Automatic conducting-liquid bottling device

A conductive liquid, automatic technology, applied in liquid bottling, liquid filling, liquid processing and other directions, can solve the problems of restricting the development of enterprises, high procurement costs, large floor space, etc., achieving simple structure, low cost, and overall floor space small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to further illustrate the present invention. The following examples are illustrative and not restrictive. The following examples cannot be used to limit the protection scope of the present invention.

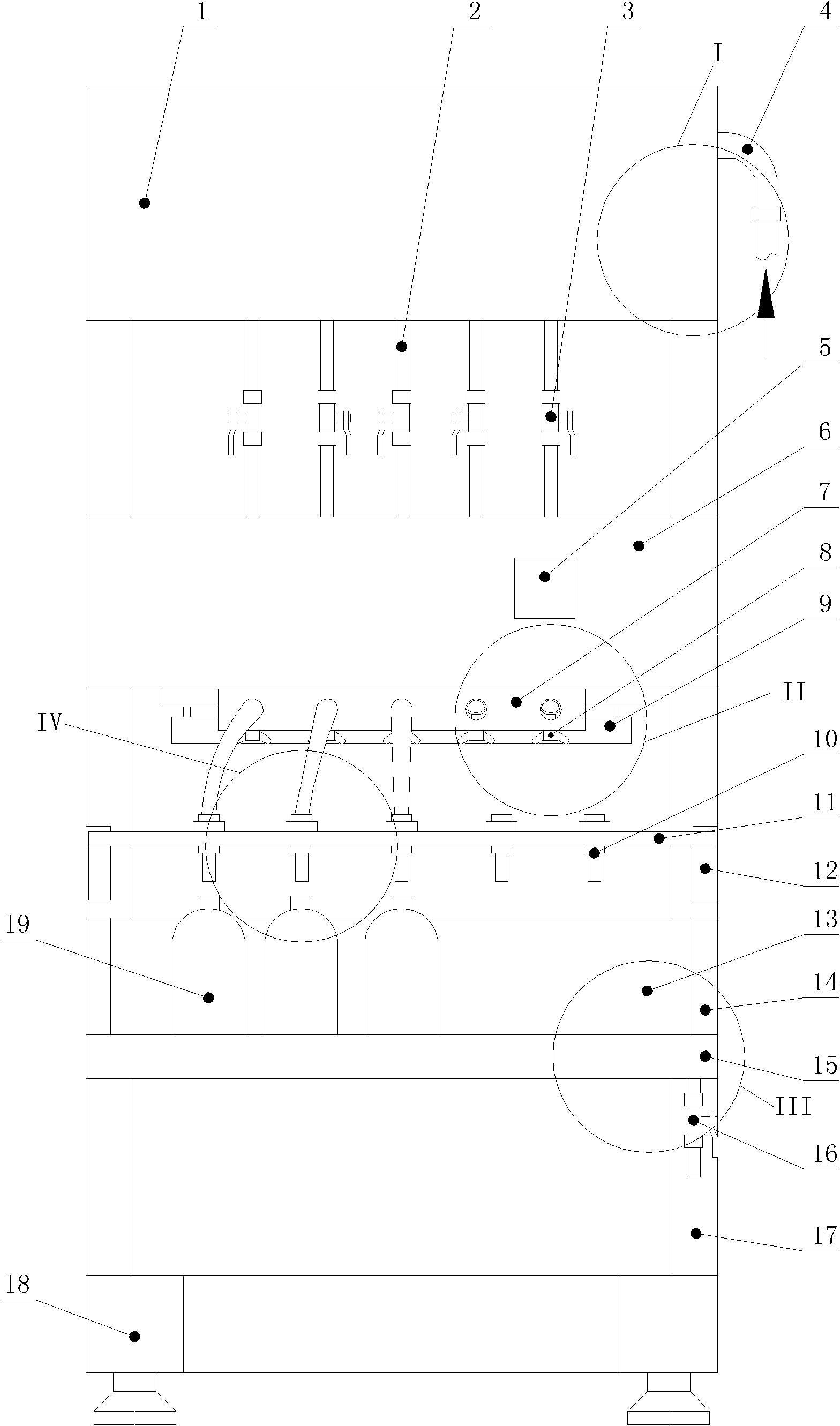

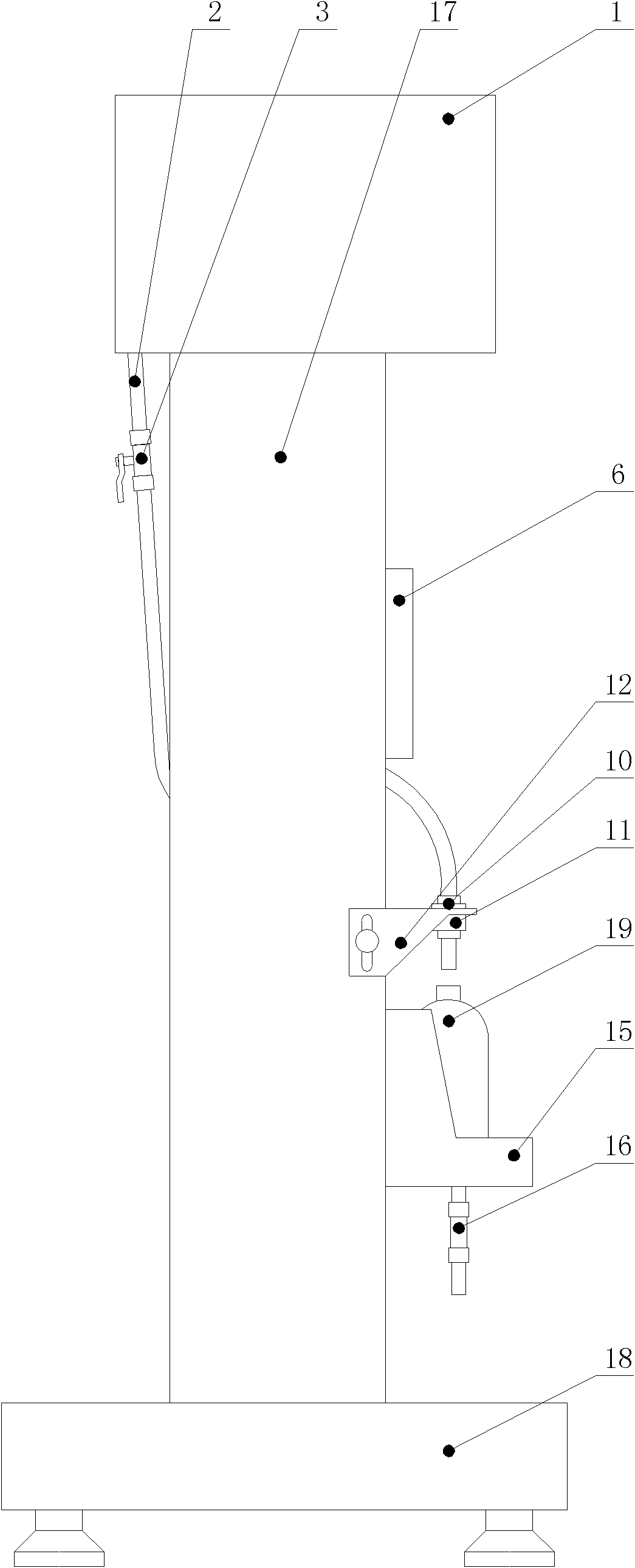

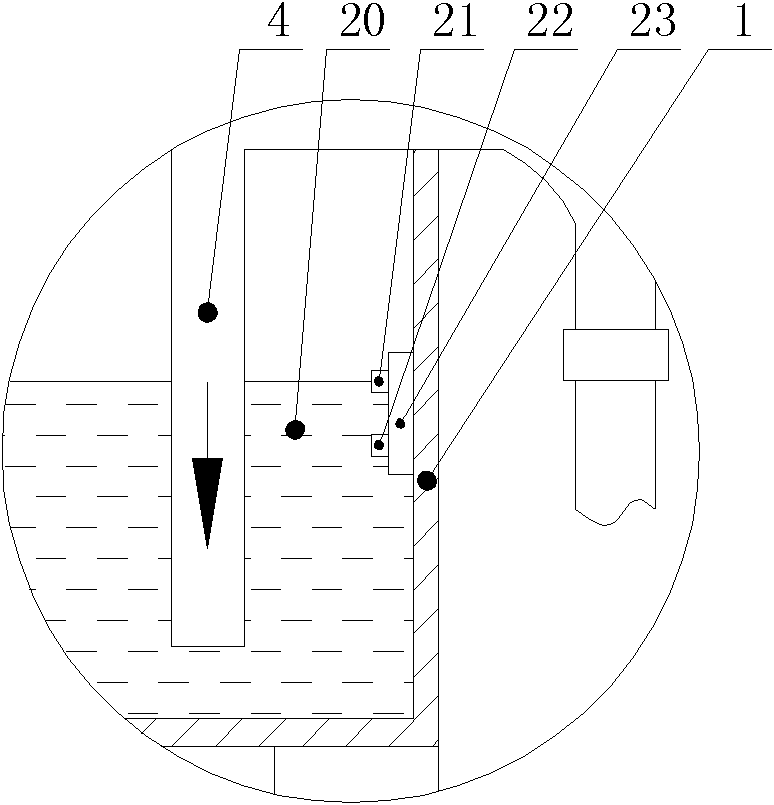

[0025] An automatic bottle filling device for conductive liquid, such as Figure 1~10 As shown, the innovation of the present invention is that it includes the liquid tank 1, the bottle tray 15, the support frame 17, the water pump 36, the replenishing tank 37 and the electric control box 6. The lower end of the support frame is installed with an "H"-shaped base 18, and the support frame A liquid tank is installed at the upper end, and a liquid level detection device is installed on the inner wall of the liquid tank. The liquid tank is connected to the liquid supplement tank through the liquid supplement pipe 4 and the water pump is connected to the middle of the support frame respectively. A plurality of filling heads 10 on the installed beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com