Air cylinder crankcase, and internal combustion engine having same

A technology of crankcase and cylinder, applied in the field of internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

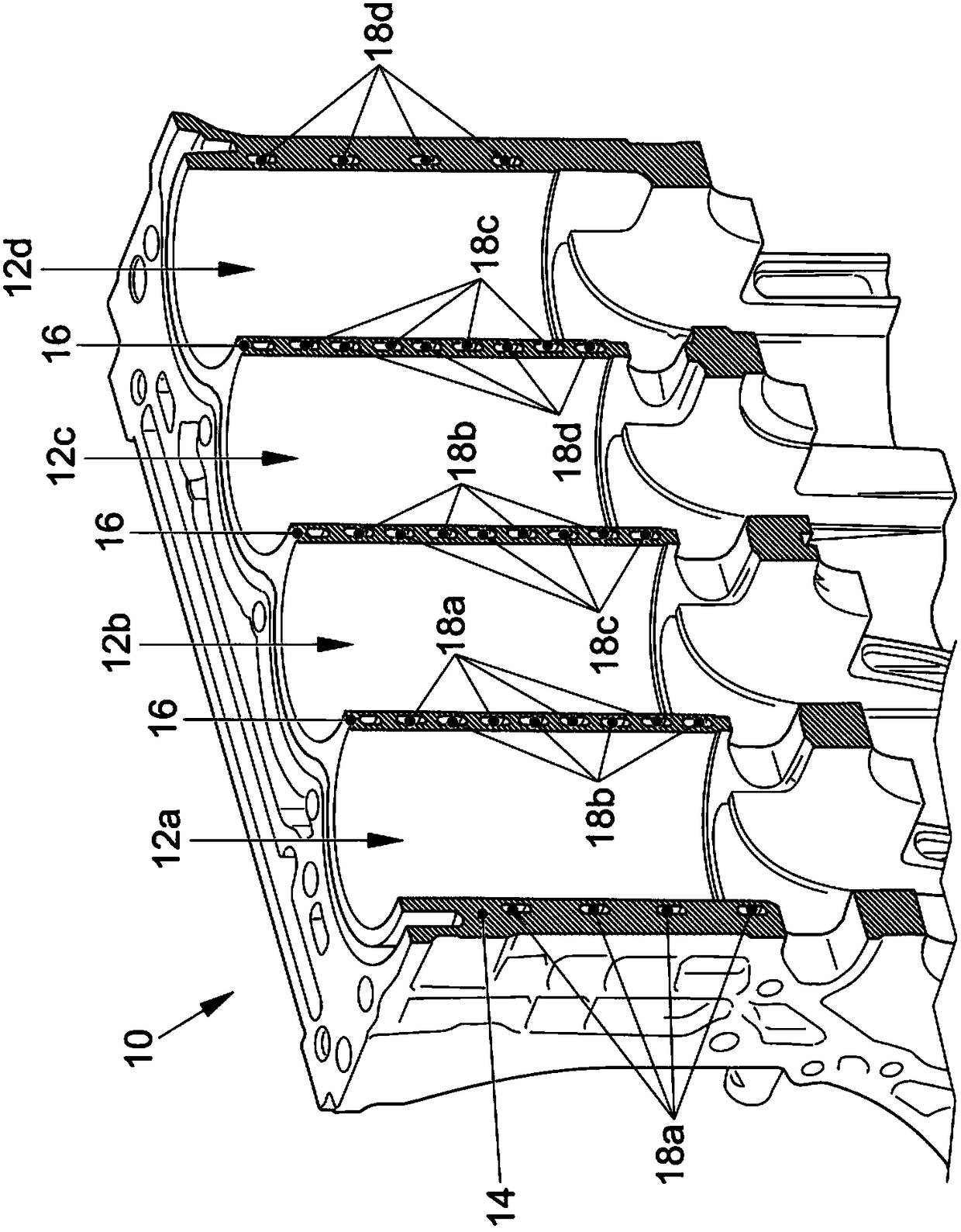

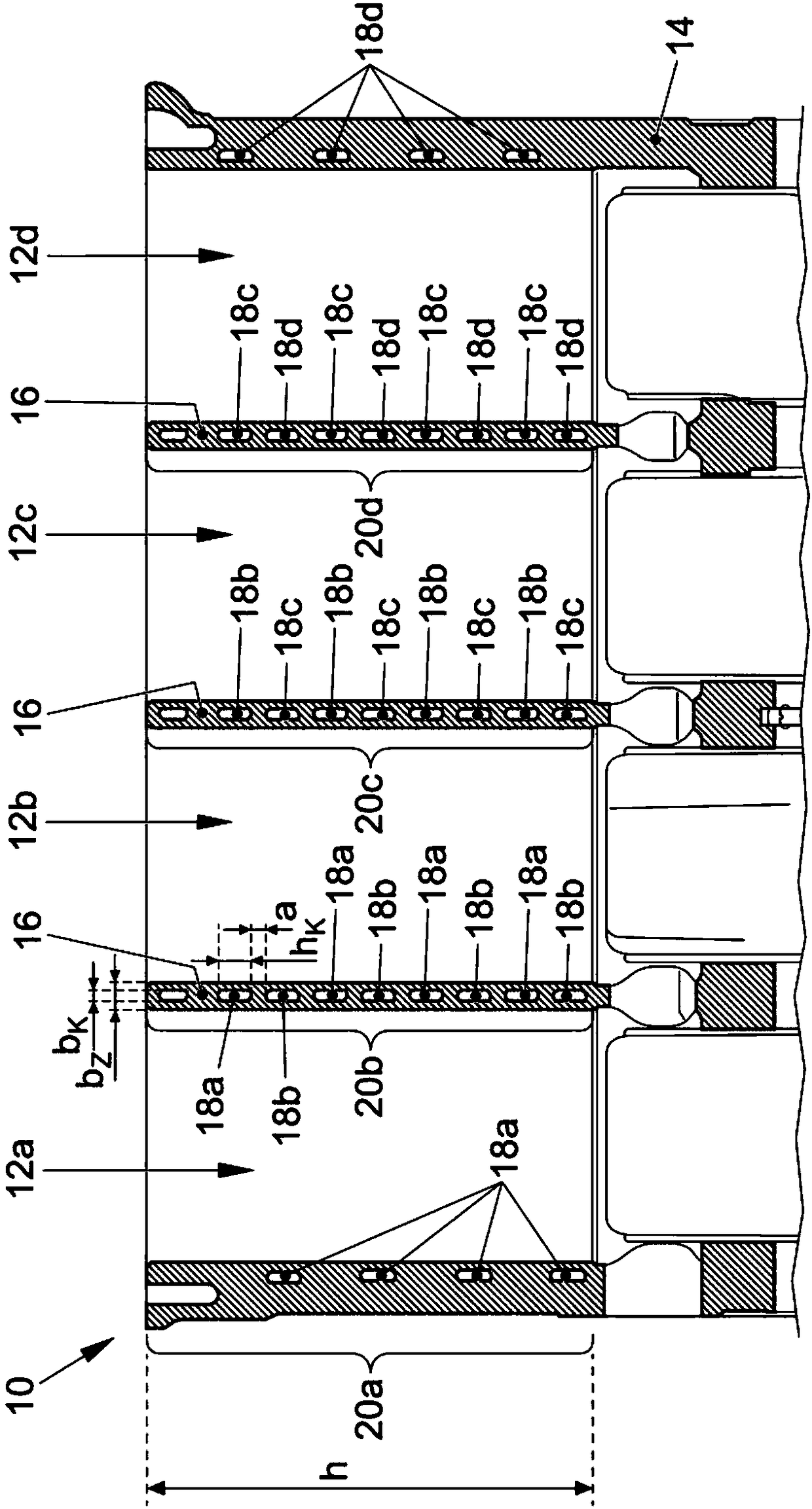

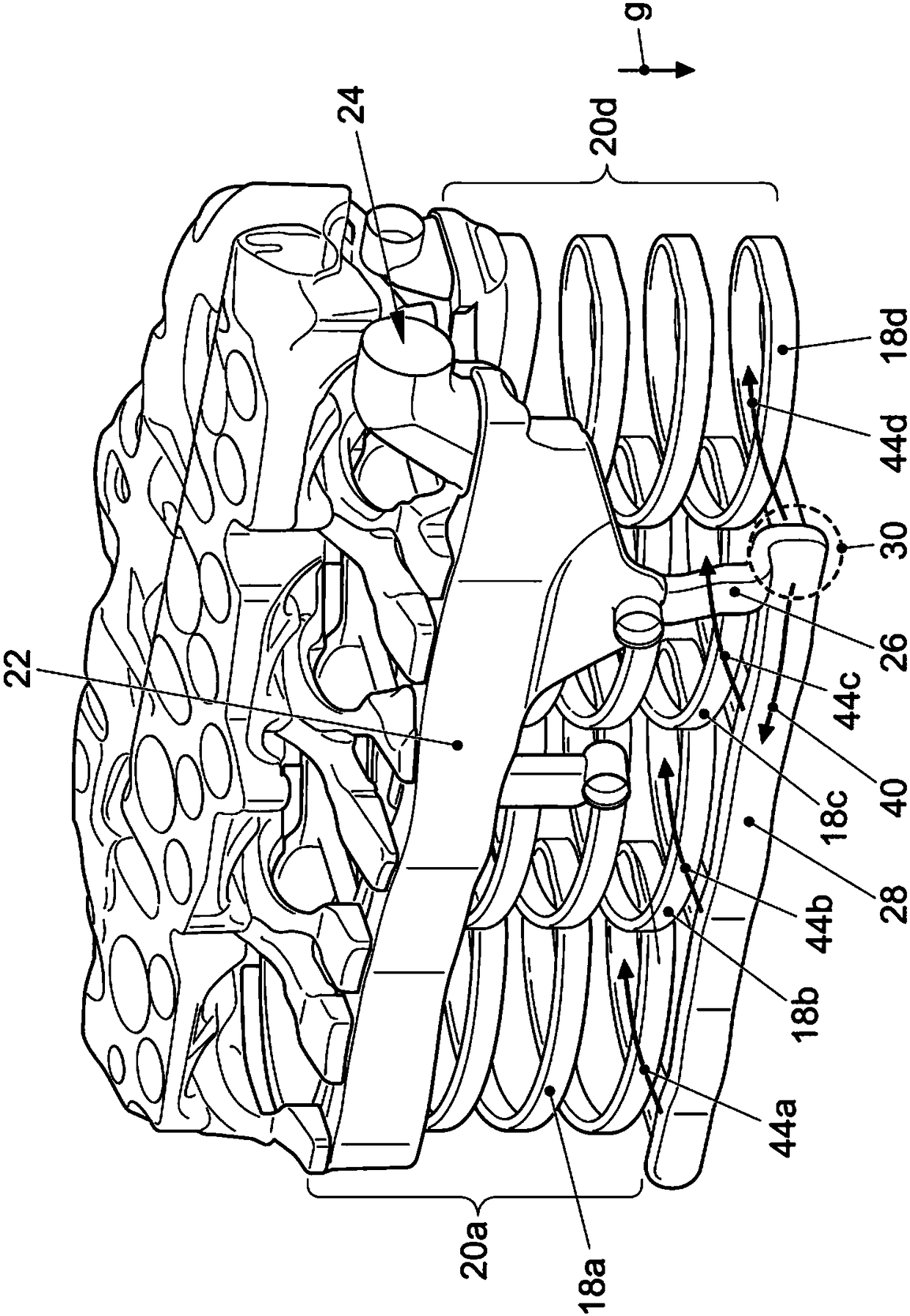

[0038] figure 1 with figure 2 A cylinder crankcase 10 according to the invention is shown having a first cylinder 12a, a second cylinder 12b, a third cylinder 12c and a fourth cylinder 12d. Such as figure 1 As shown, the cylinder crankcase 10 together with all the cylinders 12 a , 12 b , 12 c , 12 d consists of an integrally produced cylinder block 14 , wherein the cylinders 12 a , 12 b , 12 c , 12 d are surrounded by the cylinder block 14 . Intermediate partitions 16 are formed between the first cylinder 12a and the second cylinder 12b, between the second cylinder 12b and the third cylinder 12c, and between the third cylinder 12c and the fourth cylinder 12d, which will be opposite to each other. Adjacent cylinders 12a, 12b; 12b, 12c; 12c, 12d are separated from each other, respectively.

[0039] In particular by adding figure 1 and figure 2 as well as image 3 with Figure 7 In combination, it can be seen that in the cylinder block 14 a first cooling channel 18a with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com