Robot

A technology of robots and driving mechanisms, applied in instruments, educational appliances, teaching models, etc., can solve the problems of labor consumption, cycle growth, inconvenience, etc., and achieve the effect of saving manpower, material resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

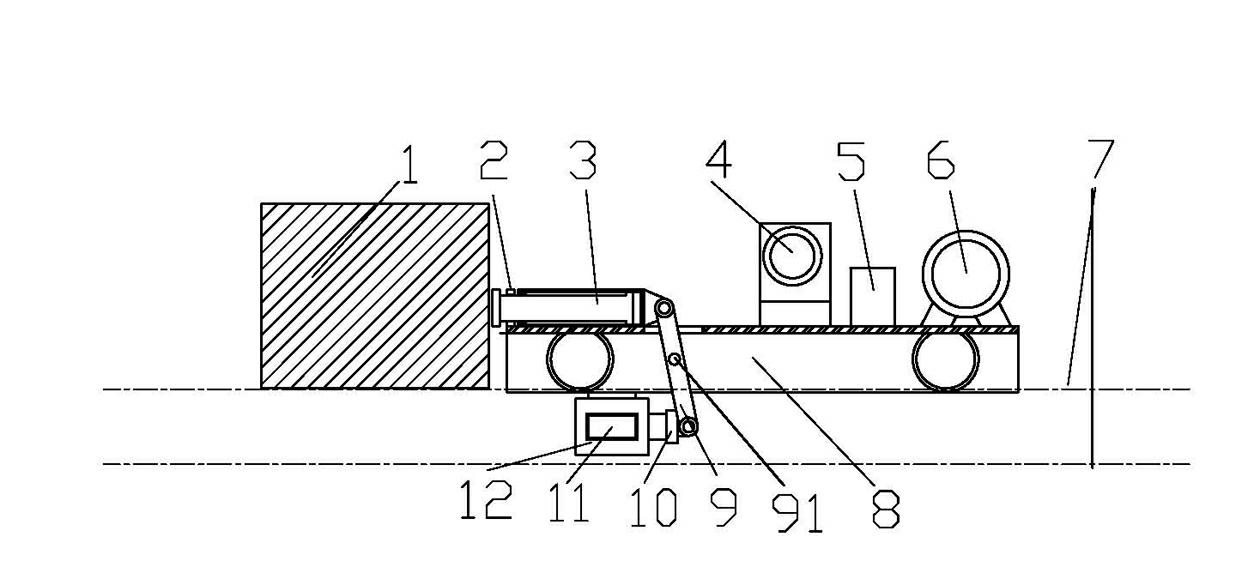

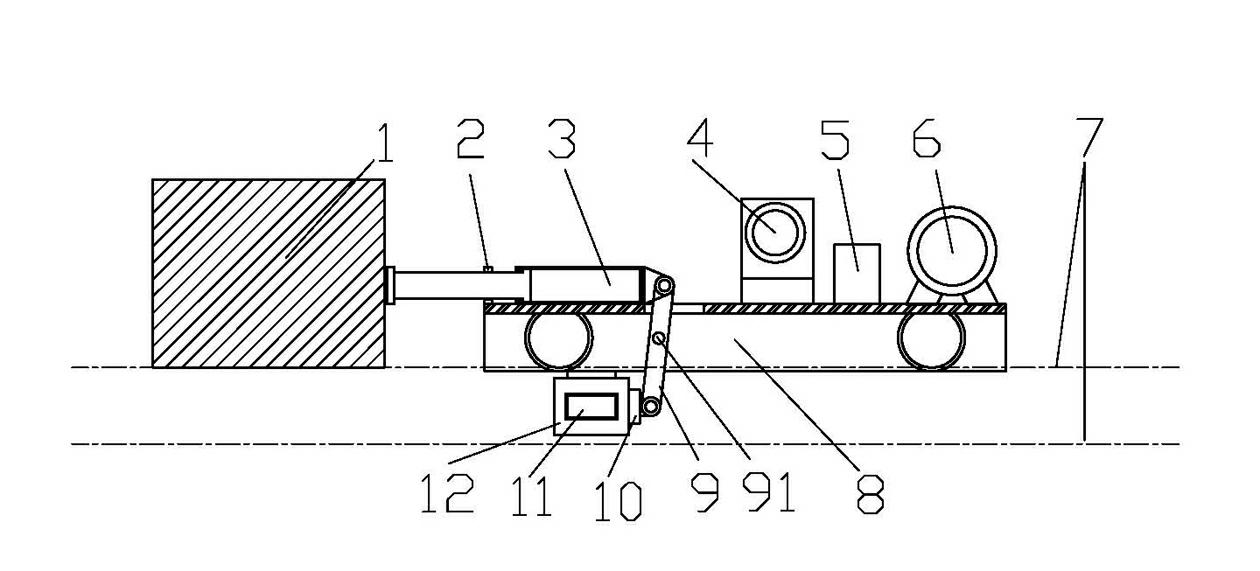

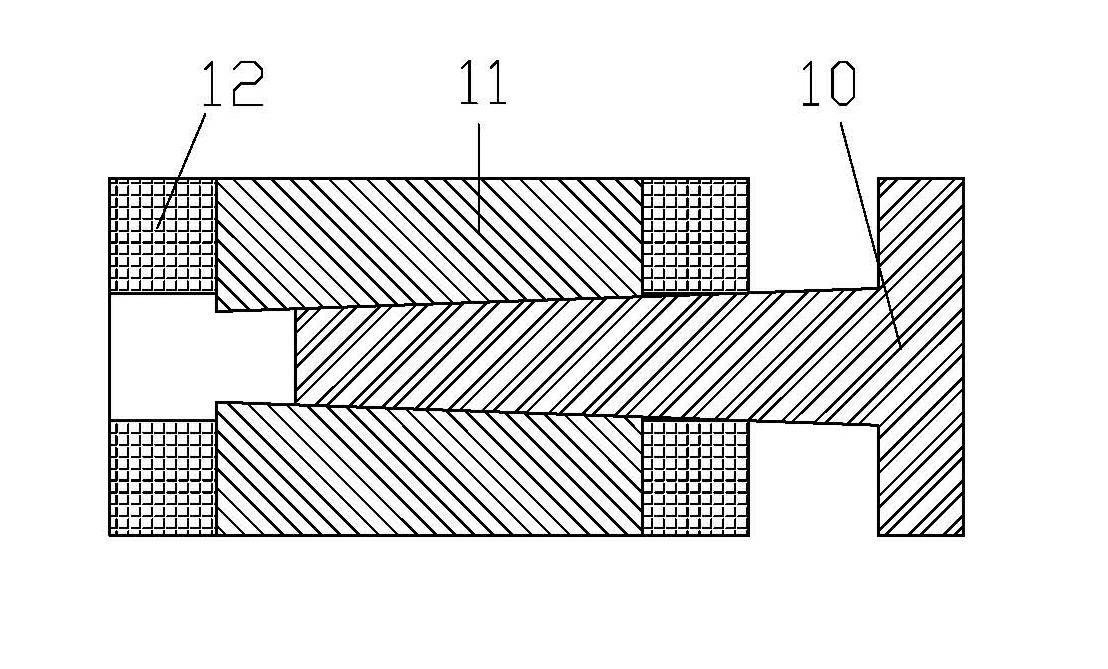

[0016] Such as figure 1 , 2 Shown, " dung beetle " formula robot among the present invention mainly comprises, dolly 8, driving mechanism, hydraulic oil cylinder 3 and composite braking mechanism. Wherein, dolly 8 is arranged on track 7 by the wheel on it, and can move on track 7. Hydraulic cylinder 3 and driving mechanism are arranged on the dolly, and hydraulic cylinder 3 is arranged on one end of dolly 8, and in its extended state, the piston rod of hydraulic cylinder 3 can be stretched out outside dolly 8, is used for pushing obstacle. On the trolley, a loose block 2 is also arranged at the piston rod extension end of the cylinder barrel near the hydraulic cylinder 3 . The composite braking mechanism is arranged under the trolley and is fixedly connected with the trolley. Such as image 3 As shown, the composite brake mechanism includes: a composite brake block 12 , a fixed block 11 and a wedge block 10 ; the fixed block 11 and the wedge block 10 are arranged in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com