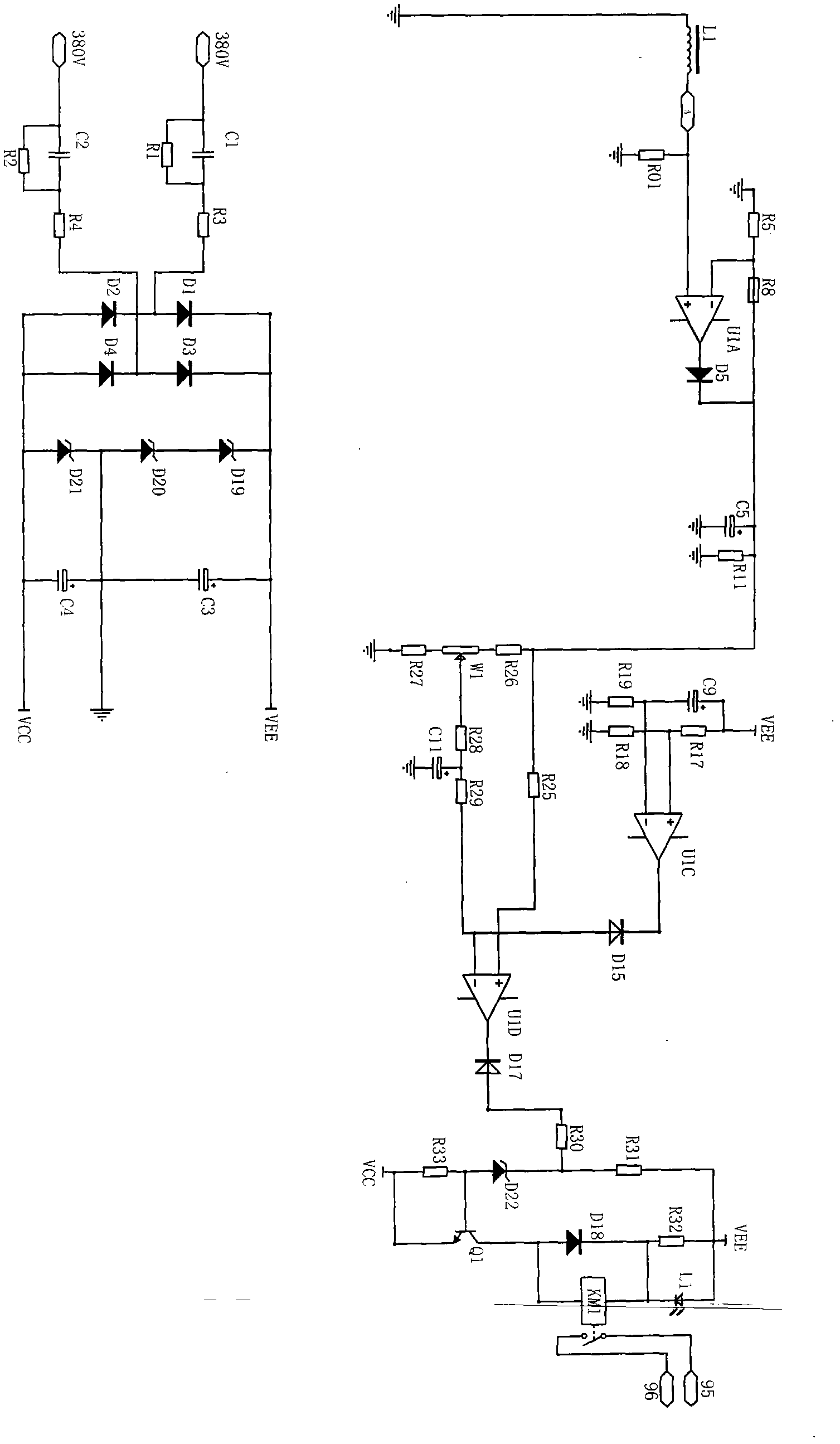

[0013]Three-phase non-setting pump aneroid anti-idling protector, the working current of the pump motor detected by the three-phase current transformer is respectively taken from the signal resistor to amplify and rectify the synthesized, through the pump aneroid anti-idling self-determined benchmark The memory module controls the pump motor through the control circuit to realize no-load protection. Specifically, one end of the current transformer L1, current transformer L2, and current transformer L3 is connected to the common terminal, and the other end of the current transformer L1 is connected to the signal resistor R01 and The positive input terminal of the operational amplifier U1A, the other end of the current transformer L2 is connected to the signal resistor R02 and the positive input terminal of the operational amplifier U1B, the other end of the current transformer L3 is connected to the signal resistor R03 and the positive input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com