Backlight module and assembly method thereof

The technology of a backlight module and an assembly method, which is applied in the field of backlight modules and its assembly, can solve problems such as the inability to cover light-emitting diode components 12, light loss, and reduce light utilization, so as to achieve the effect of improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

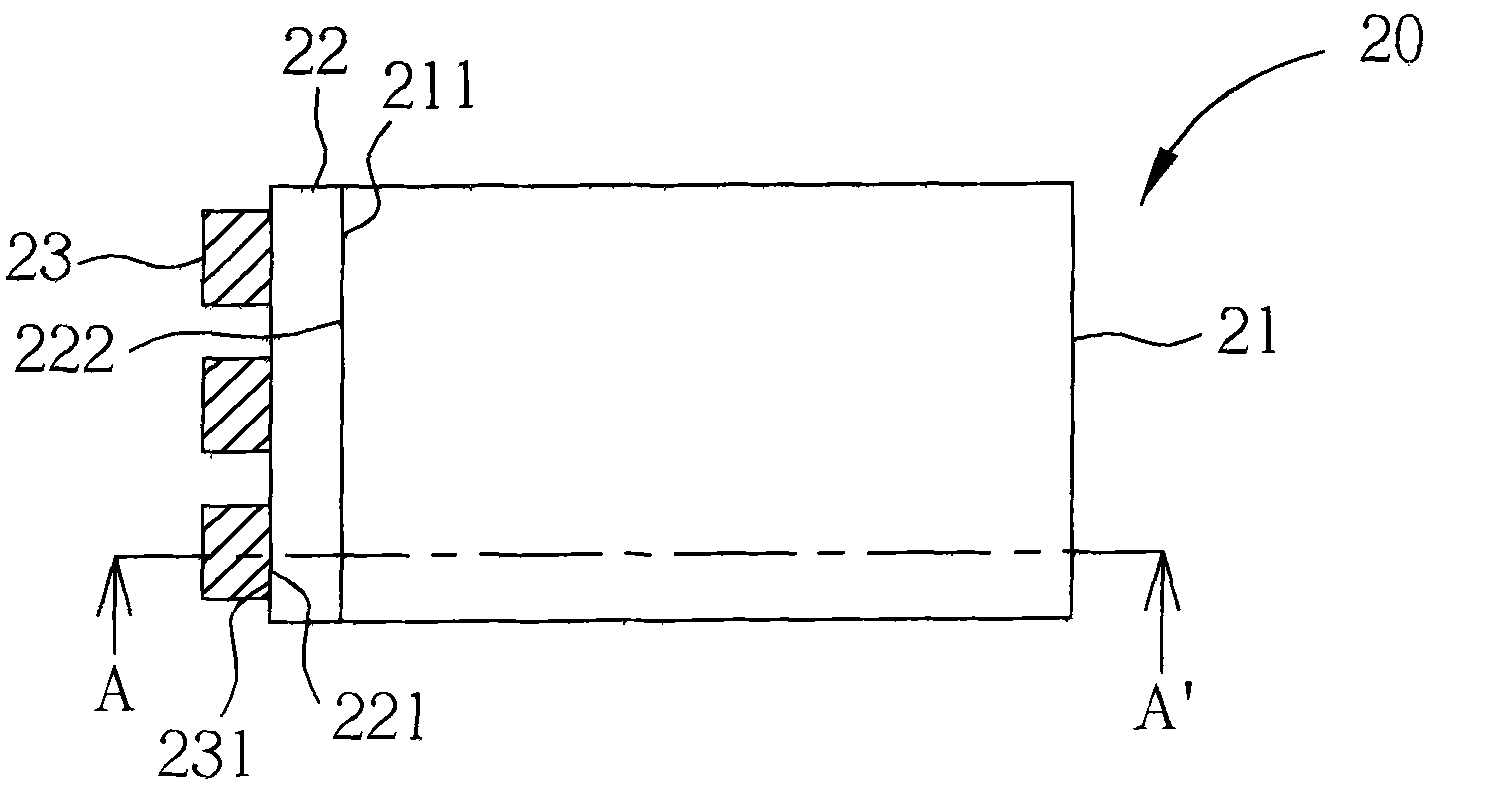

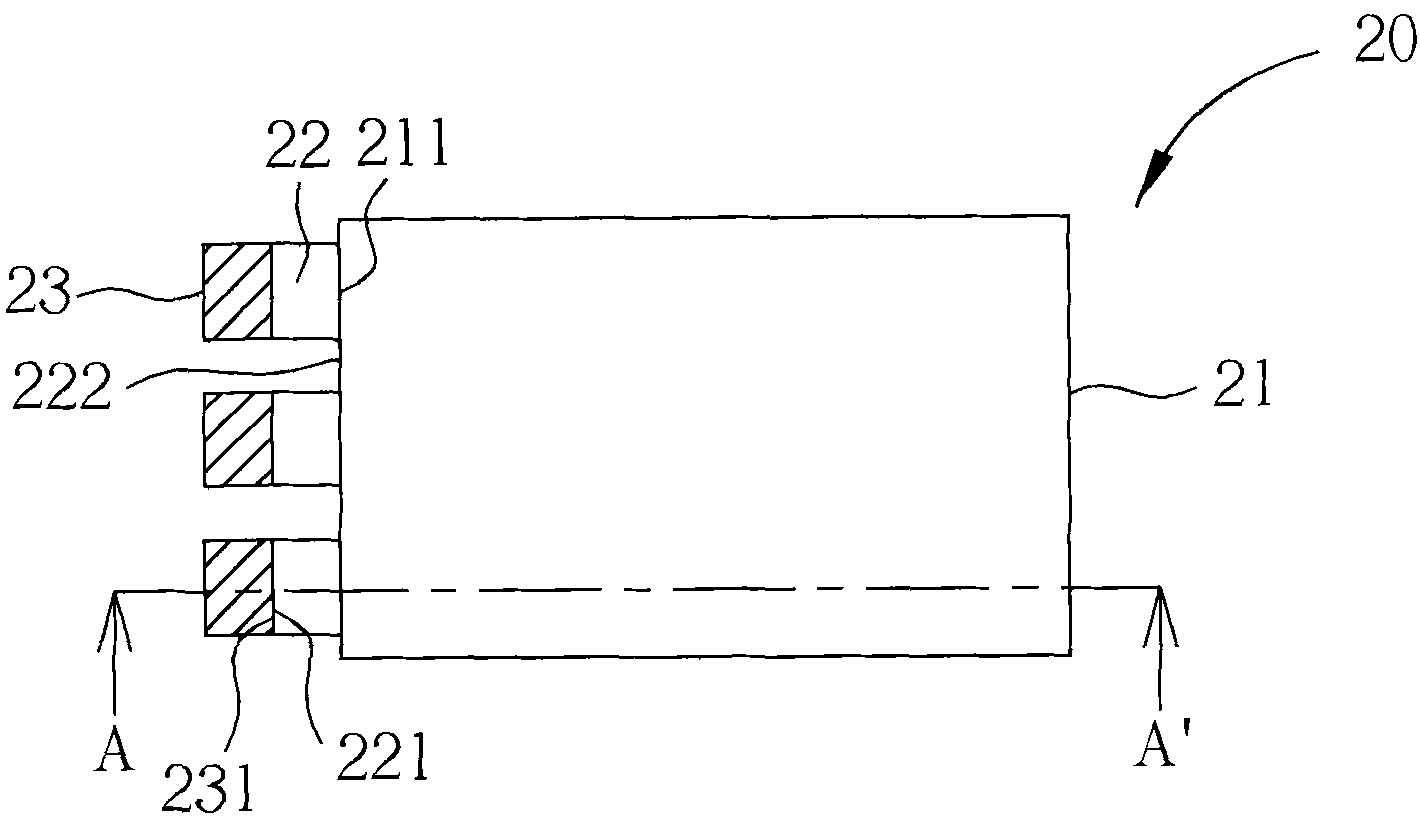

[0038] Please refer to Figure 2A , Figure 2B and image 3 . Figure 2A It is a schematic top view of a backlight module in a first preferred embodiment of the present invention, Figure 2B It is a schematic top view of a variant embodiment of the backlight module of a second preferred embodiment of the present invention, image 3 along Figure 2A and Figure 2B The cross-sectional schematic diagram of the backlight module of the cross-section line A-A', wherein due to the different angles of drawing, some components are not shown in the part of the figure. Such as Figure 2A , Figure 2B and image 3 As shown, the backlight module 20 of this embodiment includes a light guide plate 21, at least one light guide block 22, a plurality of light emitting components 23, and a reflector 24 (for convenience of description, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com