Shell fabric for three-dimensional stereoscopic bullet-proof vest

A three-dimensional, body armor technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor plasticity of two-dimensional fabrics and inability to form fit female body curves, etc., to achieve comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

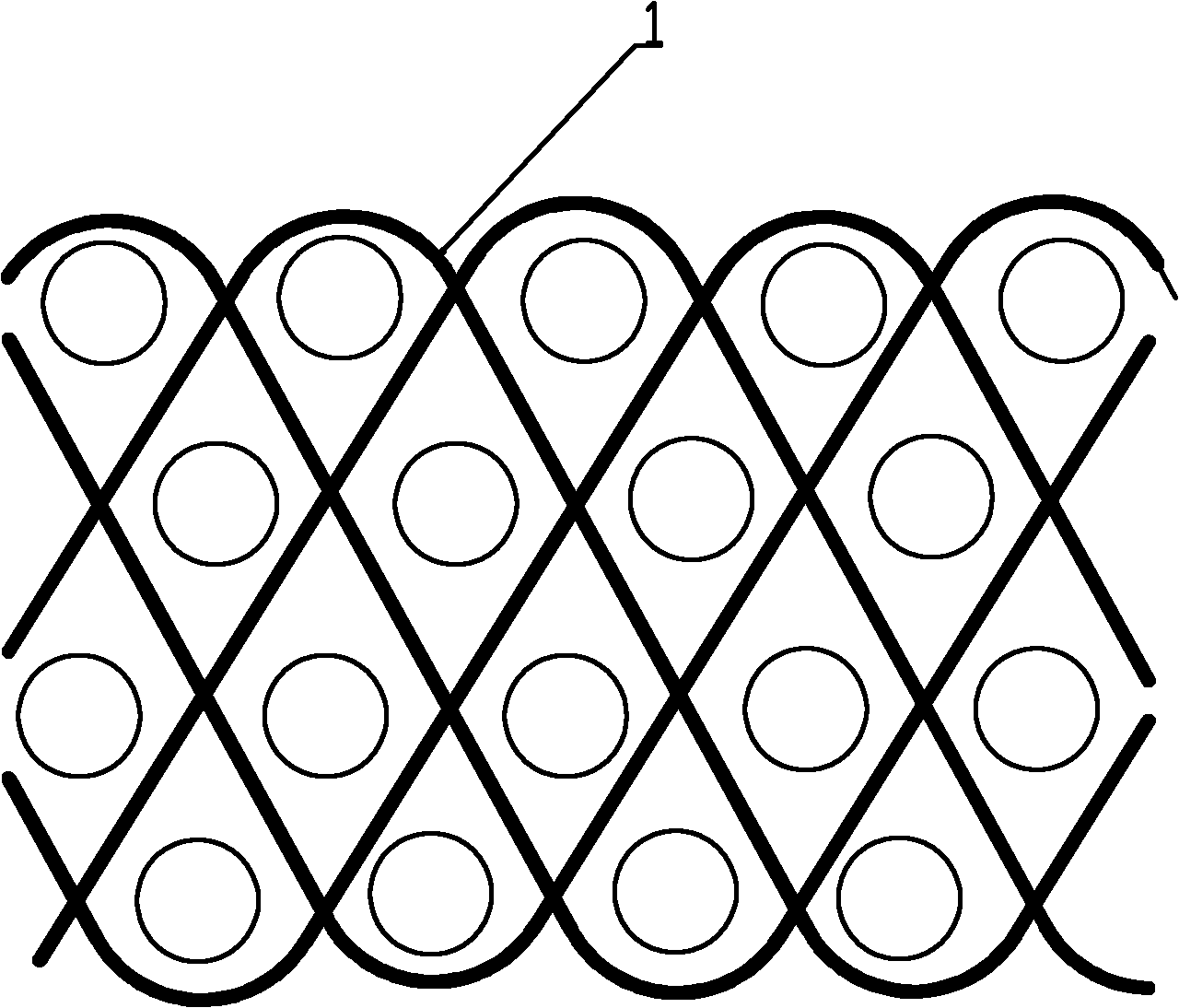

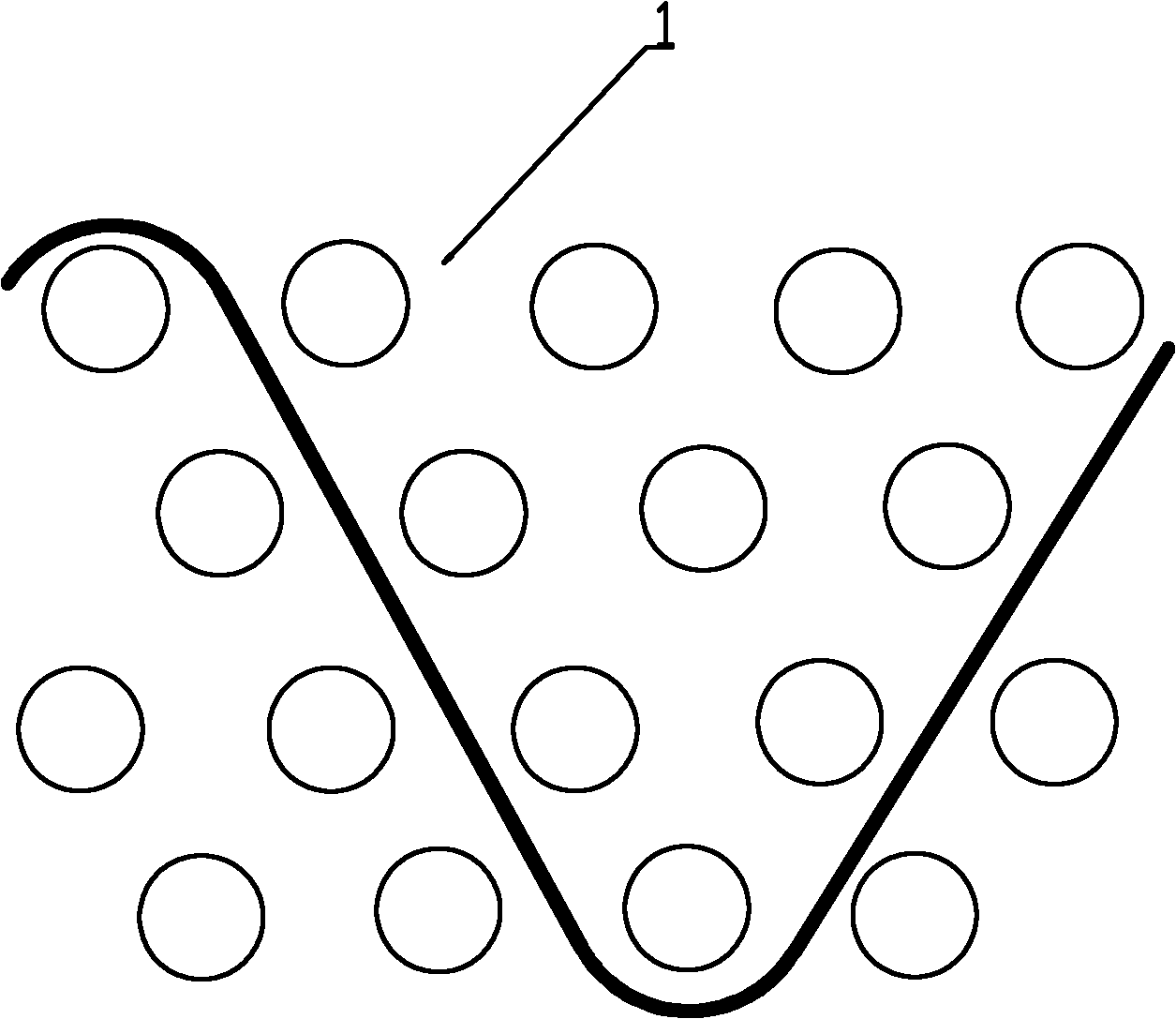

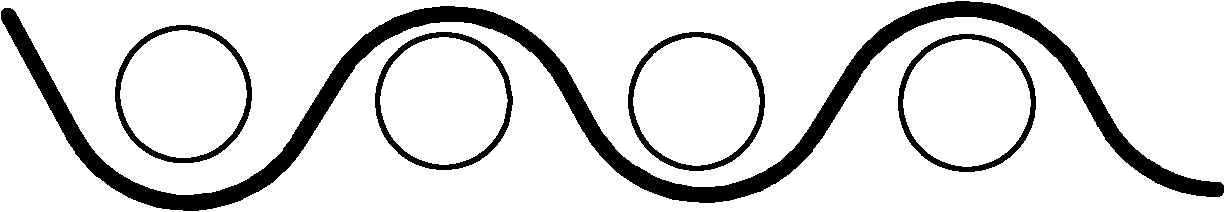

[0020] like figure 1 The fabric for three-dimensional body armor is a three-dimensional bulletproof fabric, the fabric structure is a three-dimensional corner interlocking woven fabric structure, and the material of the warp and weft is aramid. The three-dimensional angular interlocking woven fabric structure includes yarn layers formed by interweaving multiple layers of warp yarns and weft yarns, and the yarn layers are obliquely run through the entire thickness through the binding yarn 1 to bind all the yarn layers.

[0021] Taking the three-dimensional body armor for women as an example, firstly, a mathematical model is established by simulating the three-dimensional geometric shape of the female chest. The contour slices the three-dimensional bulletproof fabric, and makes a three-dimensional body armor that fits the female curve through a three-dimensional parametric numerical modeling process.

[0022] The plasticity of the three-dimensional bulletproof fabric:

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com