PVC (polyvinyl chloride) organic composite heat stabilizer, PVC product and preparation method of PVC product

A composite thermal stabilizer, organic technology, applied in the field of organic composite materials, can solve problems such as poor thermal stability, and achieve the effects of alleviating the phenomenon of zinc burning, strong operability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

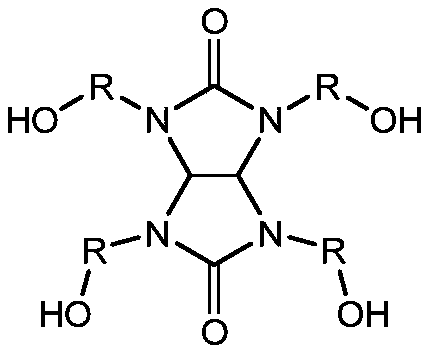

Method used

Image

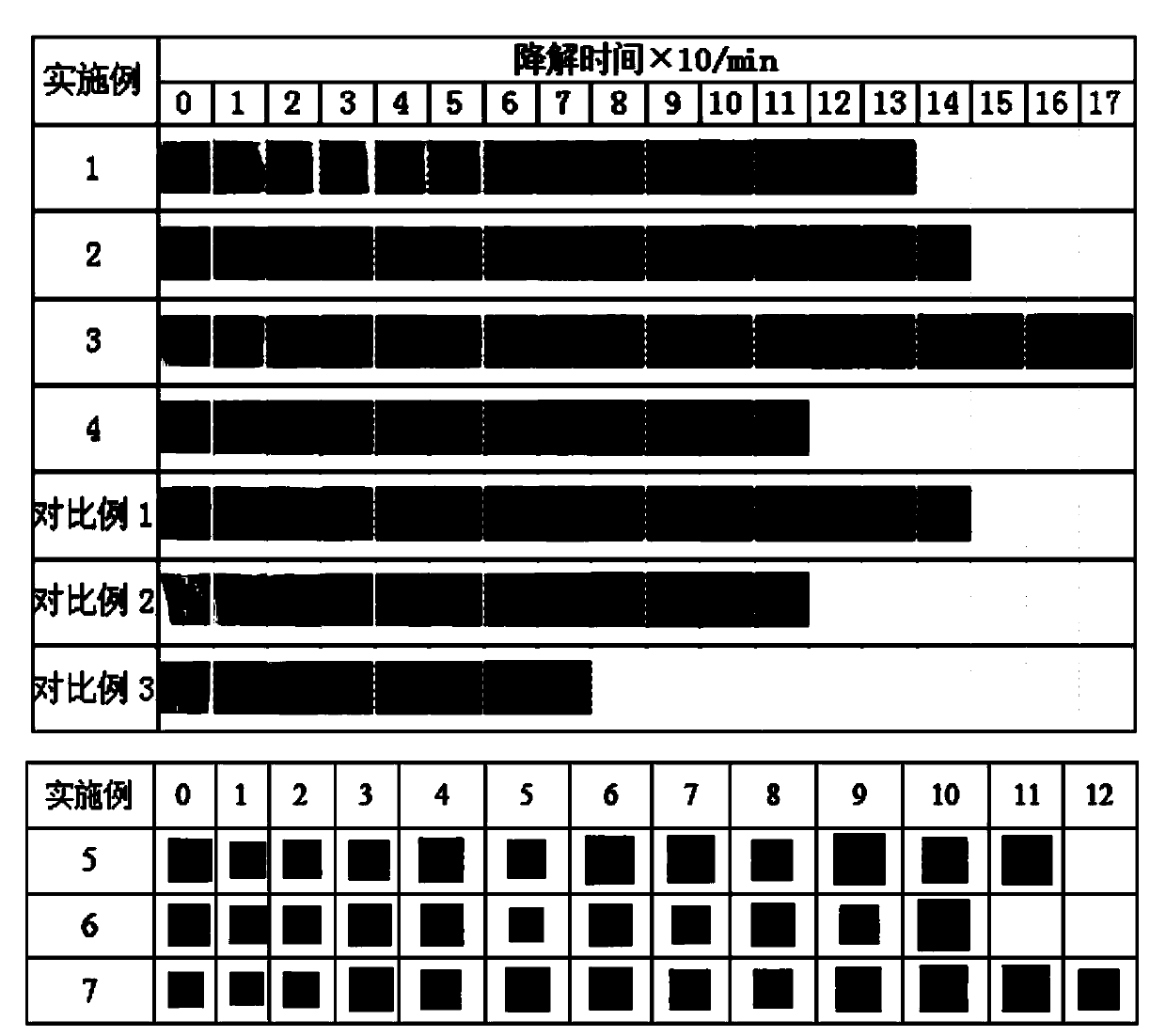

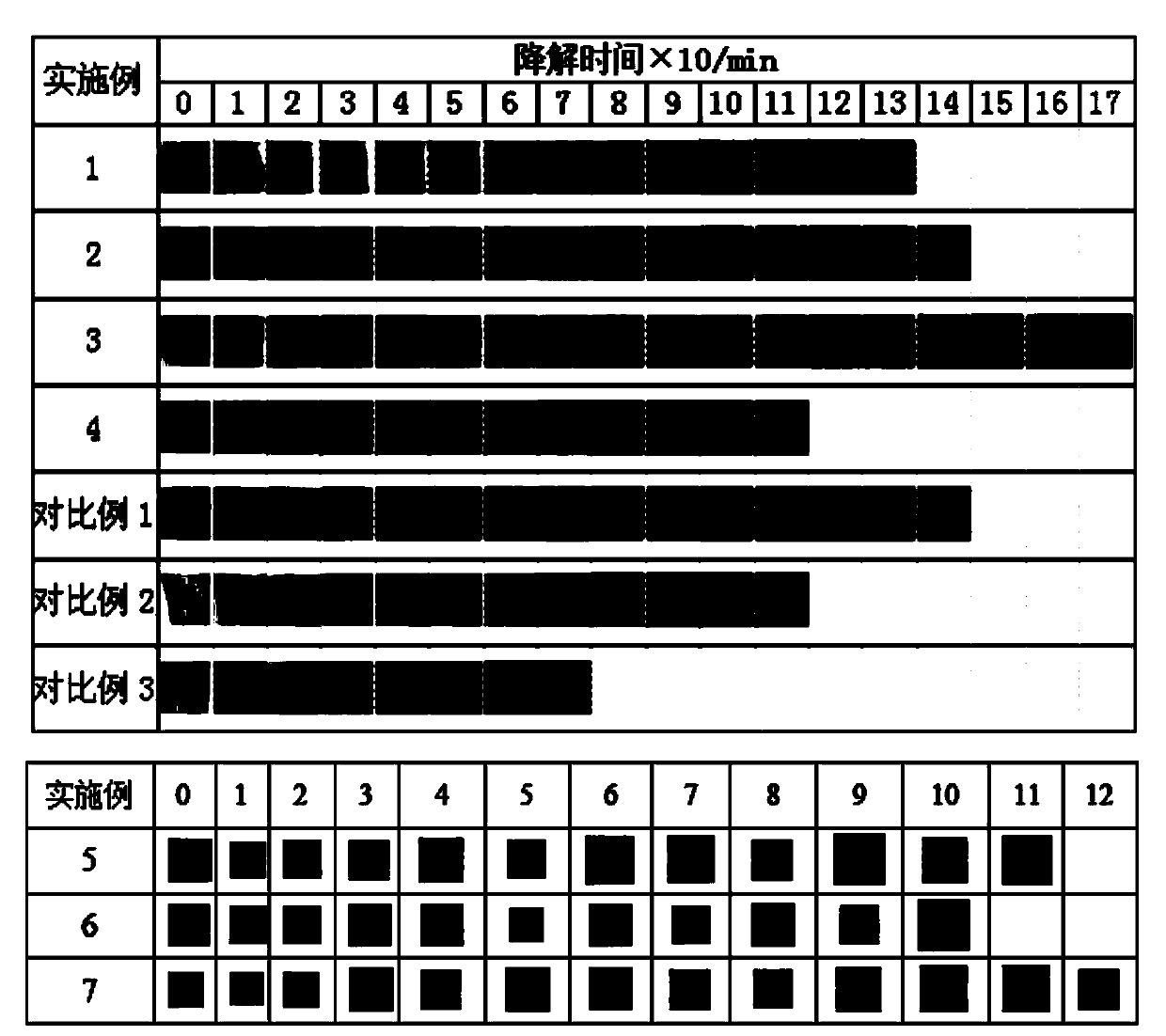

Examples

Embodiment 1

[0034] A PVC product, including 100 parts of PVC, 1 part of tetramethylol glycoluril, 1 part of 1,3-dimethyl-6-aminouracil, 0.6 parts of zinc stearate, 2.4 parts of calcium stearate, 5 parts Part Dioctyl Phthalate, 0.5 Part Stearic Acid,

[0035] The preparation method is as follows: Weigh the raw materials of each component, stir and mix evenly through a high-speed agitator at a high speed, and the mixture is mixed and plasticized into sheets on a two-roll mill. In this embodiment, each part is 1 gram. The roller temperature of the two-roll mill is 170°C, roller distance 1mm, roller speed: 45r / min, mixing time 5min.

Embodiment 2

[0037] A PVC product, including 100 parts of PVC, 5 parts of tetramethylol glycoluril, 1 part of 1,3-dimethyl-6-aminouracil, 0.6 parts of zinc stearate, 2.4 parts of calcium stearate, 5 parts Part Dioctyl Phthalate, 0.5 Part Stearic Acid,

[0038] The preparation method is as follows: Weigh the raw materials of each component, stir and mix evenly through a high-speed agitator at a high speed, and the mixture is mixed and plasticized into sheets on a two-roll mill. In this embodiment, each part is 1 gram. The roller temperature of the two-roll mill is 170°C, roller distance 1mm, roller speed: 45r / min, mixing time 5min.

Embodiment 3

[0040] A PVC product, including 100 parts of PVC, 1 part of tetramethylol glycoluril, 5 parts of 1,3-dimethyl-6-aminouracil, 0.6 parts of zinc stearate, 2.4 parts of calcium stearate, 5 parts Part Dioctyl Phthalate, 0.5 Part Stearic Acid,

[0041] The preparation method is as follows: Weigh the raw materials of each component, stir and mix evenly through a high-speed agitator at a high speed, and the mixture is mixed and plasticized into sheets on a two-roll mill. In this embodiment, each part is 1 gram. The roller temperature of the two-roll mill is 170°C, roller distance 1mm, roller speed: 45r / min, mixing time 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com