Amine-blocked sulfonic acid catalyst

An amine-blocked sulfonic acid and catalyst technology, used in polyester coatings, coatings, powder coatings, etc., can solve the problems of high catalyst sales price and restrictions on the development, production, sales and application of powder coatings.

Inactive Publication Date: 2011-07-27

商新学

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The amine-blocked sulfonic acid catalyst imported from abroad, because this kind of product is in the monopoly position of foreign companies' technology secrecy and product sales, leads to the extremely high sales price of this kind of catalyst in China, which undoubtedly limits the development, production and sales of this kind of powder coating in China and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

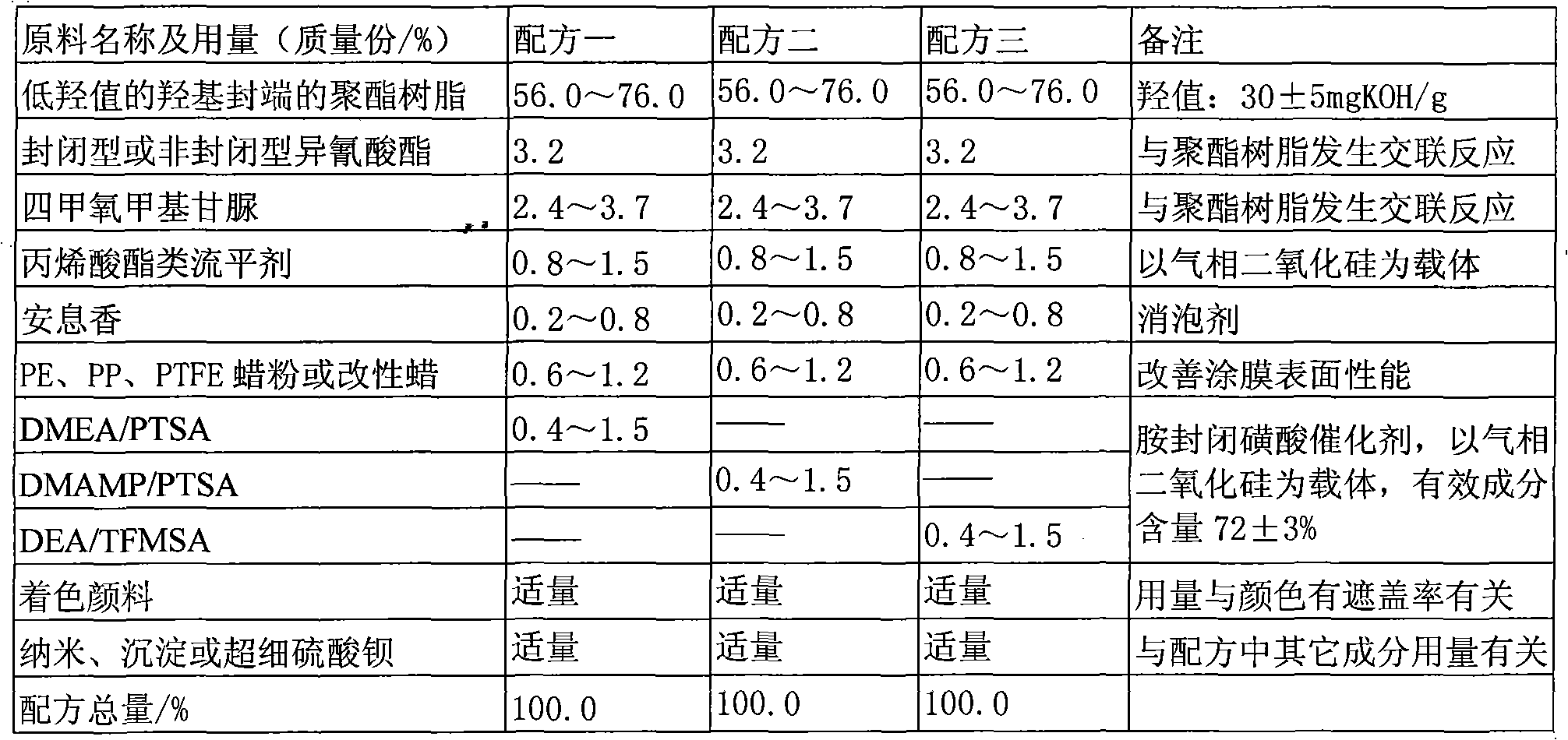

[0039] The liquid amine-blocked sulfonic acid obtained in the present invention has three intermediate products and three final products. The final powder product is an intermediate product that is adsorbed by fumed silica, stirred and mixed to form three free-flowing powder or tiny granular products. These three products are amines with fumed silica as the carrier. Blocked sulfonic acid catalyst. The specific implementation is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a catalyst applied to thermosetting powder coatings, which is used for catalyzing the powder coating with polyester resin end-capped by hydroxyl with low hydroxyl value and 1,3,4,6-tetrakis(methoxymethyl) glycoluril as main base materials so that the coating generates the surface effects including wrinkle, reticulate pattern, moire, spot pattern and the like, and the thermosetting powder coating has superior outdoor weatherability and outstanding decorative property. If the amine-blocked sulfonic acid catalyst, as an indispensible ingredient of the wrinkle thermosetting powder coating, is not used, the coating does not have appearances, such as wrinkle, reticulate pattern, moire, spot pattern and other effects.

Description

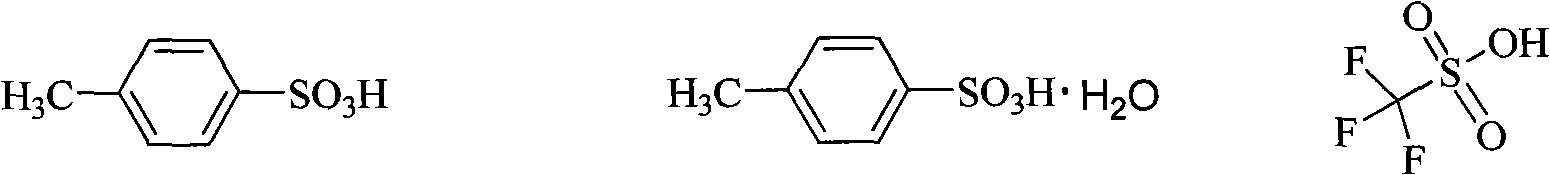

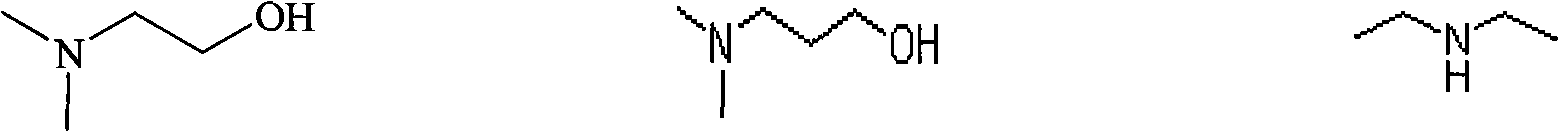

[0001] [Application technology field] [0002] The invention relates to a type of catalyst applied to thermosetting powder coatings, which is used to catalyze the powder coatings with low hydroxyl value hydroxyl-terminated polyester resin and tetramethoxymethyl glycoluril as the main base material, so that the coating film has wrinkles, Surface effects such as net pattern, moiré pattern, dot pattern, etc., this kind of thermosetting powder coating has excellent outdoor weather resistance and excellent decoration. [Background technique] [0003] In the development of thermosetting powder coatings, a wrinkled powder coating for outdoor use needs to use amine blocked sulfonic acid as a catalyst to form the required surface effect. This type of thermosetting powder coating formulation is the use of low hydroxyl value hydroxyl terminated saturated polyester resin, tetramethoxymethyl glycoluril, blocked or unblocked isocyanate, amine blocked sulfonic acid catalyst, pigment (includin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D7/12C09D167/00C09D5/03C09D5/28

Inventor 商新学

Owner 商新学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com