Power socket with automatic-rotating contact copper sheet

A power socket, automatic rotation technology, applied in the direction of contact parts, etc., can solve the problems of temperature rise at the contact point, weakened insertion and extraction force, and reduced elasticity of the fixed copper sheet, and achieves strong elasticity, fatigue resistance, and clamping force. Reliable, increased contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

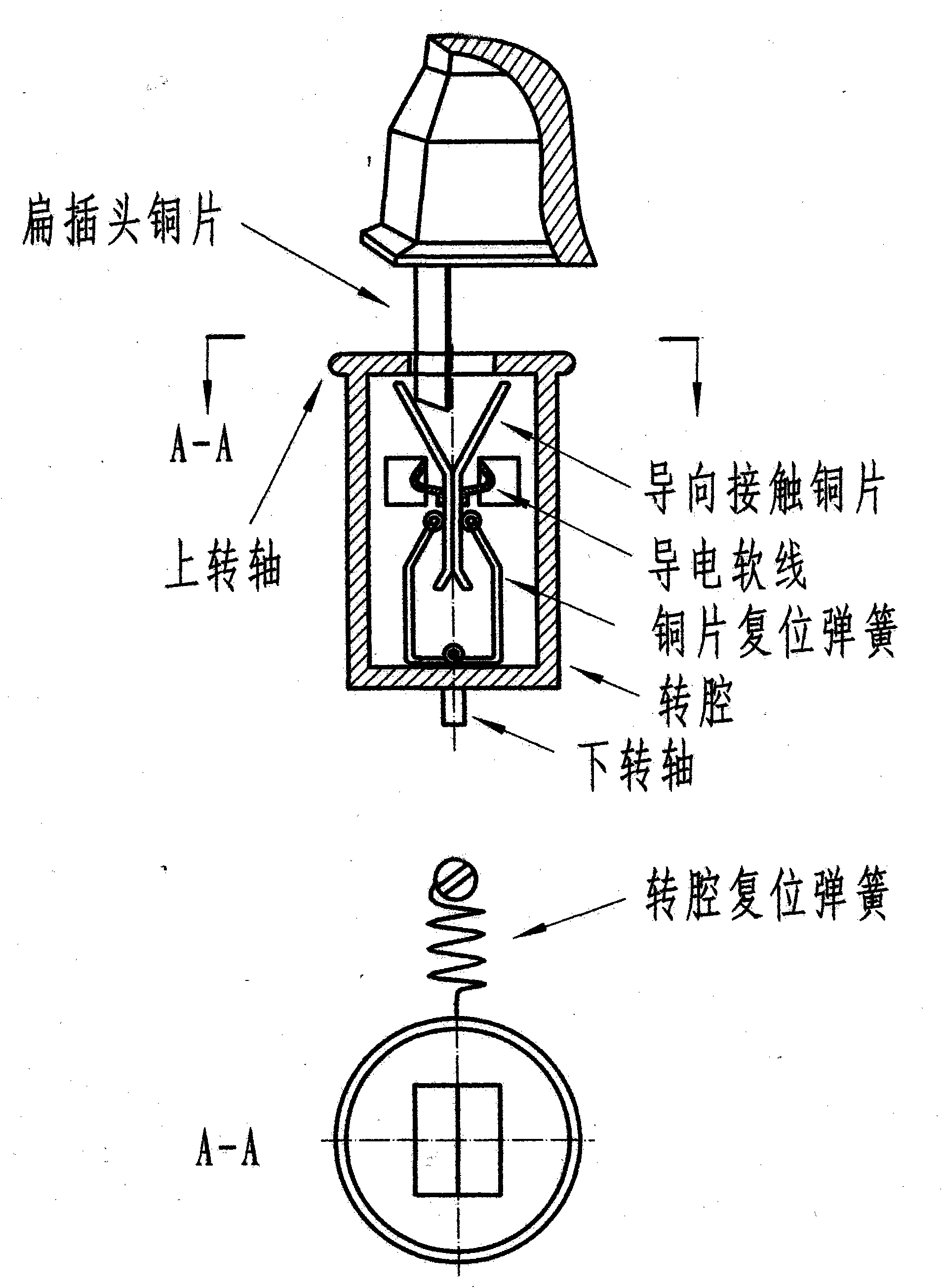

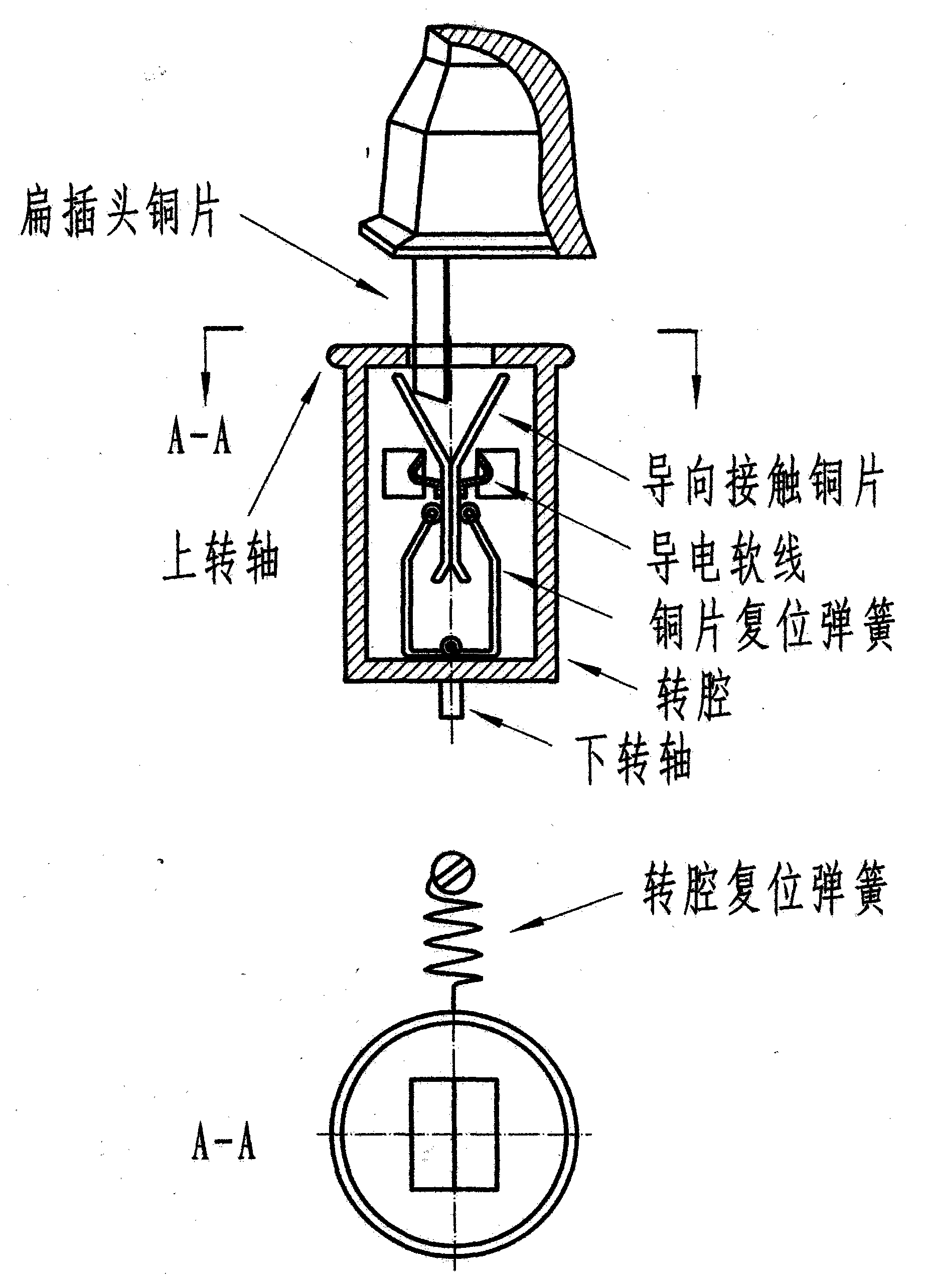

[0016] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

[0017] As shown in the figure, a socket includes: a rotary cavity, an upper rotary shaft, a lower rotary shaft, and a return spring of the rotary cavity.

[0018] The receptacle revolving cavity also includes: a conductive flexible wire, a guide contact copper sheet, and a copper sheet return spring.

[0019] The working principle is described as shown in the figure:

[0020] 1. When the vertical direction of the "plug copper sheet" and the socket "guiding contact copper sheet" are consistent, the "plug copper sheet" falls in the gap between the two "guiding contact copper sheets", and the "turning chamber" can be inserted into the socket without rotating. Due to the closed elastic force of the two ends of the "copper sheet return spring", the two ends have chasing properties. If the "plug copper sheet" does not fall in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com