Flexible coupling structure and ship thruster device with same

A coupling and thrust technology, which is applied to ship propulsion, elastic couplings, propulsion transmission devices, etc., can solve problems such as large influence, poor rotation balance accuracy, and large unbalanced force, so as to save production costs, The effect of preventing lateral vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The first embodiment

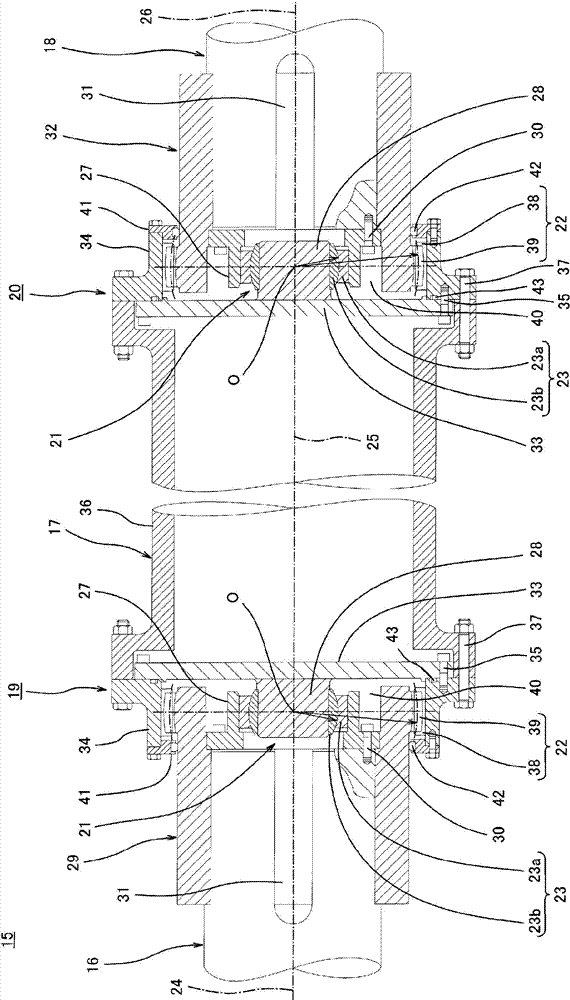

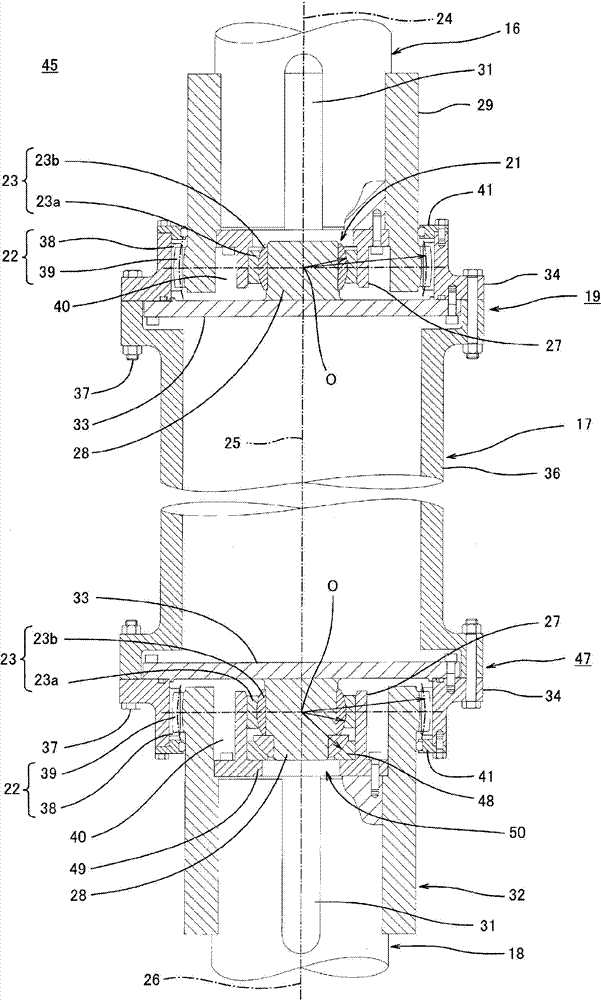

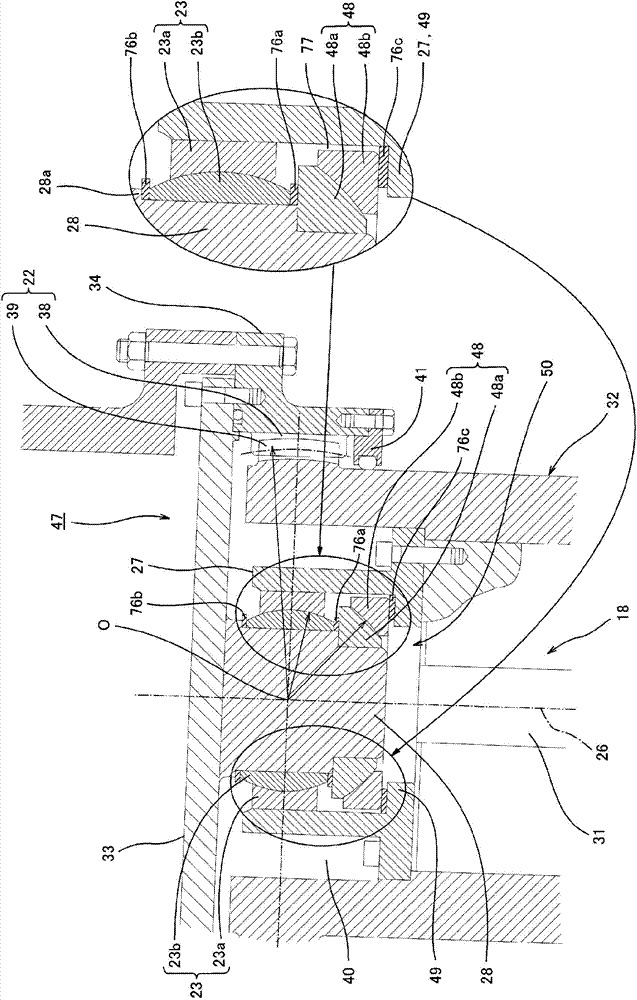

[0063] Refer below figure 1 The first embodiment of the flexible coupling structure of the present invention will be described. figure 1 The flexible coupling 15 shown, through the first flexible coupling structure 19, the connecting shaft 17, the second flexible coupling structure 20, and the driven shaft 18, will serve as a drive unit (not The rotation of the drive-side shaft 16 provided in the figure is transmitted to the propeller of a ship propulsion (not shown). The driving shaft 16, the first flexible coupling structure 19, the connecting shaft 17, the second flexible coupling structure 20, and the driven shaft 18 are arranged substantially horizontally.

[0064] In addition, the connecting shaft 17 has a relatively long size and rotates at a rotation speed of, for example, several hundred revolutions per minute or higher. The driving shaft 16 is rotatably provided in the driving part, and the driven shaft 18 is rotatably provided in the thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com