Micro-center PDC (polycrystalline diamond compact) bit with conical tooth structure

A technology of bevel teeth and drill bits, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems of less footage, cone loss, and damage to cutting teeth, so as to protect the early damage, prevent lateral vibration, and prolong the life of the drill bit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

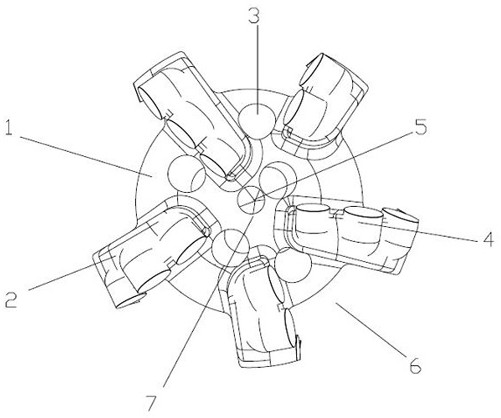

[0022] Micro-center PDC bit with bevel tooth structure, including bit body 1, blade 2, and cutting teeth 4.

[0023] A flow channel is opened inside the drill body, and a nozzle communicating with the flow channel is arranged on the surface. The blades are fixed at the end of the drill body and arranged in a circular array around the axis of the drill body, leaving a space for opening a core groove in the center of the circular array. The cutting teeth are fixed on the blade.

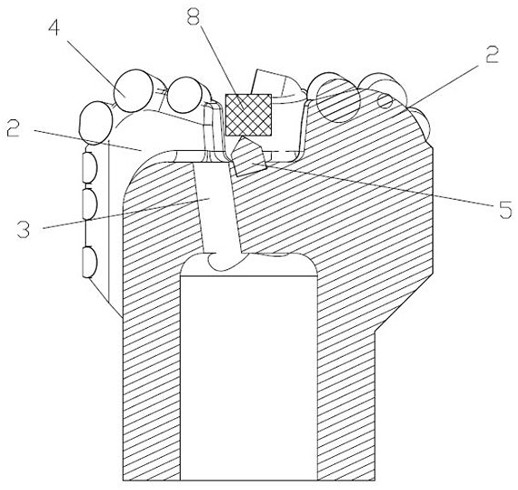

[0024] A core groove coaxial with the drill body is provided at the center of the end of the drill bit body, and the core groove is a cylindrical groove located in the central area of the circumferential array.

[0025] Bevel teeth are arranged in the rock core groove, and the function of the bevel teeth is to interrupt the rock core 8 entering the rock core groove.

Embodiment 2

[0027] Micro-center PDC bit with bevel tooth structure, including bit body 1, blade 2, and cutting teeth 4. Among them, there are 5 blades, which are arranged in a circular array at the end of the drill body, and nozzles are arranged in the interval between the blades, and the nozzles communicate with the flow channel inside the drill body.

[0028] The bevel teeth are fixed on the bit body, located in the central area of the circular array, and are not coaxial with the bit body.

[0029] The bevel tooth is a conical cutting tooth.

Embodiment 3

[0031] Refer to the attached Figures 1 to 2 , a micro-center PDC drill bit with bevel tooth structure of the present invention is composed of a drill body 1, a blade 2, a nozzle 3, a cutting tooth 4, a bevel tooth 5 and a water tank 6, the nozzle 3 is installed on the drill body 1, and the blade 2 It is fixed on the bit body 1, and the cutting teeth 4 are installed on the blade 2. No cutting teeth are arranged in the central area of the bit body 1. There is a core groove 7 in the center of the bit body 1 that allows the core 8 to enter when the drill bit is drilled. The core groove 7 is Cylindrical groove. The bottom of the core groove 7 is arranged with bevel teeth 5, the axis of the bevel teeth 5 and the axis of the drill bit body 1 are not in the same plane, the axis of the bevel teeth 5 points to a larger water tank 6, the circumferential width of the water tank 6 It is larger than the diameter of the core groove 7 and the core 8.

[0032] The working principle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com