Polishing apparatus

A technology of equipment and polishing head, which is applied in the direction of grinding/polishing equipment, metal processing equipment, sounding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

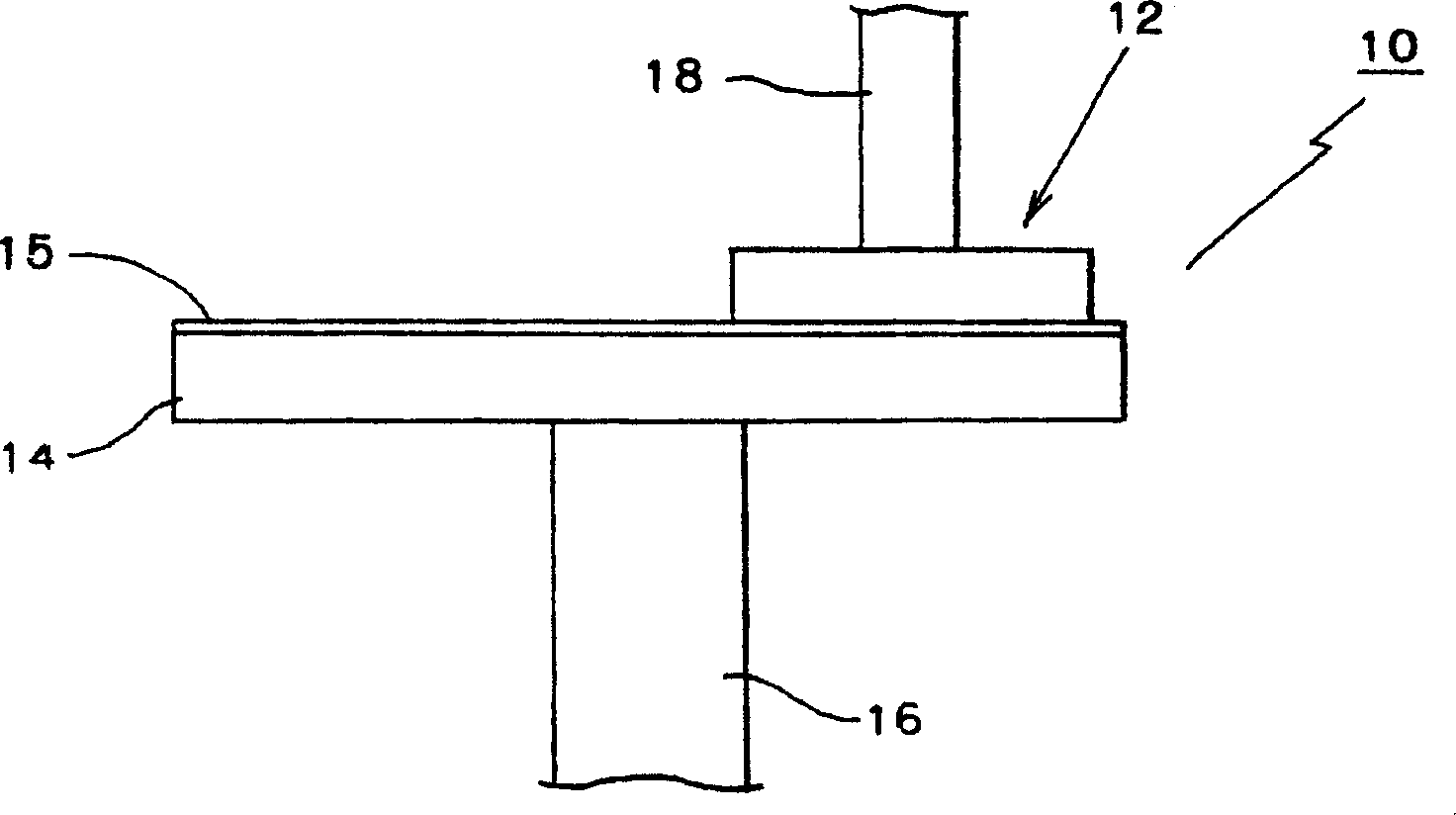

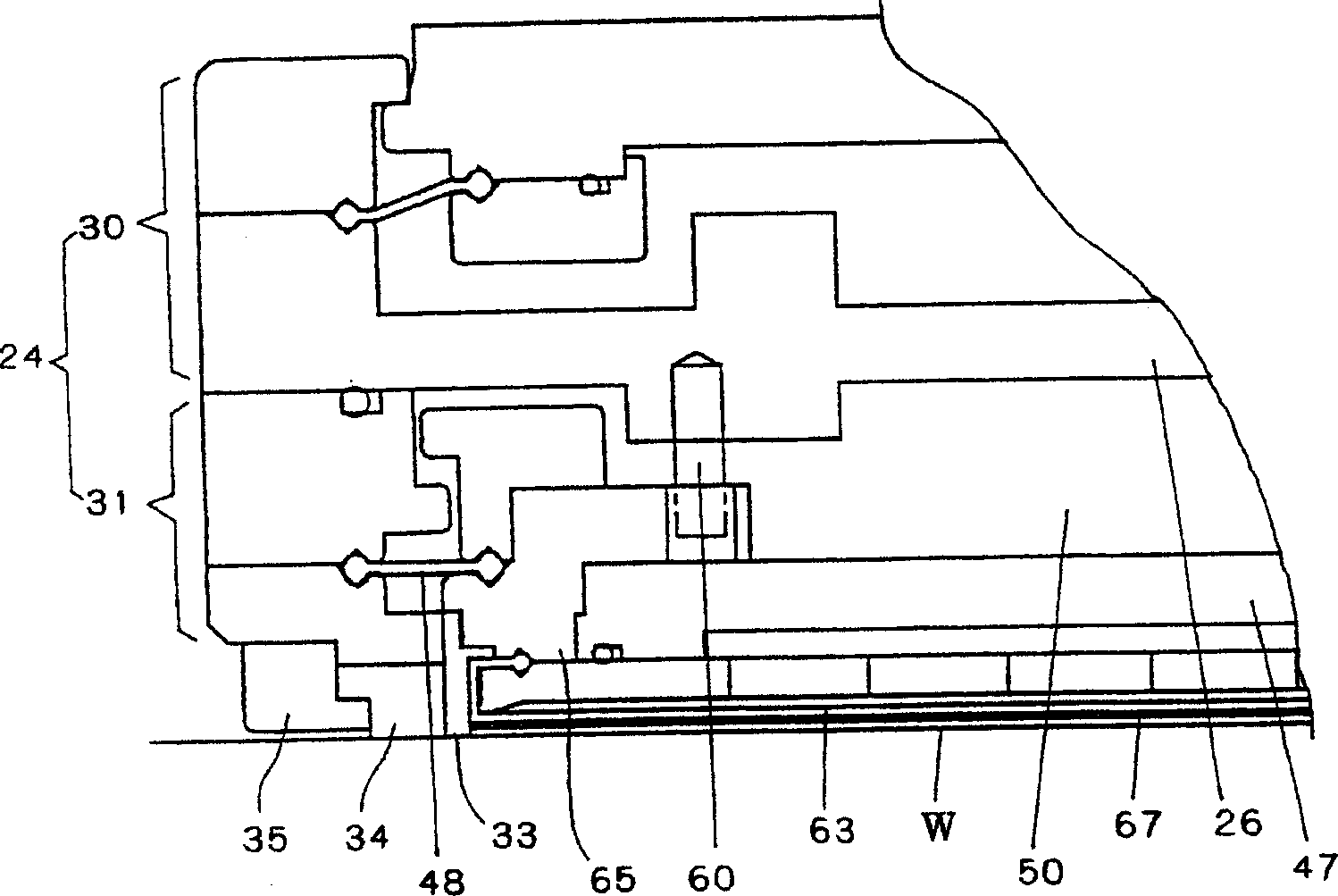

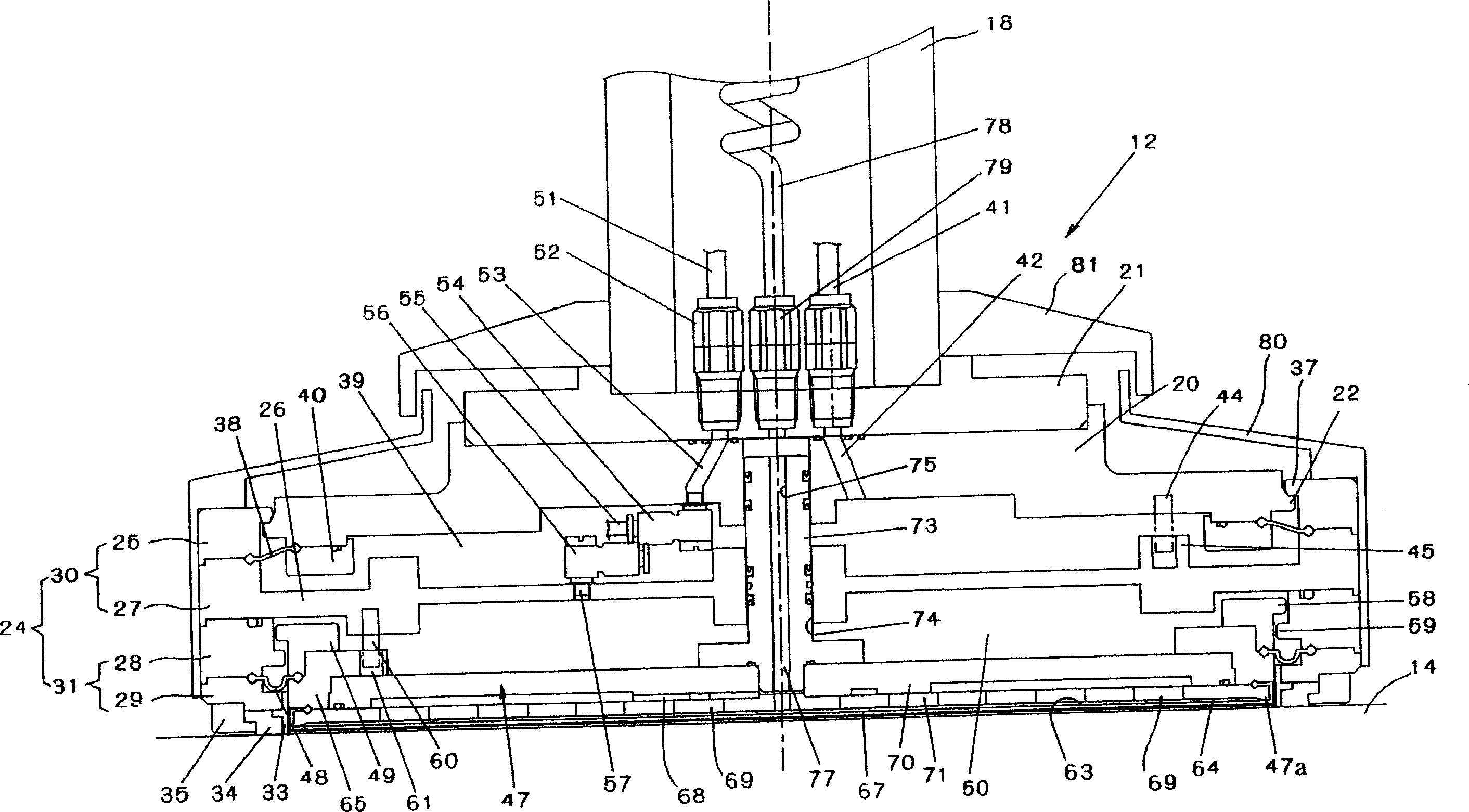

[0066] figure 1 is a schematic diagram of a polishing apparatus 10 related to the present invention, figure 2 is a sectional view of the fixed plate 12 of the first embodiment.

[0067] exist figure 1 In this case, a polishing pad 15 made of non-woven fabric, such as polyurethane, is attached to the upper surface of the polishing wheel 14, such as by an adhesive. The polishing wheel 14 rotates with the shaft 16 in a horizontal plane. Shaft 16 is rotated by a known drive mechanism (not shown).

[0068] The fixed disk 12 is connected to the lower end of the rotating shaft 18 . The rotary shaft 18 rotates about its axis and is moved up and down by a known mechanism (not shown). The fixed plate 12 is movable between a position on the upper side of the polishing wheel 14 and a position on the outer side of the polishing wheel 14 .

[0069] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com