Lithium ion battery casing, its manufacturing method and battery

A technology of lithium-ion batteries and manufacturing methods, which is applied to the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as life-threatening, easy to tear, and safety issues, and achieve safety and yield , Improved safety and yield, high accuracy and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

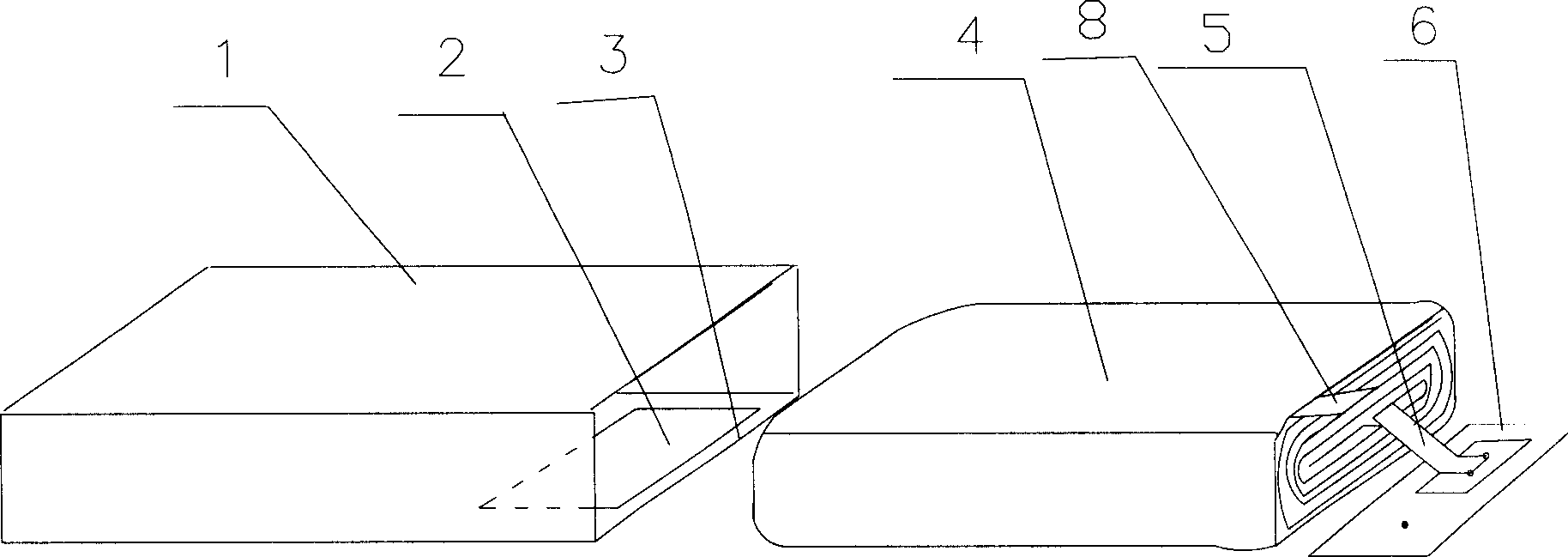

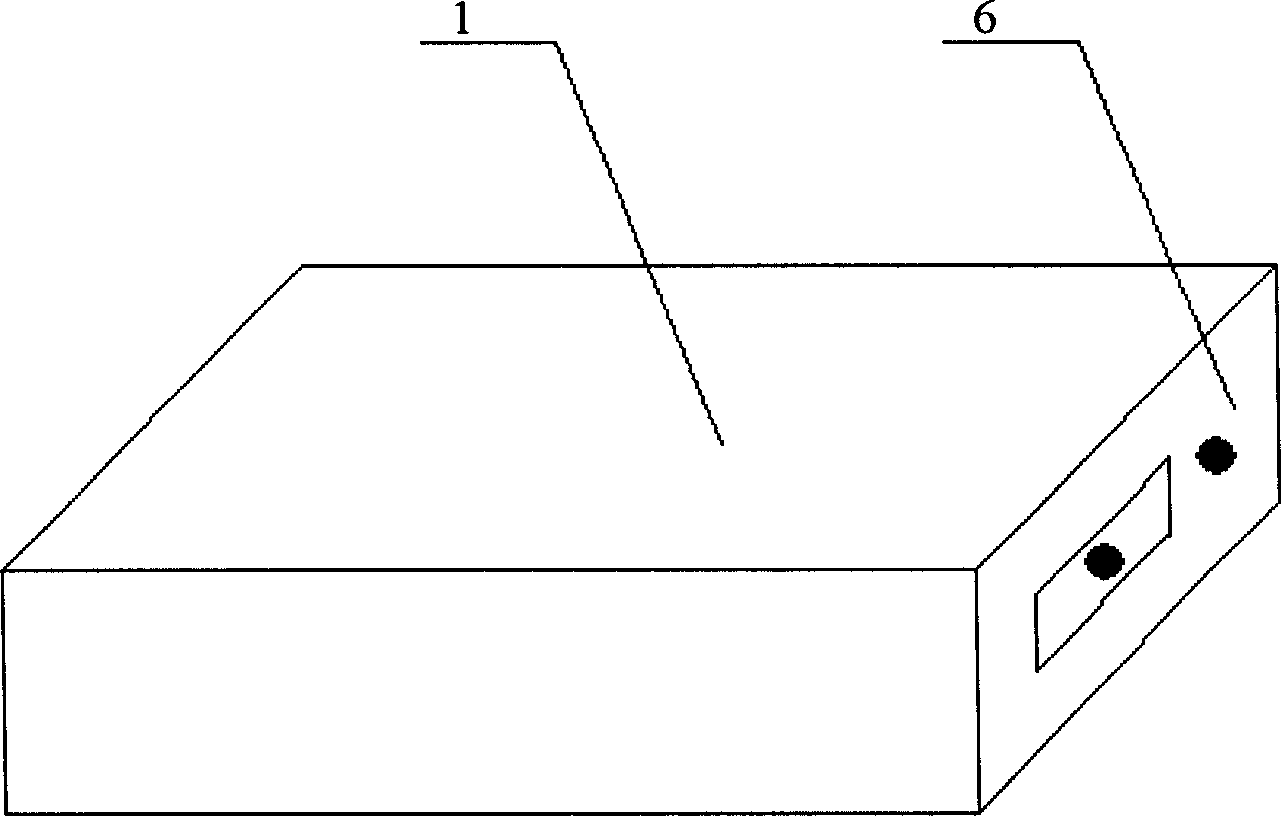

[0017] Embodiment 1, a kind of lithium-ion battery case, combined with figure 1 , including a battery case 1 and a high-temperature adhesive tape 2 as an insulating layer. The high-temperature tape 2 is pasted on the inner wall of the battery case near the opening of the battery case 1, and the distance between the high-temperature tape 2 and the cutout 3 of the battery case is 1 mm.

[0018] When manufacturing a lithium-ion battery, the battery cell 4 is put into the battery case 1 . Note that the welding curved surface of the conductive terminal 5 connecting the battery cell 4 to the cover plate 6 corresponds to the insulating layer 2 on the battery case 1, because the curved part of the conductive terminal 5 is the closest part to the inner wall of the battery case 1 . Then another conductive terminal 8 is welded to the other side of the cover plate as the positive lead. The parts where the conductive terminal 5 and the conductive terminal 8 are welded on the cover plate ...

Embodiment 2

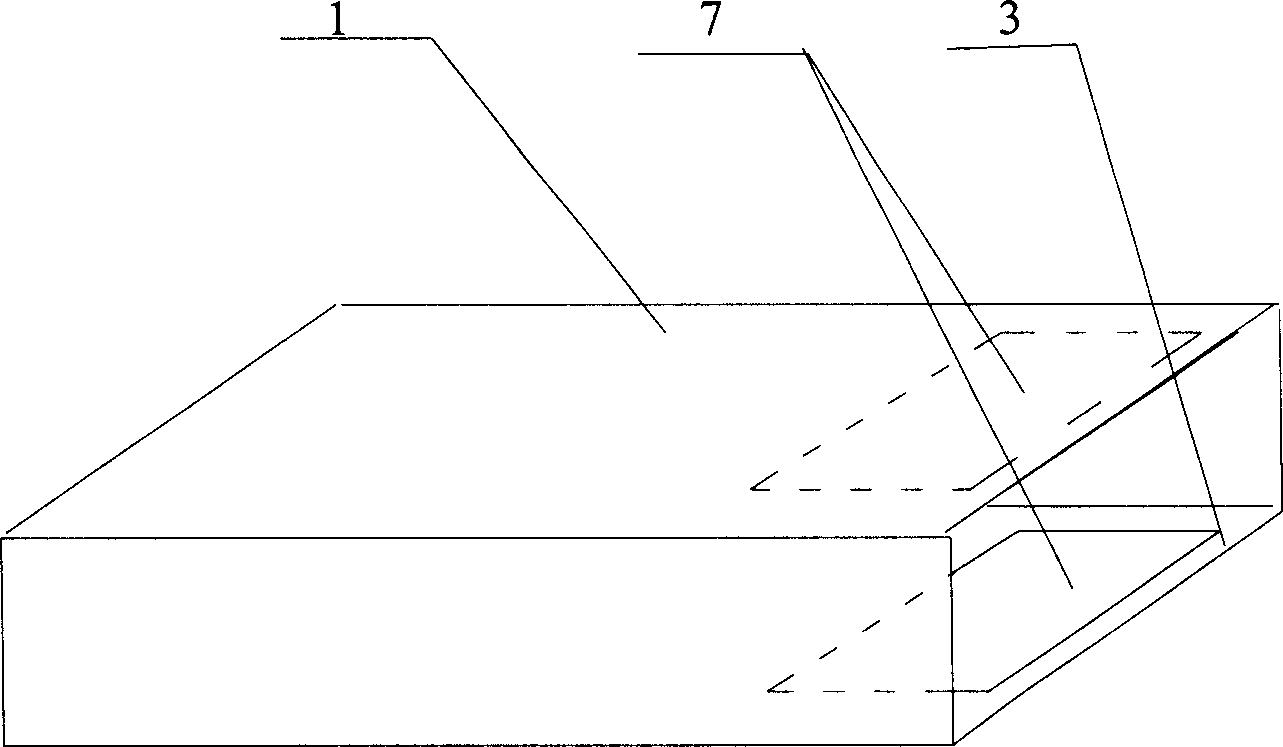

[0023] Embodiment 2, another kind of lithium-ion battery case, combined with figure 2 , its structure is basically the same as that of Embodiment 1, except that an insulating layer is also provided on the inner wall of the housing opposite to the position where the insulating layer is provided in Embodiment 1. The insulating layer 7 is formed by coating high temperature resistant insulating glue at this position.

[0024] Comparative analysis:

[0025] Using the battery case in Example 2, the finished lithium-ion battery model 053048A1 was manufactured according to the conventional process as 3 groups.

[0026] Table 2

[0027]

[0028] It can be seen from Table 1 and Table 2 that the short-circuit rate of the lithium-ion battery using the battery case of the present invention is significantly reduced, indicating that the battery case of the present invention has a good effect of improving battery yield and safety. It can also be fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com