Lighting device

A light-emitting device and light-emitting mechanism technology, applied in the direction of lighting devices, light sources, components of lighting devices, etc., can solve problems such as large structural forms, achieve compact structure, high safety requirements, and improve the effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

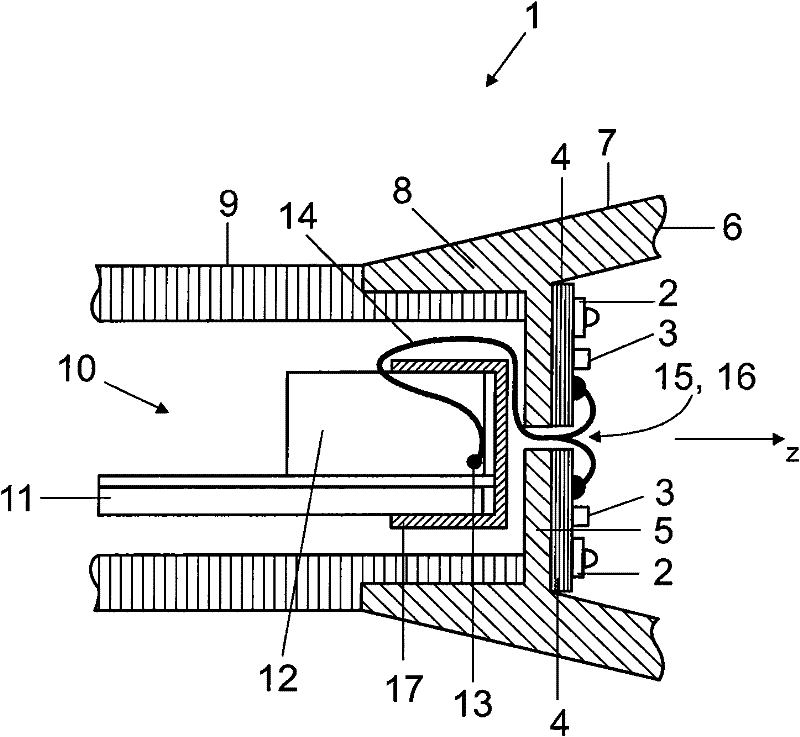

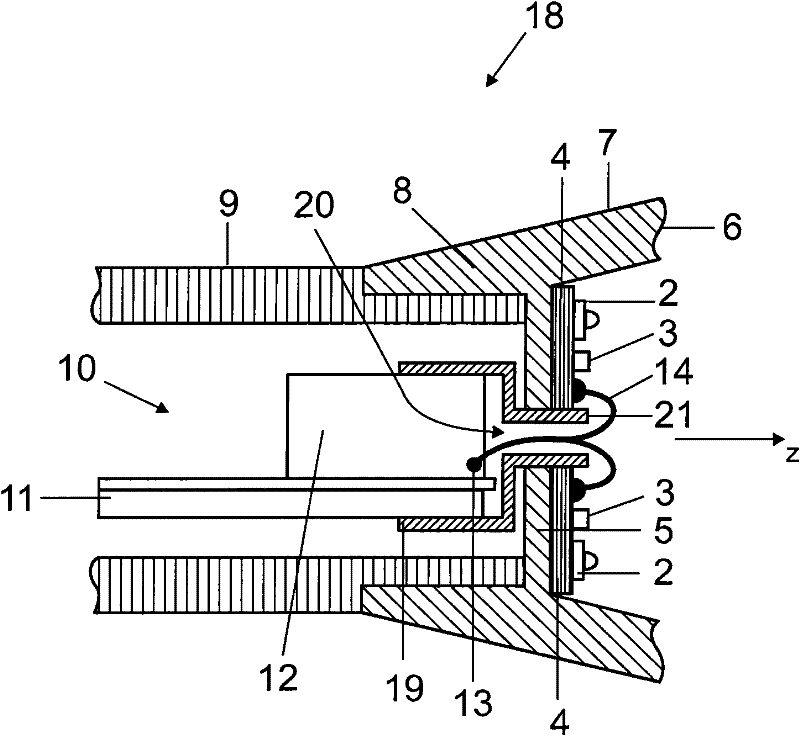

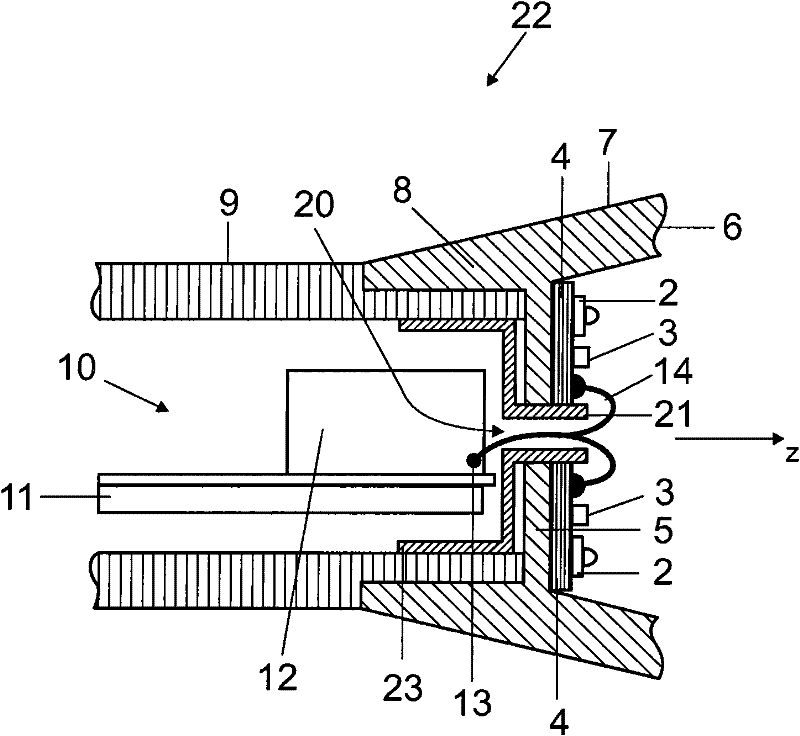

[0028] figure 1 The LED lighting device 1 according to the first embodiment is shown. The device has a plurality of light-emitting diodes 2 which are mounted together with associated electronic components 3 on the upper side of a printed circuit board 4 . The electronics provide at least one driver for feeding the light-emitting diodes in a controlled manner. In order to dissipate heat from the light-emitting diodes 2 and the electronic components 3 , the printed circuit board 4 is embodied as a metal-core printed circuit board, which is placed with its bottom side on the planar mounting area 5 of the metal heat sink 6 . The mounting area 5 is surrounded laterally by a surrounding side wall 7 which (to the right of the mounting area 5 , in the z direction) together with the mounting area 5 forms a cup shape for the light emitted by the LED 2 reflector. Below the placement area 5 (in relation to the z-direction), the surrounding side walls 7 form a connection area 8 for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com