Camera module

A technology for camera modules and moving components, applied in cameras, optics, instruments, etc., can solve the problems of hand vibration, blur, and prone to hand vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

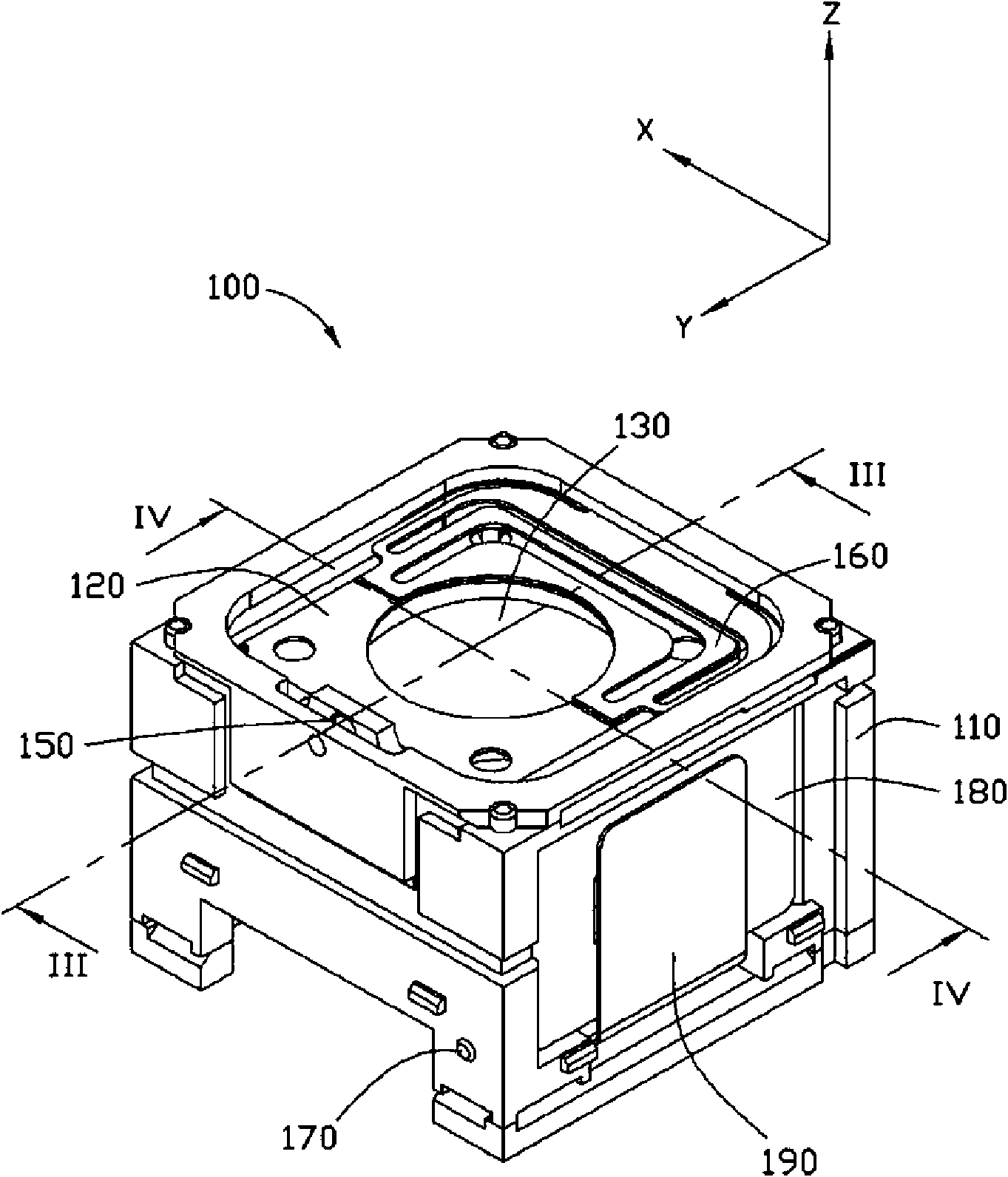

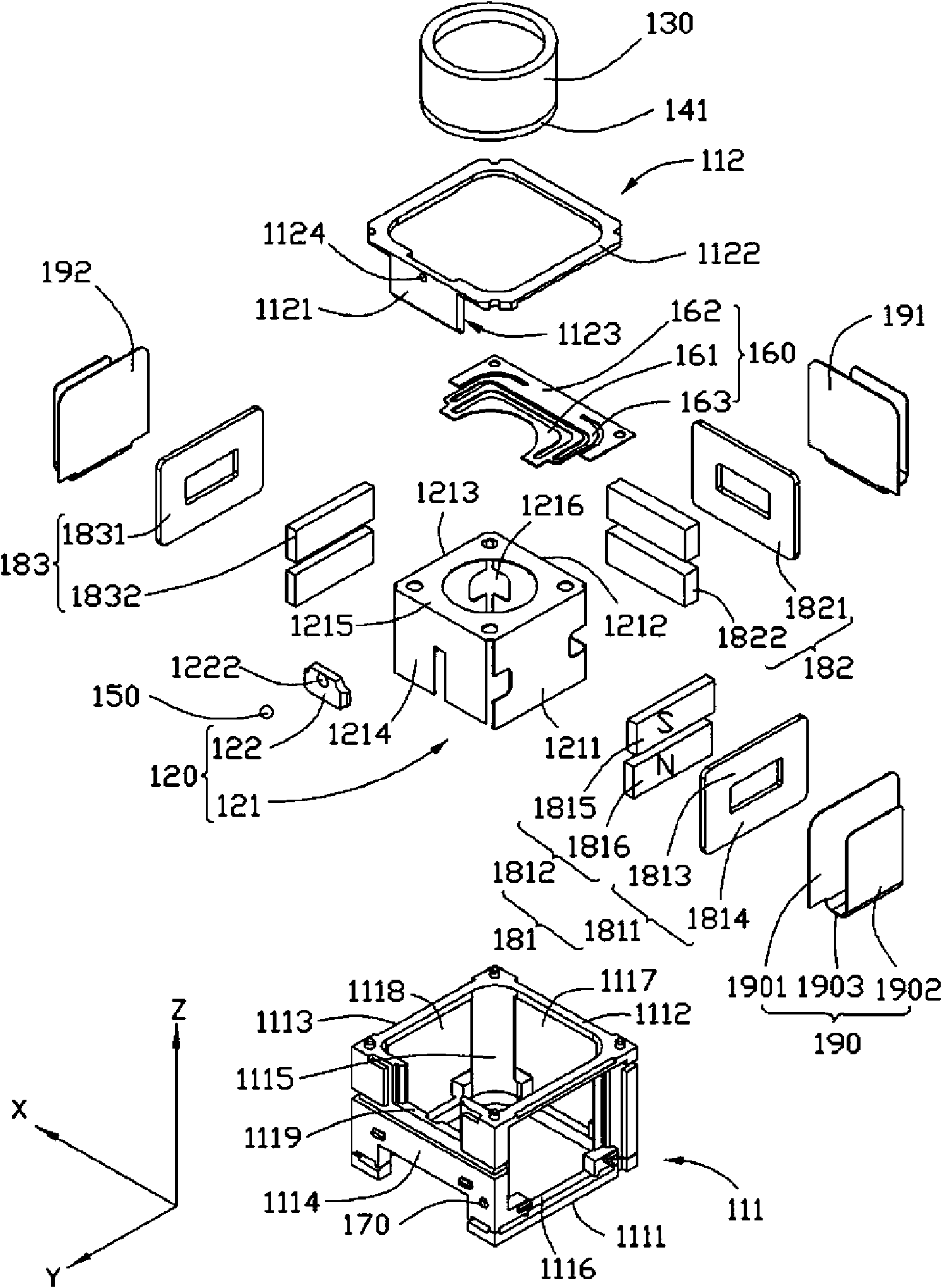

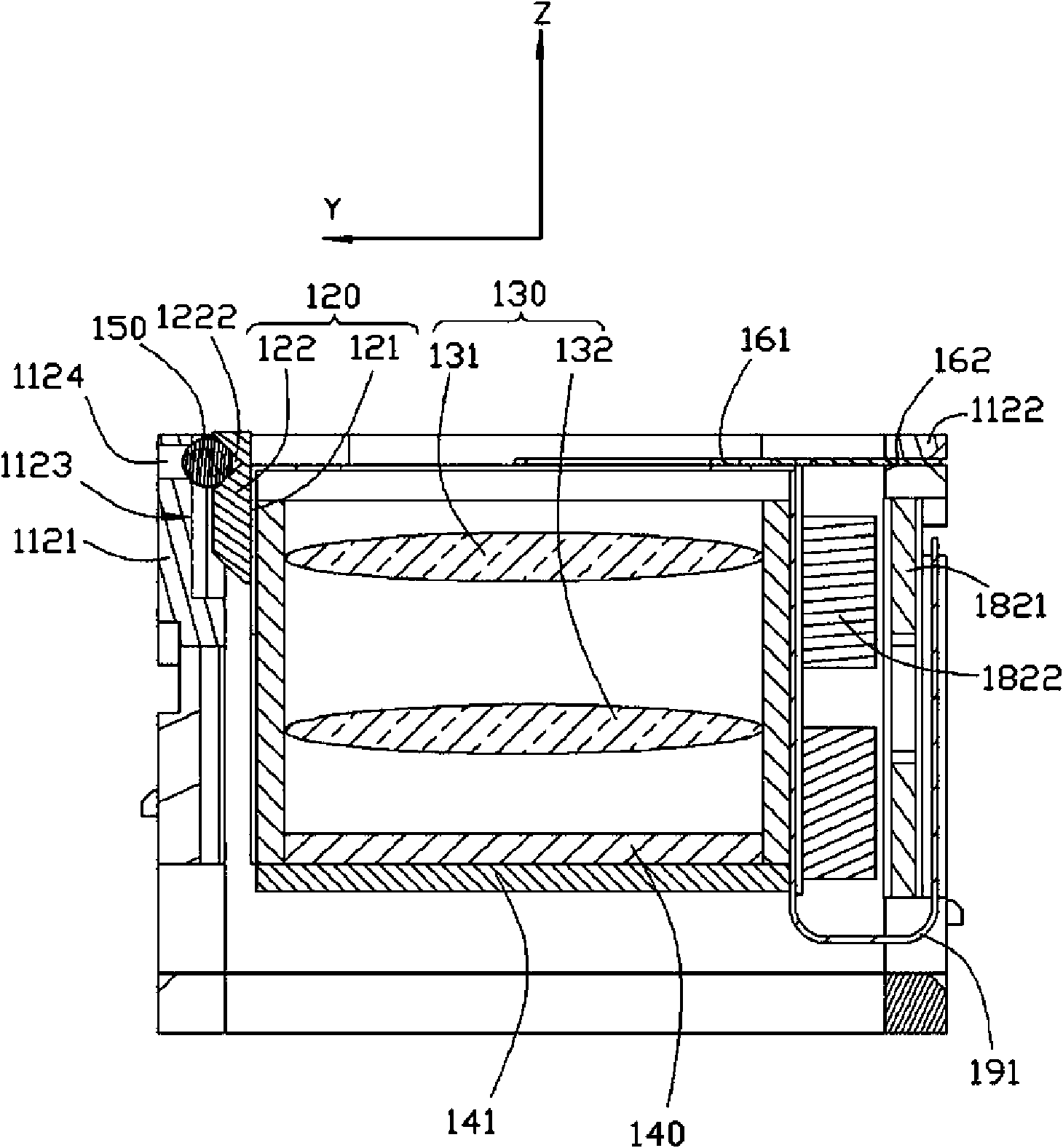

[0018] Please also refer to Figure 1 to Figure 5 , the technical solution provides a camera module 100 with an anti-shake function, which includes a fixed assembly 110, a movable assembly 120, a focusing assembly 130, an image sensing element 140, a fulcrum element 150, an elastic element 160, a displacement sensing The element 170 , the magnetic drive assembly 180 , the U-shaped magnetic permeable part 190 , the U-shaped magnetic permeable part 191 and the U-shaped magnetic permeable part 192 .

[0019] The fixing component 110 is installed on the main body of the camera module 100 (not shown), and includes a main frame 111 and an auxiliary frame 112 .

[0020] The main frame 111 is a cube-shaped frame, which includes a first side wall 1111 , a second side wall 1112 , a third side wall 1113 and a fourth side wall 1114 connected end to end. The first side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com