Integral leather-shoes wiping machine

An all-in-one, leather shoe technology, applied in the direction of cleaning boots and shoes, cleaning equipment, household appliances, etc., can solve the problems of high difficulty, insecurity, time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

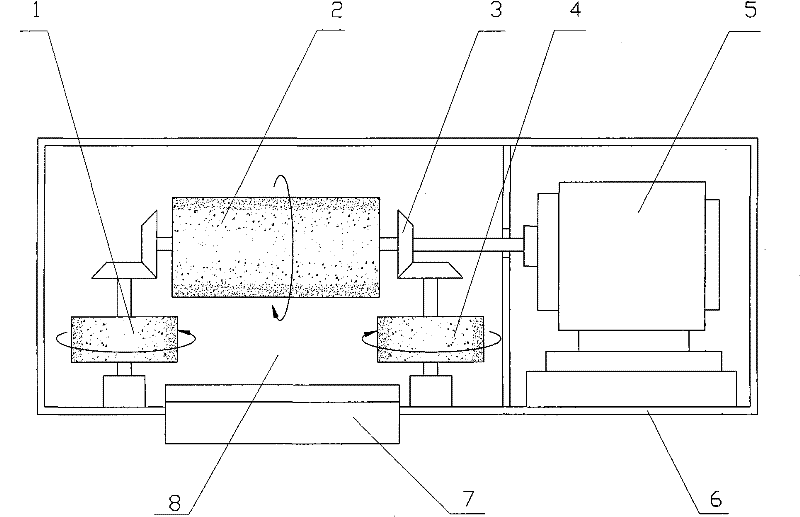

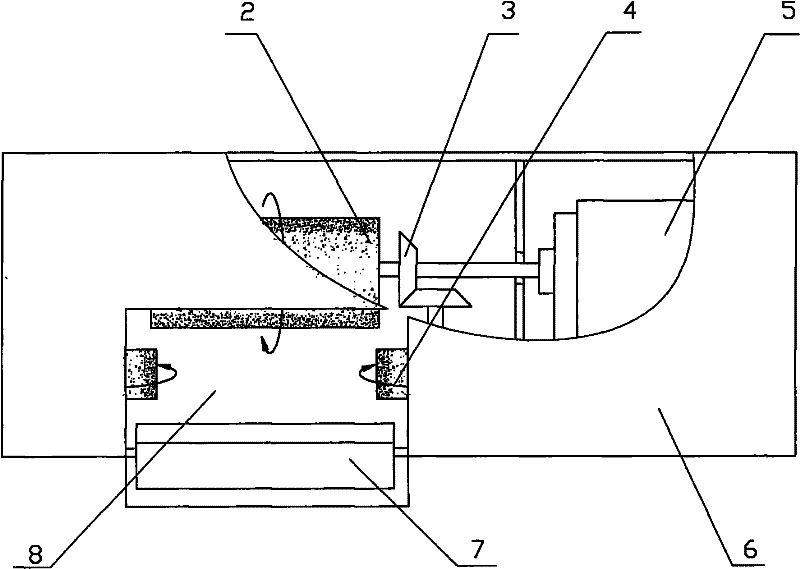

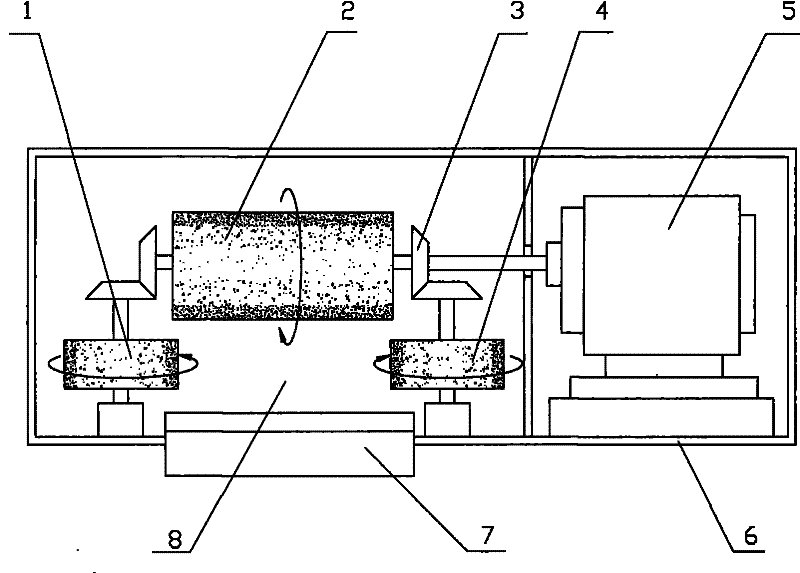

[0017] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] The integrated leather shoe wiping machine includes a box body 6 and a horizontal brush 2 placed horizontally in the box body 6. Below the left and right sides of the horizontal brush 2, vertically arranged left and right vertical brushes 1 and 4 are arranged respectively. , the three surround and form the shoe-shine cavity 8, and the horizontal hair brush 2 and the left and right vertical hair brushes 1, 4 are respectively engaged with vertical bevel gears, and the motor 5 is used as the driving force. The invention has compact structure, reliable gear meshing transmission, leather shoes are directly inserted into the shoe-shine cavity 8, and wiped by three brushes at the same time, which is fast and clean without changing the posture, action angle and position of feet and leather shoes, which is safe, convenient and comfortable .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com