Method for confirming optimal suspension force of offshore test tubular column

A technology for offshore testing and testing tubes, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as safety accidents, self-excited vibration of test strings, and failure to meet production adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The method for confirming the optimal suspension force of the offshore test string includes the following steps:

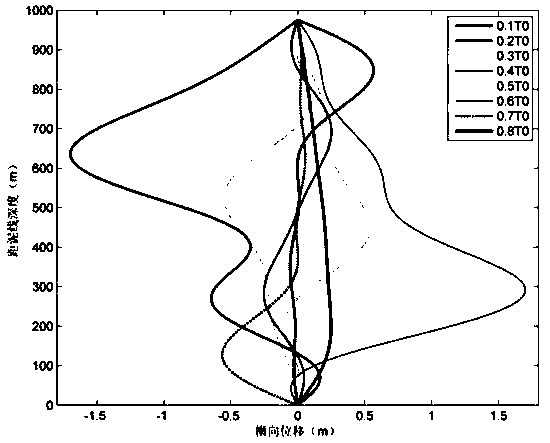

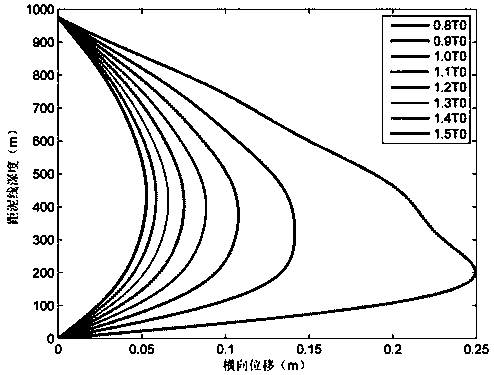

[0089] (1) Establishment of the lateral vibration model of the offshore test string:

[0090] During the test, assuming that the test string is concentrically aligned with the riser, and the bending of the test string is in a steady state during the external environment and test production process, is the string length, In order to test the lateral vibration displacement of the pipe string, is time, and the length is The test string unit, the inclination angle of the midpoint of the string is , the buoyant weight of the string is ;

[0091] Neglecting the influence of lateral vibration between the internal and external fluid and the test string, the energy method is used to analyze the lateral vibration of the test string during the test;

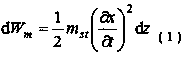

[0092] For the pipe string unit in the test process, the energy of the pipe string unit is mainly the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com