Compound sandwich layer assembled building

A technology for buildings and sandwich layers, applied in the direction of building structures, buildings, building components, etc., can solve the problem that the contribution of the stability of the wall system is not enough to counteract the damage caused by earthquakes, and achieve a unique degree of reliability, unique cost-effective advantages, and cost-effective Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

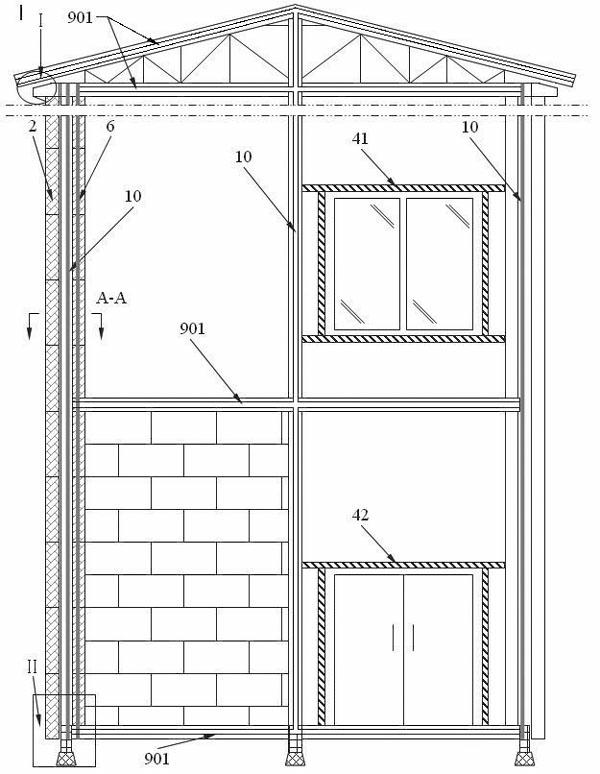

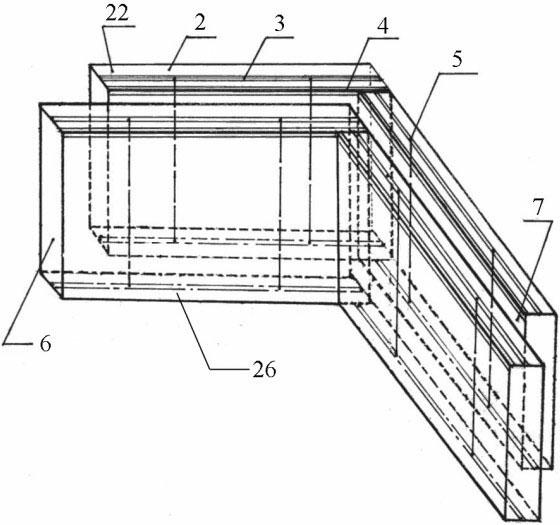

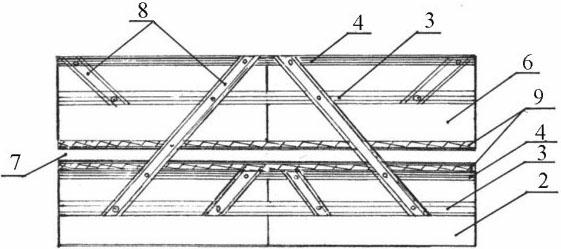

[0052] A kind of composite sandwich layer prefabricated building, such as figure 1 As shown, the enclosure wall is assembled by blocks and keels, and is composed of columns combined with keels, floor frames, roof frames, hoop beams and ring beams, and consists of outer wall blocks 2, U-shaped keels 3, and L-shaped Keel 4, serial screw 5, inner wall block 6, combined sandwich block 201, cladding strip 8, insulation material 9, column 10, L-shaped keel connector 11, fastener 12, truss 13, window purlin 41 , door purlin 42, ring beam 43, corner keel 701, corrugated keel and waterproof and heat-insulating bedding are assembled with plastic materials, and the specific structure is as follows Figure 2 to Figure 9 and Figure 28 ~ Figure 30 Shown:

[0053]The combined sandwich block 201 composed of the outer wall block 2 and the inner wall block 6 on the hoop beam wall foundation 12 of the building foundation is assembled and connected in the horizontal direction to form a double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com