Combined inner ring gear rotary filter screen

A technology of filter screen and inner gear, which is applied in harvesting machines, agricultural machinery and implements, etc. It can solve the problems of easy damage to cotton fibers, high impurity content of cotton wool, and poor filtering effect, so as to reduce labor force and clean harvesting. High efficiency and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

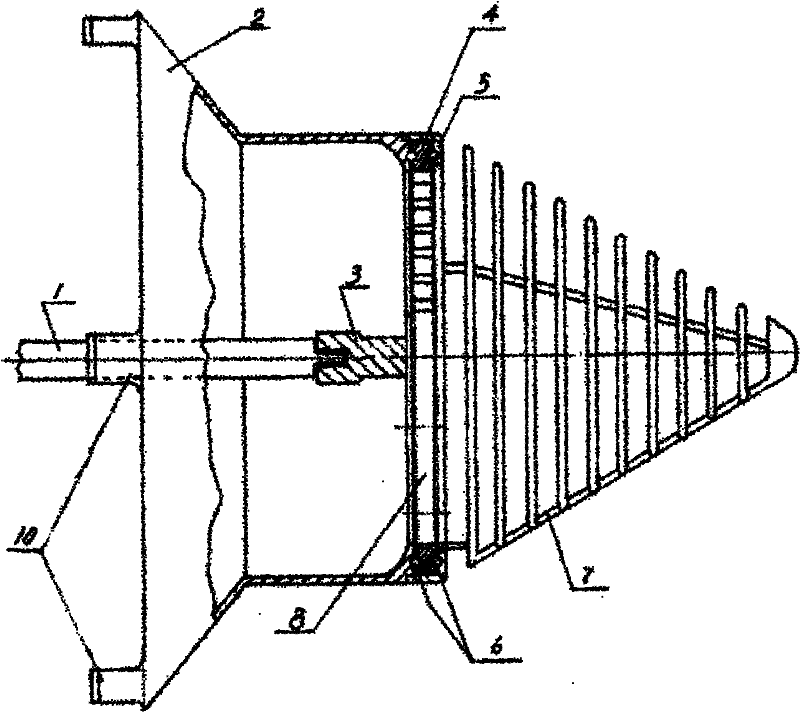

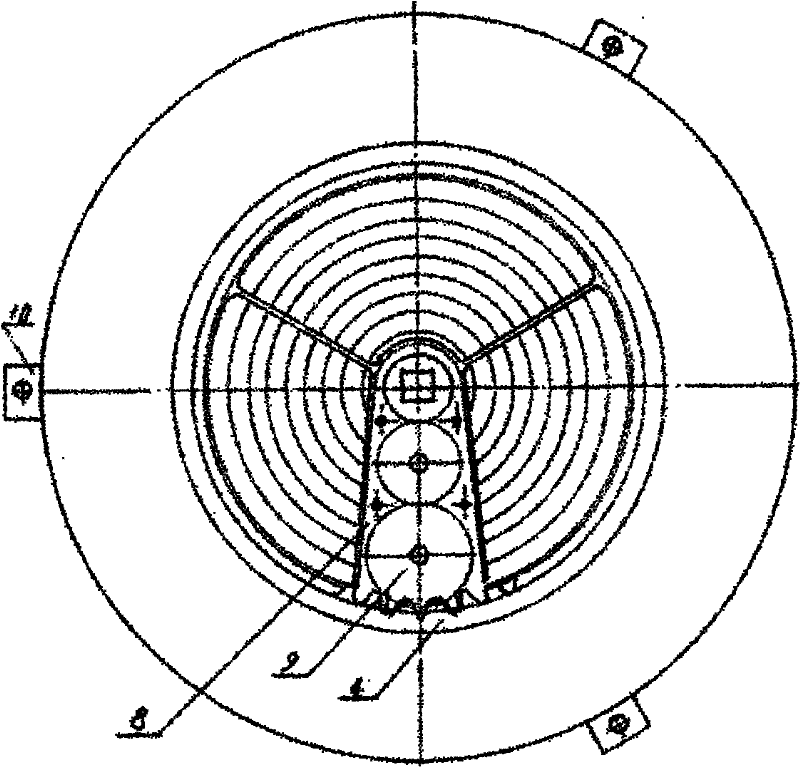

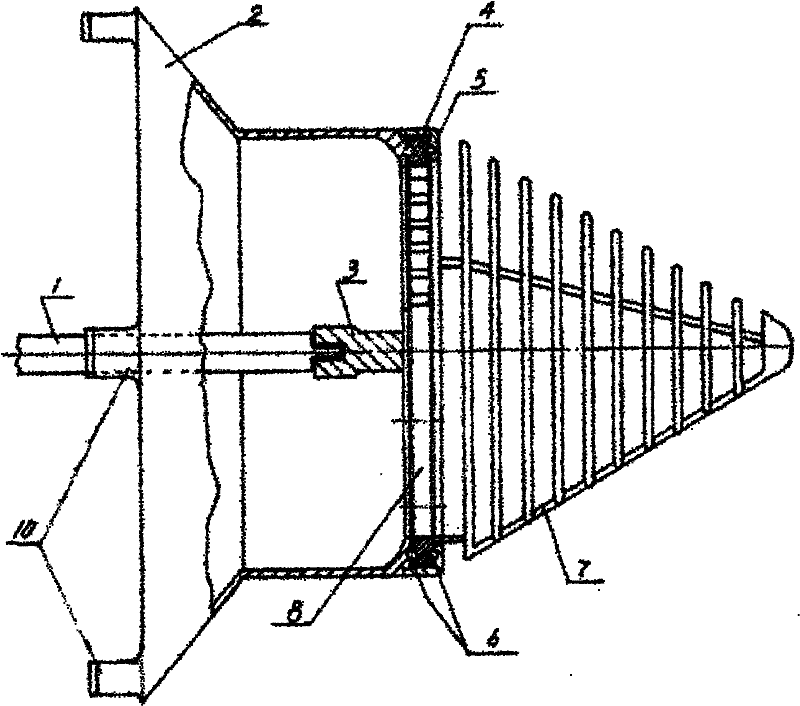

[0013] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0014] When the output rotating shaft 1 rotates, it drives the square tenon bridging shaft 3 connected to the output end of the output rotating shaft 1 to rotate, and the square tenon bridging shaft 3 drives the inner ring gear box 8 connected to the support bracket 2 at the output end of the square tenon bridging shaft 3 and The gear combination 9 in the box rotates, the inner ring gear box 8 and the gear combination 9 in the box mesh with the inner large ring gear 4 to decelerate and rotate, the rotating filter 7 is fixedly installed on the inner large ring gear 4, and the inner large ring gear 4 drives the rotation The filter screen 7 decelerates and rotates, and the cotton rolls along the rotary filter screen 7 under the rotation of the rotary filter screen 7, while the sundries are separated from the cotton under the action of gravity, thereby meeting the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com