Electronic chip with dredging gap and substrate

A technology for electronic chips and substrates, which is applied to circuits, electrical components, electrical solid devices, etc., can solve the problems of increasing the probability of conductive particles 14A being connected to each other, and difficult to flow smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

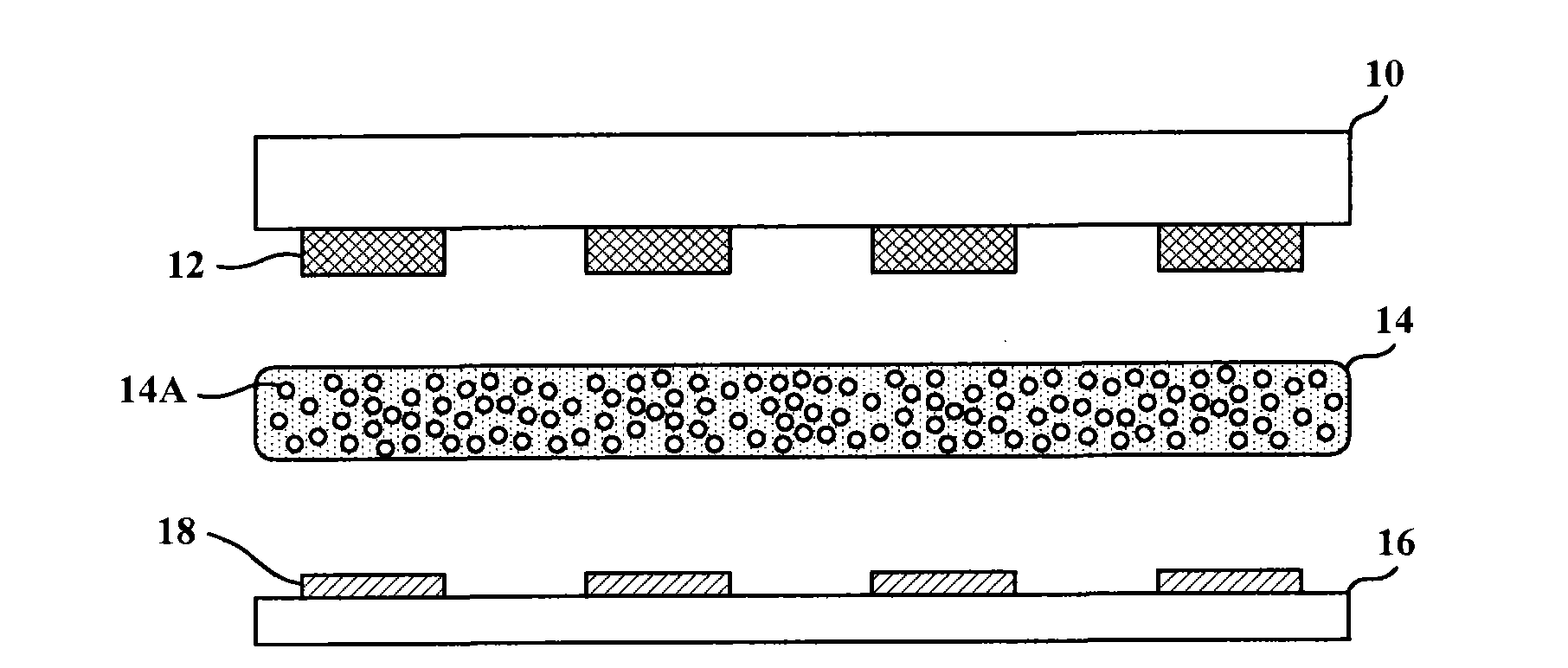

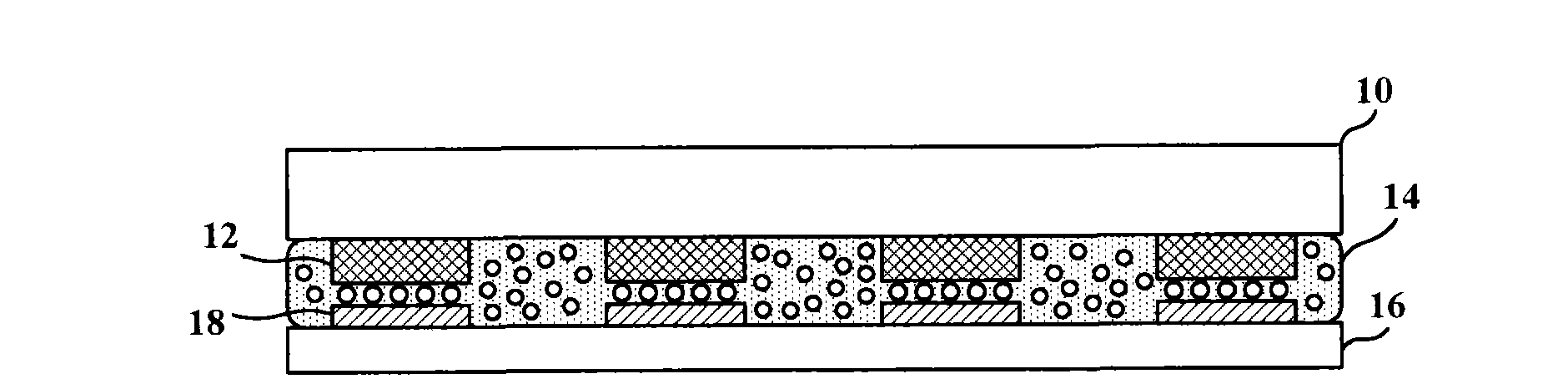

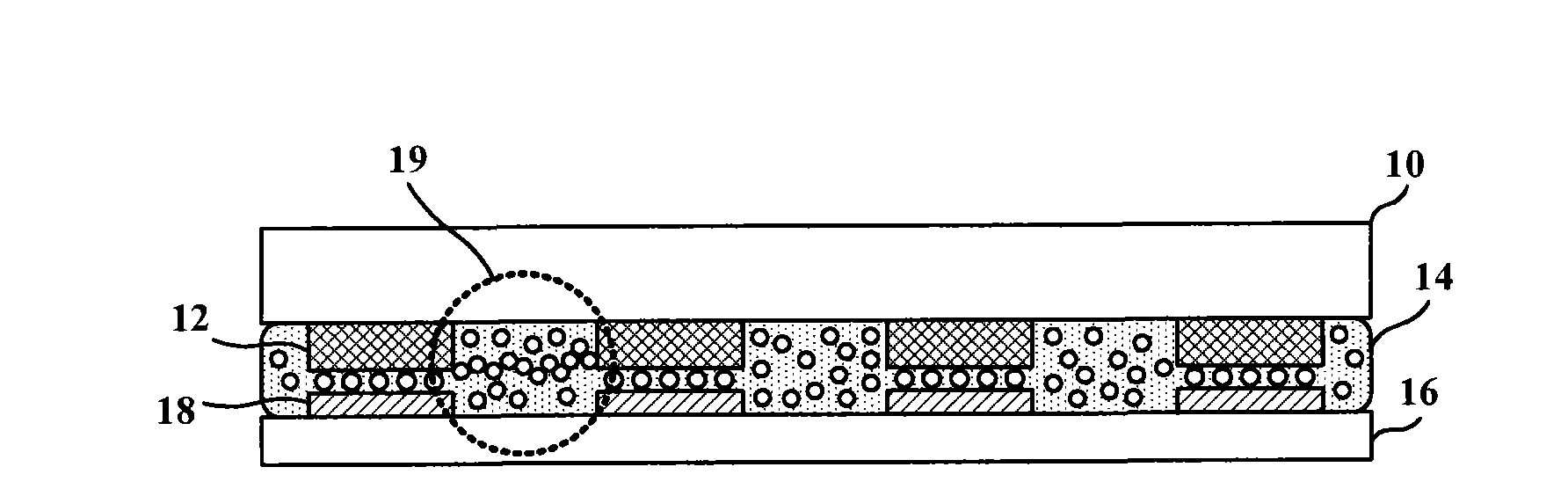

[0026] A first embodiment according to the present invention is an electronic chip including a plurality of conductive pins. The conductive pins are disposed on the outer surface of the electronic chip, and provide multiple electrical connections between the electronic chip and external circuits through conductive glue. Please refer to FIG. 2(A). FIG. 2(A) is a perspective view of the conductive pin 22 according to the present invention. In this example, the conductive pin 22 can be regarded as a polygonal column formed by truncating four corners of a rectangular column. As shown in FIG. 2(A), the cross section of the cylinder parallel to the outer surface of the electronic chip is approximately octagonal.

[0027] In practical application, the above-mentioned conductive adhesive for bonding the electronic chip and the external circuit may be anisotropic conductive adhesive (ACA), anisotropic conductive film (ACF), or Other types of jelly contain conductive particles.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com