Saw band vibration eliminating structure of high-speed band sawing machine

A high-speed belt and sawing machine technology, used in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of unguaranteed saw blade movement and feed accuracy, low control accuracy, and workpiece incision skew, etc. Promote and use value, improve machining accuracy, and stabilize the effect of high-speed cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail, is not to limit the implementation scope of the present invention hereto, and this embodiment does not limit protection scope of the present invention, and those who are familiar with this art will not deviate from the present invention Reasonable changes made under the protection scope and spirit of the invention should all belong to the protection scope of the present invention.

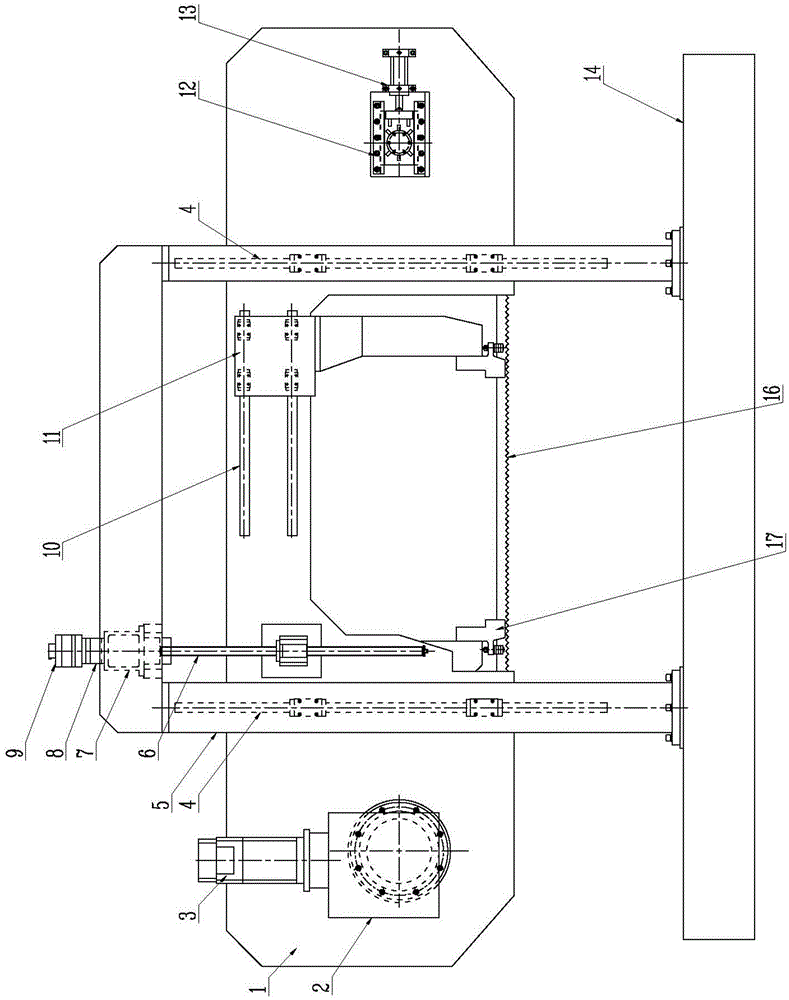

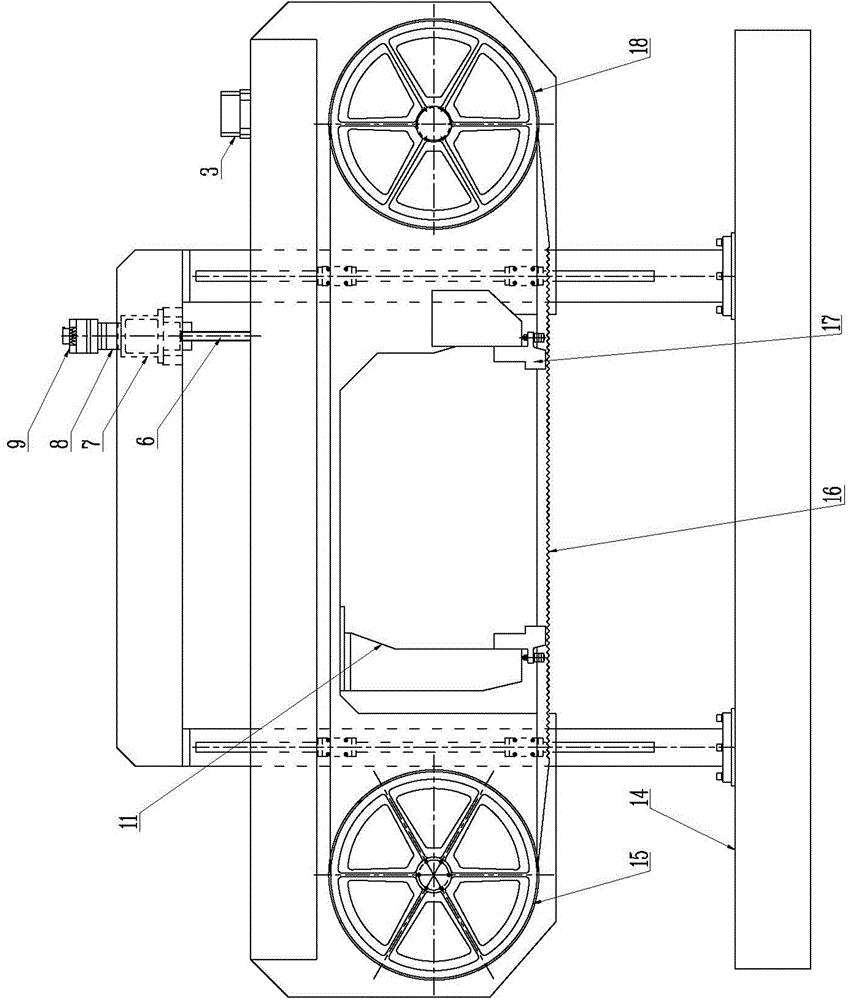

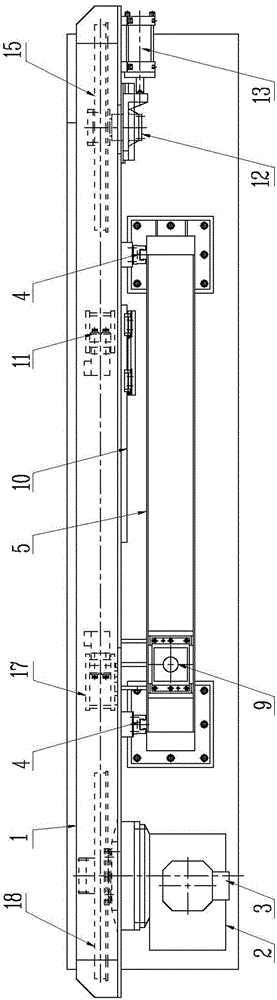

[0023] Such as Figure 1 to Figure 4 As shown, the structure of the high-speed band sawing machine described in this embodiment to eliminate the vibration of the saw band includes the saw bow 1, the gantry beam 5 and the fixed base 14, the gantry beam 5 is installed on the fixed base 14, the saw bow 1 and the gantry beam 5 assembled together, the structure of the high-speed band sawing machine to eliminate the vibration of the saw band also includes a numerical control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com