Patents

Literature

31results about How to "Prevent lateral vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

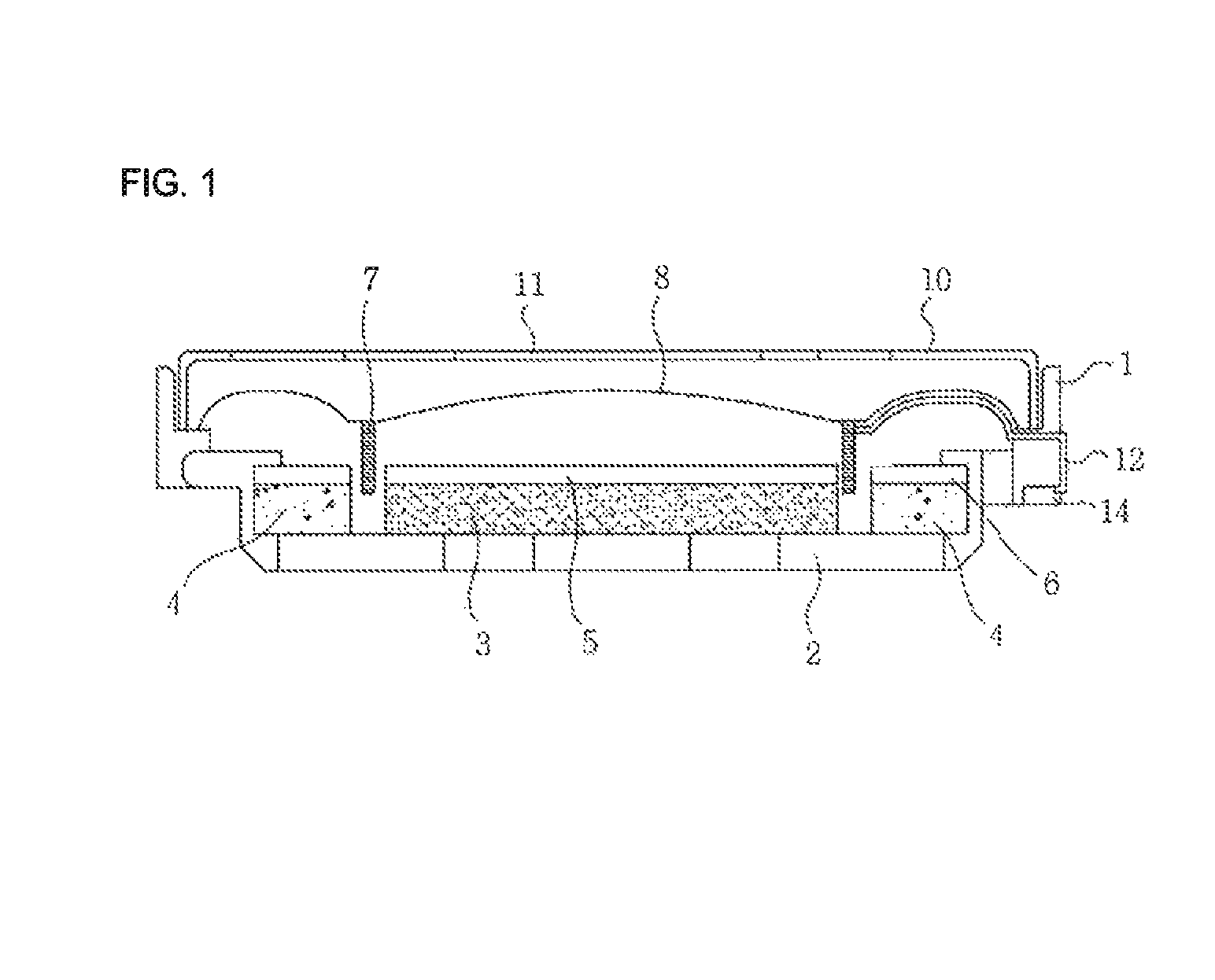

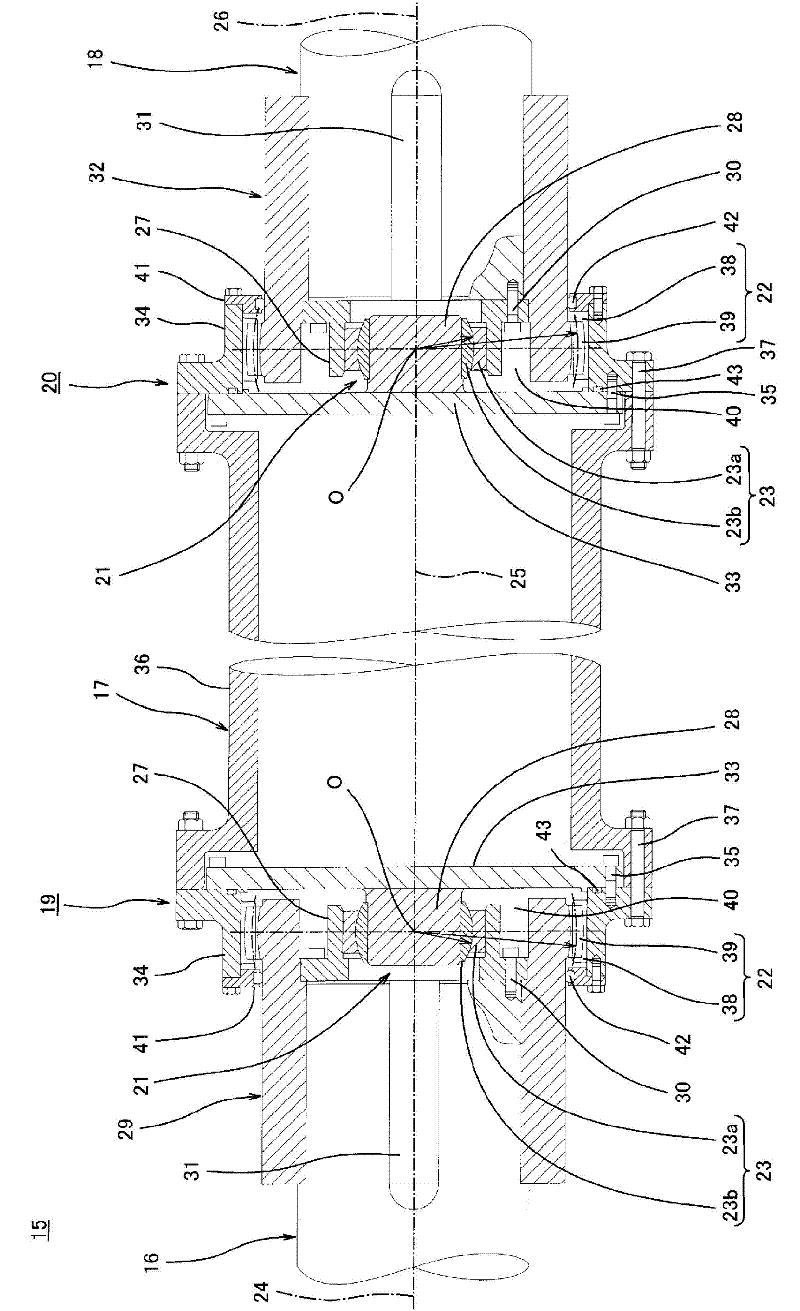

Method and apparatus for producing polybutylene terephthalate film, and shape-memory polybutylene terephthalate laminate film

InactiveUS20060057405A1Good film uniformityGood shape memoryLamination ancillary operationsLayered product treatmentPolytetramethylene terephthalatePolybutylene terephthalate

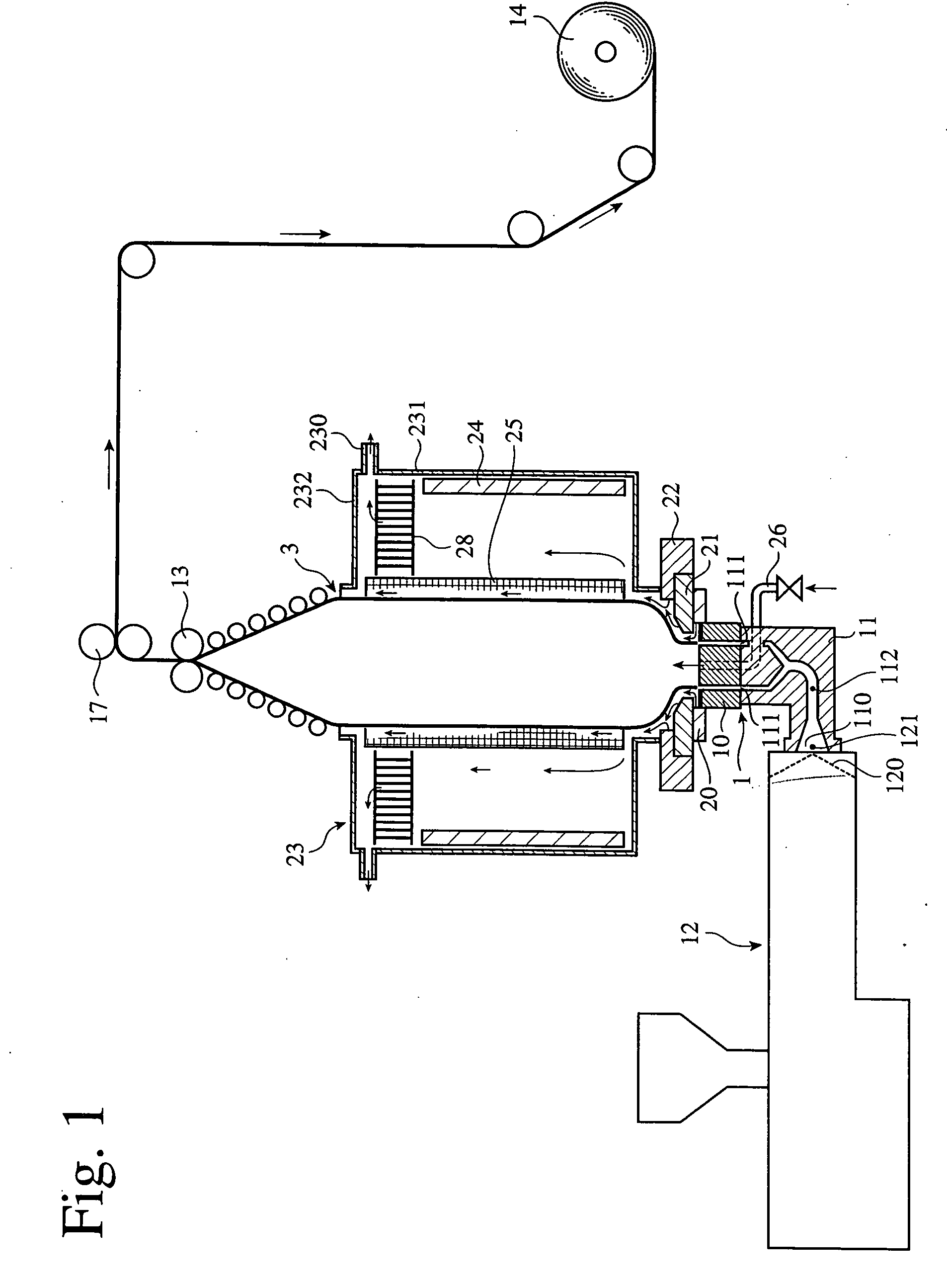

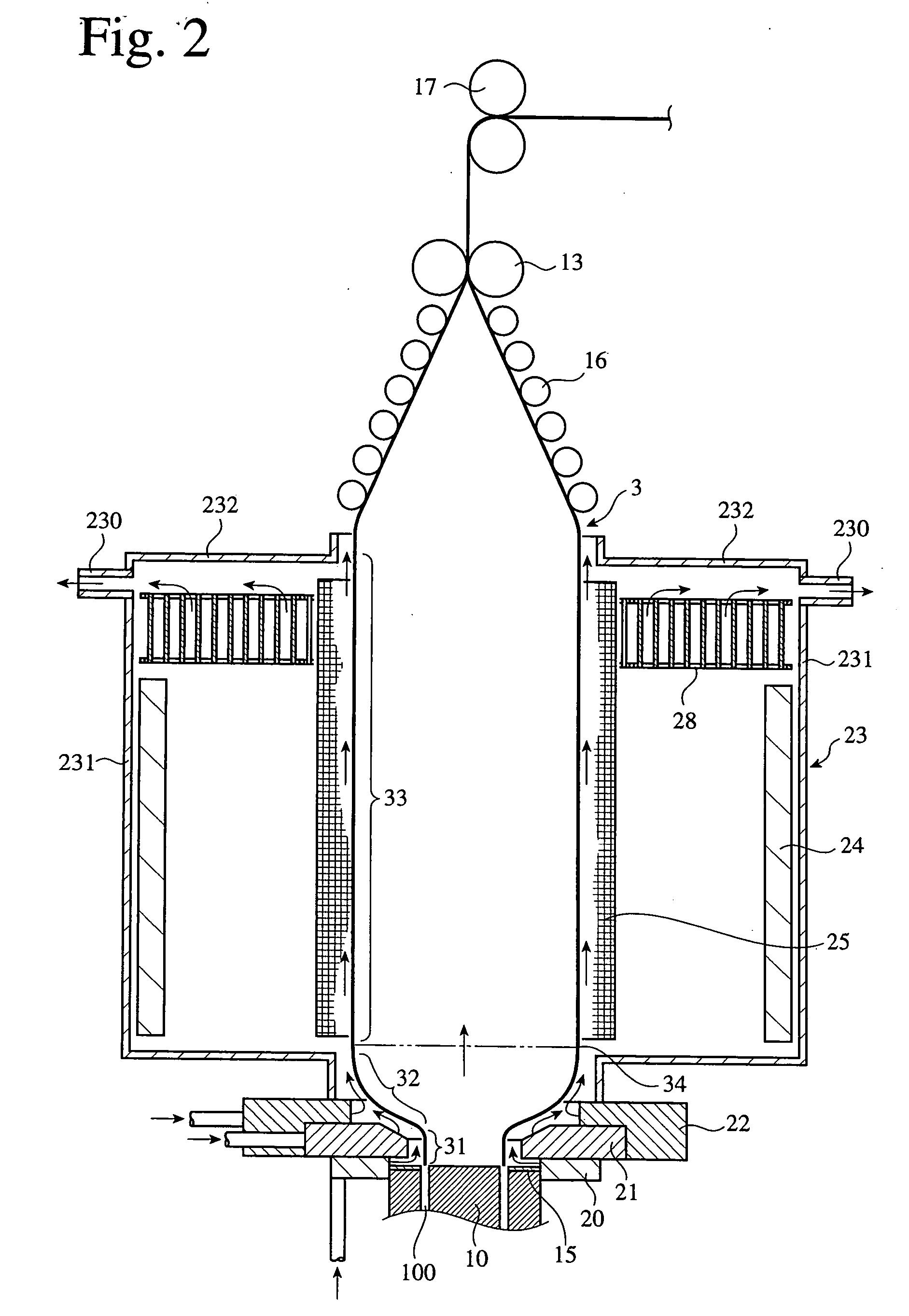

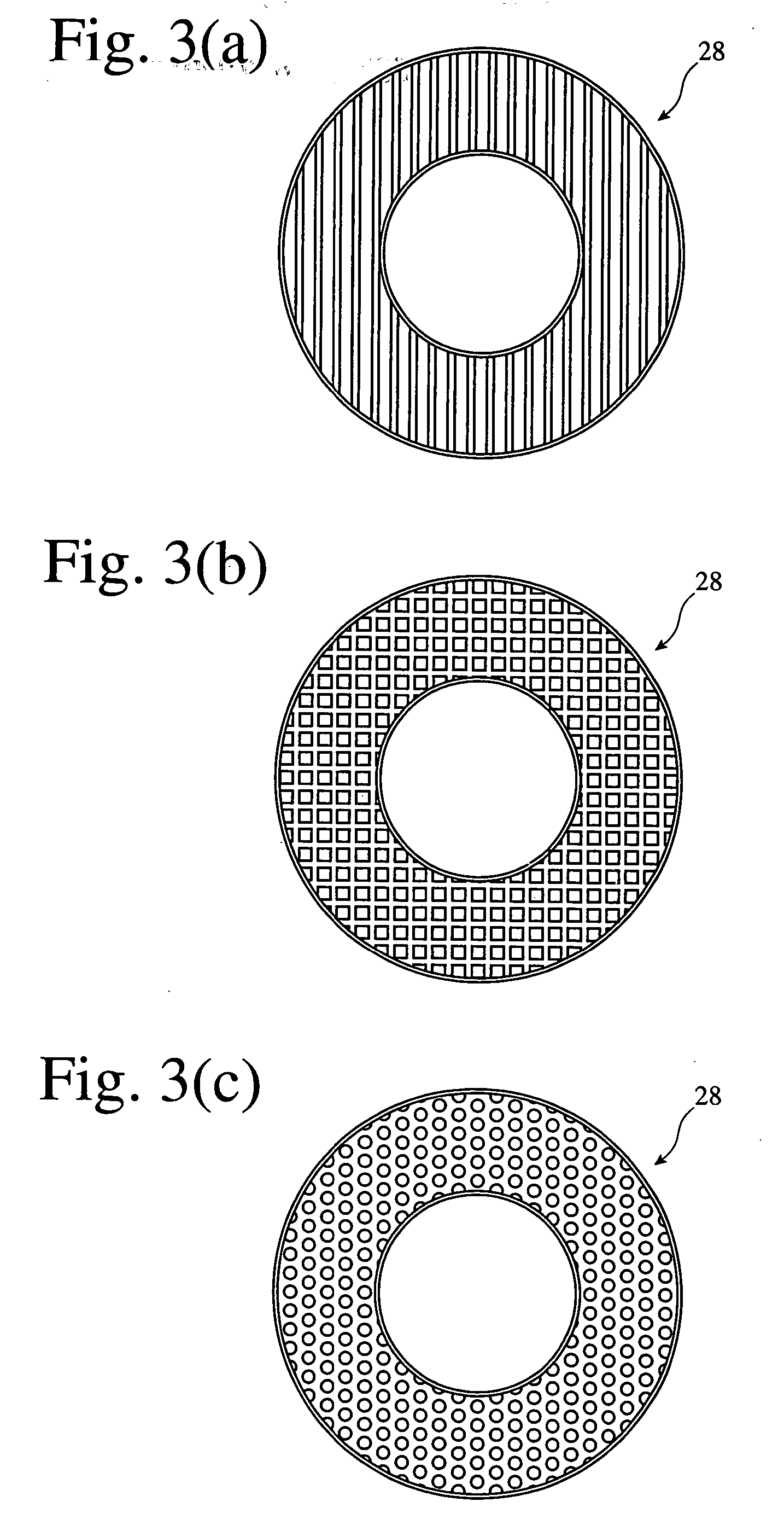

A method for producing a polybutylene terephthalate film by an air-cooled inflation method of inflating a tube of a molten polybutylene terephthalate resin extruded from an annular die by the injection of air, the resin-extruding pressure being 8.3 to 13.7 MPa, and the resin-extruding temperature being a temperature ranging from the melting point of the polybutylene terephthalate resin −15° C. to the melting point −5° C.

Owner:KAGAWA SEIJI

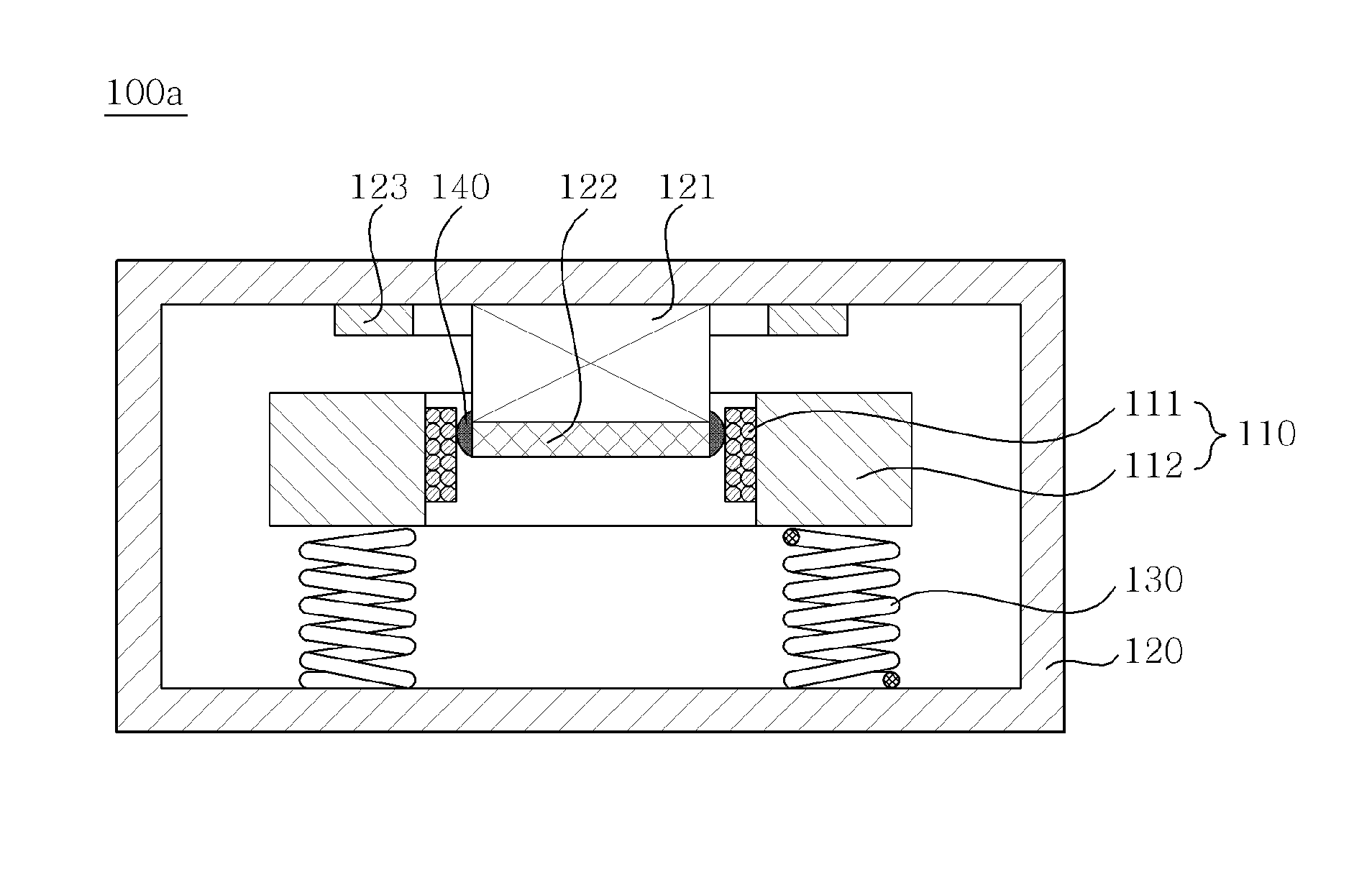

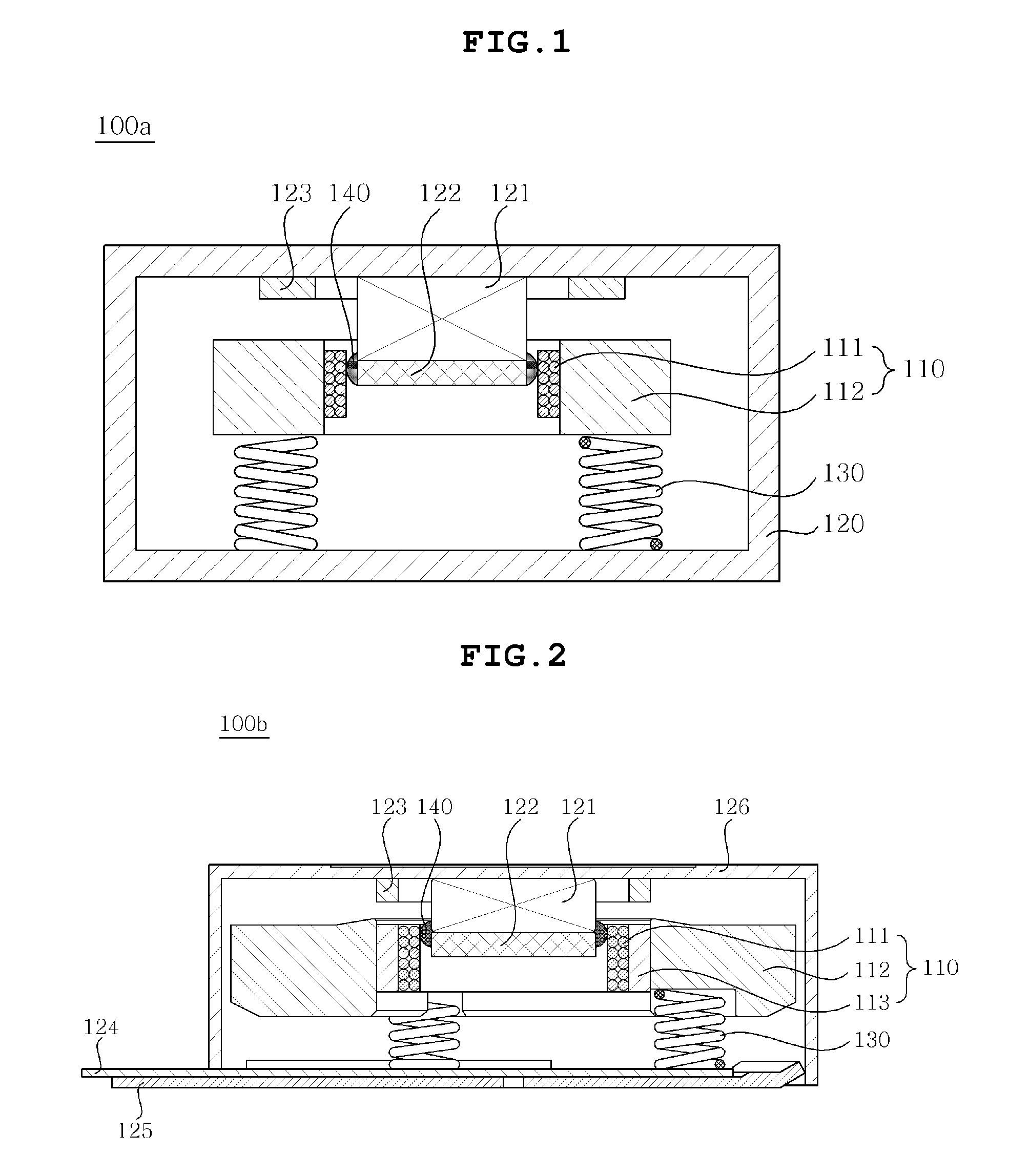

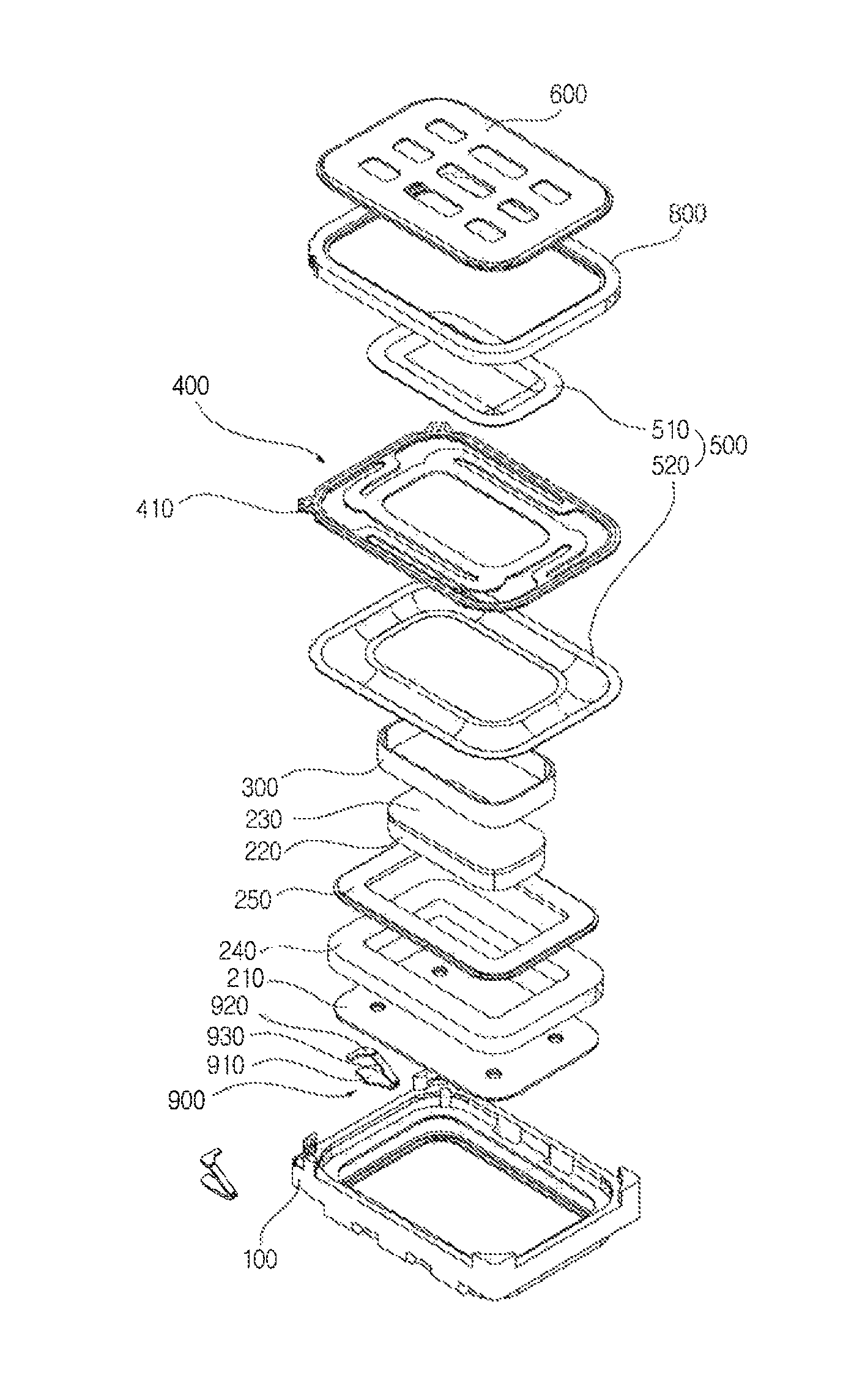

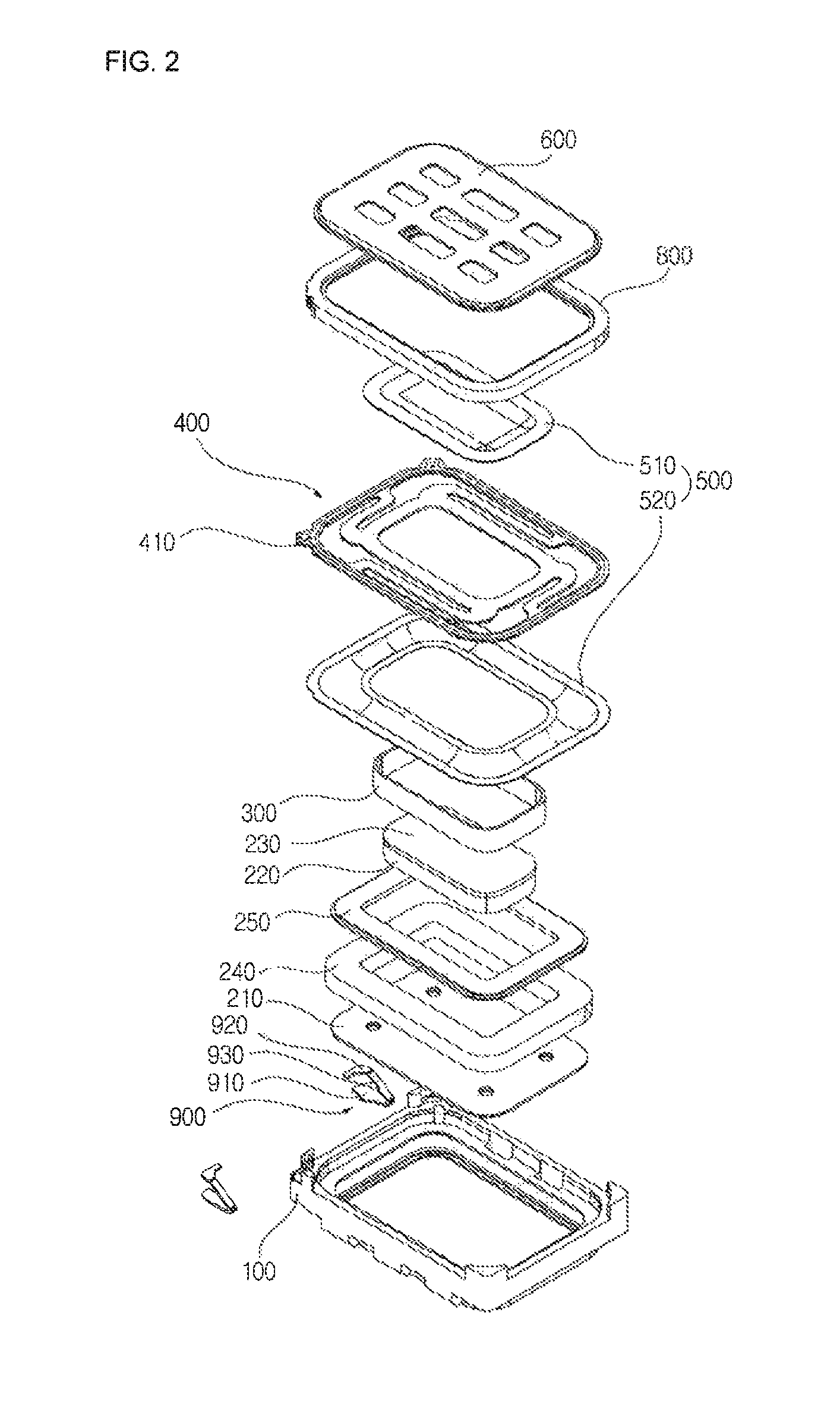

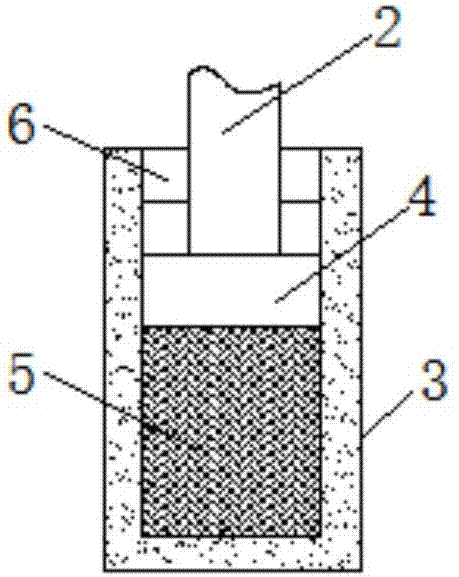

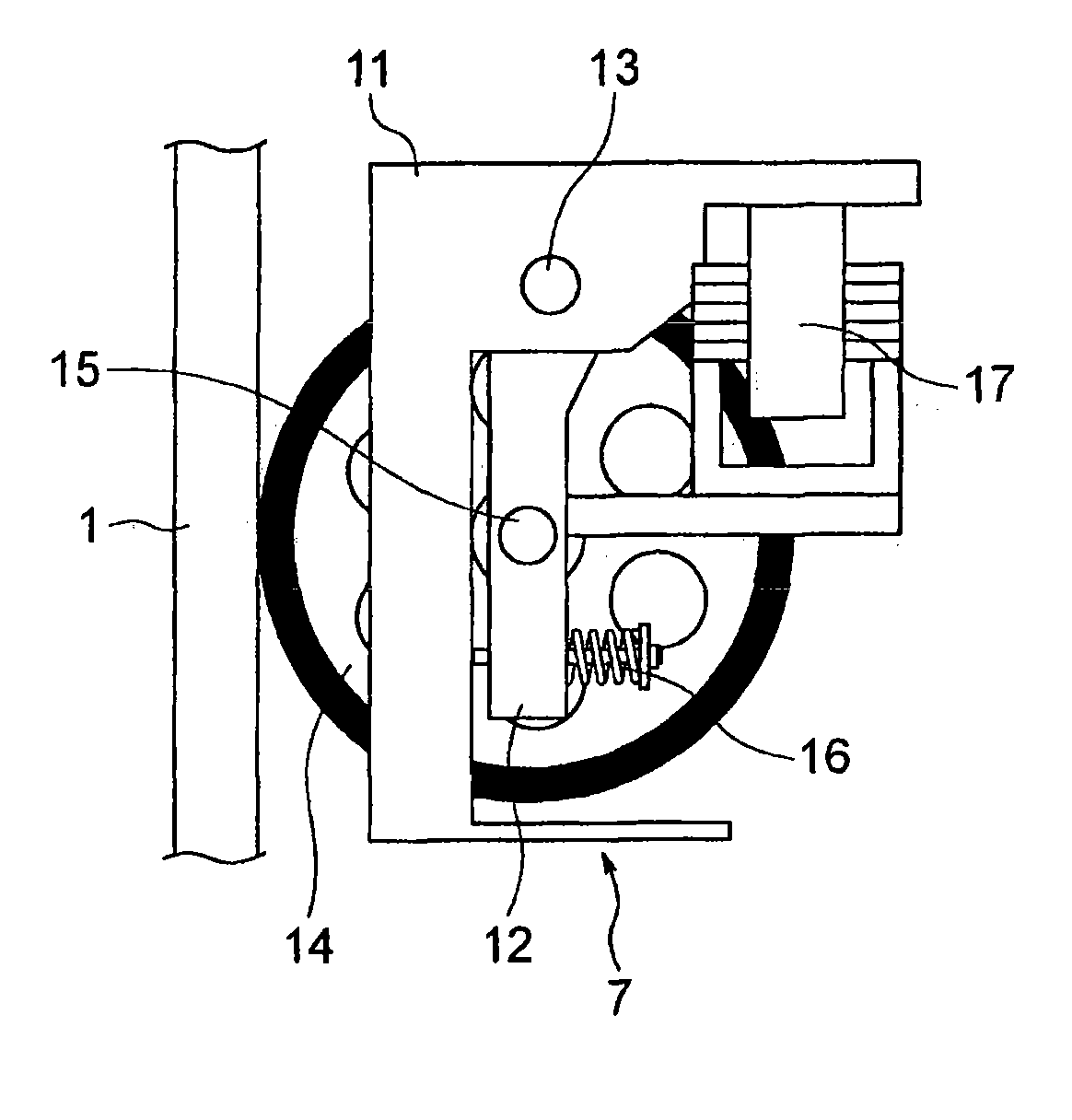

Linear vibrator

ActiveUS8134259B2More stably vibrate linearlyRapidly and stably stop vibratingWindingsMechanical energy handlingLinear motionPower flow

Disclosed herein is a linear vibrator. The linear vibrator includes a stationary unit which has on an upper portion thereof a magnet generating a predetermined magnetic force and a yoke, and defines an internal space. A vibratory unit includes a coil mounted to face the magnet and applying an electric current, and a mass body. A spring is secured at a lower end thereof to the stationary unit and secured at an upper end thereof to the vibratory unit, thus elastically supporting the linear motion of the vibratory unit. A lubricating part is provided between an outer circumference of each of the magnet and the yoke and the coil, thus preventing noise and abrasion when the vibratory unit moves linearly, in addition to maintaining a vibration.

Owner:MPLUS

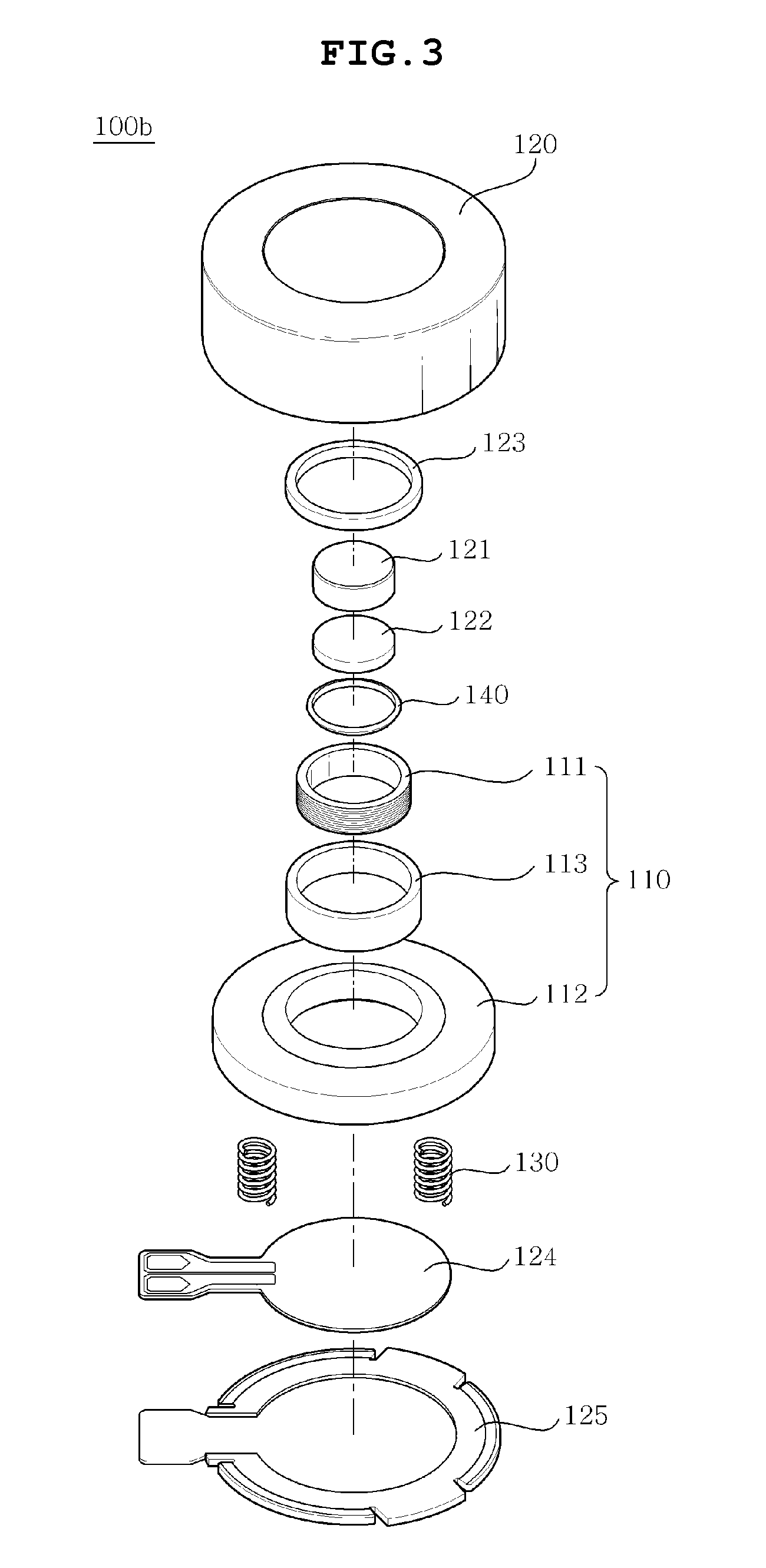

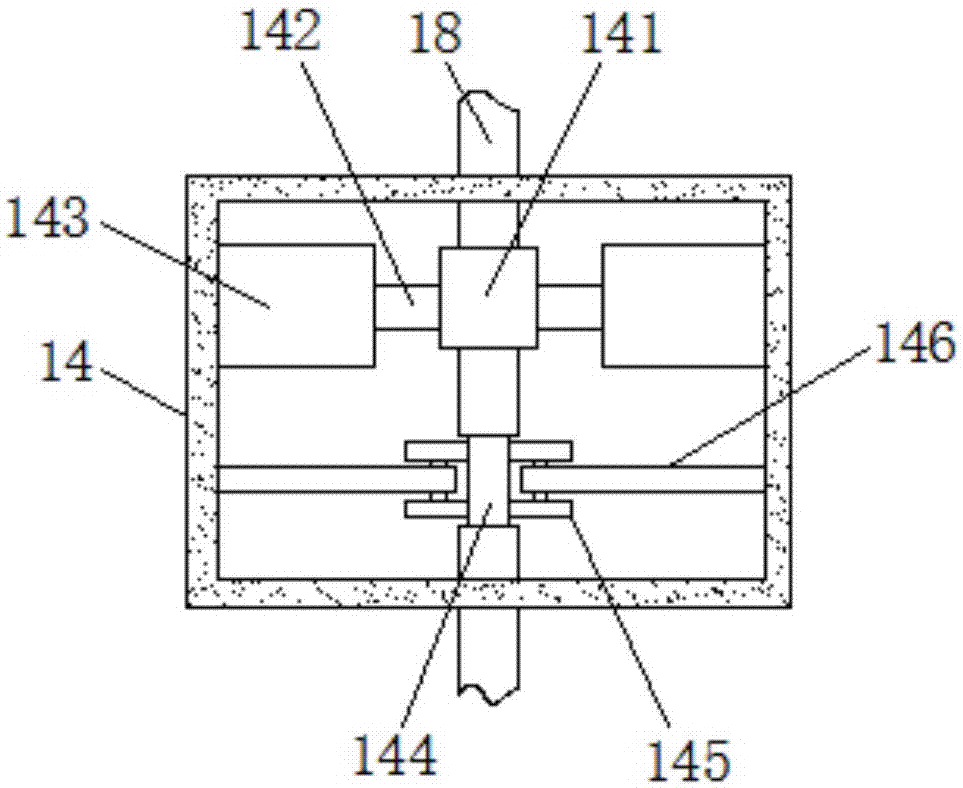

High-output microspeaker

InactiveUS9025808B2Improve reliabilityPrevent lateral vibrationTransducer detailsDeaf-aid setsElectrical connectionEngineering

The present invention relates to a high-output microspeaker, and more particularly, to a high-output microspeaker which includes a damper for preventing lateral vibrations of a diaphragm. The present invention discloses a high-output microspeaker, comprising: a frame; a protector; a yoke assembly coupled to the frame and including a magnet; a diaphragm provided in the frame and producing vibration; a voice coil coupled to the diaphragm and vibrating the diaphragm; a terminal provided on one side of the frame and providing an electrical connection between the lead wire of the voice coil and an external terminal; and a damper formed of an FPCB that includes an inner portion to which a center diaphragm, a side diaphragm and the voice coil are attached, an outer portion to which the side diaphragm is attached and which is in contact with the frame and the protector, a support portion functioning to connect the voice coil, the outer portion and the inner portion and including a land portion to which the lead-in wire of the coil is soldered or welded, and a connecting portion extending outward from the outer portion and providing an electrical connection between the terminal provided on the frame and the outer portion.

Owner:EM TECHNOLOGY CO LTD

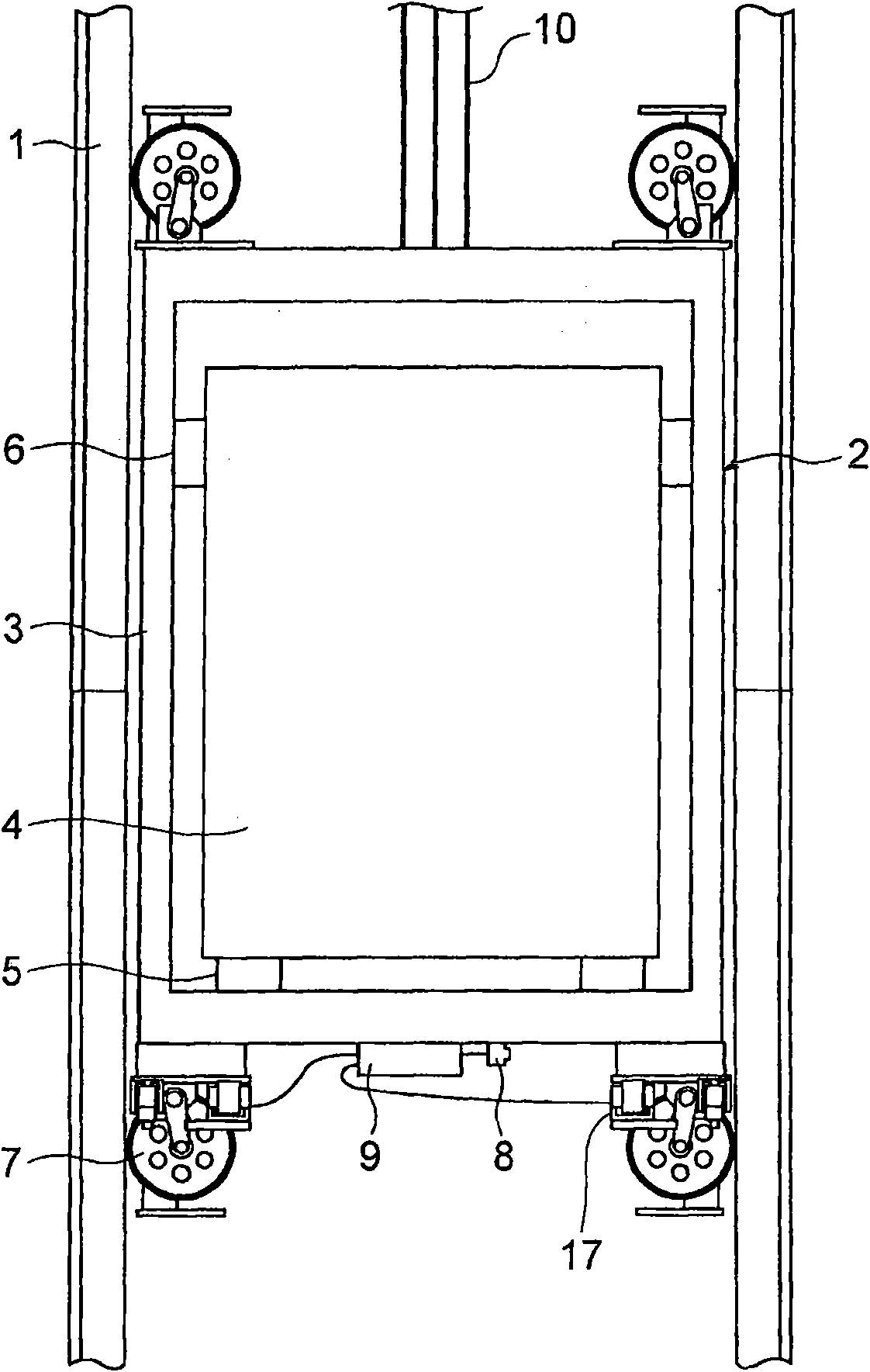

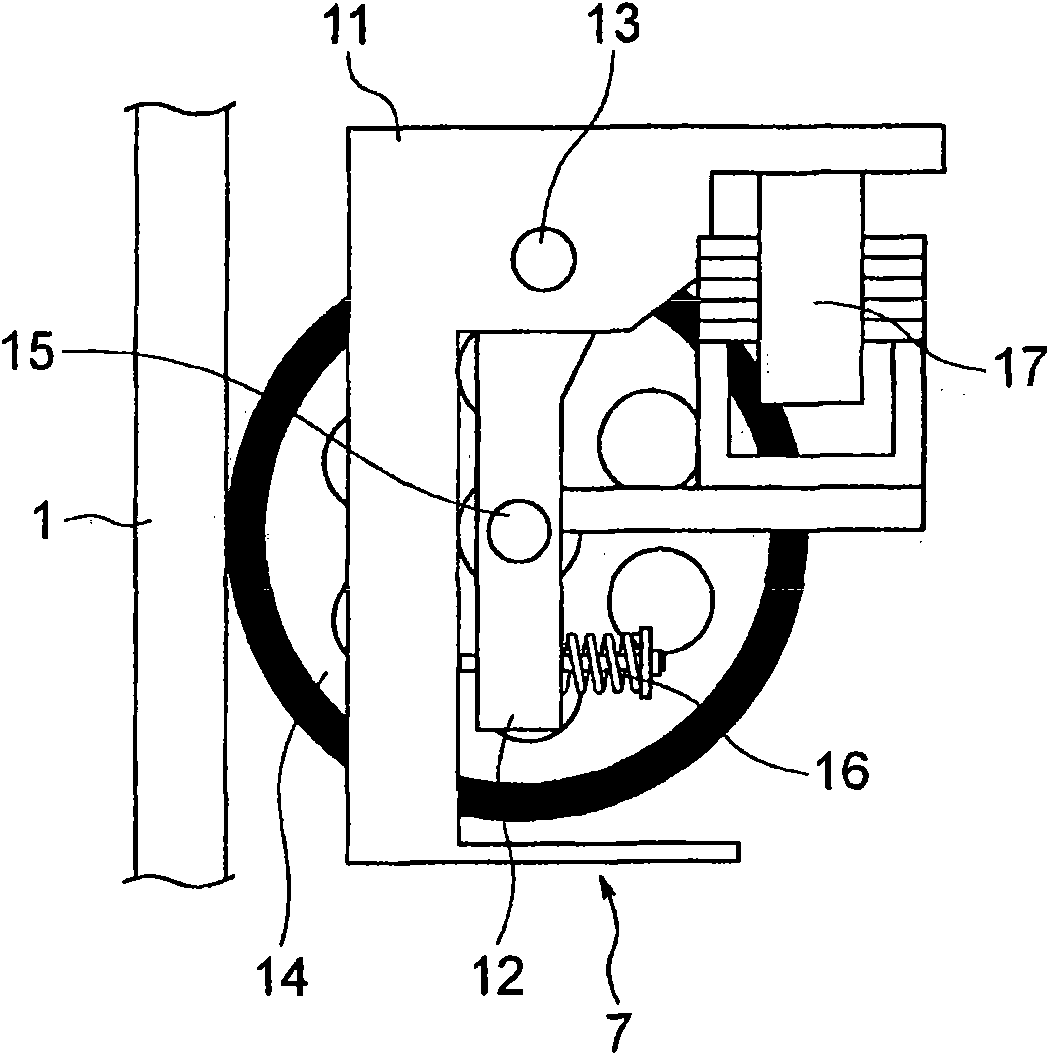

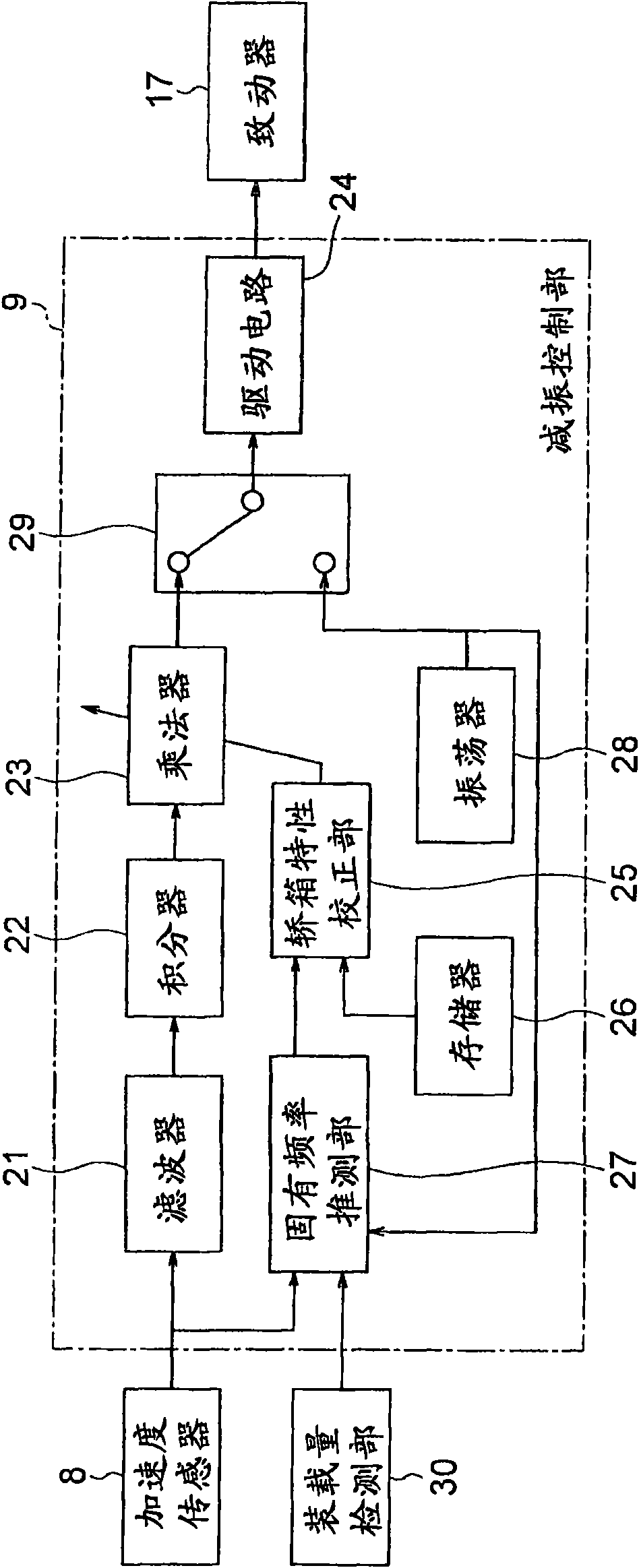

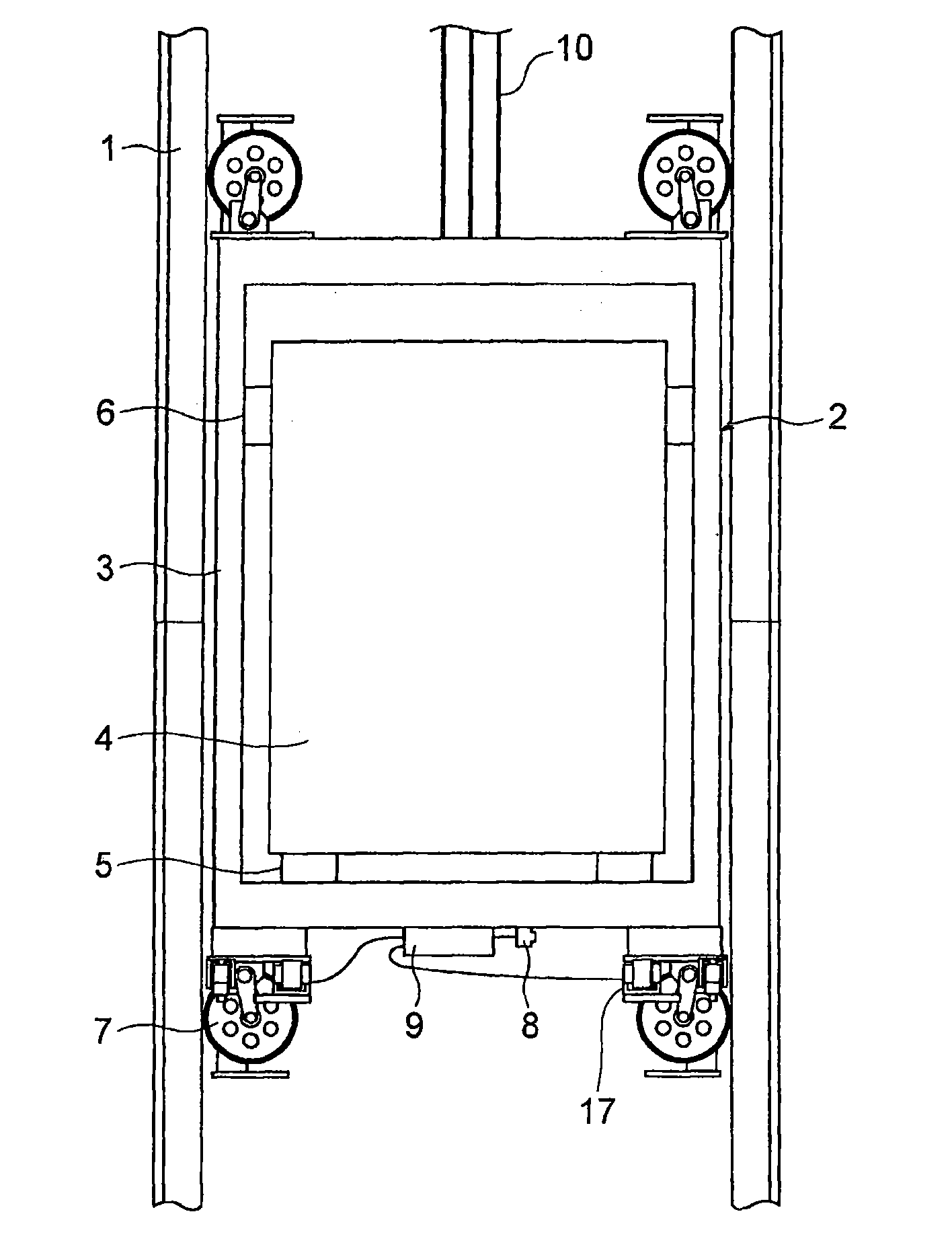

Elevator device

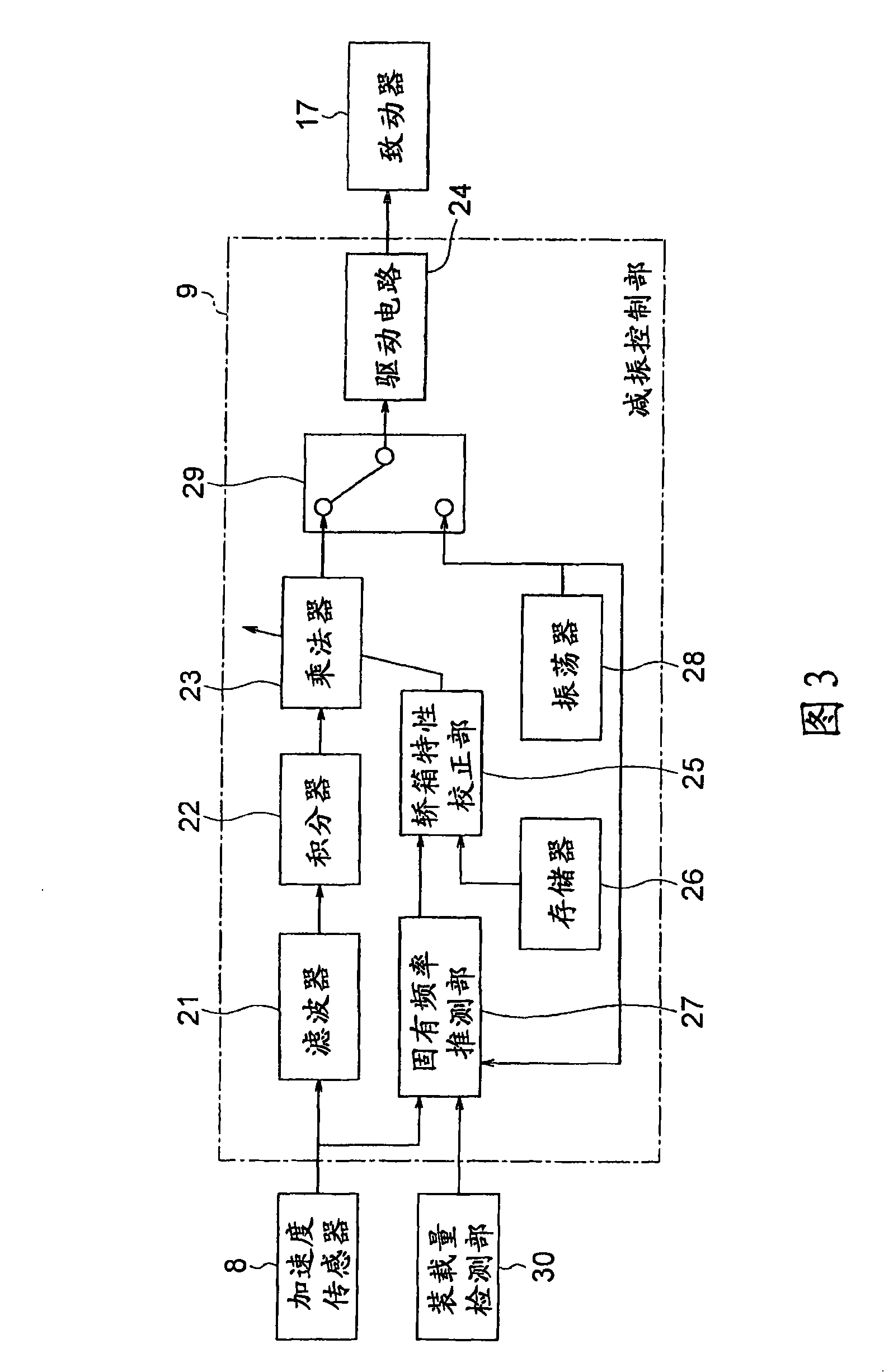

The present invention provides a elevator device. In the elevator device, an actuator for generating a vibration-damping force against the lateral vibration of a car is installed in parallel to an elastic body for preventing the lateral vibration. The actuator is controlled by a vibration-damping control unit. The control unit estimates the inherent frequency of the lateral vibration of the car, and finds a gain value based on the estimated inherent frequency and the rigidity value of the elastic body. Then, the damping control part drives the actuator according to an instruction signal with multiplication of the found gain value.

Owner:MITSUBISHI ELECTRIC CORP

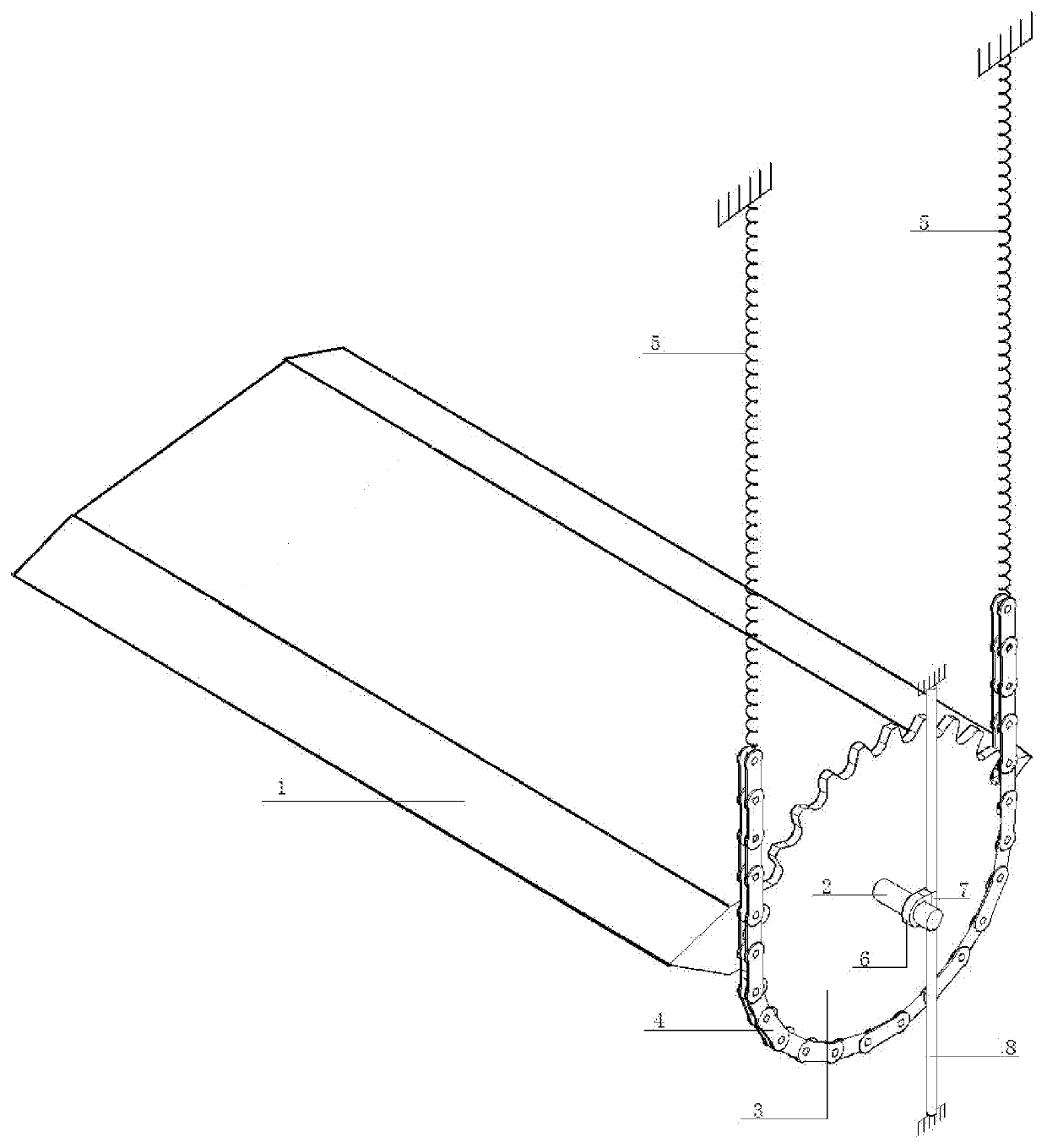

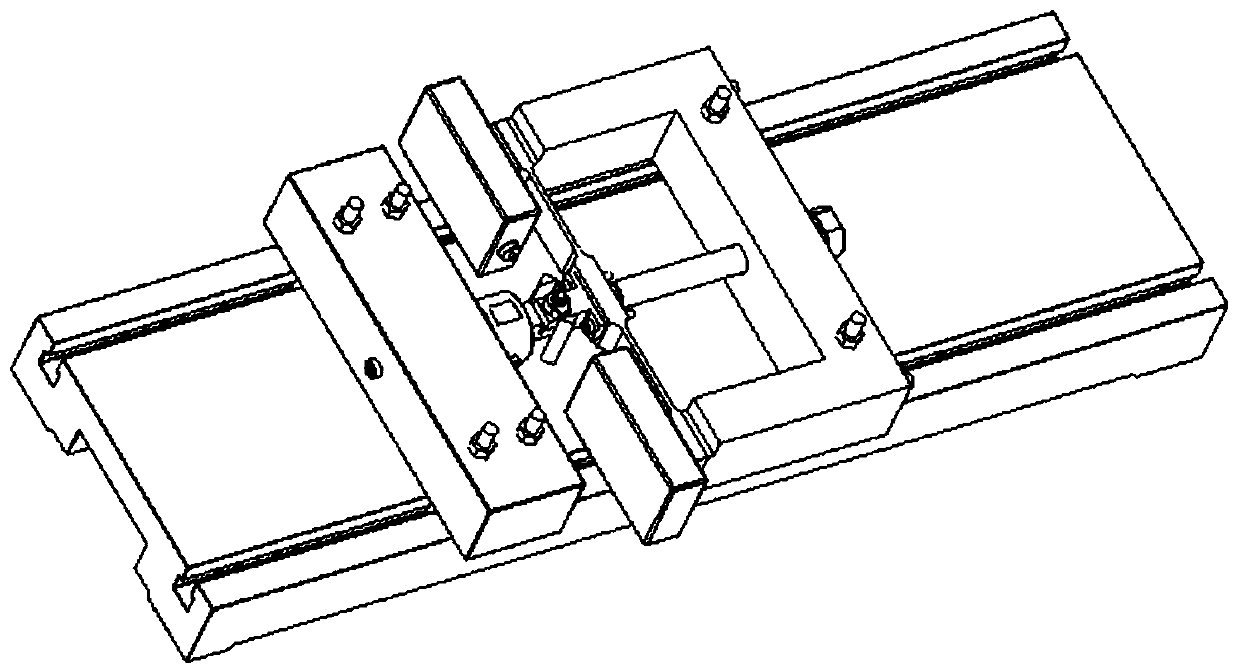

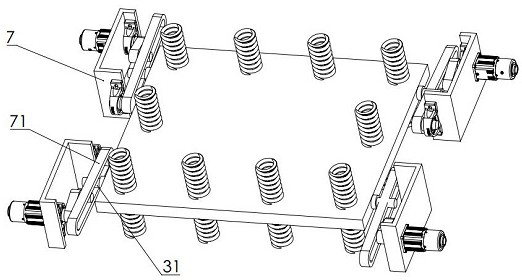

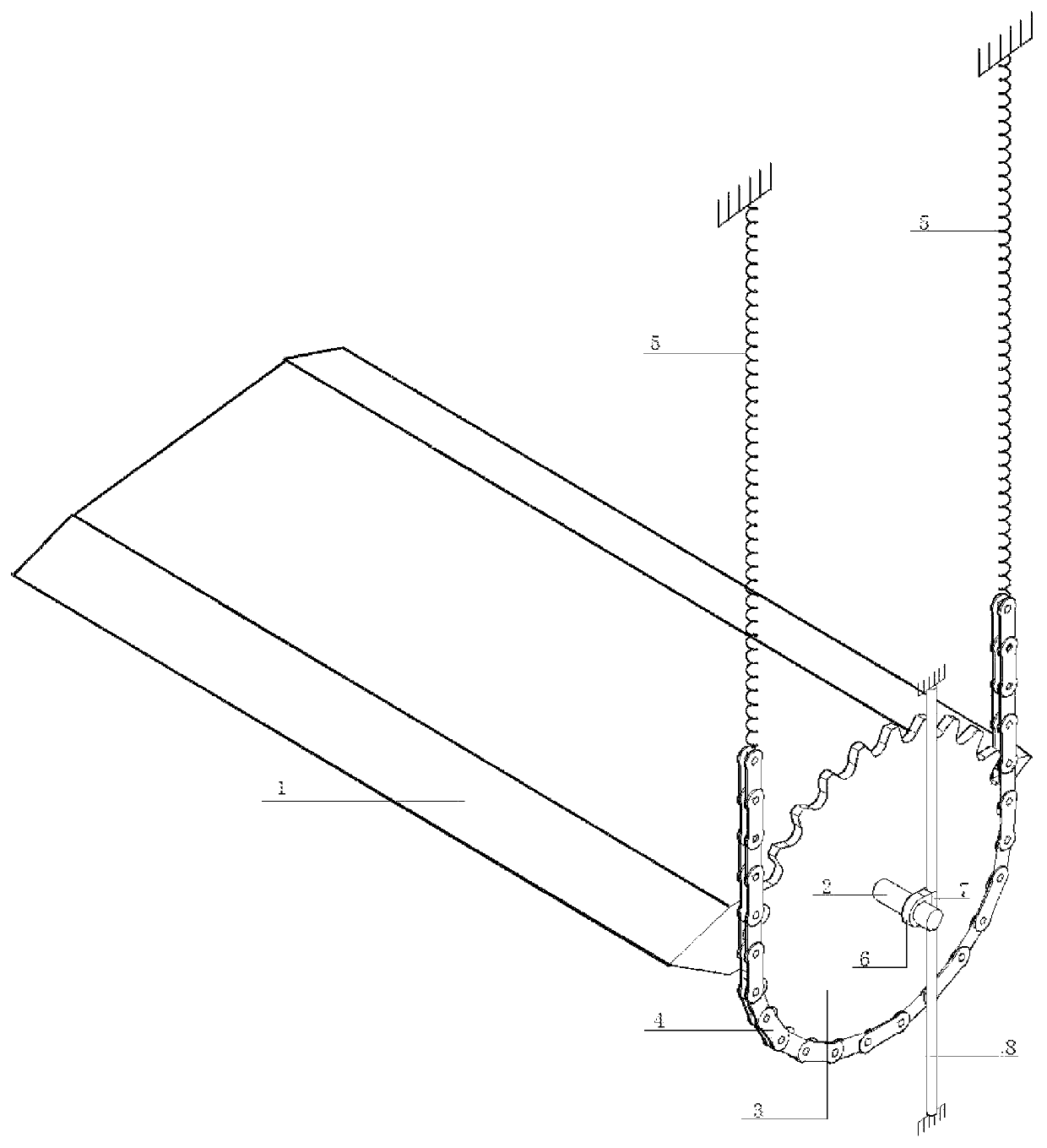

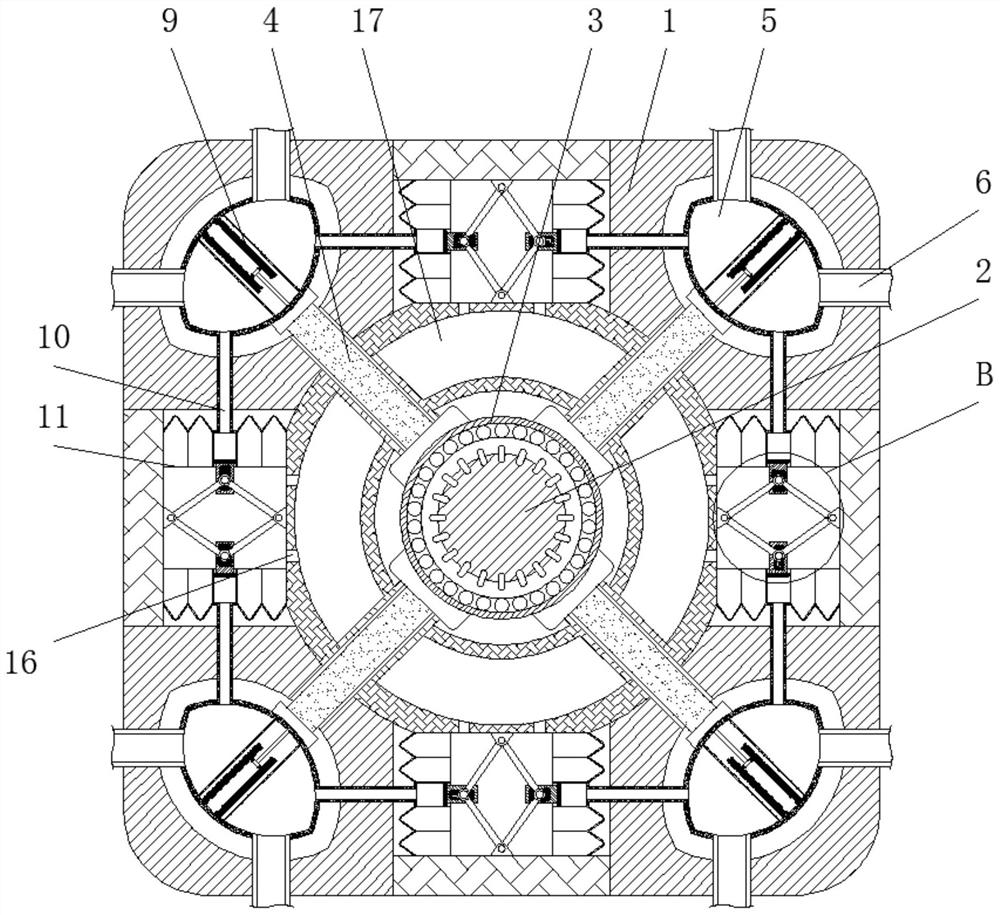

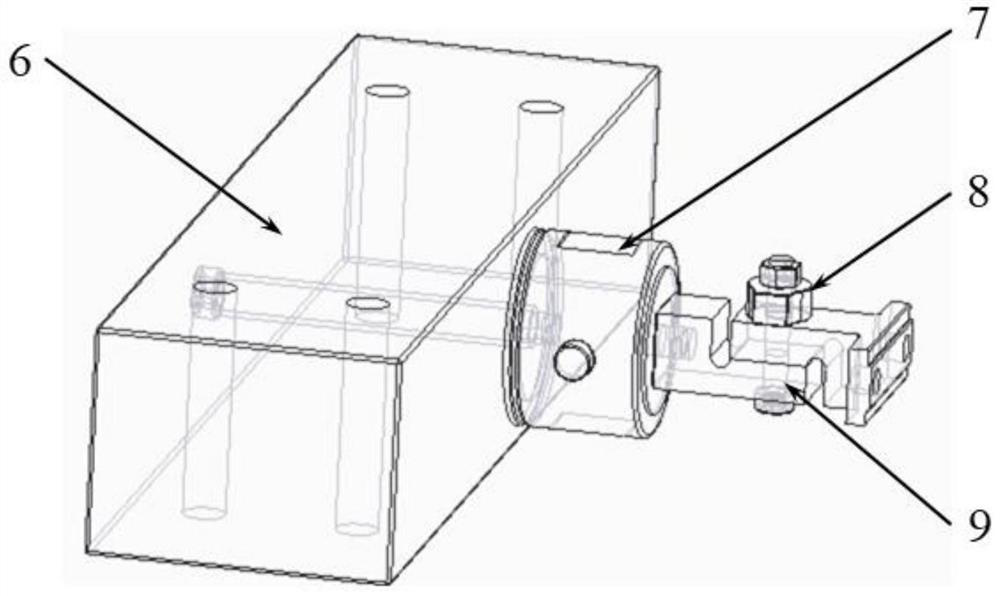

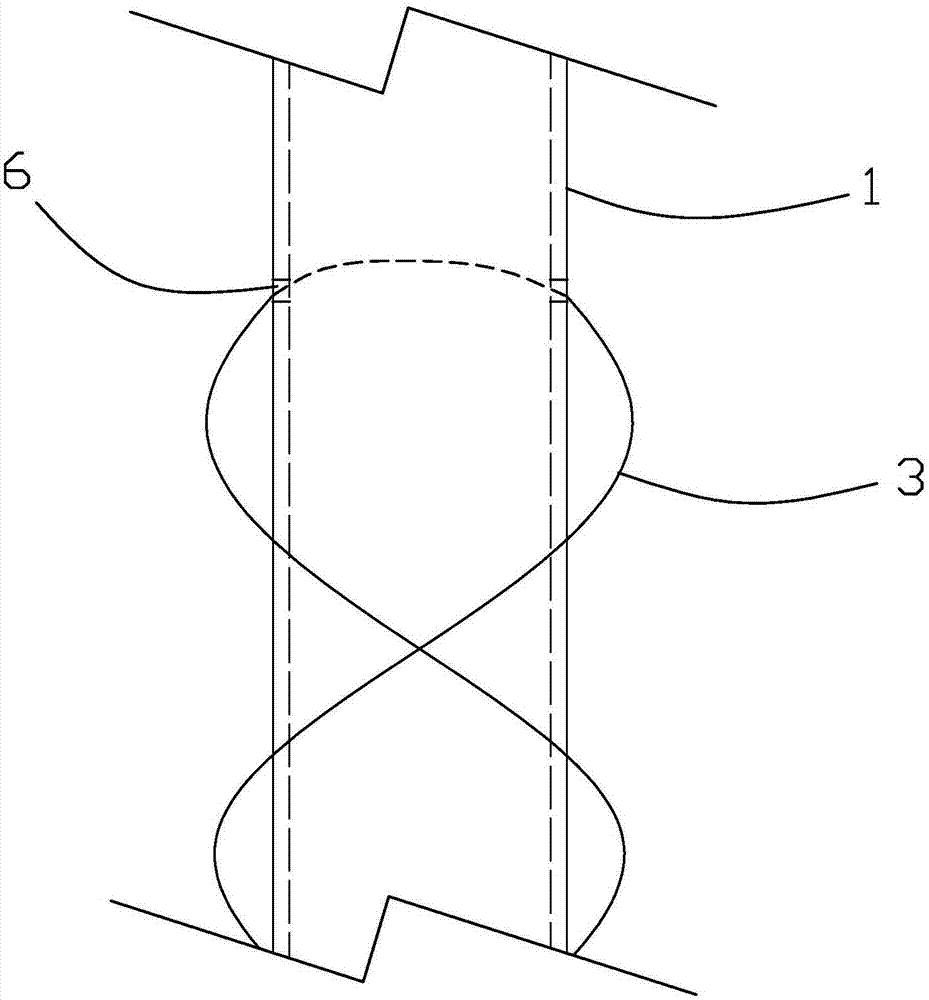

A large-amplitude vertical-torsional coupled free vibration setup for wind tunnel test

ActiveUS20200232875A1Avoid nonlinearityAvoid stiffnessAerodynamic testingVibration amplitudeRigid model

An experimental setup for bridge deck large-amplitude vertical-torsional coupled free vibration in wind tunnel test, which belongs to the technical field of wind tunnel test apparatus. The experimental setup includes the rigid model, the rigid circular rods, the lightweight rigid circular sprockets, the chains, the linear tensile vertical springs, the bearings, the sliders, and the guides. For the new setup, large-amplitude vertical-torsional coupled free vibration of a rigid deck model that failed in conventional testing device can be adapted by the vertical deformation of the springs without any lateral tilt. As a result, the possible nonlinear mechanical stiffness due to the springs tilt in conventional testing device is excluded. In addition, owing to the low rolling friction and damping between the sprockets and the chains, the mechanical damping ratio of the system are quite low and stable for very large-amplitude vibrations.

Owner:DALIAN UNIV OF TECH

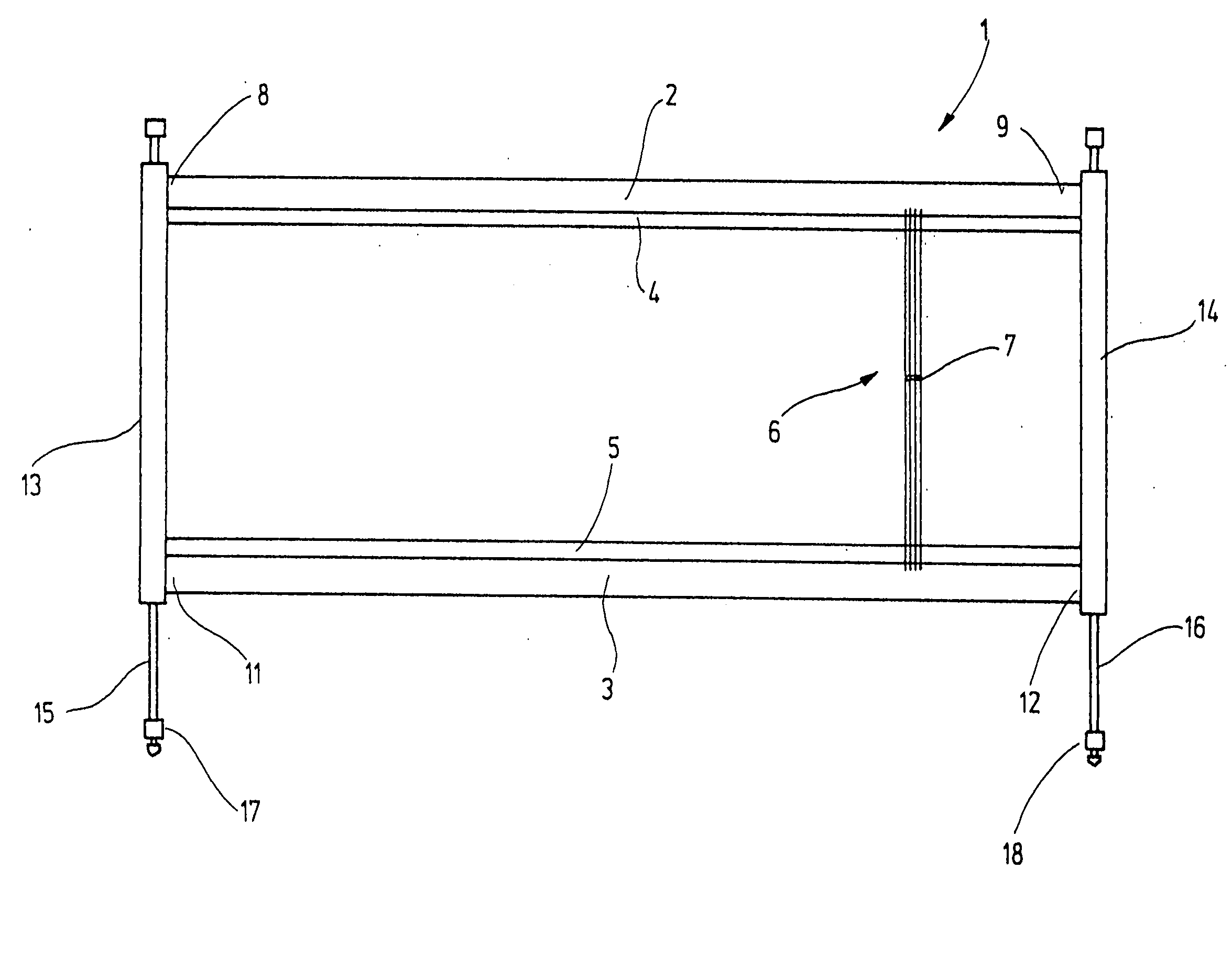

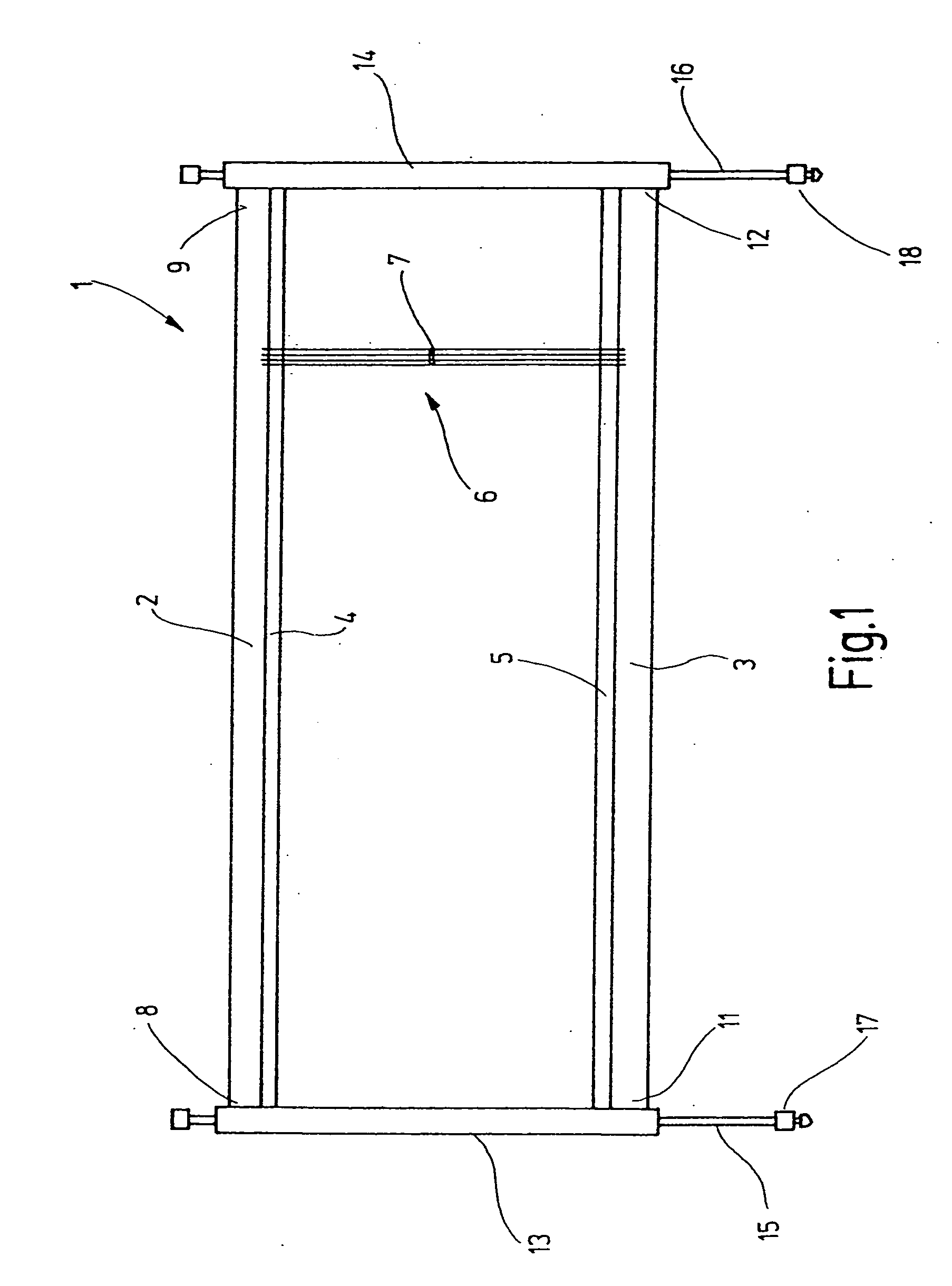

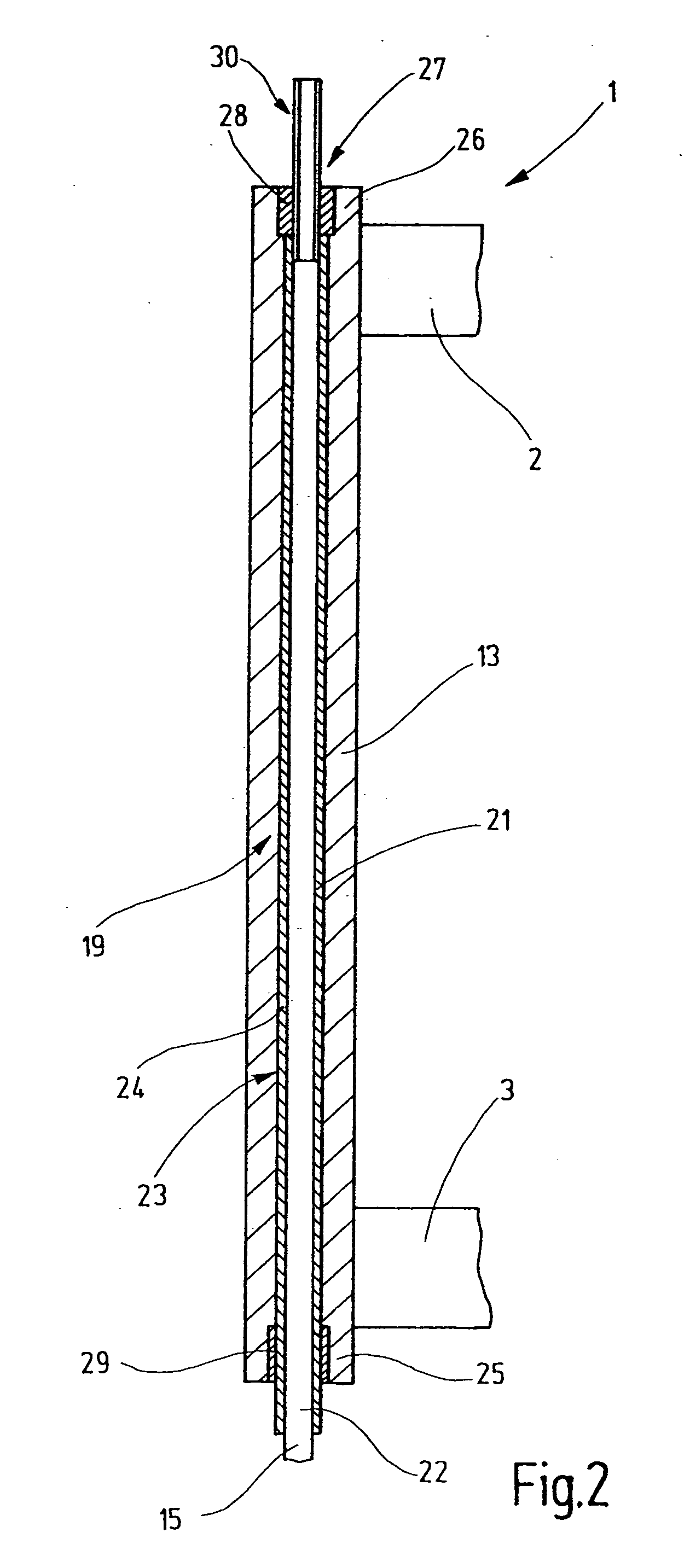

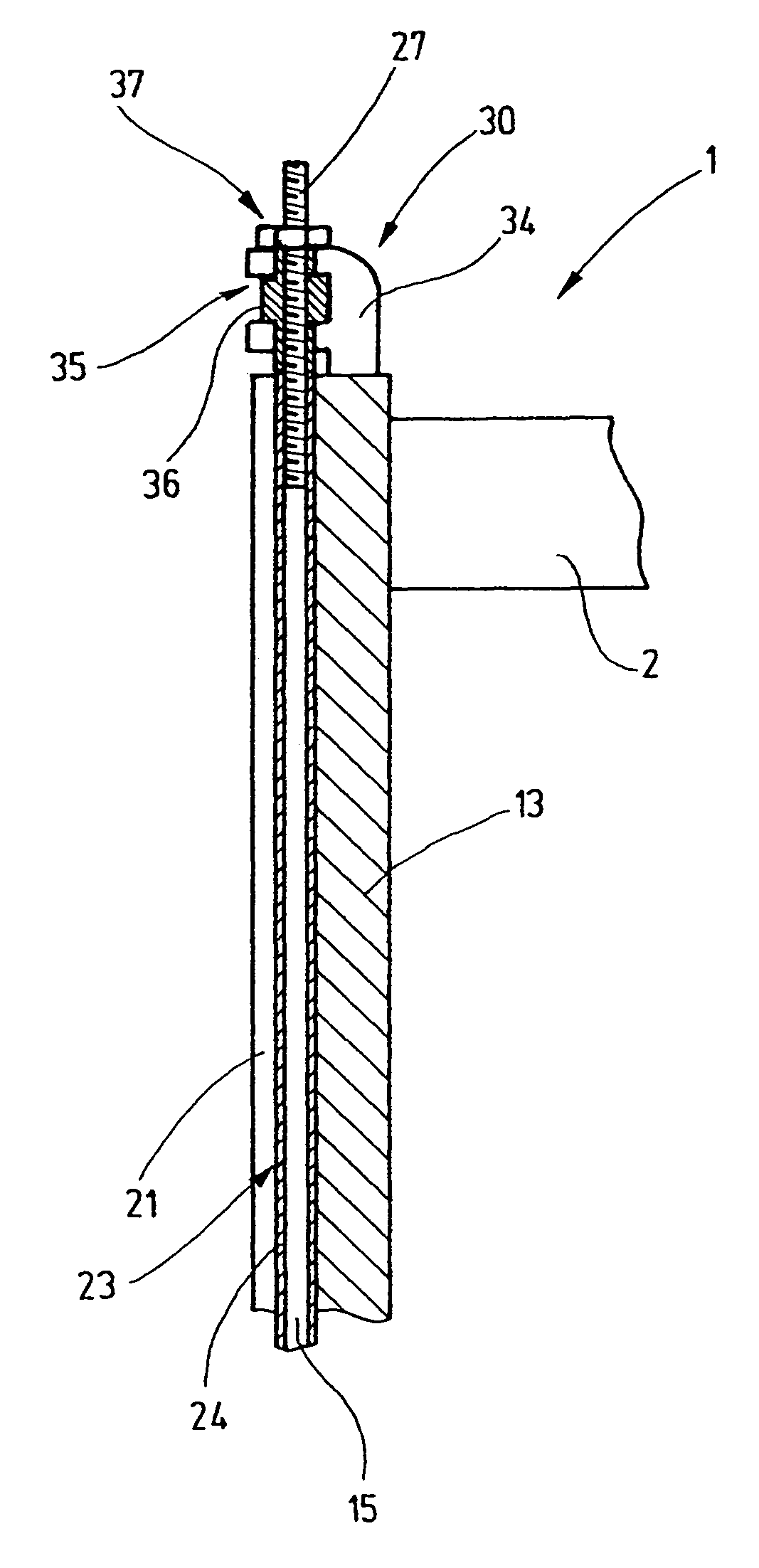

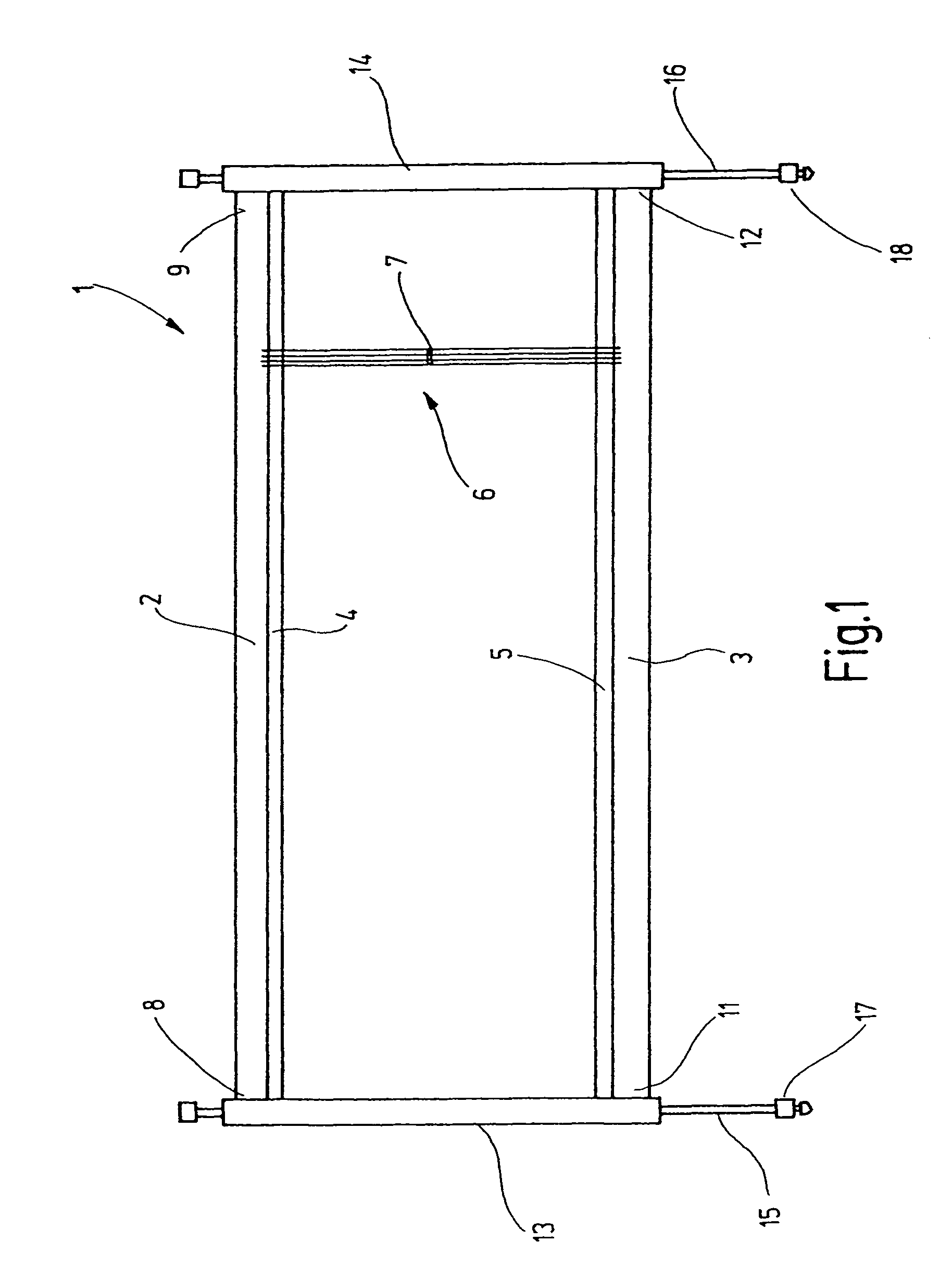

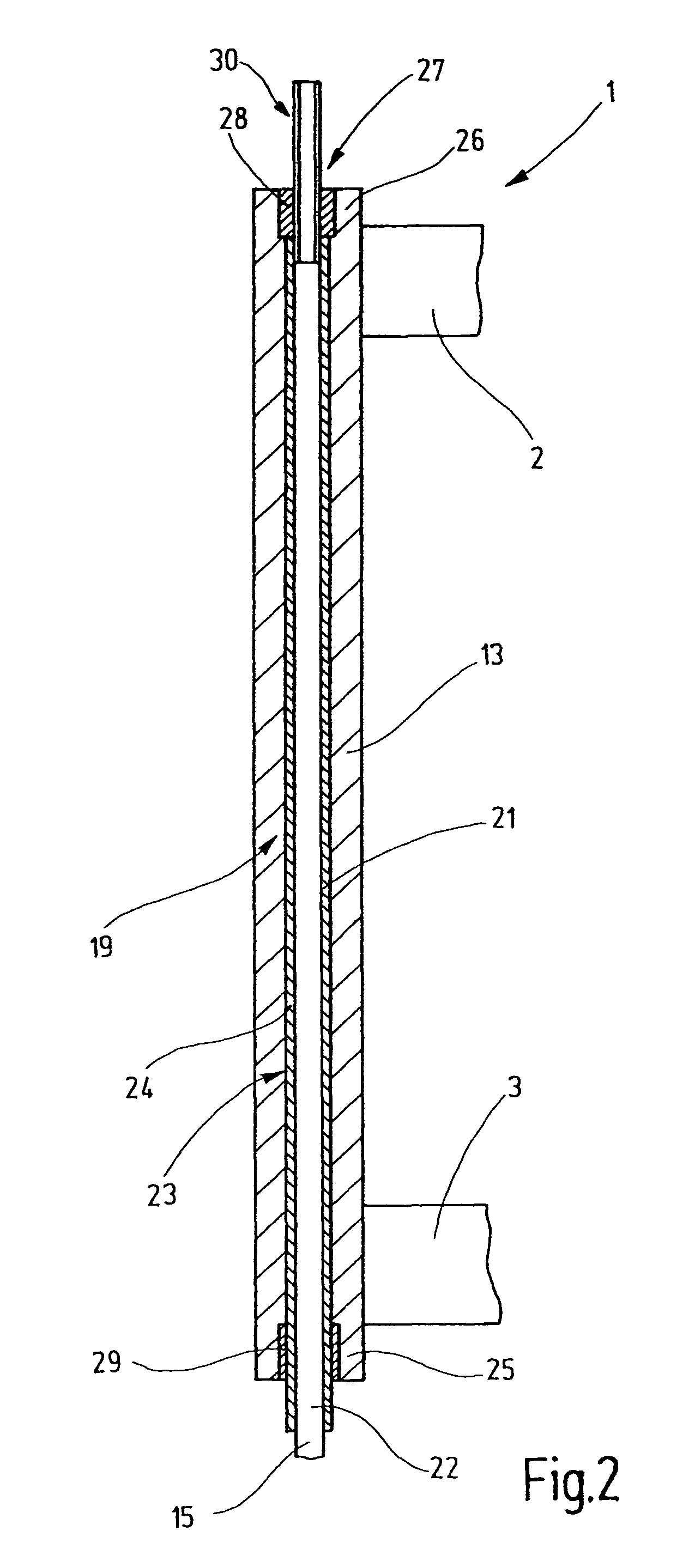

Heddle frame

A heddle frame (1) is driven via drive rods (15), which pass through its lateral sampsons (13). To that end, the lateral sampsons (13) each have a corresponding channel (19). The play between the circumferential face (22) of the drive rods (15) and the channel wall face (21) of the respective channel (19) has an intermediate layer (24), which extends over the full length, or portions, of the drive rod (15). The intermediate layer (24) preferably comprises an impact-proof, permanent-elastic, damping material. A slight residual play allows the introduction of the drive rods (15) and the intermediate layer (24) into the channel (19) without force.

Owner:GROZ BECKERT KG

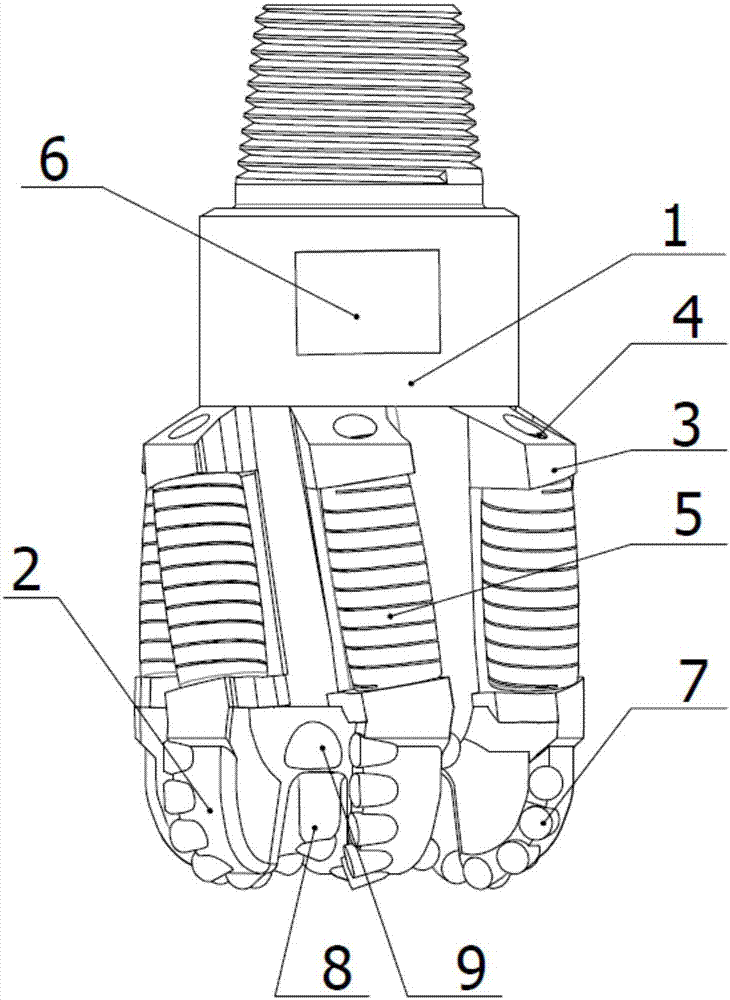

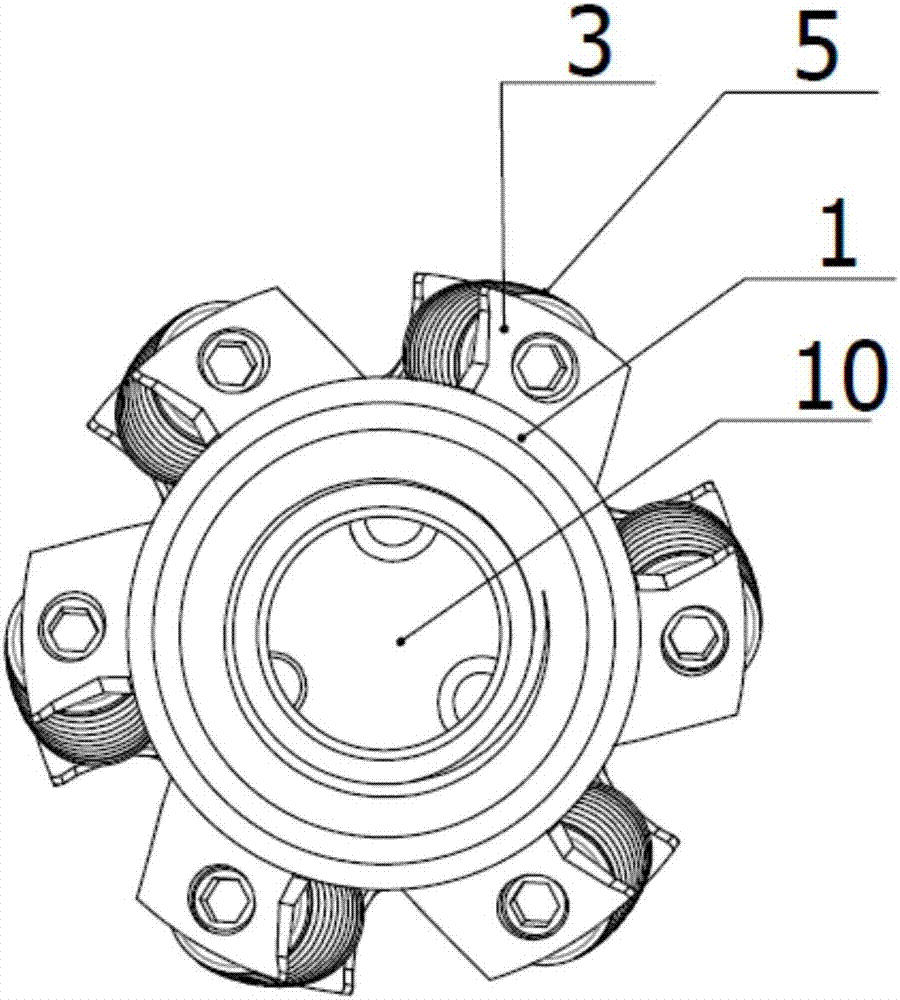

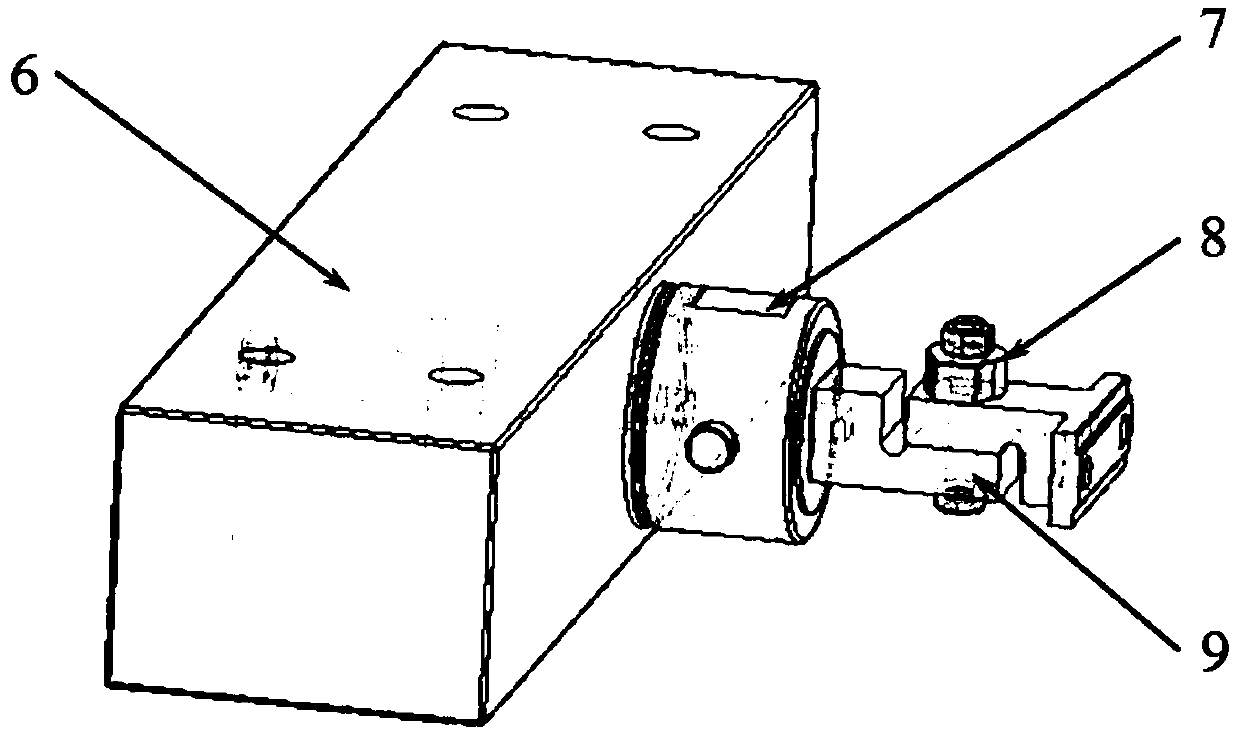

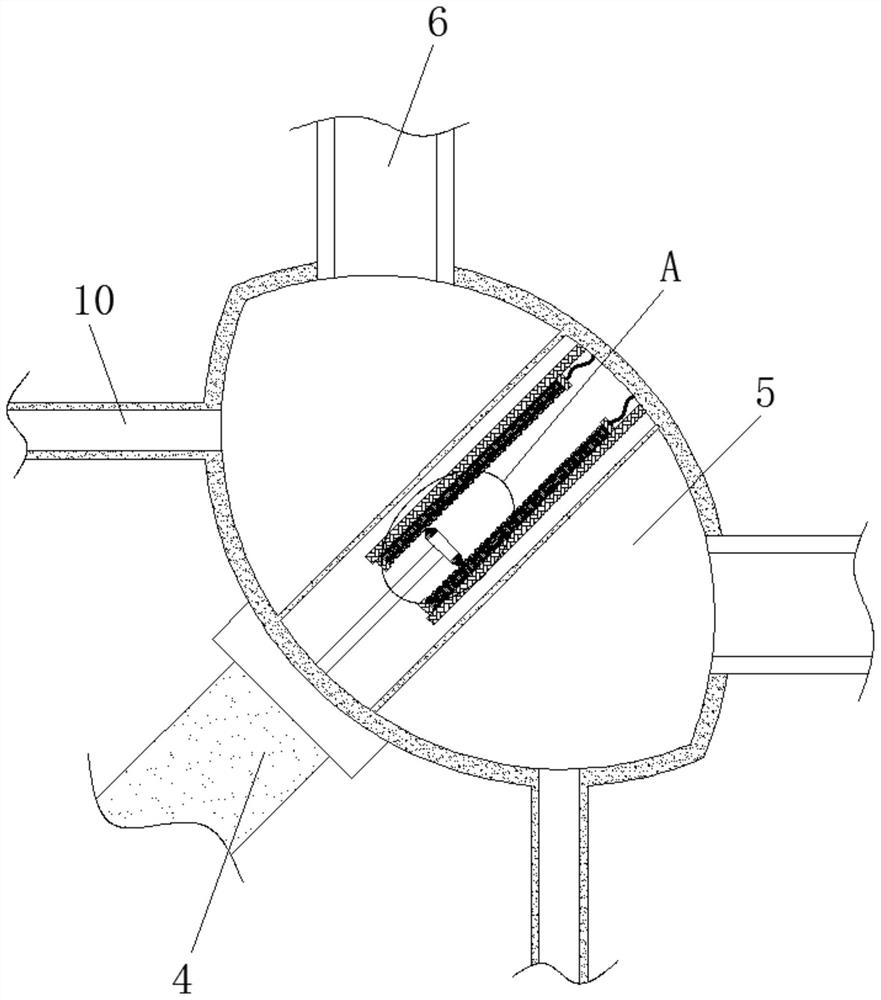

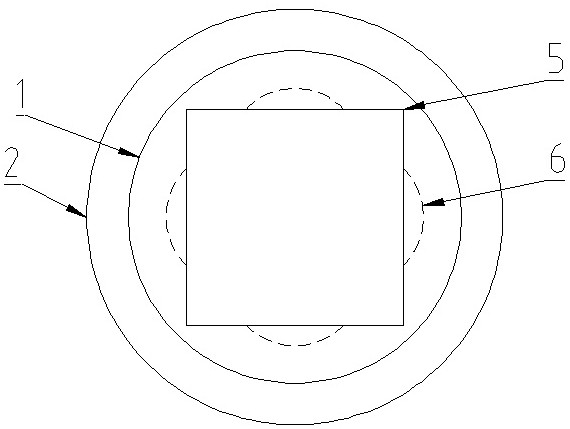

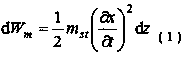

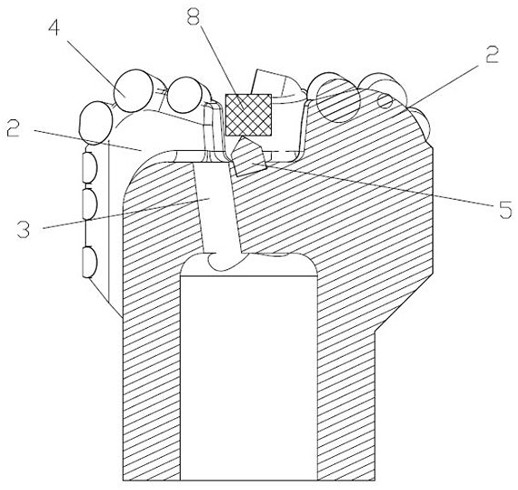

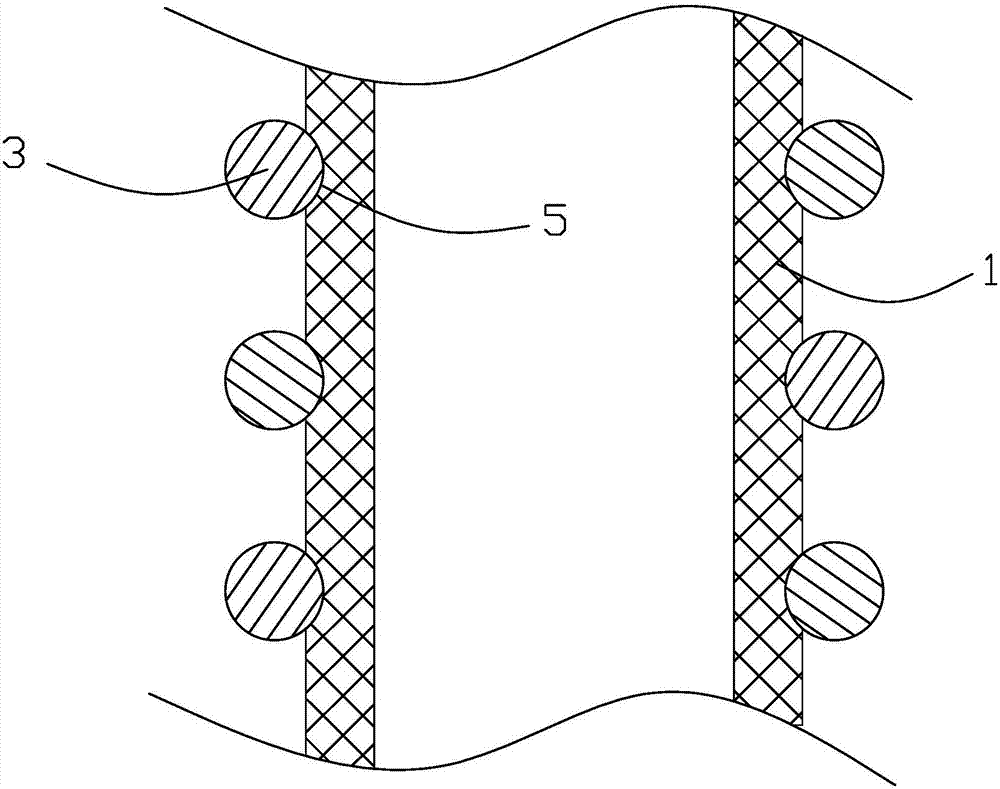

Axial thrust roller type centralizer bit

PendingCN107882511AIncrease bit pressureImprove drilling efficiencyEarth drilling toolsDrilling rodsStructural engineeringAxial thrust

The invention relates to an axial thrust roller type centralizer bit, and belongs to the technical field of bits. The axial thrust roller type centralizer bit comprises a bit main body. One end of thebit main body is provided with a plurality of blades in the circumferential direction. Each blade is connected with a diameter retaining block. The axial thrust roller type centralizer bit is characterized in that each diameter retaining block is provided with a groove with an opening facing outwards, and each groove is internally and fixedly provided with a roller rotating shaft; each roller rotating shaft is rotationally provided with a thrust roller provided with a protruding diameter retaining block, and the thrust rollers are arranged in the circumferential direction of the bit main bodyin an inclined and deflected mode; and the deflection direction is the left rotating direction of the axial direction, and a bus of each thrust roller is curved. The axial thrust roller type centralizer bit has the beneficial effects that during drilling, the thrust rollers can produce axial splitting force, the drilling pressure can be improved, pressure taking off can be effectively reduced, the bit is pushed to drill forwards, and the drilling efficiency is improved; and the contact widths between the thrust rollers and the wellbore are increased, the circumferential stability of the bit is increased, and transverse vibration produced by the bit is reduced effectively.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

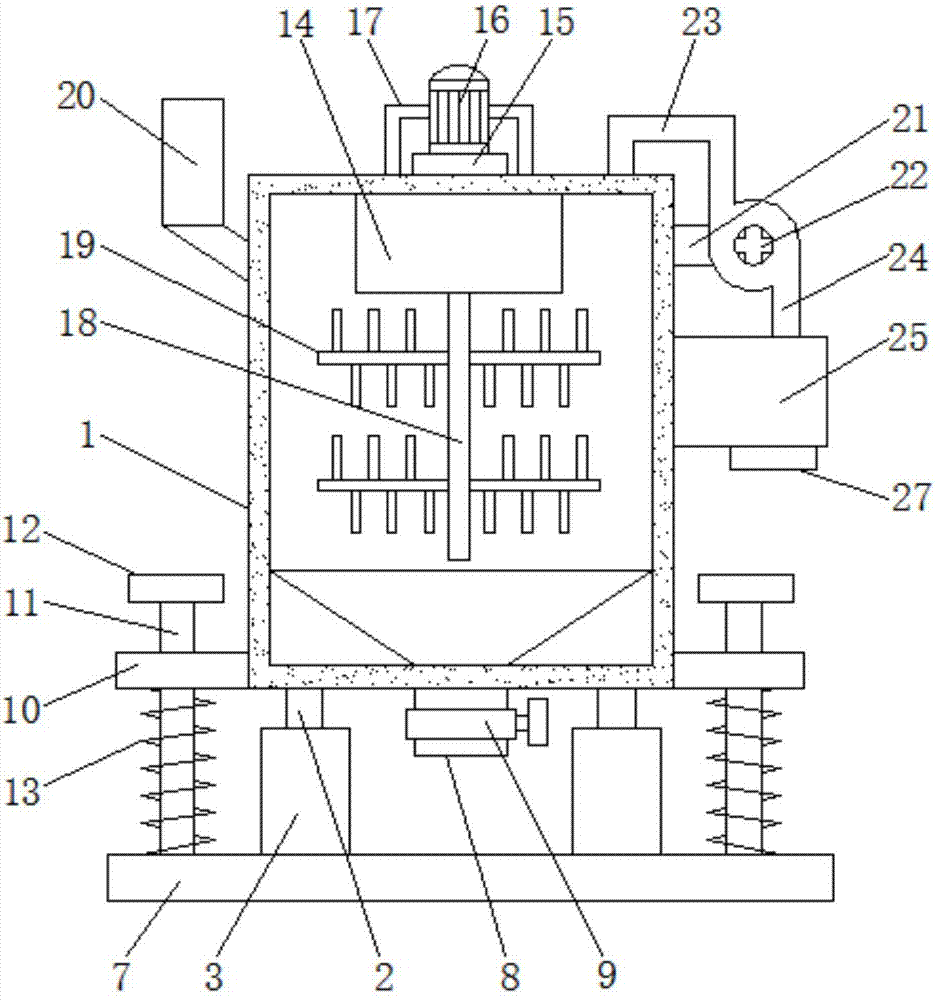

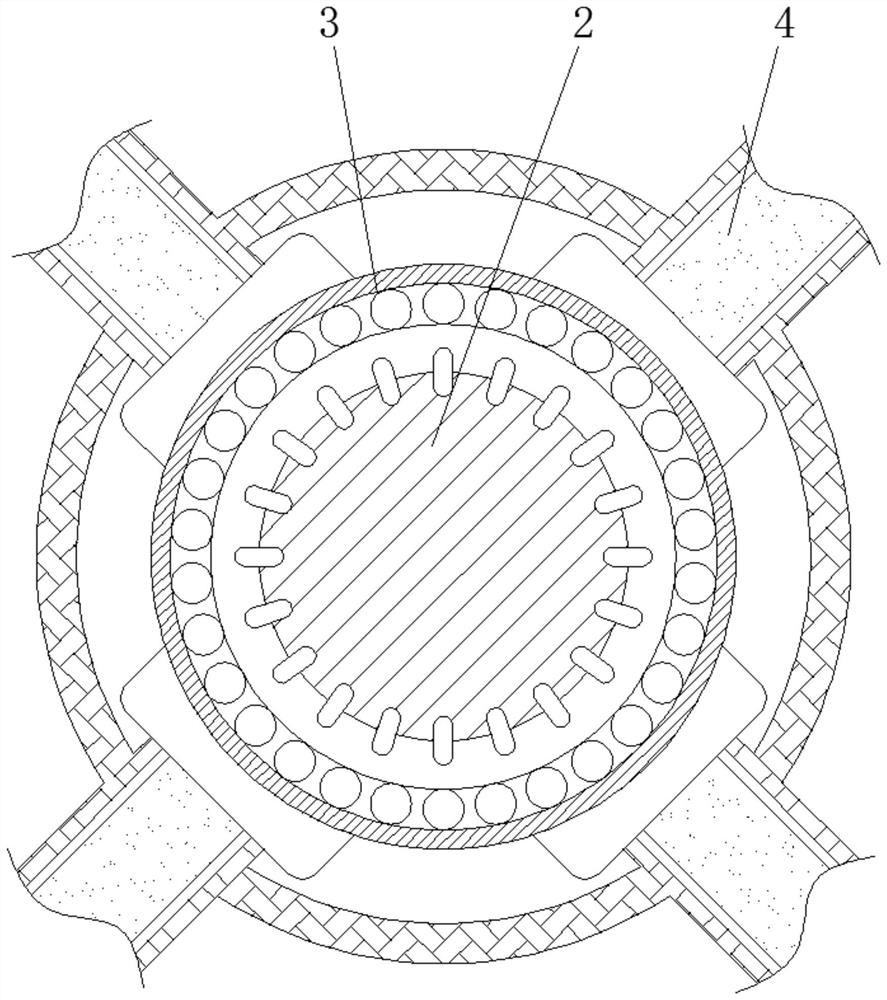

Mechanical stirring device for buildings

InactiveCN108000713AEffective protectionImprove rigidityDirt cleaningCement mixing apparatusMotor driveElectric machinery

The invention provides a mechanical stirring device for buildings, relating to the field of a stirring device. The mechanical stirring device comprises a box body, and the four corners of the bottom of the box body are fixedly connected with the top end of a press rod. The bottom end of the press rod penertates through a shock absorber and extends to the inner part of the shock absorber to be fixedly connected with the top of a press block, hydraulic oil is arranged in the shock absorber and is positioned at the bottom of the press block, and the bottom of the shock absorber is fixedly connected with the top of the press block. A discharge hopper is arranged in the box body, the bottom of the discharge hopper penertates through the box body and extends to the lower part of the box body, and a discharge valve is arranged on the surface of the discharge hopper and is positioned at the bottom of the box body. When a motor drives a rotation shaft to rotate, a fixing sleeve is fixed througha stabilizer in a stable box, and the rotation shaft slides along a concave ring groove through a roller. Therefore, the rotation shaft is effectively protected and is not easy to deform, and the impact on the stirring quality is effectively reduced.

Owner:绍兴韵足针纺织有限公司

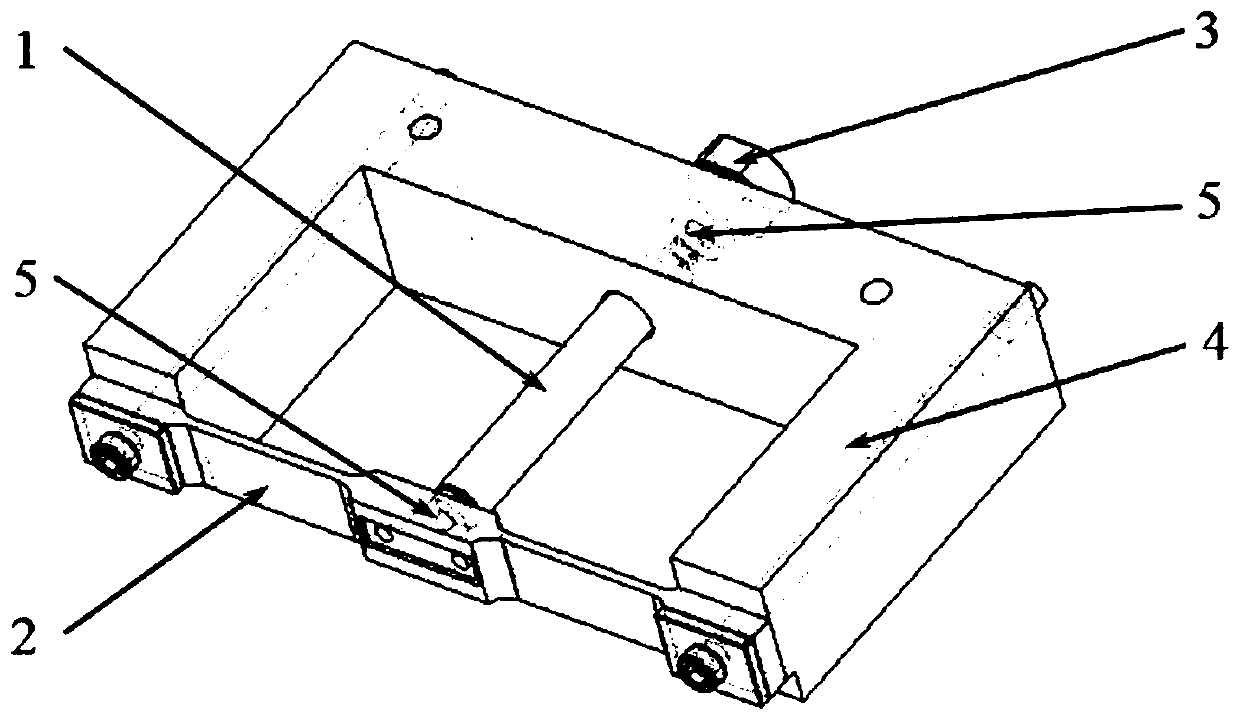

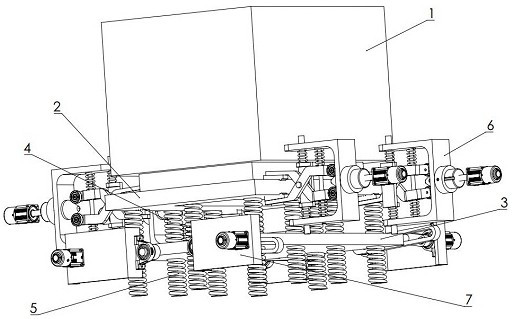

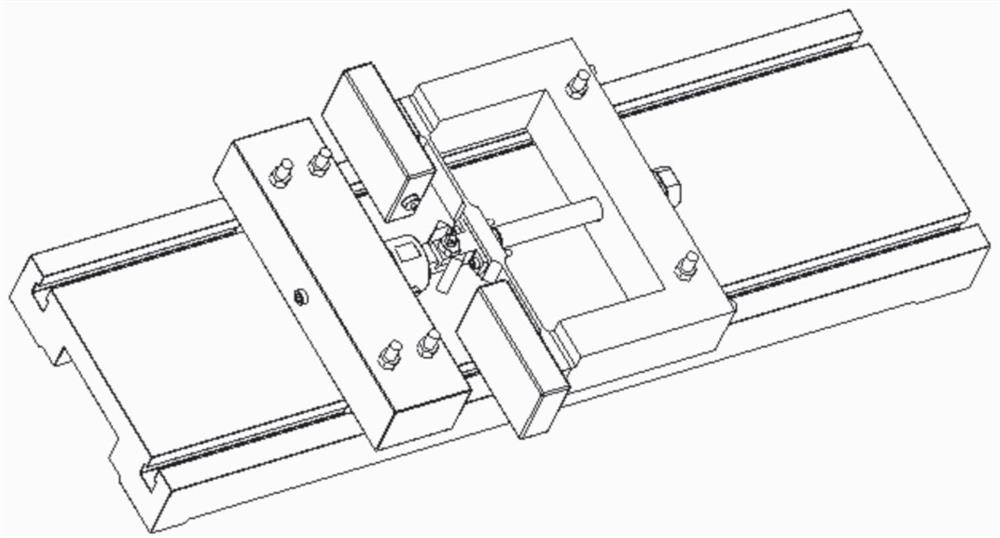

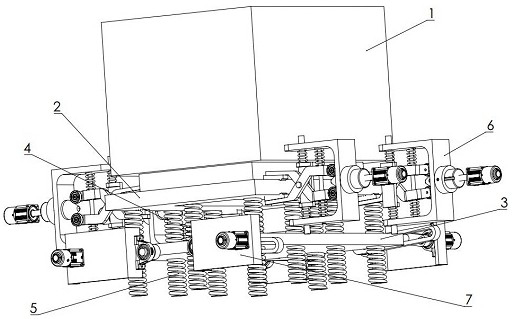

Bolt connection interface micro-motion friction wear test device and method thereof

ActiveCN110146397AHigh stability control abilityAvoid rotational movementInvestigating abrasion/wear resistanceData collectorMicro motion

The invention discloses a bolt connection interface micro-motion friction wear test device, which comprises an excitation system, a measurement system and a sample and support system, wherein the sample and support system comprises a bolt connection sample, a flexible guide plate, an outer support frame and a base; the excitation system comprises a piezoelectric actuator, a signal generator, a power amplifier, a knob and a force transferring ball; and the measurement system comprises a support block, a dynamic force sensor, a ring dynamic force sensor, a laser vibrometer, an optical lens, anda data collector. By using the piezoelectric actuator-driven closed-loop controlled high-precision bolt interface friction wear test device, broadband excitation, closed-loop control and precision optical displacement measurement are considered at the same time, friction wear test under various working conditions can be realized, and expansion to other connection forms and samples is easy. Besides, the device also has multiple protective measures to avoid equipment damage.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

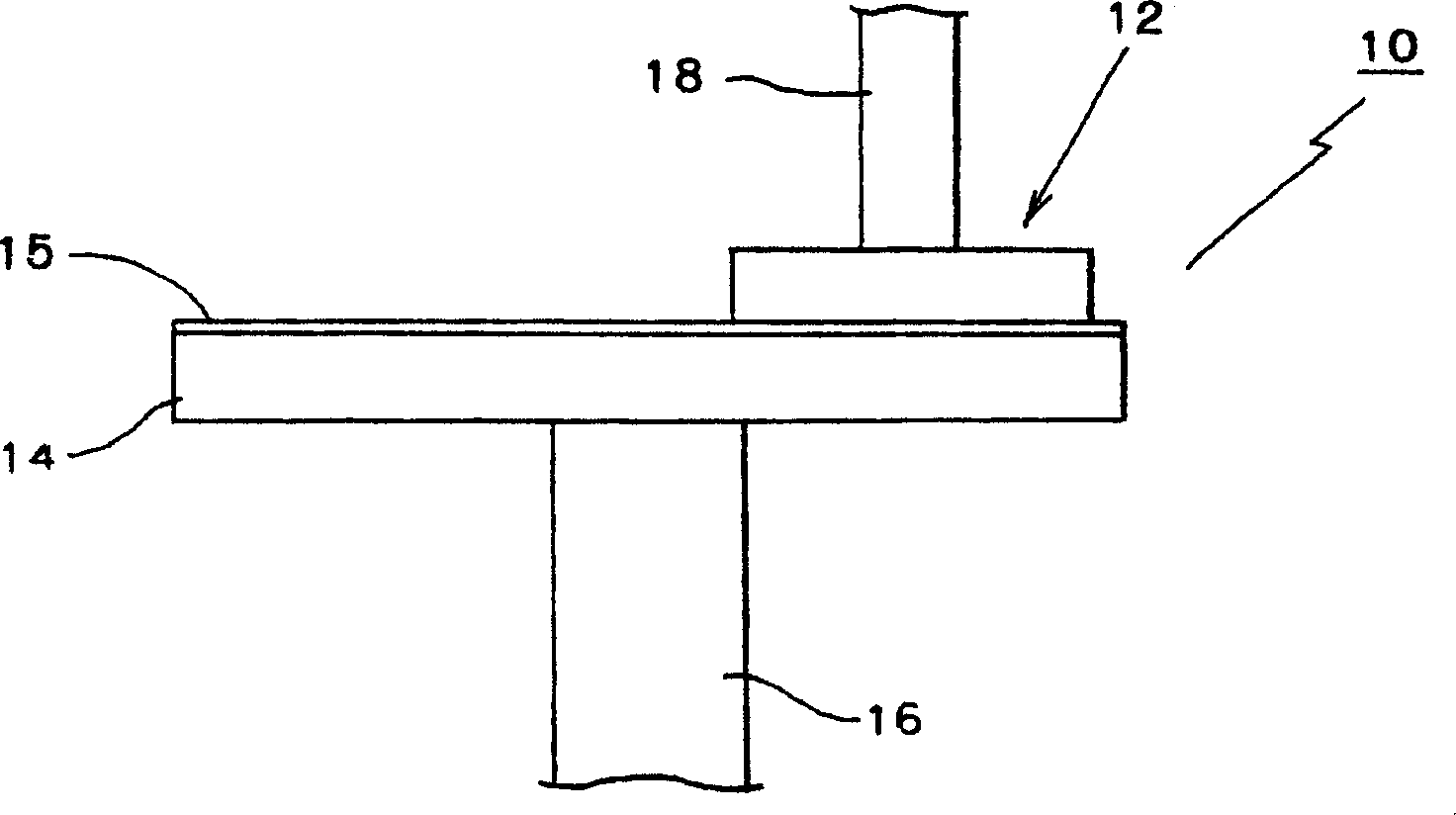

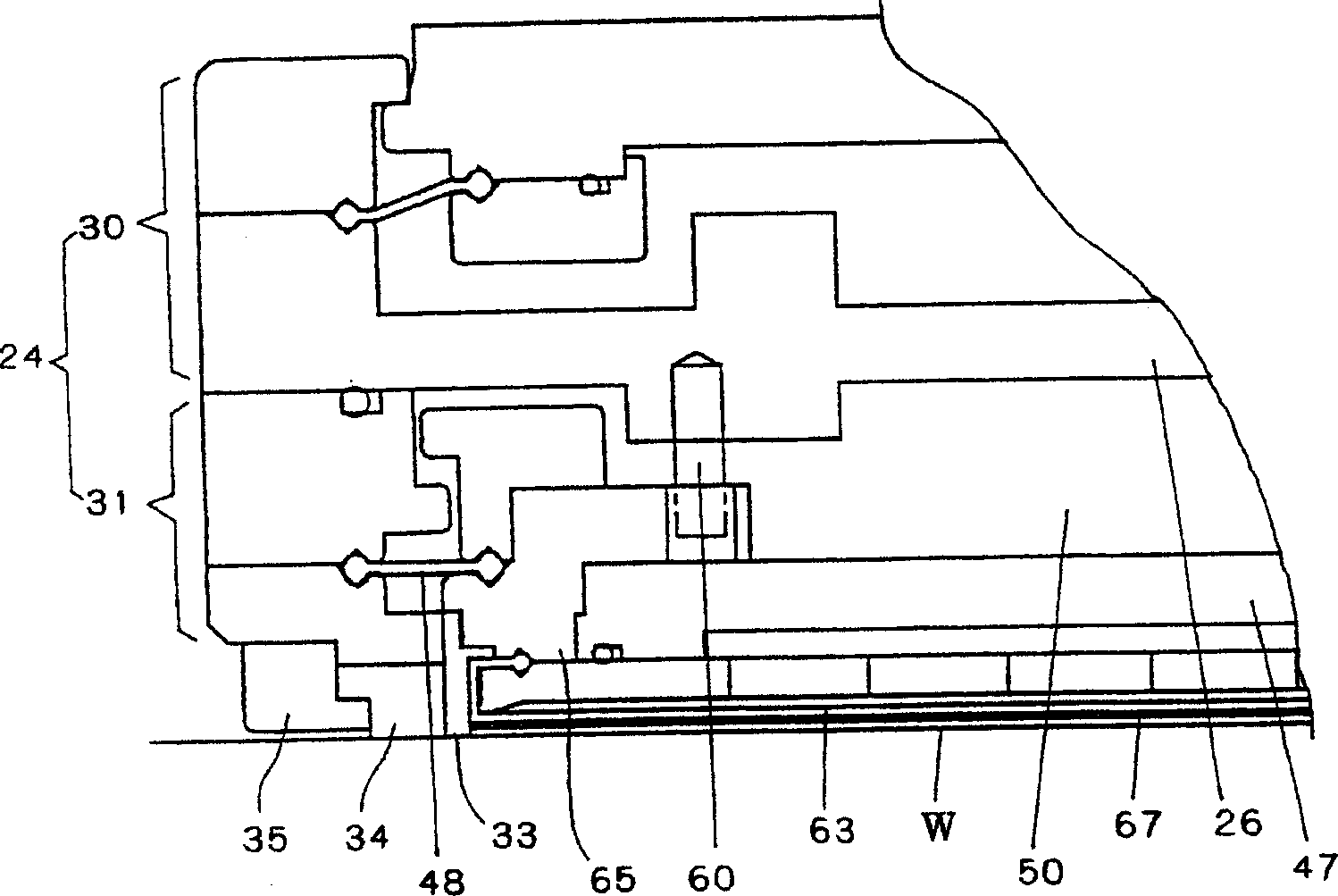

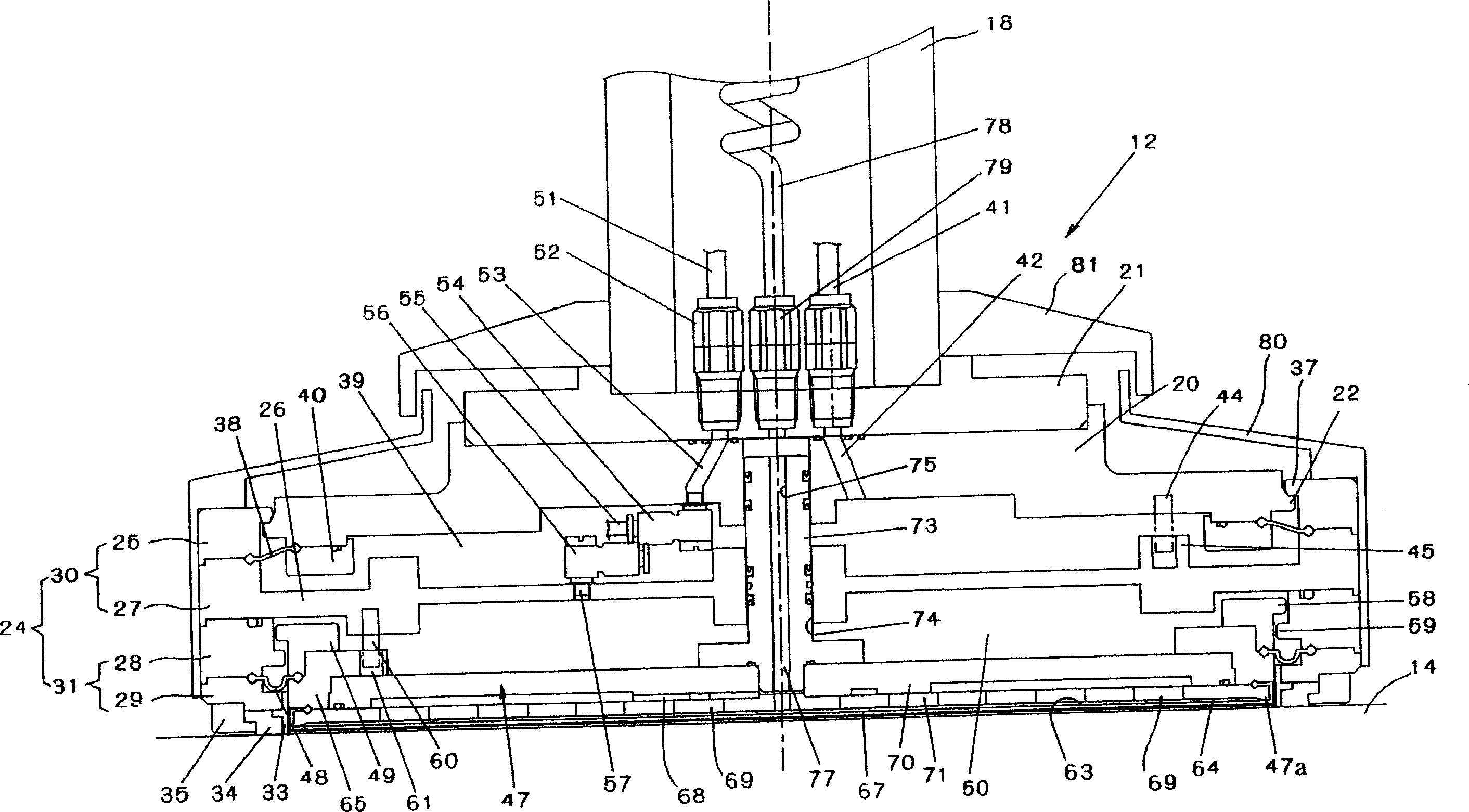

Polishing apparatus

InactiveCN1683112AAvoid distortionAvoid damageSemiconductor/solid-state device manufacturingLapping machinesEngineeringLower face

The polishing apparatus (10) is capable of precisely controlling polishing pressure, correctly positioning a press plate (47) and uniformly polishing a workpiece (W). In the polishing apparatus (10), a holding head comprises: first pressing means for introducing a pressurized fluid into a first fluid chamber (39) and pressing a main head section (24) downward; second pressing means for introducing a pressurized fluid into a second fluid chamber (50) and pressing a press plate (47) downward; and third pressing means for introducing a pressurized fluid into a third fluid chamber (64) and pressing the workpiece (W) downward. With this structure, the workpiece (W) is held on the lower side of an elastic sheet member (63), and the lower face of the workpiece (W) can be polished by a polishing plate (14).

Owner:FUJIKOSHI MACHINERY

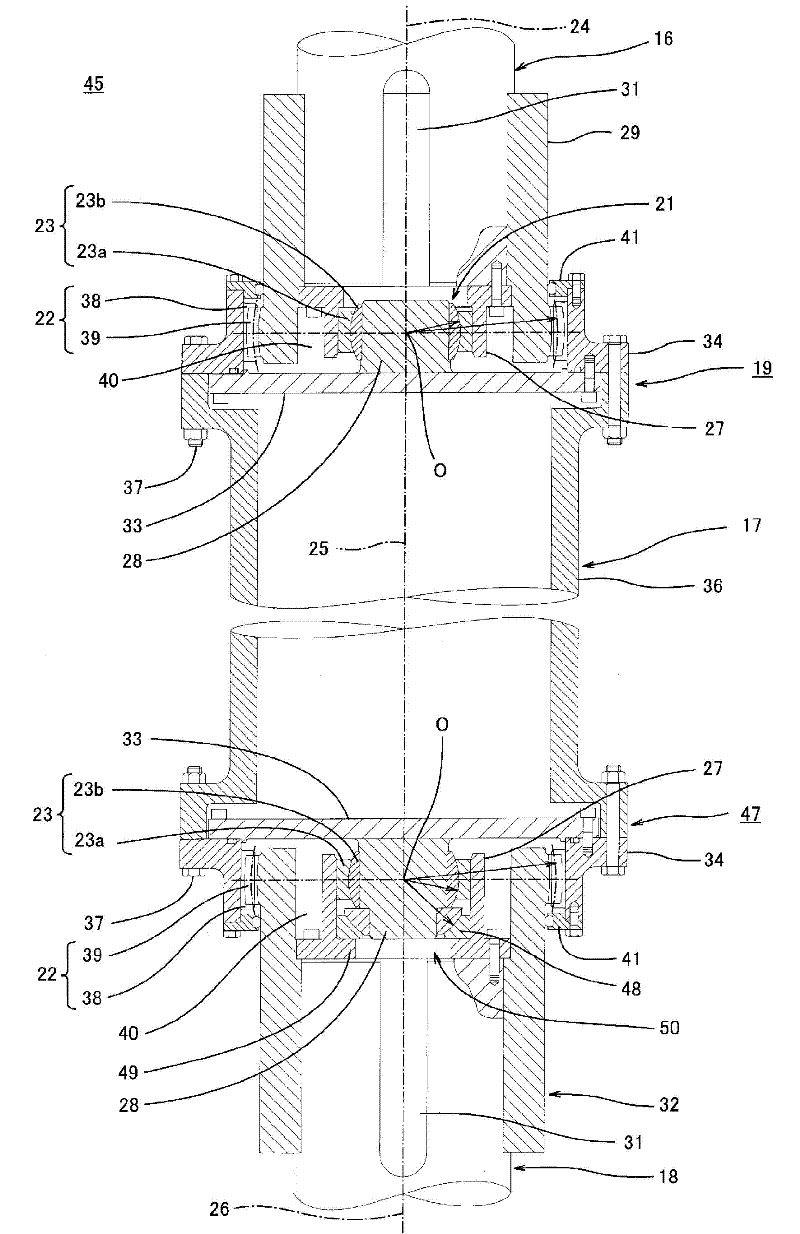

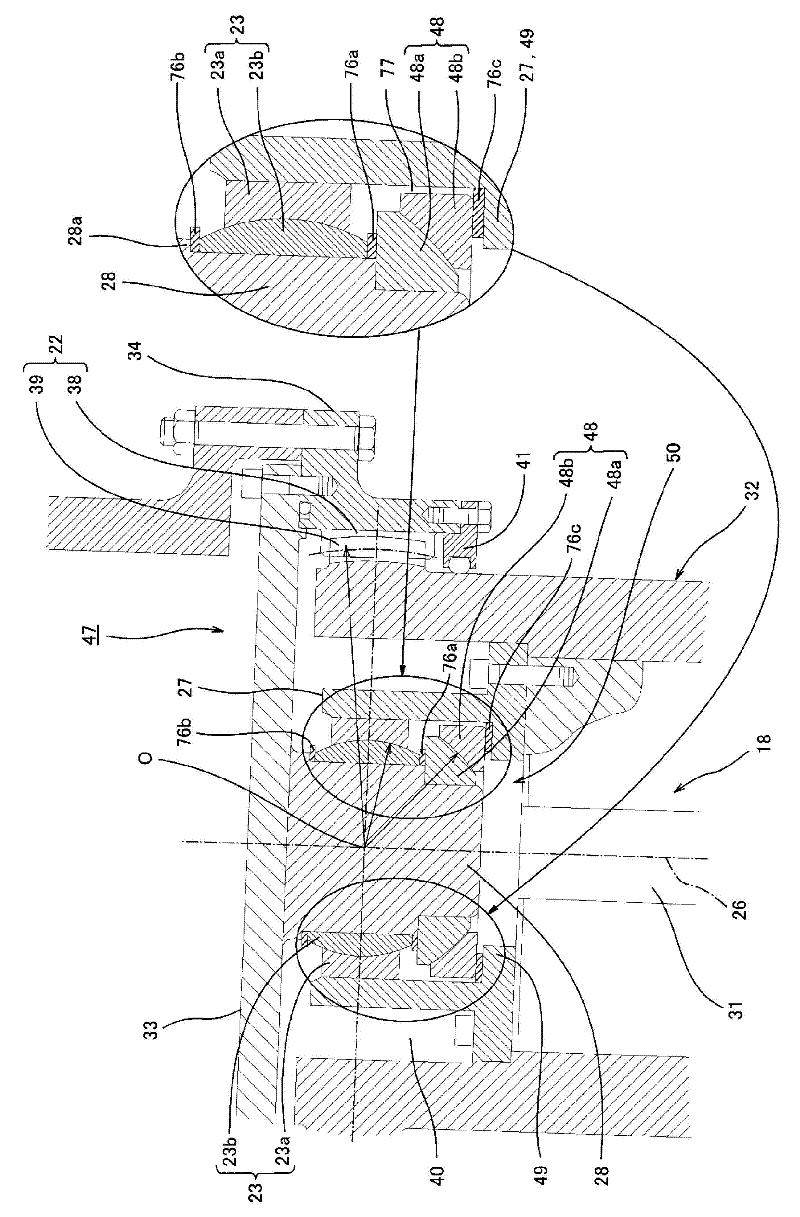

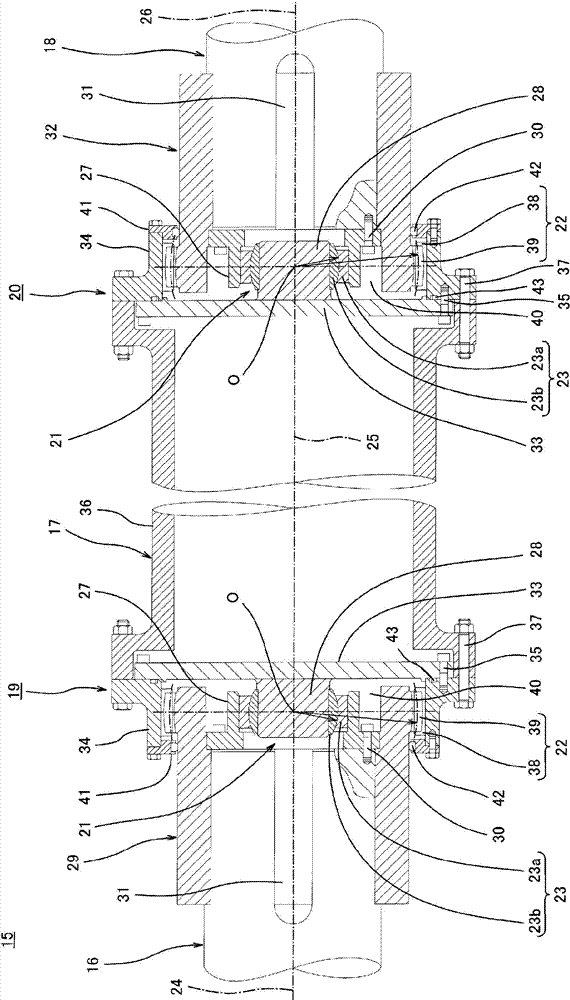

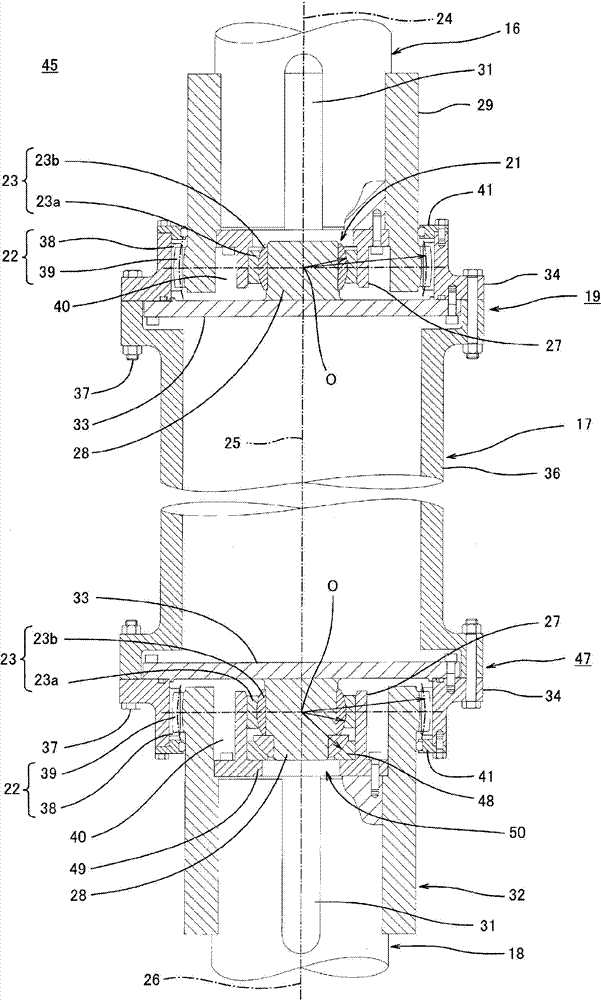

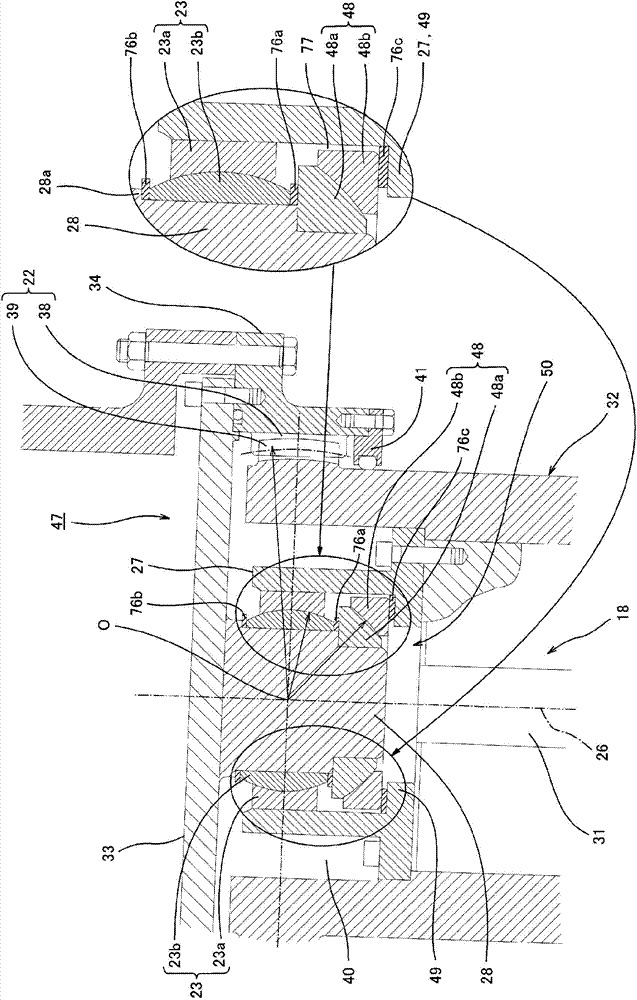

Flexible coupling structure and ship thruster device with same

InactiveCN102132056APrevent lateral vibrationLow production costYielding couplingPropulsive elementsSpherical bearingCoupling

A flexible coupling structure configured to exclusively support a load without transmitting the load to other portions, that is, a self-contained flexible coupling structure. The flexible coupling structure is free of a vibration problem despite the long overall length of the structure. In a gear coupling structure, a spherical radial bearing section (23) and a spherical thrust bearing section (48) are mounted to the center (O) of an arc crowning provided to an externally toothed gear (39), and a radial spherical bearing section (23) and a thrust spherical bearing section (48) are mounted such that the centers of rotation of the bearing sections (23, 48) are matched to each other. An internally toothed gear (38) is supported by the radial spherical bearing section (23) and the thrust spherical bearing section (48) to form a structure, by which the externally toothed gear (39) can tilt relative to the internally toothed gear (38) about the center (O) of the arc crowning.

Owner:KAWASAKI HEAVY IND LTD

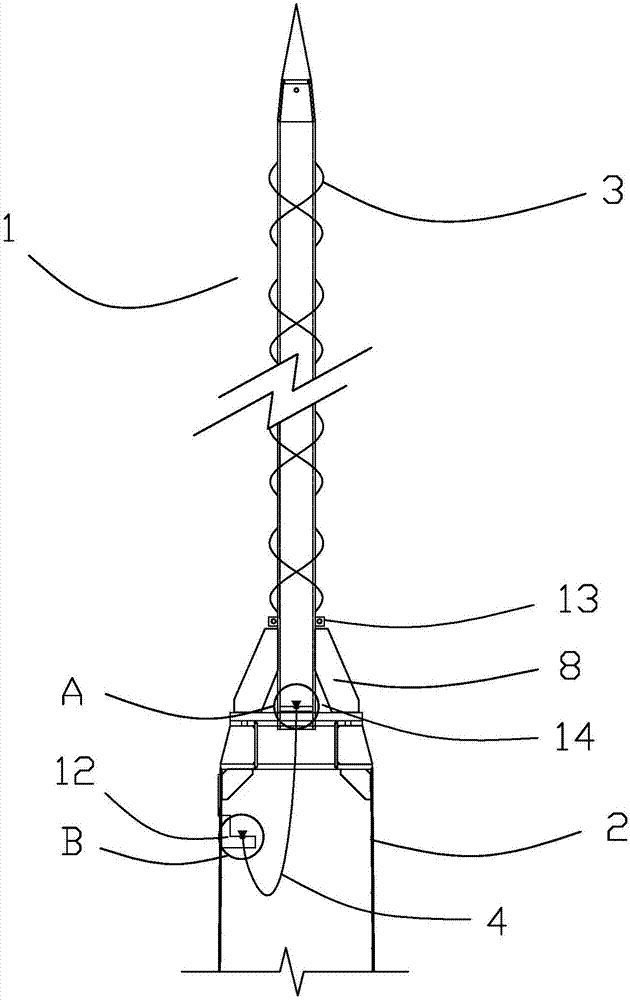

Intelligent marine diesel engine attitude adjusting device

ActiveCN114261496AEliminate lateral vibrationReduce swingPropulsion power plantsMachines/enginesDieselingPropeller

The invention relates to the technical field of marine diesel engines, discloses an intelligent marine diesel engine attitude adjusting device, and aims to solve the problems that when a propulsion shafting of a ship runs, vibration is inevitably generated due to the influence of dynamic factors such as propeller hydrodynamic force, hull deformation and a lubricating film, and meanwhile, the operation of a diesel engine connected with the propulsion shafting also generates vibration; according to specifications, the marine diesel engine and the propulsion shafting must be subjected to vibration checking calculation, so that vibration sources are controlled, vibration is reduced, vibration sources are isolated, and equipment and personnel are protected; the intelligent marine diesel engine attitude adjusting device comprises a diesel engine upper-layer base, a diesel engine lower-layer base, a lateral clamping mechanism, swing jacking mechanisms, a ship body attitude sensor and a controller, and the controller controls the multiple swing jacking mechanisms to independently operate according to ship body attitude information obtained by the ship body attitude sensor. Posture adjustment of the lower-layer base of the diesel engine is achieved so as to reduce / eliminate swing amplitude of the marine diesel engine caused by stormy waves.

Owner:SHANDONG JIAOTONG UNIV

Heddle frame

A heddle frame (1) is driven via drive rods (15), which pass through its lateral sampsons (13). To that end, the lateral sampsons (13) each have a corresponding channel (19). The play between the circumferential face (22) of the drive rods (15) and the channel wall face (21) of the respective channel (19) has an intermediate layer (24), which extends over the full length, or portions, of the drive rod (15). The intermediate layer (24) preferably comprises an impact-proof, permanent-elastic, damping material. A slight residual play allows the introduction of the drive rods (15) and the intermediate layer (24) into the channel (19) without force.

Owner:GROZ BECKERT KG

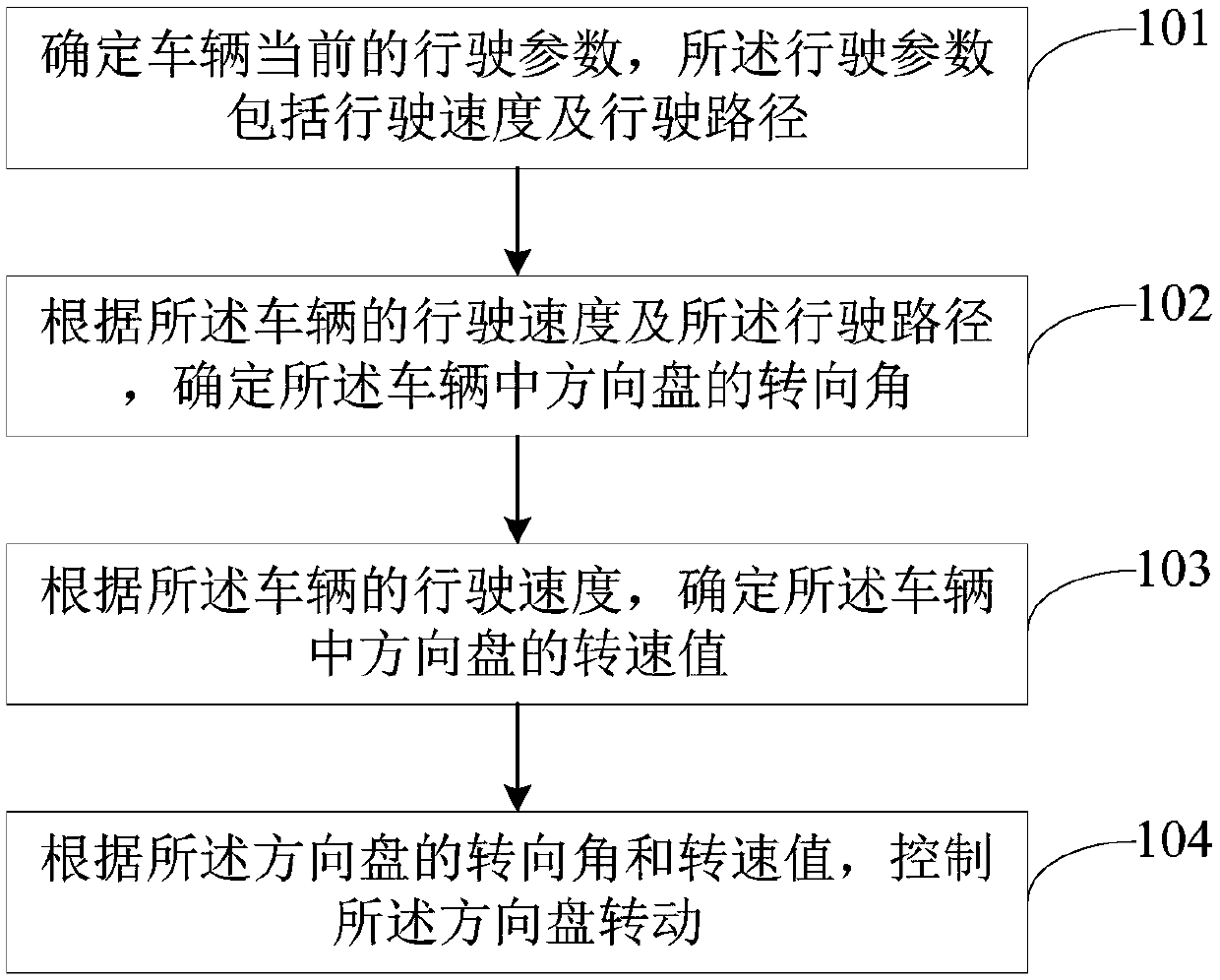

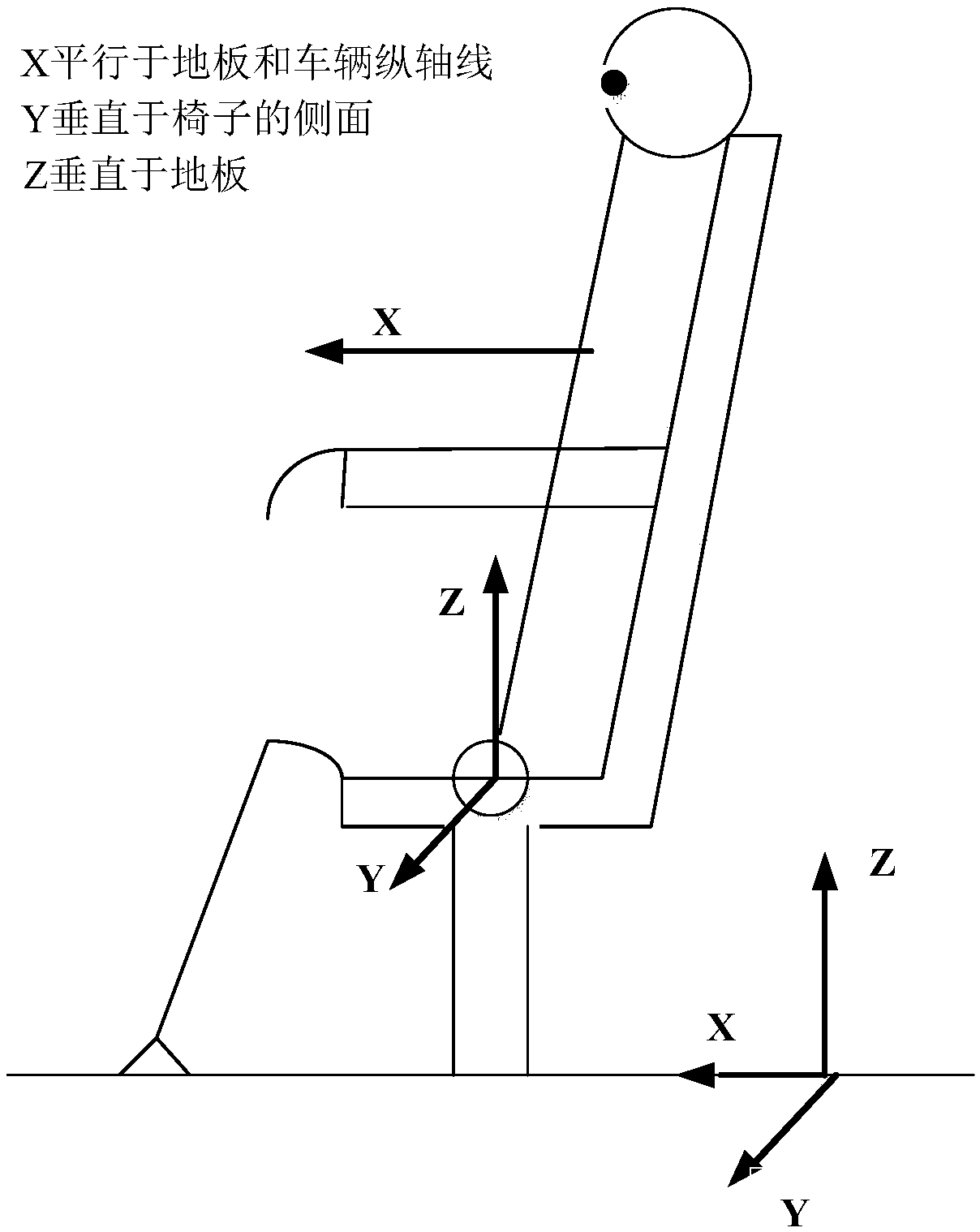

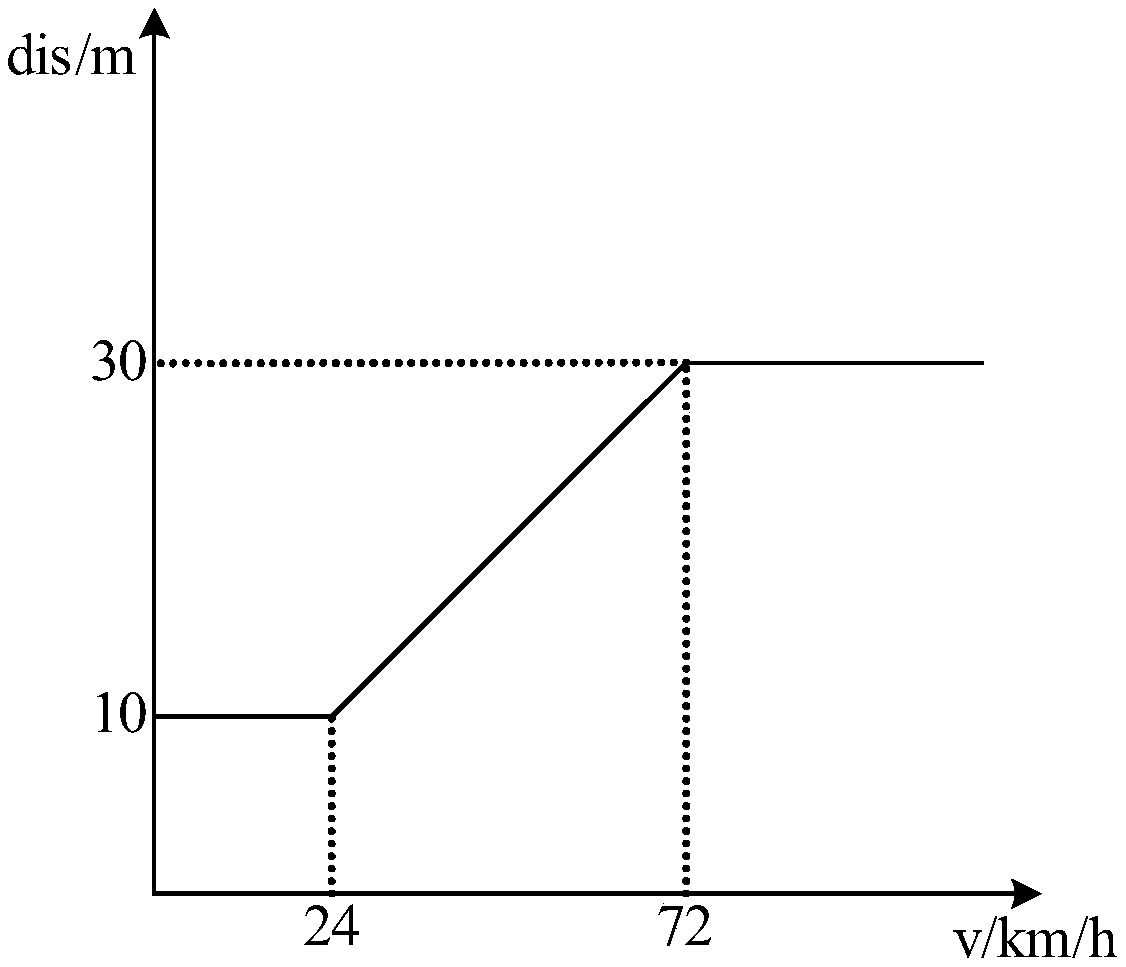

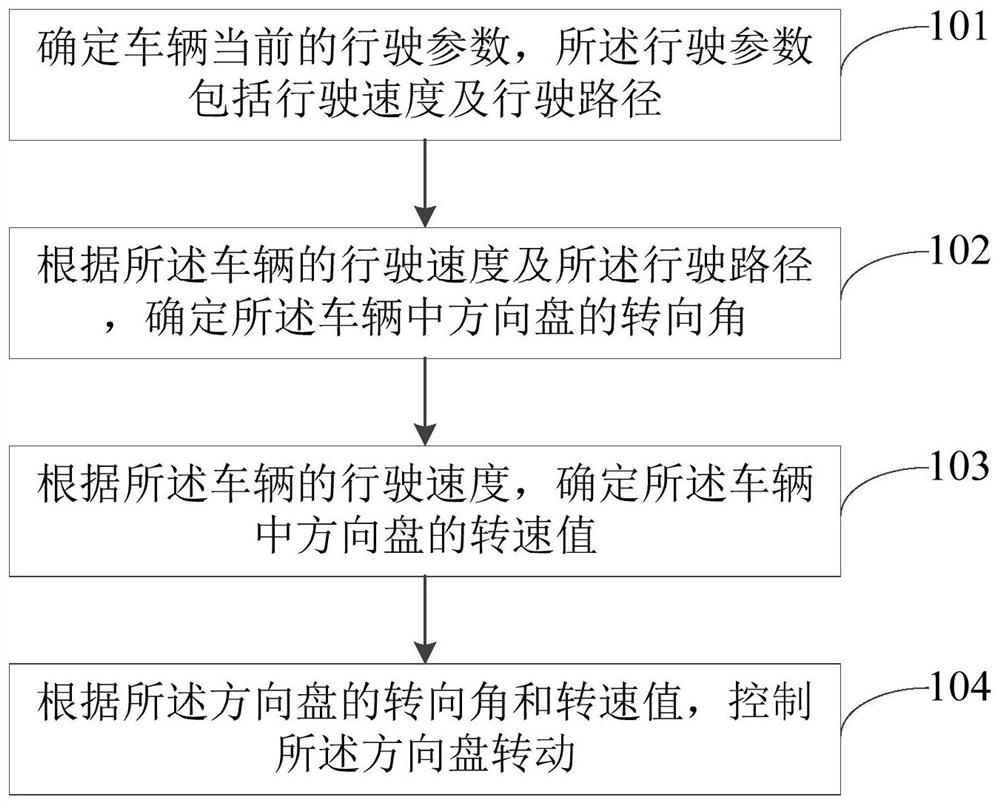

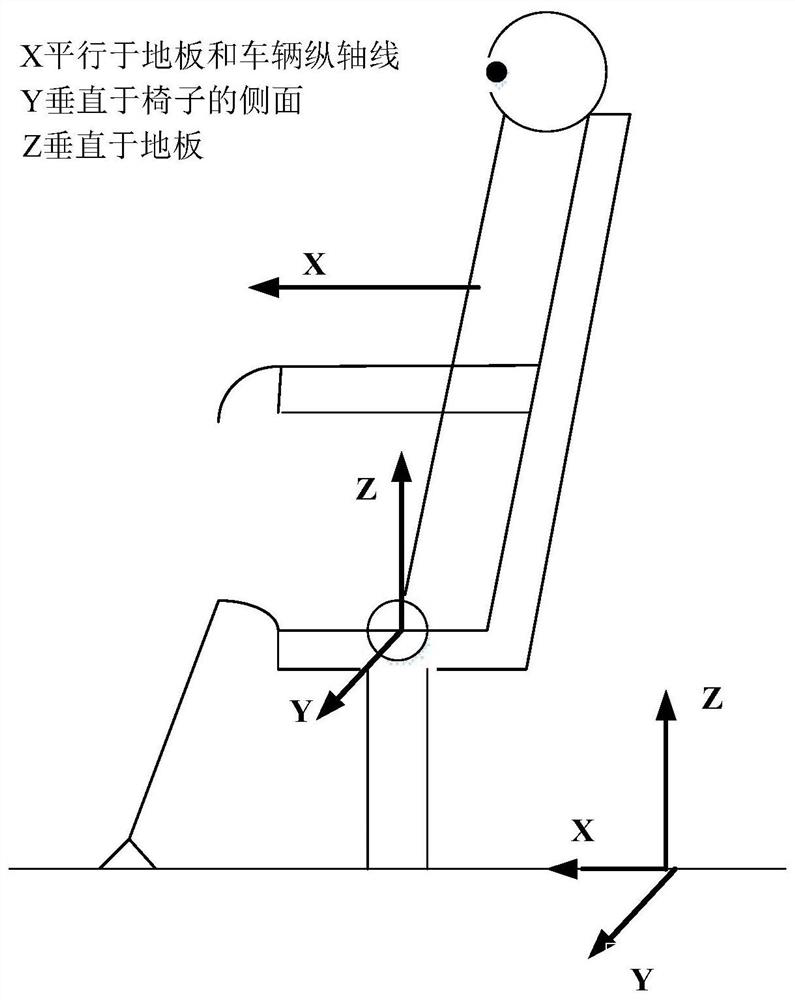

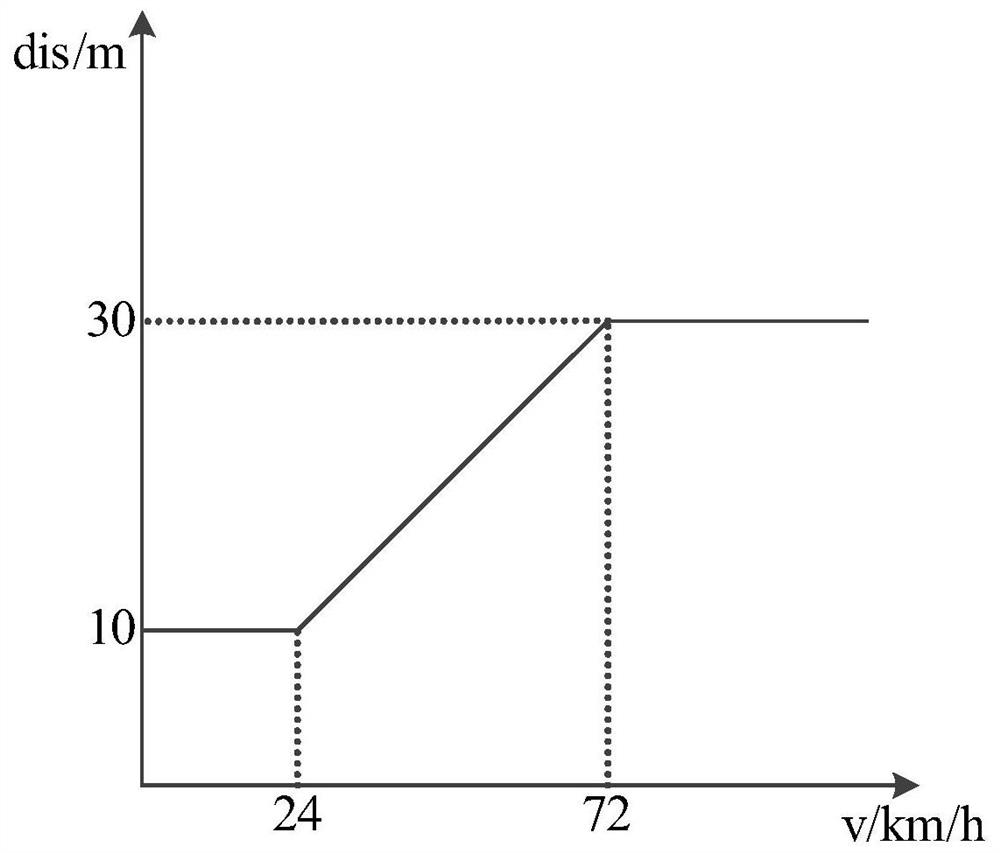

Vehicle steering wheel control method and device, computer equipment and vehicle

ActiveCN110654458APrevent lateral vibrationSmooth rideSteering partsVehicle orientationComputer equipment

The invention provides a vehicle steering wheel control method and device, computer equipment, a vehicle and a storage medium, and belongs to the technical field of vehicles. The method comprises thefollowing steps that current running parameters of the vehicle are determined, wherein the running parameters comprise the running speed and a running path; the steering angle of a steering wheel in the vehicle is determined according to the running speed and the running path of the vehicle; a rotating speed value of the steering wheel in the vehicle is determined according to the running speed ofthe vehicle; and the steering wheel is controlled to rotate according to the steering angle and the rotating speed value of the steering wheel. Therefore, through the vehicle steering wheel control method, smooth control over the intelligent driving vehicle is realized, the driving and taking comfort degree of the vehicle is improved, and the user experience is improved.

Owner:BYD CO LTD

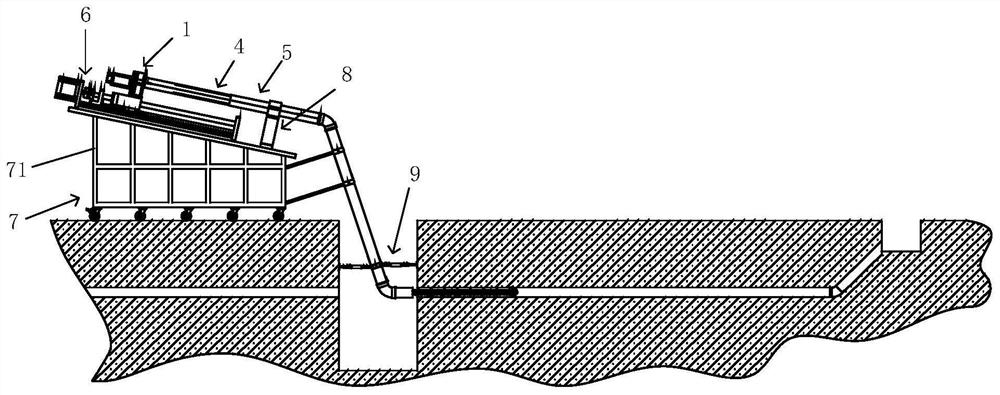

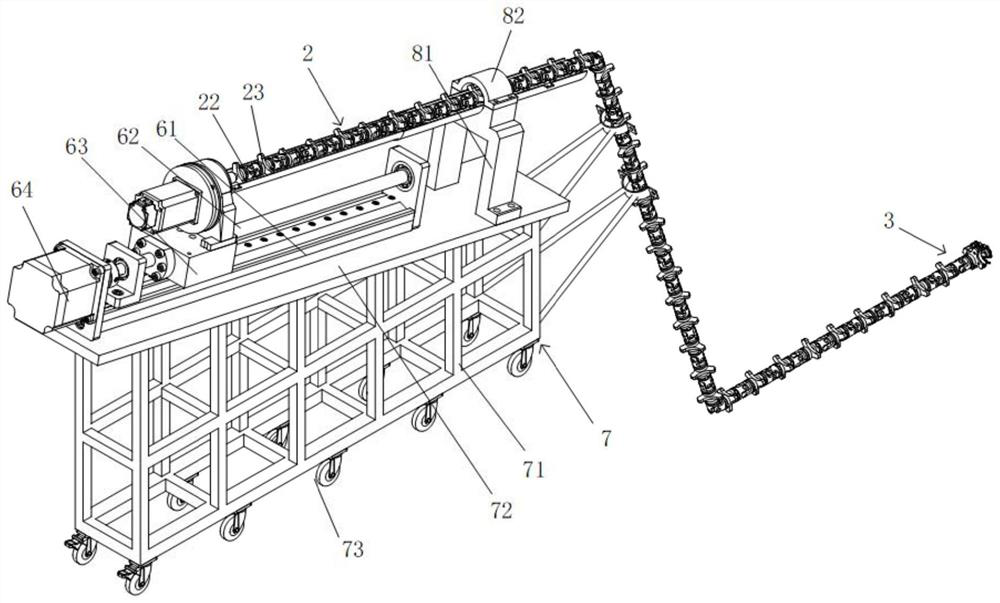

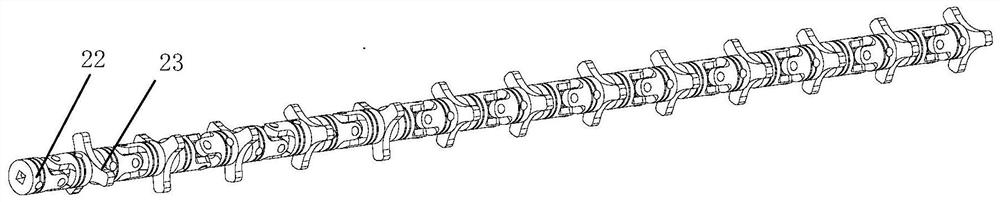

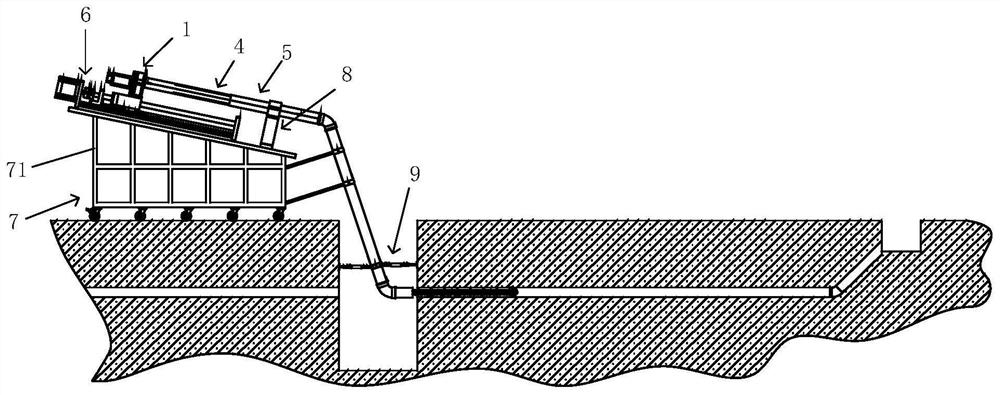

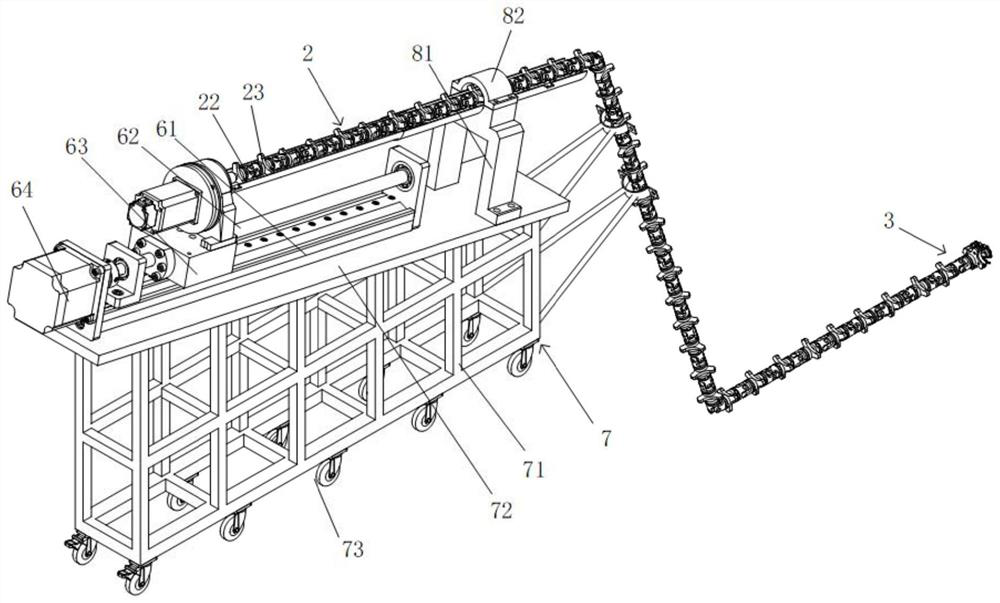

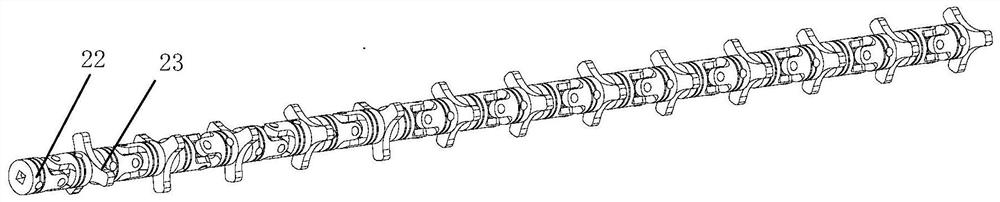

External power dredging equipment for small-pipe-diameter drainage blind pipe of tunnel and working method

ActiveCN113289991AEasy to adjustRealize reciprocating motionHollow article cleaningUniversal jointPipe

The invention discloses external power dredging equipment for a small-pipe-diameter drainage blind pipe of a tunnel and a working method. The external power dredging equipment comprises a rotary driving device; a power output end of the rotary driving device is connected with a vibration cutting mechanism through a power transmission mechanism; the power transmission mechanism is sleeved with a sliding pipe and a fixed pipe; one end of the sliding pipe is connected with the rotary driving device, the other end of the sliding pipe extends into the fixed pipe and is in sliding connection with the fixed pipe, and the vibration cutting mechanism extends out of the fixed pipe; the power transmission mechanism comprises a plurality of universal joints which are sequentially connected through connecting shafts, the universal joint at one end of the power transmission mechanism is connected with the rotary driving device, and the universal joint at the other end of the power transmission mechanism is connected with a cutting drill bit seat mounting column; and the multiple connecting shafts are rotatably sleeved with supporting pieces, and the multiple supporting pieces make contact with the inner walls of the corresponding sliding pipe and the corresponding fixed pipe. The blockage problem of the small-pipe-diameter drainage blind pipe can be quickly and conveniently dredged in a mechanical cutting and vibrating mode.

Owner:CHANGAN UNIV

Large-amplitude vertical-torsional coupled free vibration setup for wind tunnel test

ActiveUS10837864B2Avoid nonlinearityAvoid stiffnessAerodynamic testingVibration amplitudeRigid model

Owner:DALIAN UNIV OF TECH

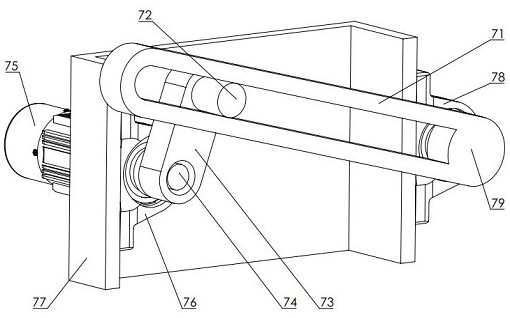

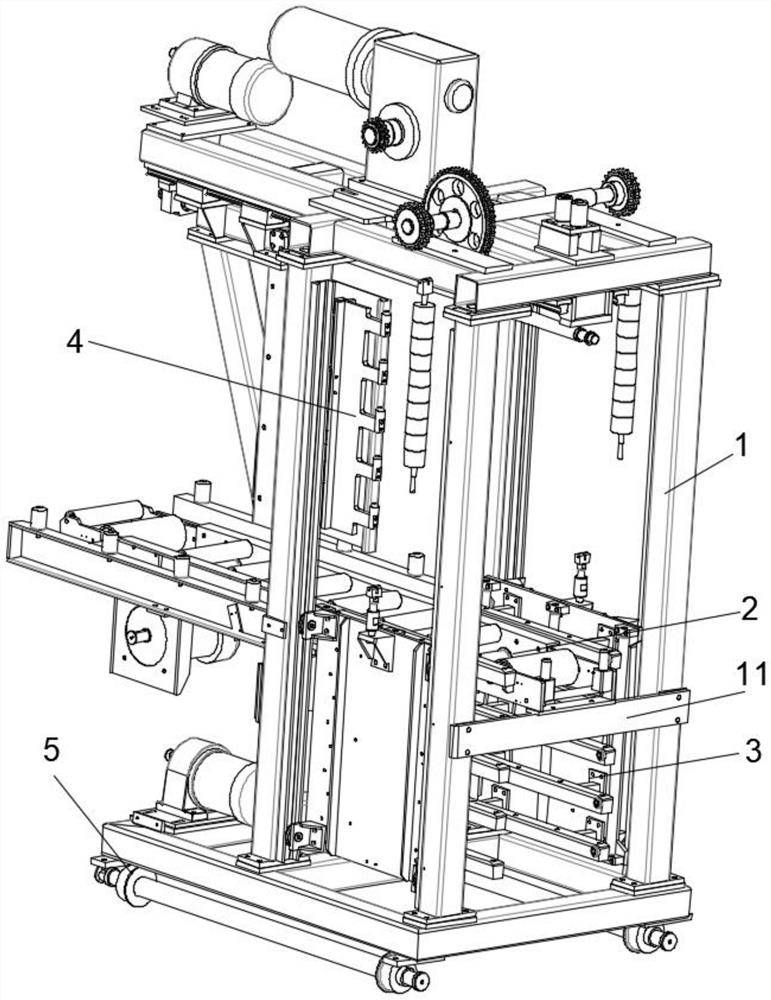

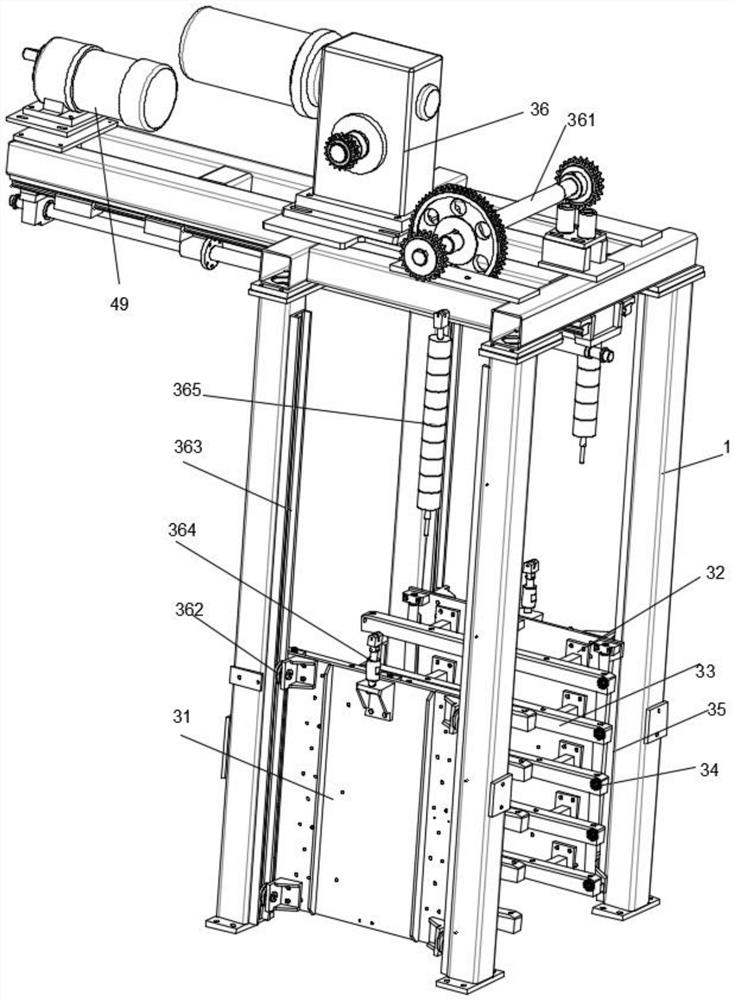

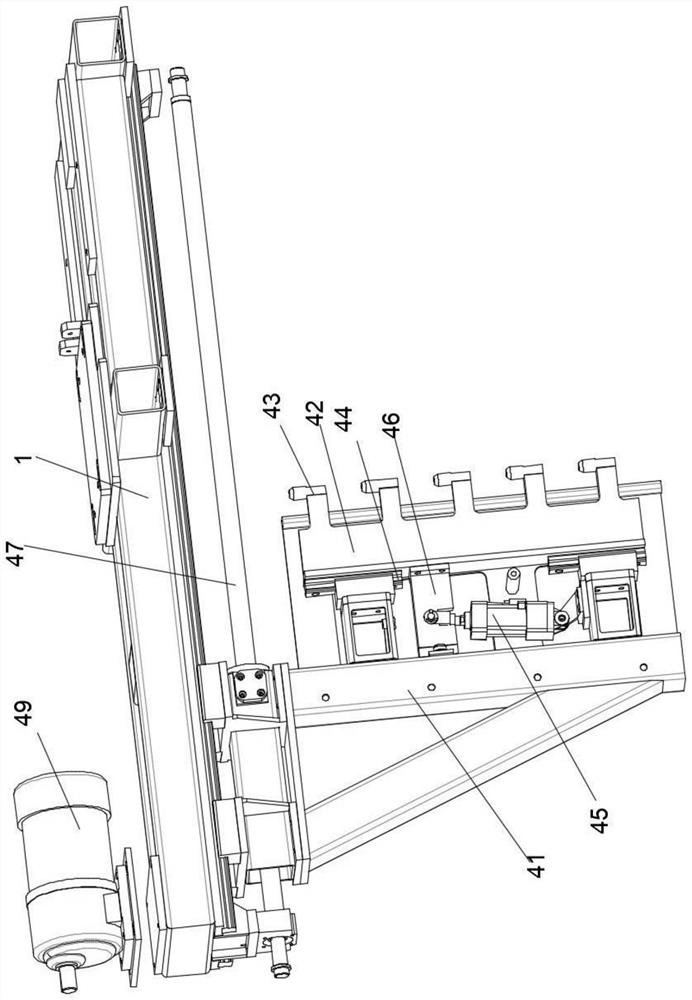

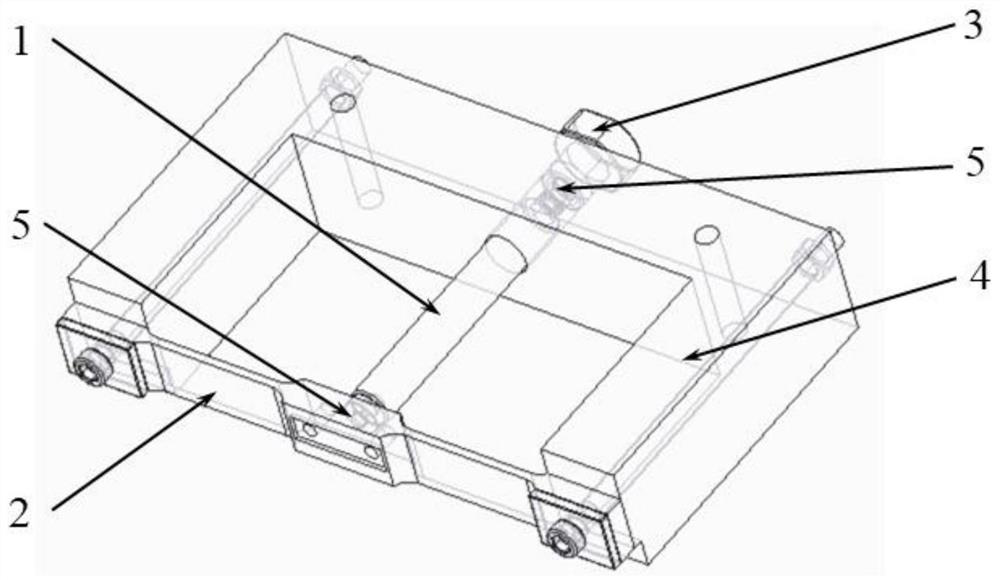

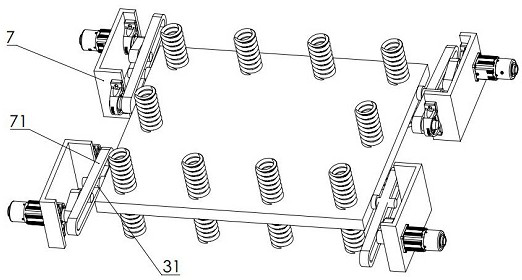

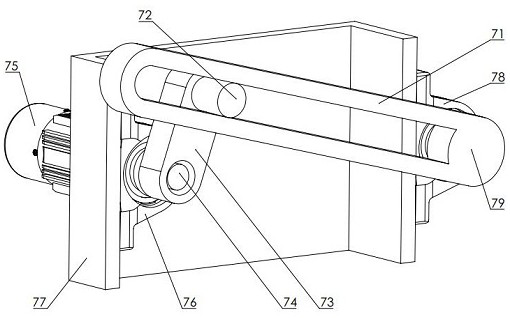

Automatic loading and unloading device

PendingCN114212473APrevent lateral vibrationImprove stabilityConveyor partsMechanical conveyorsStructural engineeringMechanical engineering

The invention relates to the technical field of circuit board processing, in particular to an automatic loading and unloading device. The driving part drives the feeding frame to move along the machine frame to load hot-pressing products on the conveying rail, the pushing mechanism pushes the hot-pressing products on the feeding station, synchronous feeding and discharging of the multiple hot-pressing products can be achieved, efficiency is effectively improved, and the automatic feeding and discharging device is compact in structure and small in occupied space; a plurality of feeding stations for loading hot-pressed products are arranged on the feeding frame, so that the situation that the hot-pressed products are damaged in the conveying process can be reduced; the driving component drives the feeding frame to move along the machine frame, transverse vibration of the feeding frame can be effectively avoided, and the stability of the hot-pressing product conveying process is improved.

Owner:SUZHOU JIAMING MACHINERY MFG

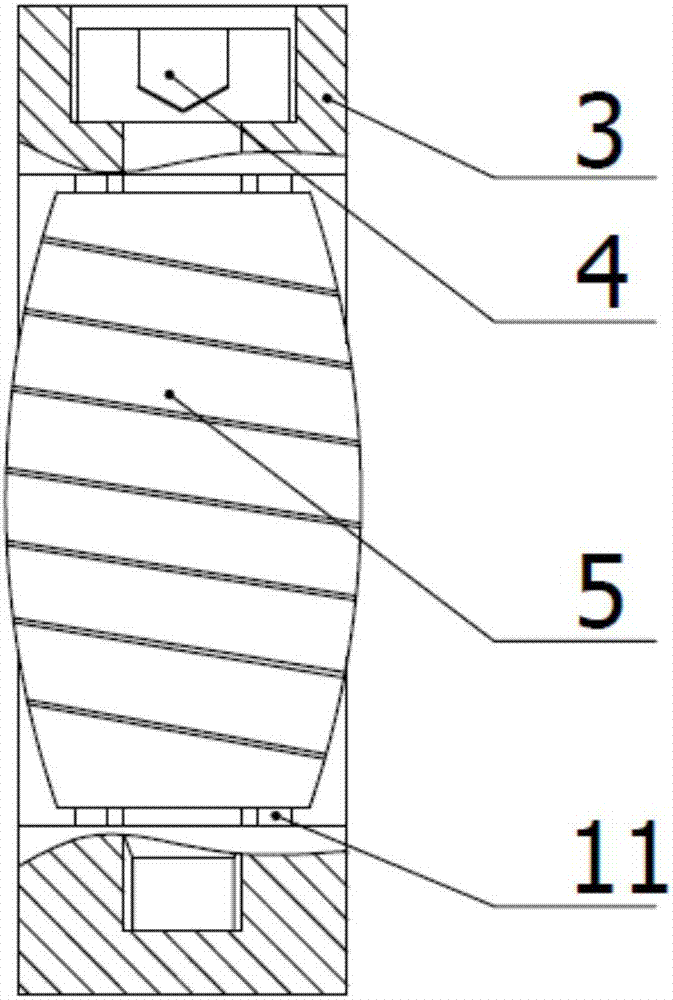

Screw protection device capable of avoiding transverse vibration and cooling

InactiveCN112743799APrevent lateral vibrationLower resistanceNon-rotating vibration suppressionOptical articlesEngineeringMechanical engineering

The invention relates to the technical field of network cables, and discloses a screw protection device capable of avoiding transverse vibration and cooling. The screw protection device comprises a rack, a rotating shaft is rotationally connected in the rack, a mounting disc is rotationally connected to the outer side of the rotating shaft, a supporting column is fixedly connected to the surface of the mounting disc, an elastic cavity is fixedly connected to the end, away from the mounting disc, of the supporting column, a water inlet hole is fixedly connected to the outer side face of the elastic cavity, a push rod is fixedly connected into the elastic cavity, and a metal contact is fixedly connected to the end, away from the elastic cavity, of the push rod. Through movement of the elastic cavity, the elastic cavity is compressed, so that the resistance, connected into the interior of the elastic cavity, of an electromagnetic rod is reduced, the electromagnetic rod and a magnetic block are close to each other, and a solution in the elastic cavity enters a water bin through a water through hole, so that vibration can be automatically filtered during slight vibration, and balance weights on the two sides of the protection device can be automatically adjusted during serious vibration, so that vibration is reduced.

Owner:长沙协创智赢技术服务有限公司

Elevator device

The present invention provides an elevator device. In the elevator device, an actuator for generating a vibration-damping force against the lateral vibration of a car is installed in parallel to an elastic body for preventing the lateral vibration. The actuator is controlled by a vibration-damping control unit. The control unit estimates the inherent frequency of the lateral vibration of the car, and finds a gain value based on the estimated inherent frequency and the rigidity value of the elastic body. Then, the damping control part drives the actuator according to an instruction signal with multiplication of the found gain value.

Owner:MITSUBISHI ELECTRIC CORP

Flexible coupling structure and ship thruster device with same

InactiveCN102132056BPrevent lateral vibrationLow production costYielding couplingPropulsive elementsSpherical bearingCoupling

Owner:KAWASAKI HEAVY IND LTD

A kind of fretting friction and wear test device and method of bolt connection interface

ActiveCN110146397BRealize closed-loop controlImproved stability controlInvestigating abrasion/wear resistanceLoop controlData acquisition

A bolt connection interface fretting friction and wear testing device of the present invention includes an excitation system, a measurement system, a test piece and a support system; the test piece and support system include a bolt connection test piece, a flexible guide plate, an external support frame and a base; The excitation system includes piezoelectric actuators, signal generators, power amplifiers, knobs and force transmission balls; the measurement system includes support blocks, dynamic force sensors, ring dynamic force sensors, laser vibrometers, optical lenses and data acquisition device; the present invention utilizes the high-precision bolt interface friction and wear testing device driven by the piezoelectric actuator for closed-loop control, and considers broadband excitation, closed-loop control, and precise optical displacement measurement at the same time, and can realize friction and wear testing in various working conditions. And it is easy to expand to other connection forms and test pieces. In addition, the device has several protective measures to avoid equipment damage.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

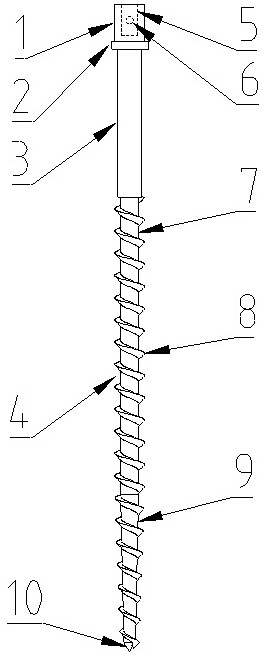

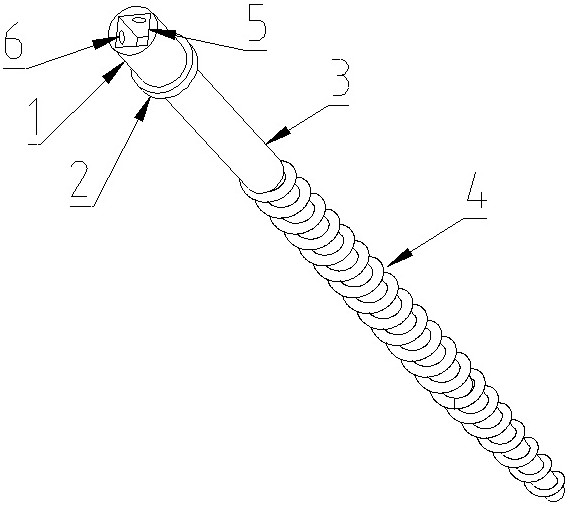

Special self-in/out type grounding electrode for grounding impedance test

InactiveCN113311245AReduce physical exertionGuaranteed contactEarth resistance measurementsMeasurement instrument housingGround impedanceImpedance testing

The invention discloses a special self-in / out grounding electrode for a grounding impedance test. The grounding electrode comprises a force application connection part, a limiting blocking plate, a transition part and an embedding part which are sequentially arranged from top to bottom, wherein the force application connection part is of a cylindrical structure, a square groove is formed in the center of the upper end surface of the force application connection part in a digging manner, four symmetrically-distributed spherical crown grooves are dug in the four side walls of the square groove, the transition part is of a cylinder structure, the embedding part comprises a connecting section, a smooth section, a tapping section and threads evenly arranged on the side faces of the connecting section and the smooth section in a surrounding mode, the connecting section, the smooth section and the tapping section are sequentially arranged from top to bottom, the connecting section is of a cylinder structure, the smooth section is of a circular truncated cone structure, the tapping section is of a cone structure, the diameters of the upper end and the lower end of the smooth section are matched with the diameters of the connecting section and the tapping section respectively, and the outer diameter of the thread is not larger than the diameter of the transition part. The grounding electrode has the advantages of being simple in structure, convenient to use, time-saving, labor-saving, high in working efficiency and good in grounding effect.

Owner:XUCHANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Vehicle steering wheel control method, device, computer equipment and vehicle

ActiveCN110654458BReduce centrifugal forcePrevent lateral vibrationSteering partsSteering wheelSteering angle

The application proposes a vehicle steering wheel control method, device, computer equipment, vehicle and storage medium, belonging to the technical field of vehicles. Wherein, the method includes: by determining the current driving parameters of the vehicle, the driving parameters include the driving speed and the driving route; determining the steering angle of the steering wheel in the vehicle according to the driving speed and the driving route of the vehicle; determining the steering angle of the steering wheel in the vehicle according to the driving speed of the vehicle. Rotational speed value; according to the steering wheel's steering angle and rotational speed value, control the rotation of the steering wheel. Therefore, through this vehicle steering wheel control method, the smooth control of the intelligent driving vehicle is realized, the driving comfort of the vehicle is improved, and the user experience is improved.

Owner:BYD CO LTD

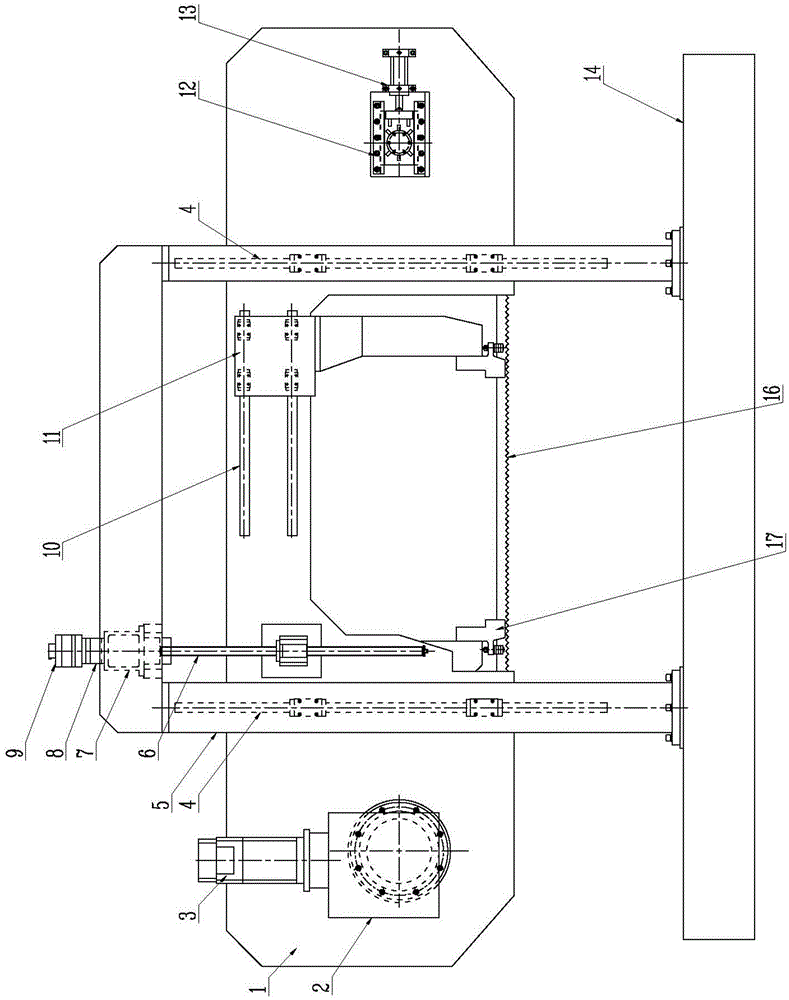

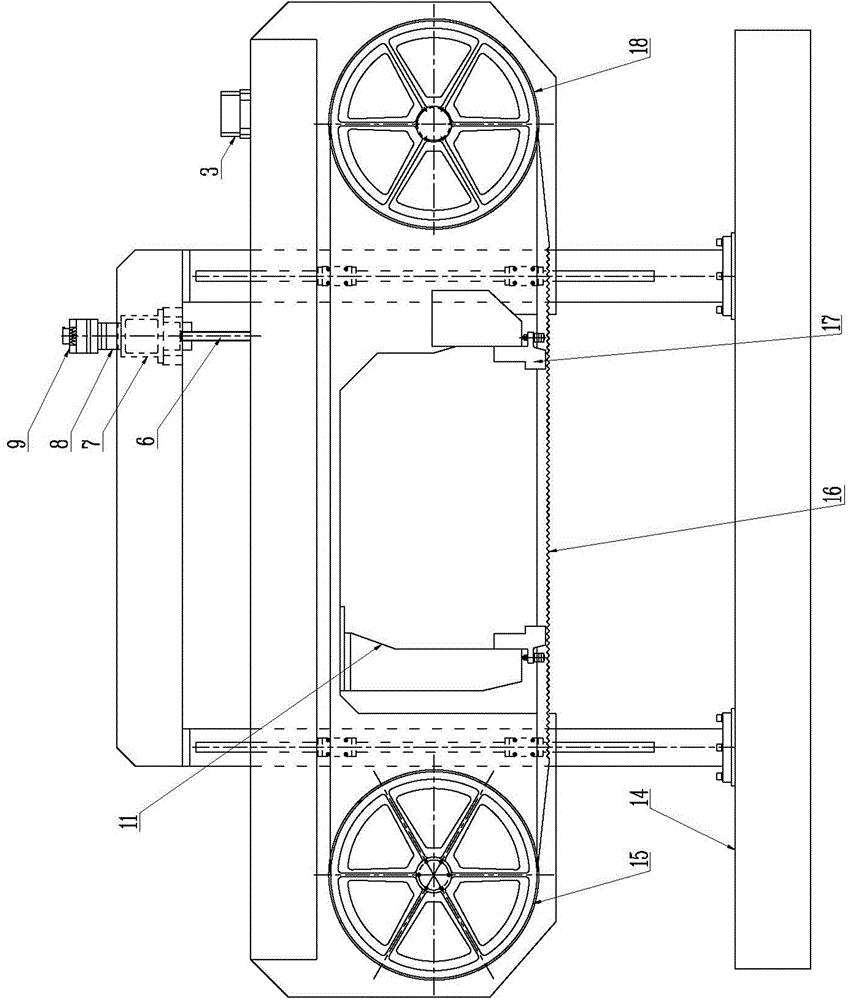

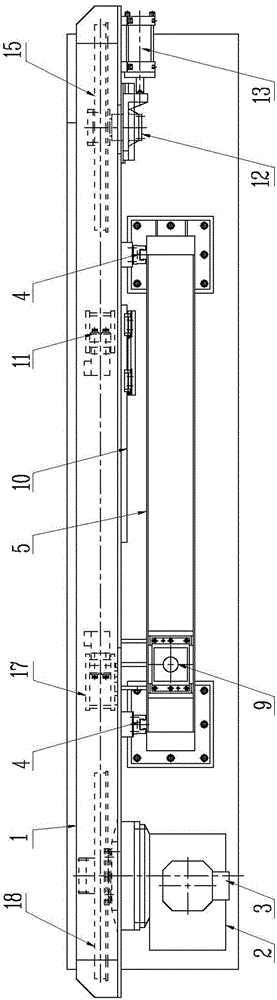

Saw band vibration eliminating structure of high-speed band sawing machine

InactiveCN103008782BReduce irregular unreleased energySave energyMetal sawing devicesMachiningNumerical control system

The invention relates to a saw band vibration eliminating structure of a high-speed band sawing machine and belongs to the field of mechanical processing equipment. The vibration phenomenon of a saw blade of the existing band sawing machine is serious in the cutting process, so cuts of processed workpieces are deflective, and in addition, the saw blade breakage can be frequently caused. The saw band vibration eliminating structure comprises a saw bow, a gantry cross beam, a fixed base, a numerical control system, a saw blade moving mechanism, a saw blade clamping mechanism, a tensioning mechanism, a tensioning oil cylinder and a saw bow moving mechanism, wherein the gantry cross beam is arranged on the fixed base, the saw bow and the gantry cross beam are assembled together, the saw blade moving mechanism, the saw blade clamping mechanism, the tensioning mechanism and the tensioning oil cylinder are respectively arranged on the saw bow, the tensioning oil cylinder is connected with the tensioning mechanism, the saw bow moving mechanism is arranged on the gantry cross beam, and the saw bow moving mechanism used for driving the saw bow to vertically move along the gantry cross beam is connected with the saw bow. The saw band vibration eliminating structure of the high-speed band sawing machine has the advantages that the vibration phenomenon of the saw blade can be lightened, the cutting quality of the processed workpieces is improved, the breakage phenomenon of the saw blade is reduced, and the stable and high-speed cutting on the workpieces is realized.

Owner:WORLDWIDE INDAL MACHINERY DONGGUAN

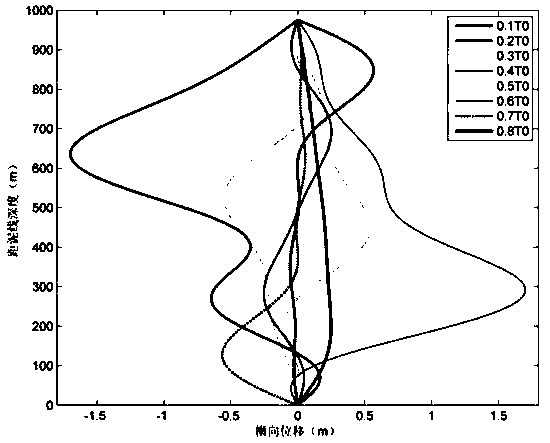

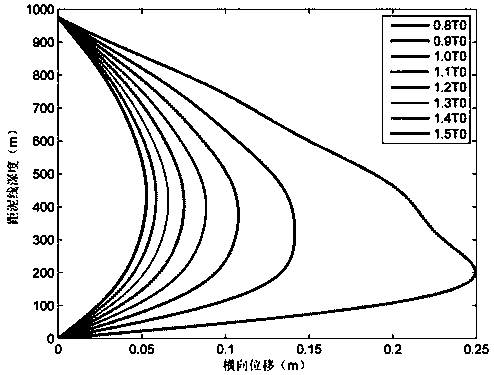

Method for confirming optimal suspension force of offshore test tubular column

InactiveCN110555287APrevent lateral vibrationSpecial data processing applicationsEngineeringSafe operation

According to the method for confirming the optimal suspension force of the offshore test tubular column, the optimal suspension force of the offshore test tubular column can be confirmed by testing the tubular column under the conditions of certain transverse acting force distribution coefficient, water depth, tubular column wall thickness and test working condition parameters; the influence of different suspension forces on the maximum transverse vibration displacement and the amplitude of each order of the test tubular column is calculated, so that the optimal suspension force of the test tubular column can be selected, and a basis is provided for adjusting the suspension force during construction of the test tubular column. The offshore test tubular column is determined; the whole tubular column is pulled to avoid complex transverse vibration of the tubular column, the maximum displacement of the transverse vibration of the tubular column is reduced along with the increase of the hanging force at the upper end, the conclusion of the transverse vibration of the test tubular column can be effectively reduced by properly increasing the hanging force of the test tubular column, andtherefore guidance can be provided for mechanical behavior control and safe operation of the test tubular column.

Owner:YANGTZE UNIVERSITY

Micro-center PDC (polycrystalline diamond compact) bit with conical tooth structure

InactiveCN113982491APrevent lateral vibrationExtend your lifeDrill bitsConstructionsRock corePolycrystalline diamond

The invention discloses a micro-center PDC (Polycrystalline Diamond Compact) drill bit with a conical tooth structure, which is characterized in that no PDC cutting teeth are arranged in the central area of the drill bit, a cylindrical groove is formed in the central area when the drill bit rotates, a conical diamond tooth is arranged at the bottom of the groove, and the axis of the conical diamond tooth and the axis of the cylindrical groove are not in the same plane; the discharge grooves pointed by the axes of the conical diamond teeth are wider and deeper than other discharge grooves, and the width of the discharge grooves in the circumferential direction of the drill bit is larger than the diameter of the grooves. When the drill bit drills in a hard stratum, a micro rock core is formed, when the micro rock core enters the groove and then makes contact with the conical diamond teeth arranged at the bottom of the groove, the micro rock core is subjected to the radial force from the conical teeth, the micro rock core is forced to be broken and enter the deep and wide large flow channel, and then the micro rock core enters the annular space of a well hole through the chip groove, and the micro rock core and other common rock debris are discharged to the ground. Therefore, the micro rock core with the size much larger than that of common rock debris can be obtained on the ground, and the micro rock core can be used for geological logging to identify rock information or strata.

Owner:中石化石油工程技术服务有限公司 +2

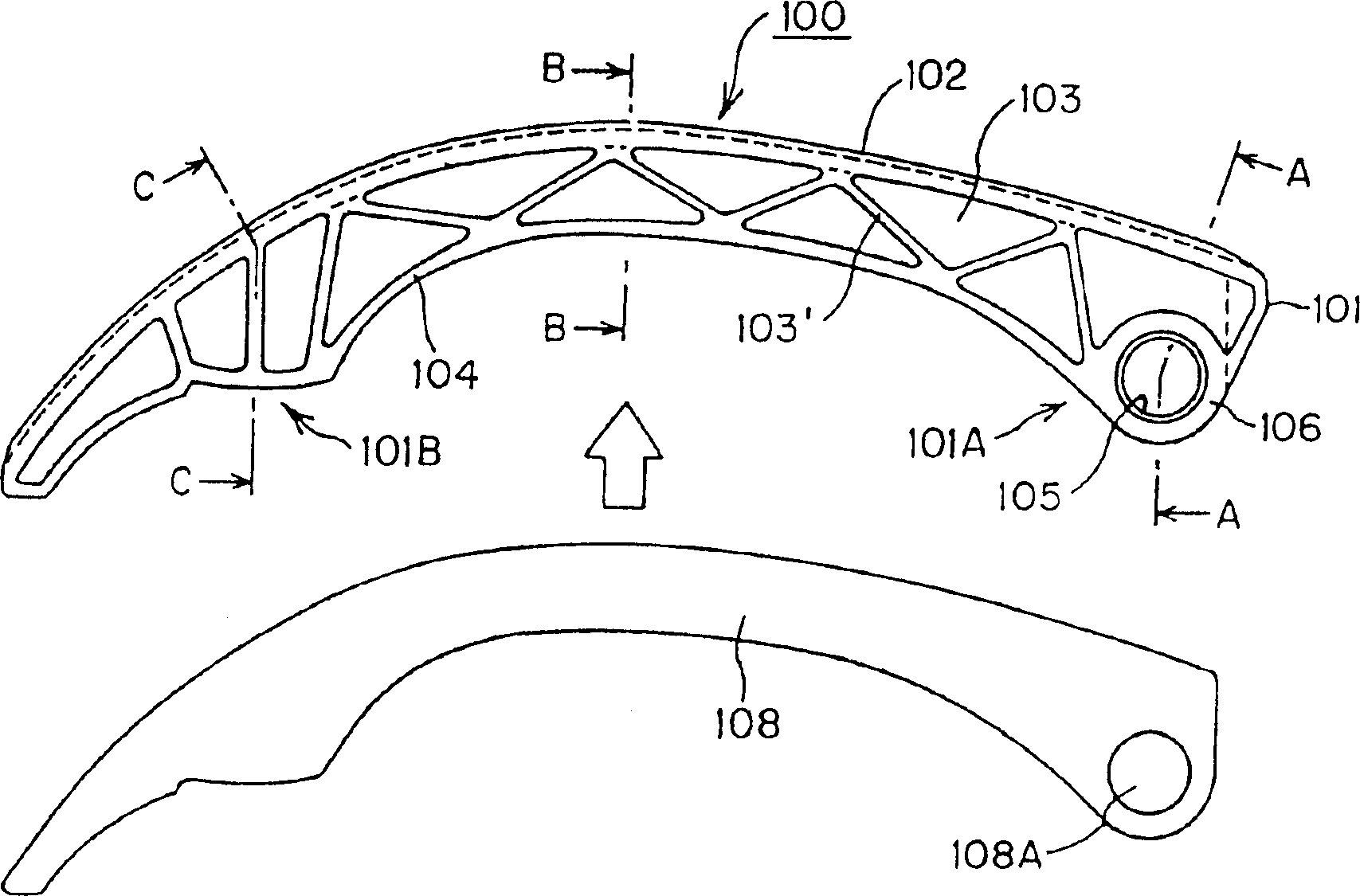

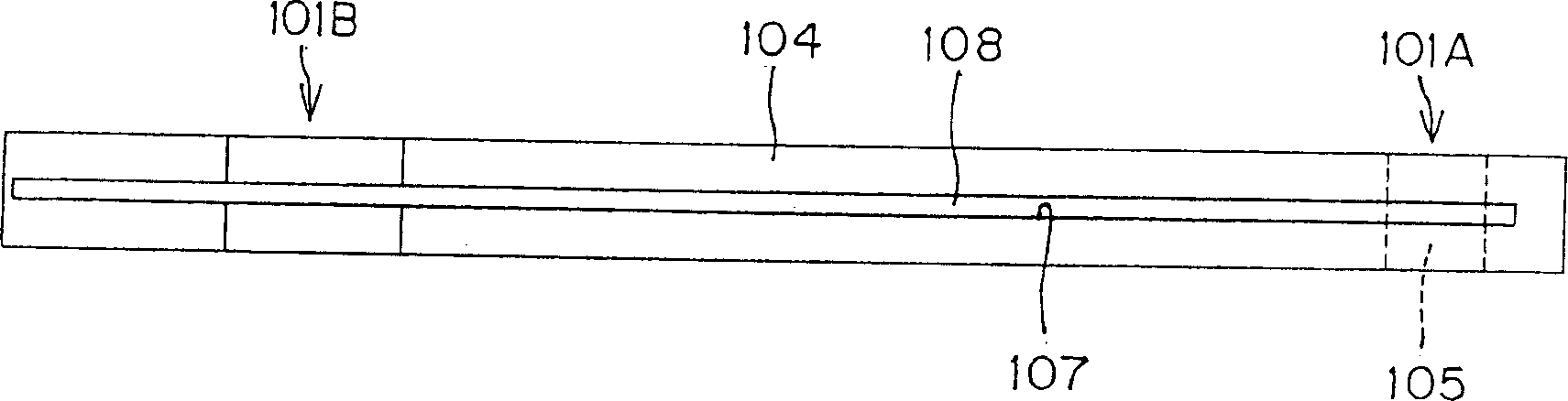

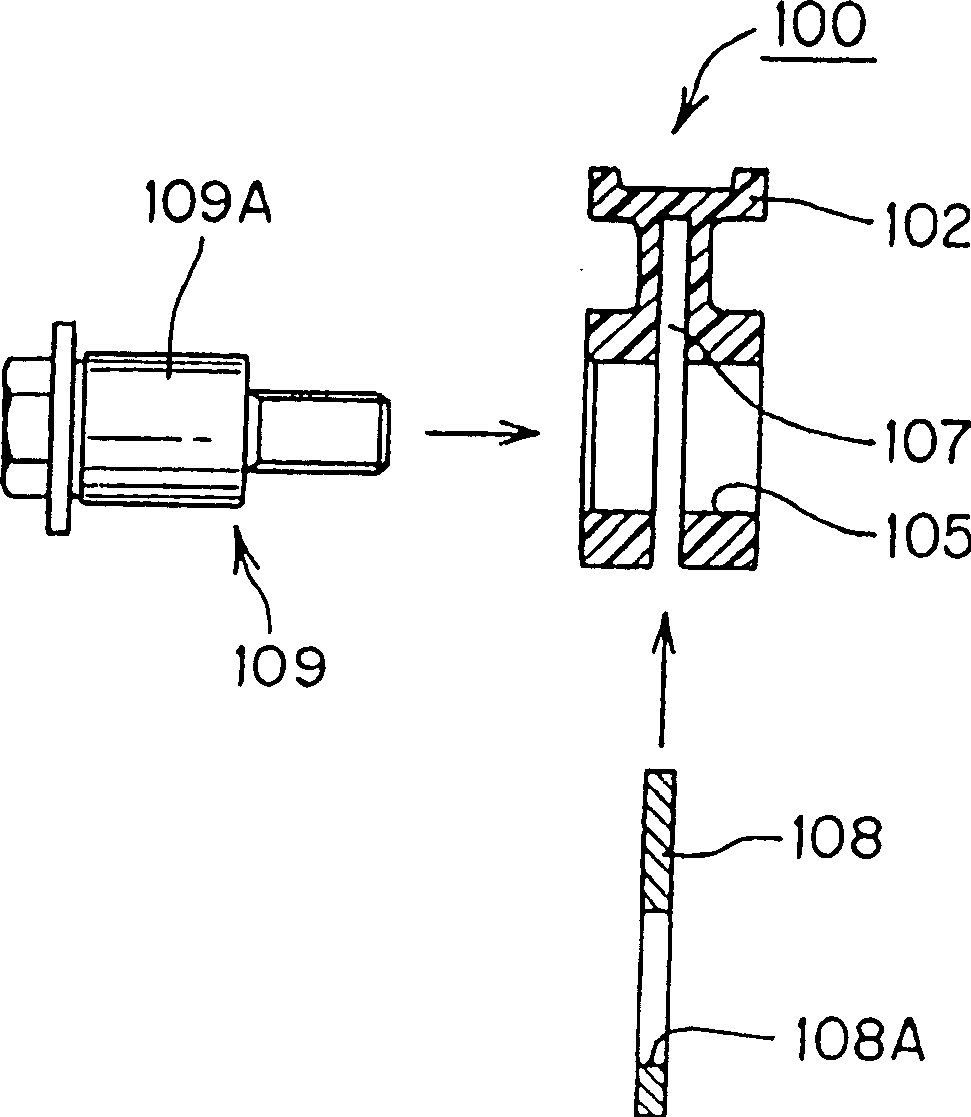

Plastic movable guide device for transmission

The present invention provides a plastic movable guide having excellent noiselessness and assembling ability and capable of reducing production cost. On the pivoting front end side of the guide body 101, a plunger accommodating portion 101B, which a plunger of the tensioner can contact and press, is provided, and a reinforcing plate 108 is provided in a slightly recessed manner. The plunger receiving portion 108 is such that the reinforcing plate 108 does not protrude from the edge of the opening in the slit.

Owner:TSUBAKIMOTO CHAIN CO

Power external dredging equipment and working method for small-diameter drainage blind pipes in tunnels

ActiveCN113289991BEasy to adjustRealize reciprocating motionHollow article cleaningUniversal jointEngineering

The invention discloses a power external dredging device and a working method for small-diameter drainage blind pipes in tunnels, including a rotary drive device, the power output end of the rotary drive device is connected with a vibration cutting mechanism through a power transmission mechanism, and the power transmission mechanism is put on the A sliding tube and a fixed tube are provided, one end of the sliding tube is connected with the rotary drive device, the other end of the sliding tube extends into the fixed tube and is slidably connected with the fixed tube, and the vibrating cutting mechanism extends out of the fixed tube; the power transmission mechanism includes several sequentially connected The universal joint connected with the shaft, the universal joint at one end of the power transmission mechanism is connected with the rotary driving device, and the universal joint at the other end is connected with the mounting column of the cutting bit seat; the rotating sleeves on several connecting shafts are provided with supporting parts, and several supporting parts are connected with the The corresponding sliding tube is in contact with the inner wall of the fixed tube. The invention can quickly and conveniently clear the clogging problem of small-diameter blind drainage pipes by means of mechanical cutting and vibration.

Owner:CHANGAN UNIV

An anti-falling lightning rod

The invention relates to an anti-shedding lightning rod, and solves the problems in the prior art that no strengthening measure is taken for a lightning rod, the vortex shedding can be easily formed to make the lightning rod shake, and as a result, the lightning rod breaks or falls off. A lightning rod is mounted at the top of a tower. A winding wire is disposed on an outer wall of the lightning rod. Two end portions of the winding wire are wound onto the outer wall of the lightning rod in opposite rotating directions in a helical cross manner. The lower portion of an inner cavity of the lightning rod is fixed with a flange plate. A safety rope is disposed on the flange plate. The safety rope penetrates through the bottom of the lightning rod and is then fixed on the tower. The invention is advantageous in that the winding wire is wound helically onto the outer wall of the lightning rod, the regular vortex shedding is prevented from forming at the rear portion of a circular tube of the lightning rod, the transverse vibration caused by the vortex shedding is avoided, therefore, the shaking amplitude of the lightning rod is reduced, the anti-fatigue degree of the lightning rod is improved, and the breaking and falling off are prevented. The case in which the lightning rod hits someone or something after long-term use due to the sudden breaking and falling caused by fatigue rupture is prevented.

Owner:HUAXIN CONSULTATING CO LTD

An intelligent marine diesel engine attitude adjustment device

ActiveCN114261496BEliminate lateral vibrationReduce swingPropulsion power plantsMachines/enginesDieselingPropeller

The invention relates to the technical field of marine diesel engines, and discloses an intelligent marine diesel engine attitude adjustment device. When the propulsion shafting of a ship is in operation, vibrations are inevitably generated under the influence of dynamic factors such as propeller hydrodynamic force, hull deformation, and lubricating film. At the same time, the operation of the diesel engine connected to the propulsion shafting will also generate vibration. According to the regulations, the marine diesel engine and the propulsion shafting must be checked and calculated to control the vibration source and reduce vibration, isolate the vibration source and protect equipment and personnel. The attitude adjustment device of the intelligent marine diesel engine of the present invention comprises an upper base of the diesel engine, a lower base of the diesel engine, a lateral clamping mechanism, a swing jacking mechanism, a hull attitude sensor and a controller. The two swing jacking mechanisms operate independently to adjust the attitude of the lower base of the diesel engine to reduce / eliminate the swing amplitude of the marine diesel engine due to wind and waves.

Owner:SHANDONG JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com