Pressure control system for plurality of chambers of CMP (chemical mechanical polishing) head

A pressure control and polishing head technology, which is applied in the direction of manufacturing tools, grinding devices, grinding machine tools, etc., can solve the problem that the installation position of the sensing unit cannot be placed in the polishing head chamber, so as to save costs and improve the error of sensing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

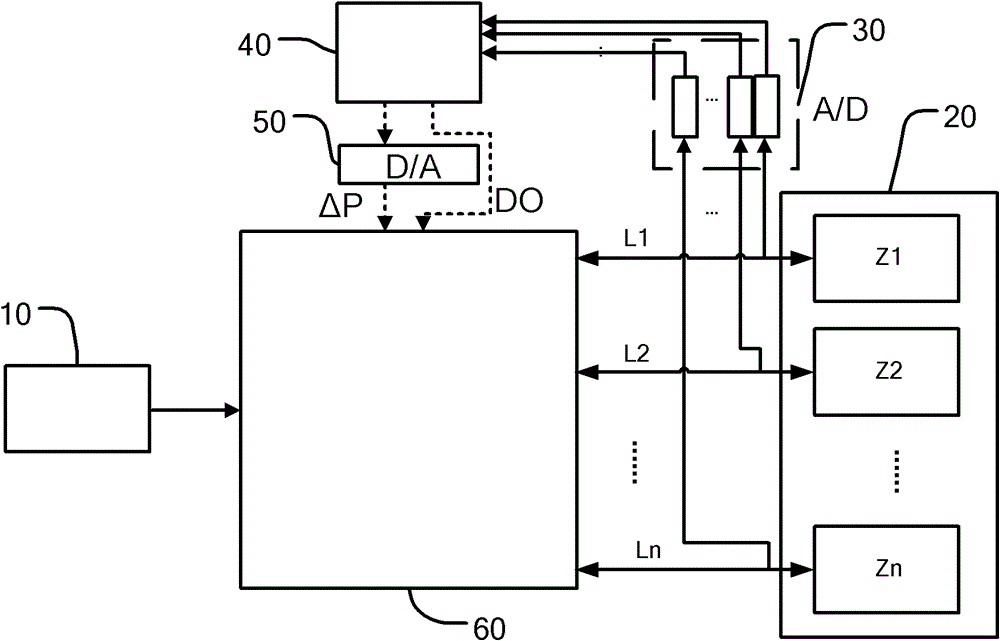

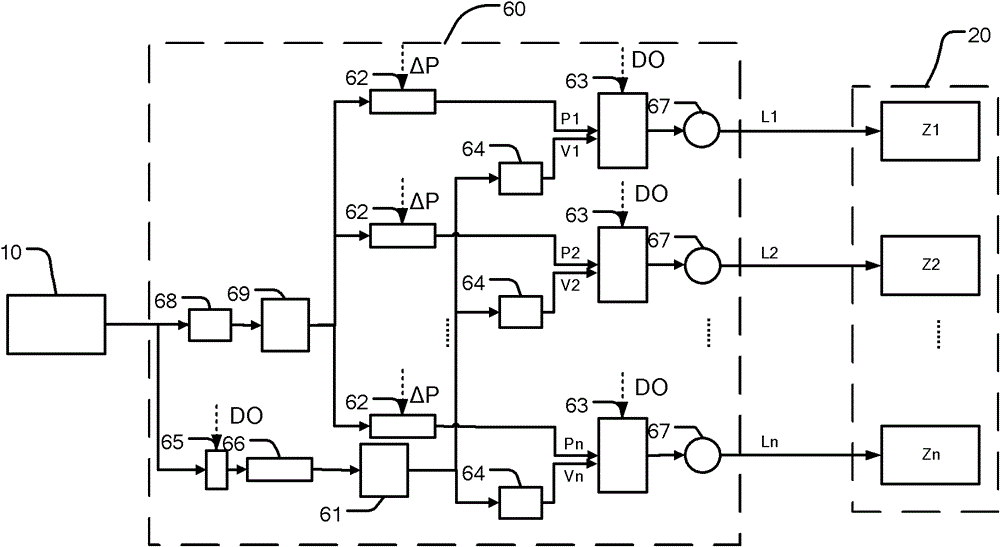

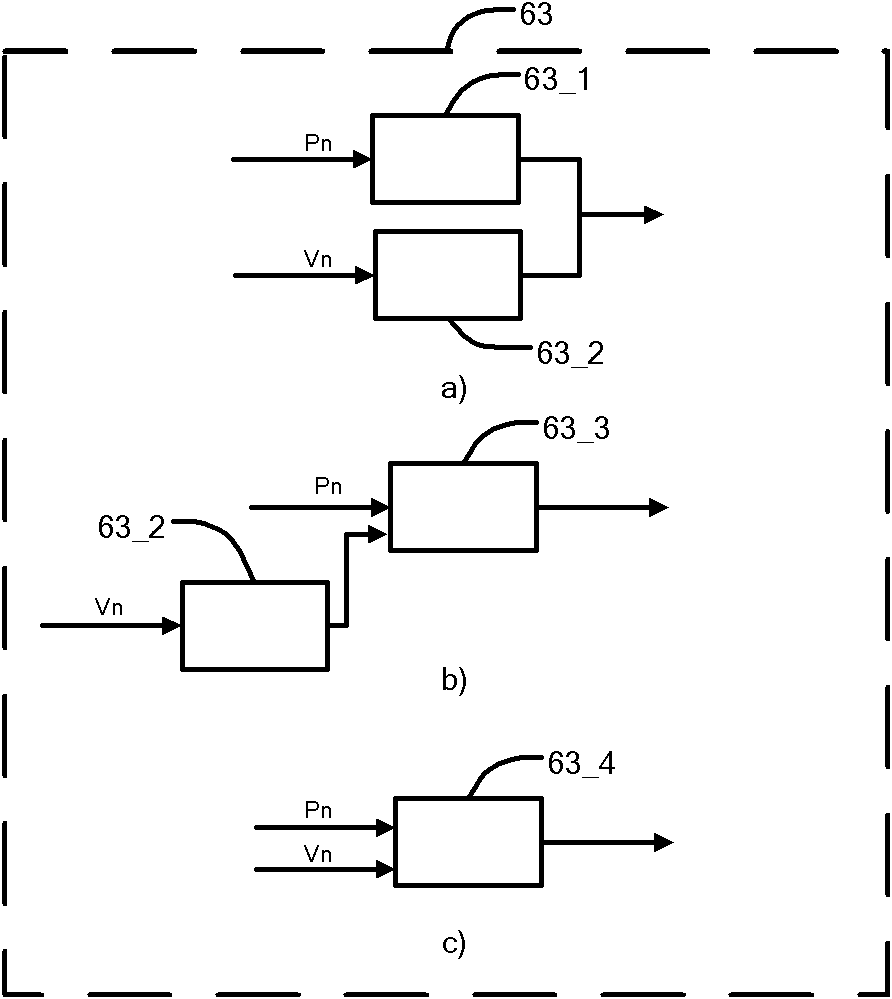

[0023] The invention provides a multi-chamber pressure control system for a CMP polishing head, which belongs to the technical field of semiconductor manufacturing, and is characterized in that it includes a pressure source, a control valve group, a pressure sensor, a CPU, a digital-to-analog and an analog-to-digital conversion circuit, and the like. The control system realizes the pressure control of each chamber at the far end by controlling the pressure and flow of each branch. Each branch of the control valve group is composed of positive pressure and negative pressure channels and a two-way filter. The positive pressure channel is composed of a pressure reducing valve, a positive pressure airbag, an electronically controlled proportional valve, and a positive and negative pressure switch valve group connected in sequence to the pressure source, wherein each positive pressure channel shares the same pressure reducing valve and positive pressure airbag. The negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com