Force-transmitting device with a calibration weight that can be coupled and uncoupled

A technology for transferring devices and calibrating weights, which can be used in measuring devices, weighing equipment testing/calibration, weighing, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

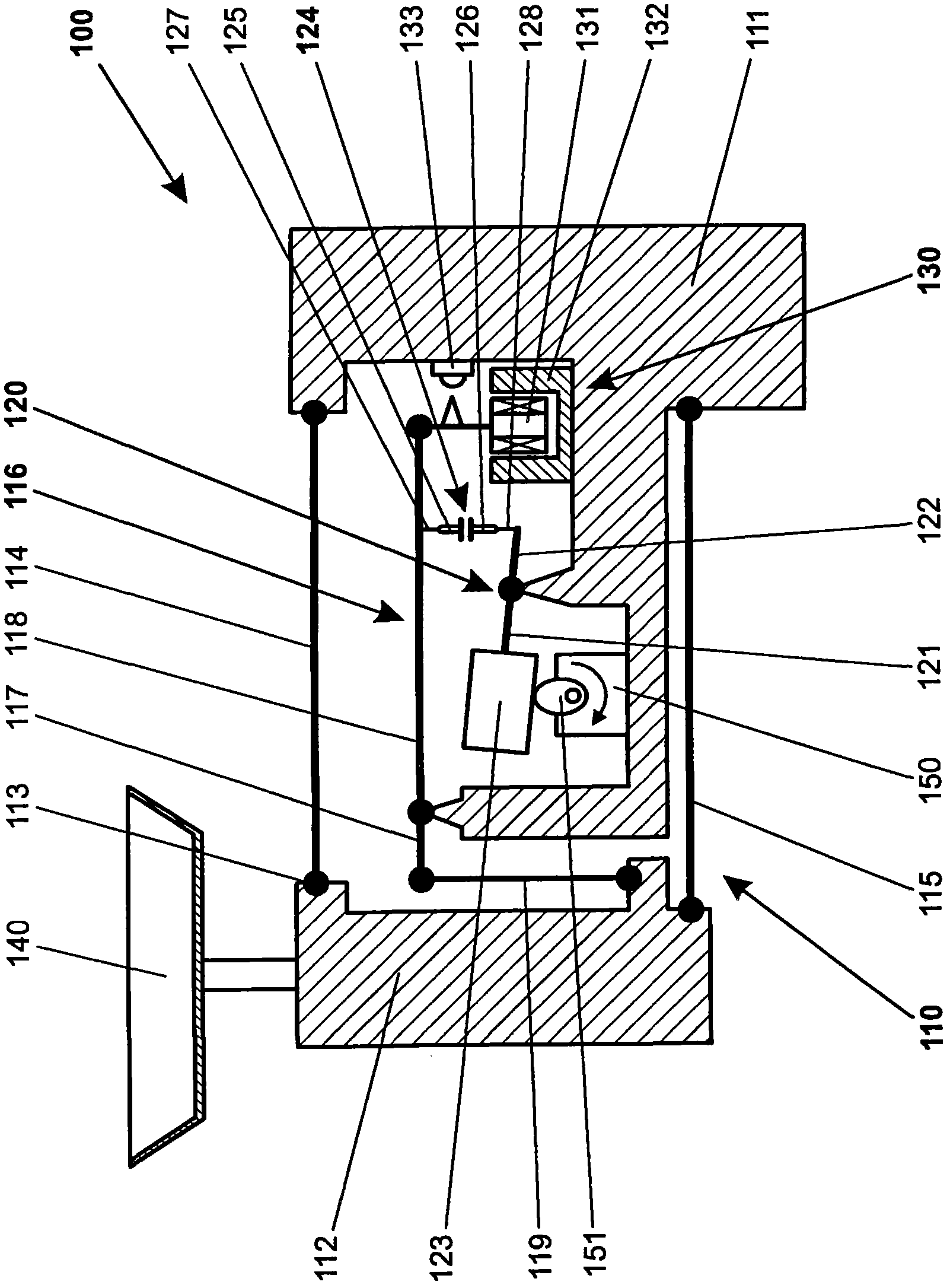

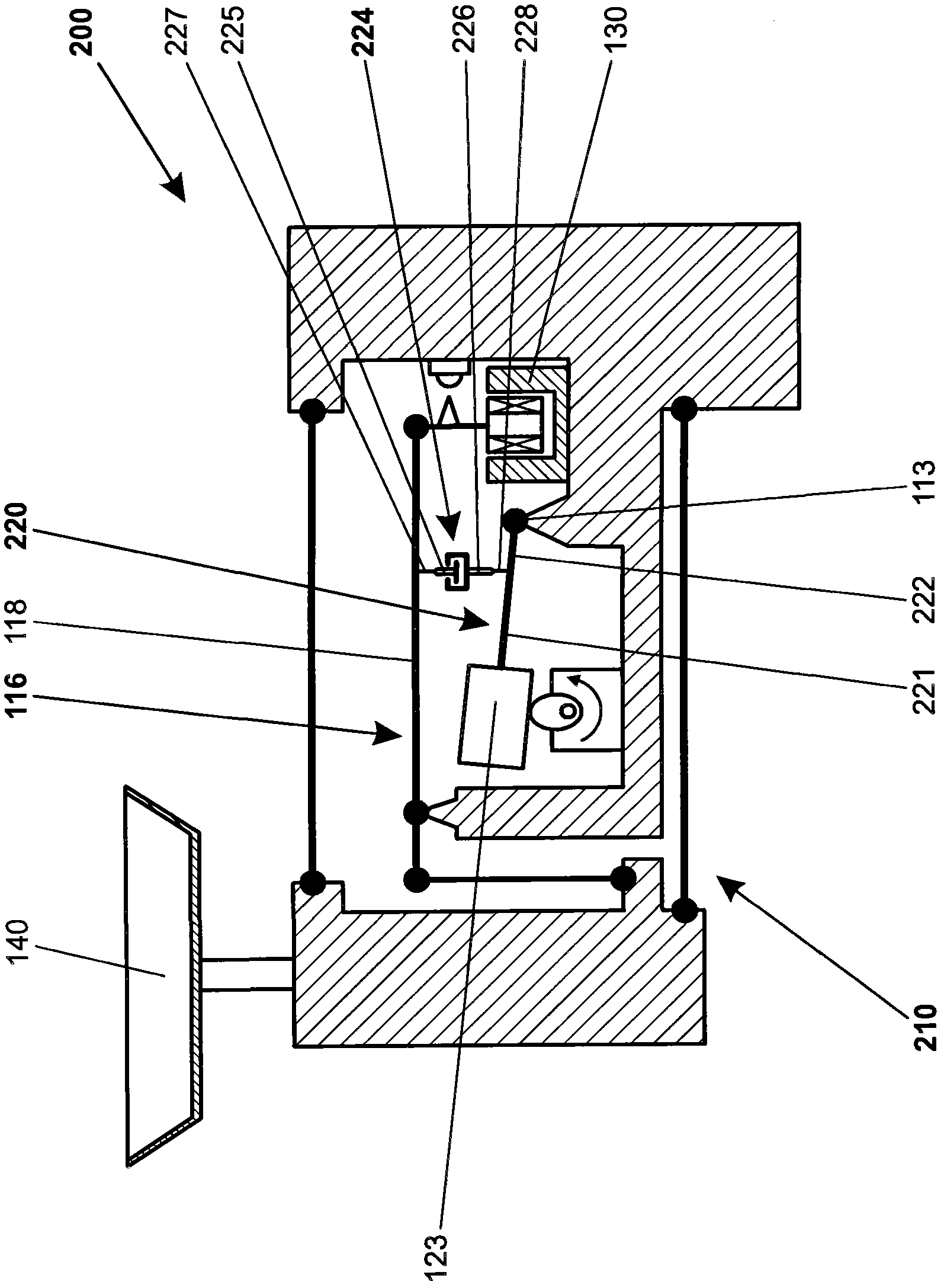

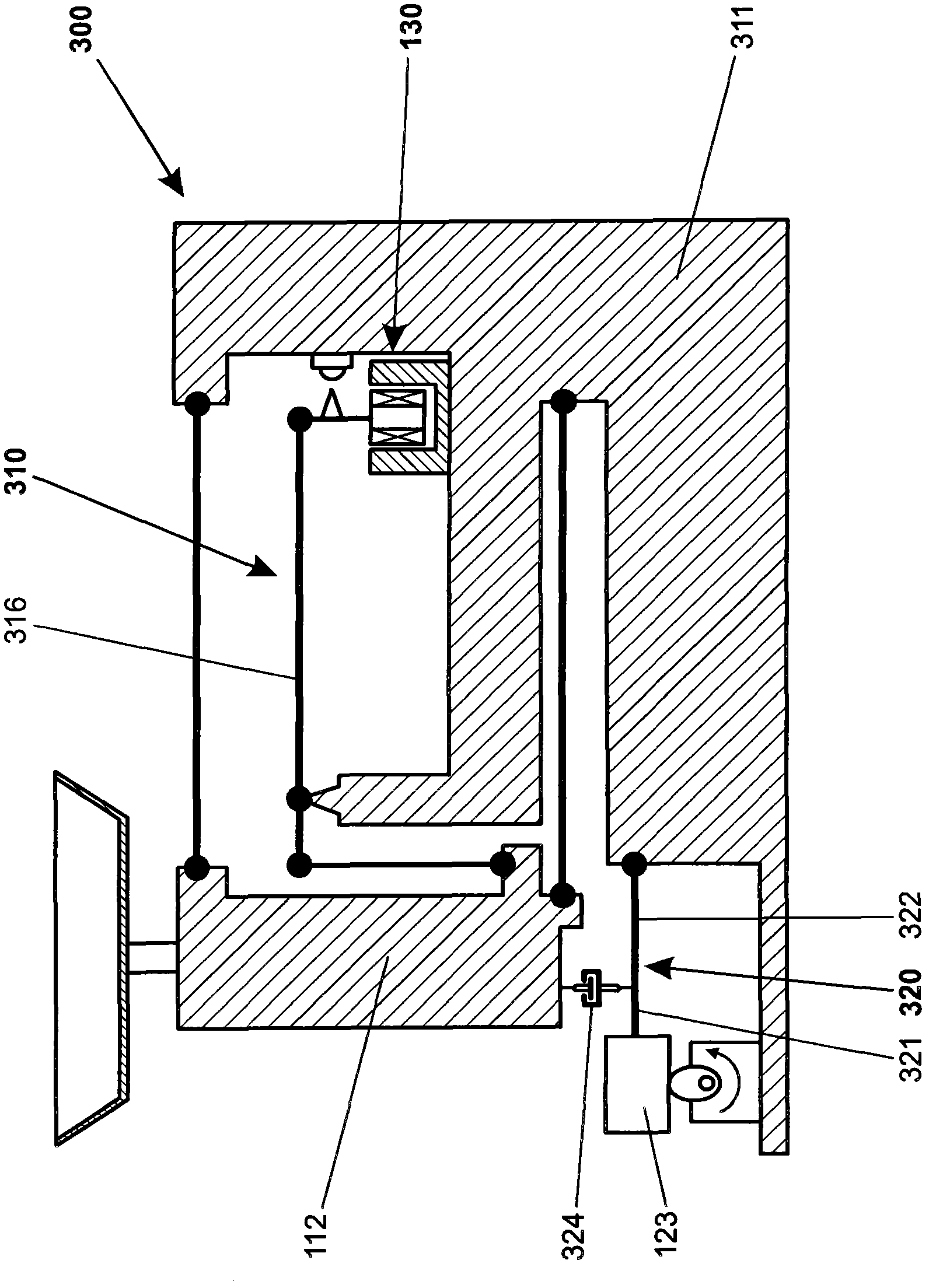

[0040] figure 1 A schematic side view of a weighing cell 100 with a force transmission device 110 of the first embodiment is shown. The force transmission device 100 has a stationary part 111 and a load receiving part 112 . The load receiving part 112 is guided in parallel motion by being connected to the stationary part 111 by a first parallel guide 114 and a second parallel guide 115 . All pivotal connections 113 of the force transfer device 110 are pictorially represented by solid black circles in the figure and may be implemented in any known design in the prior art. These pivot connections 113 are usually designed as Figure 5-7 This flexure pivot is shown in .

[0041] A load receiving member 140 in the form of a weighing pan is connected to the load receiving part 112 . Furthermore, a measuring transducer 130 capable of generating a force-dependent weighing signal is rigidly mounted on the stationary part 111 . The measuring transducer 130 shown in the figure has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com