Mold and method for manufacturing an automobile part partially covered in plastic

A technology for auto parts and molds, applied in the field of mixed parts manufacturing, can solve the problems of multiple time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

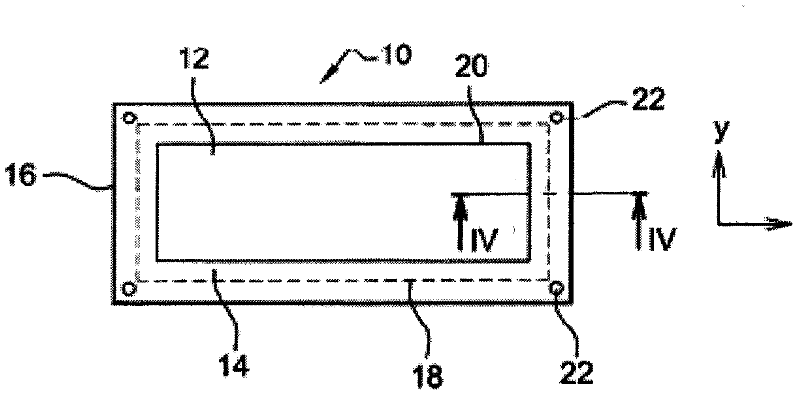

[0040] FIG. 1 shows an automotive part, generally designated 10 , comprising a metal plate 12 for forming a metal body and comprising a peripheral region 14 covered with a plastic body 16 . The outer boundary 18 of the metal plate 12 defines a first frontier of the peripheral area 14 , the inner boundary line of the peripheral area 14 , ie the limit of the metal plate 12 covered by the plastic 16 , is indicated by 20 . Metal plate 12 includes two opposing planes 40 and 42 that meet at outer boundary 18 .

[0041] The plastic body 16 includes a plurality of studs 22 integrally formed therewith for positioning automotive parts. Other functional elements can also be integrally formed with the plastic body 16 . In the example shown, the car part is the roof. However, the part could also be an underbody panel.

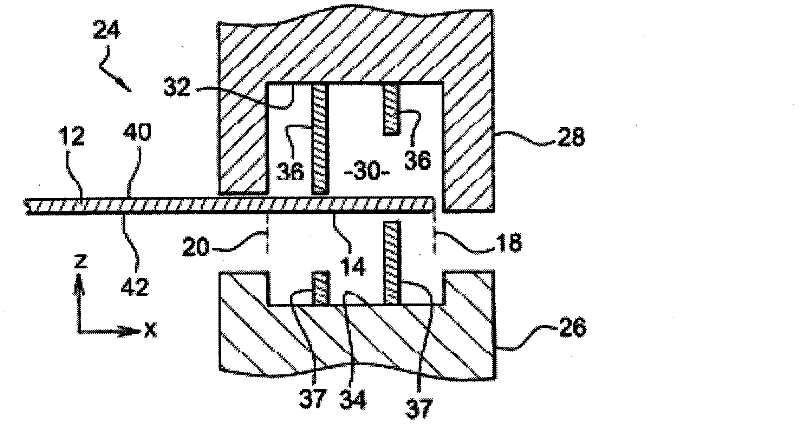

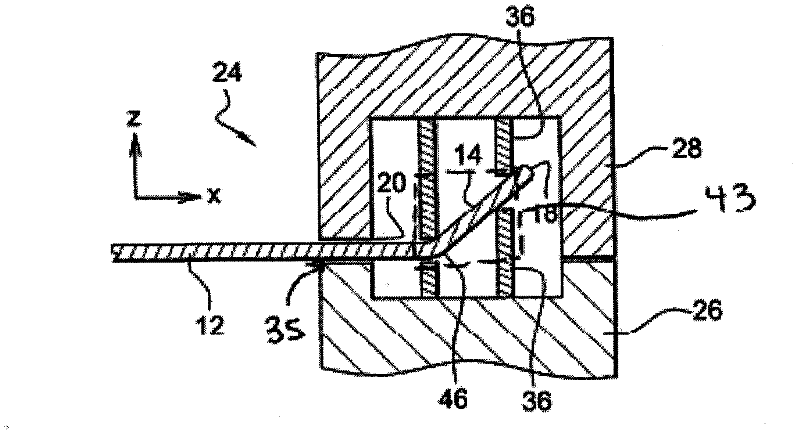

[0042] FIG. 2 shows a mold 24 according to the invention for making part 10 of FIG. 1 . The mold 24 comprises two half-moulds 26 and 28 capable of relative translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com