Multi-person collaborative virtual-real mixed disassembly and assembly system and multi-person collaborative virtual-real mixed disassembly and assembly method

A virtual-real fusion and protocol technology, applied in transmission systems, special data processing applications, instruments, etc., can solve problems such as lack of operator interaction and cooperation, difficult equipment maintenance requirements, etc., to facilitate expansion and maintenance, improve scalability and The effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

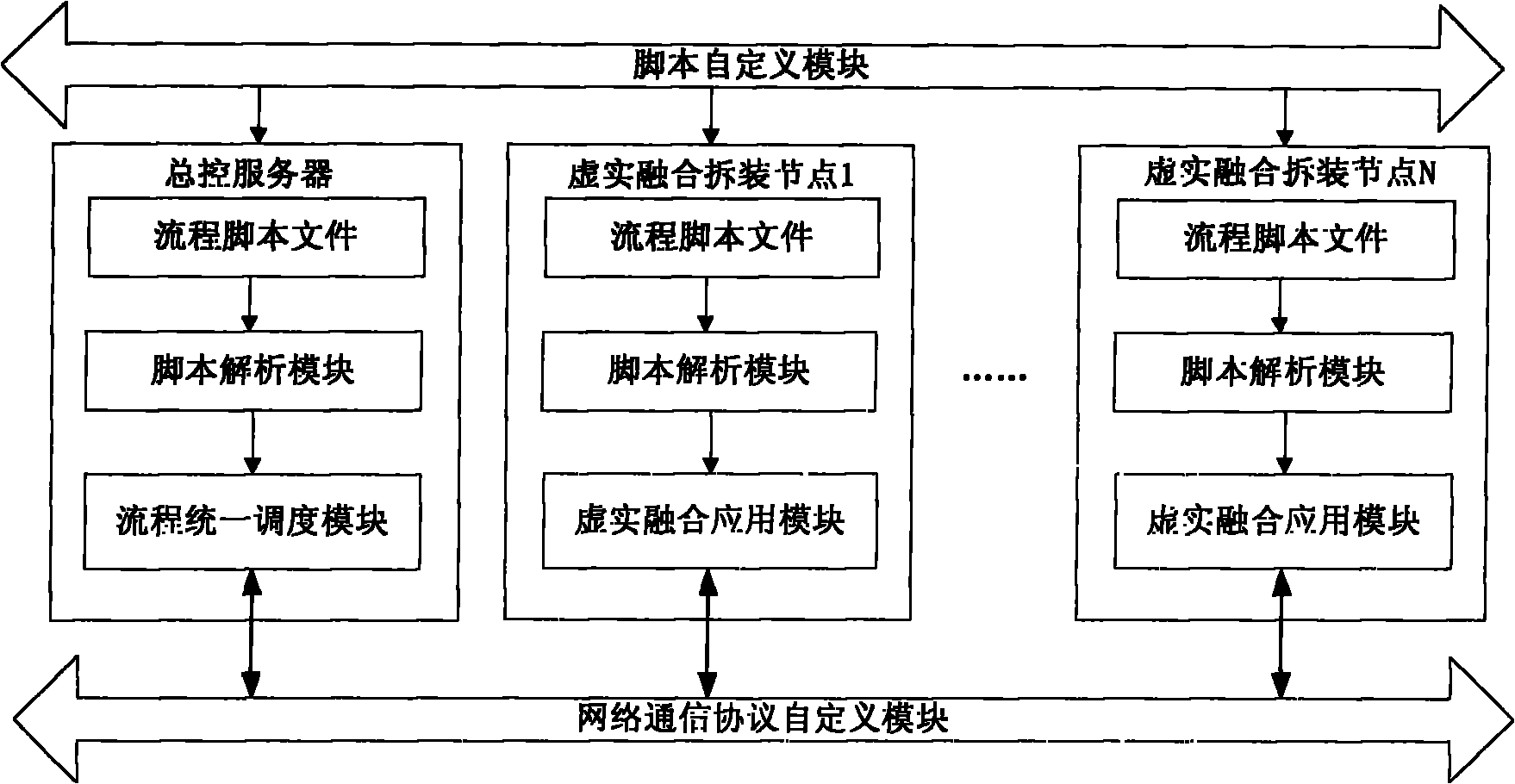

[0043] like figure 1 As shown, the basic structure of the system of the present invention includes a process script customization module, a script parsing module, a network communication protocol customization module, a coordinated disassembly process unified scheduling module, and a virtual-real integration application module. The whole implementation process is as follows:

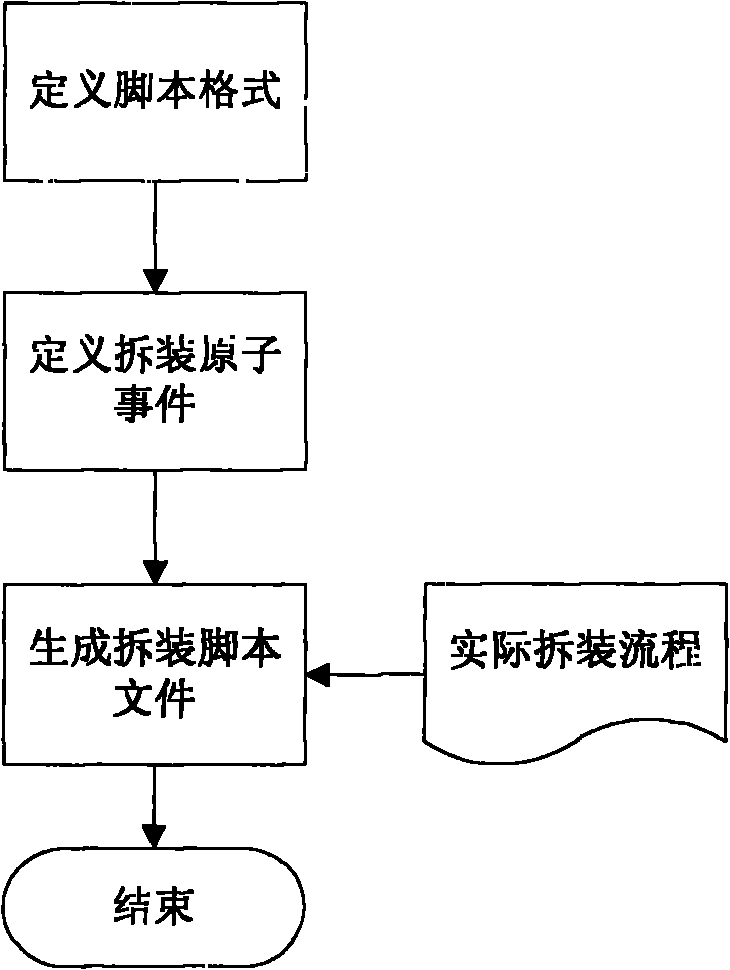

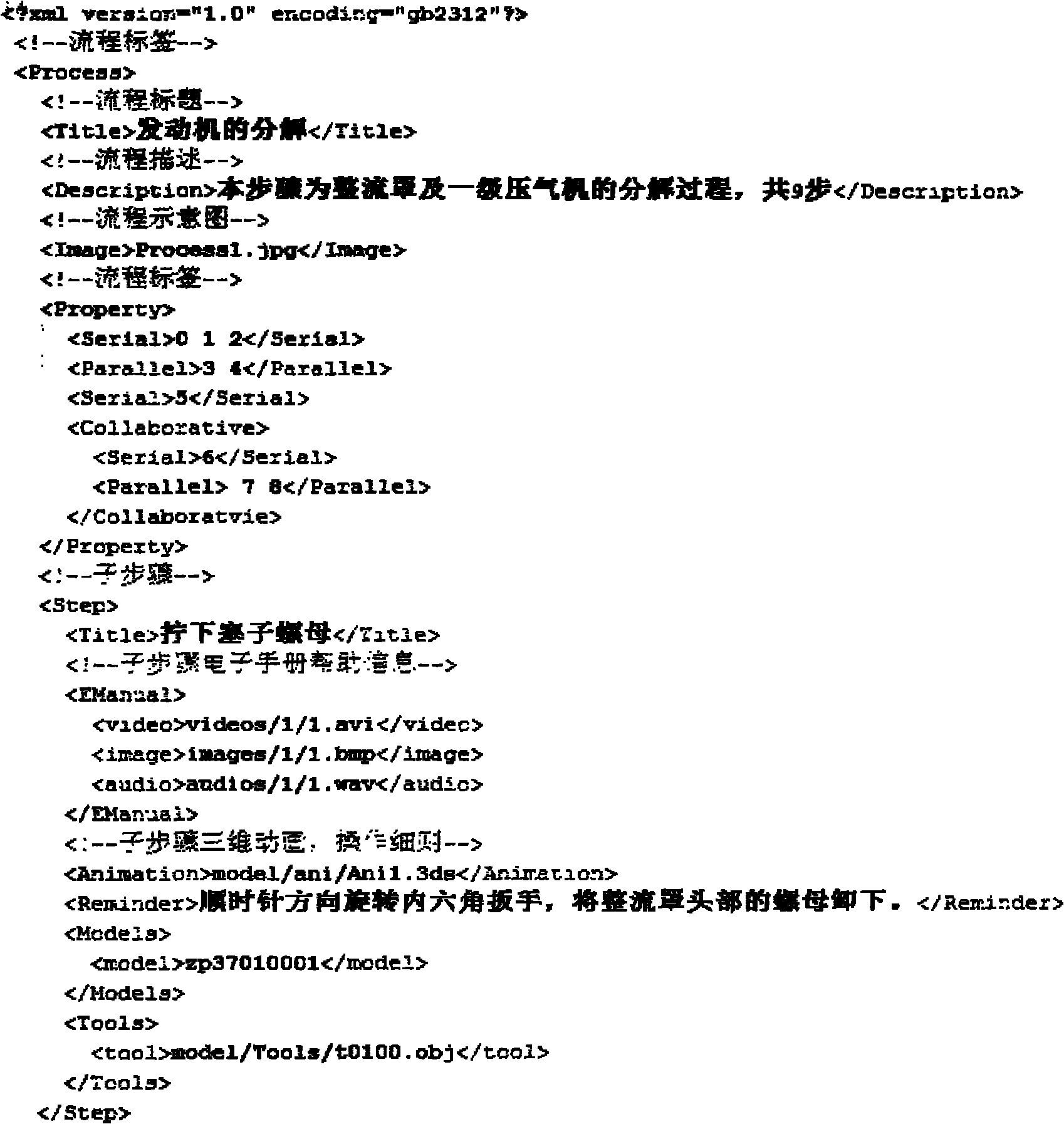

[0044] (1) Define a general XML script format describing the disassembly process, then define the disassembly atomic event according to the actual disassembly process, and quickly generate an XML disassembly process script of a custom format, and the generated script file is used for script analysis;

[0045] (2) Parse the XML script file to generate intermediate files, including the disassembly workflow file and the virtual-real fusion resource directory file, the former is used for process scheduling, and the latter is used for the virtual-real fusion application to call resources;

[0046] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com