Device for sealing plate valve through pretightening

A technology of valve device and sealing plate, which is applied in the direction of wellbore/well valve device, sealing/packing, and undisturbed core extraction device, etc. It can solve the problem of poor sealing effect, low success rate of pressure holding, and failure to meet actual needs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

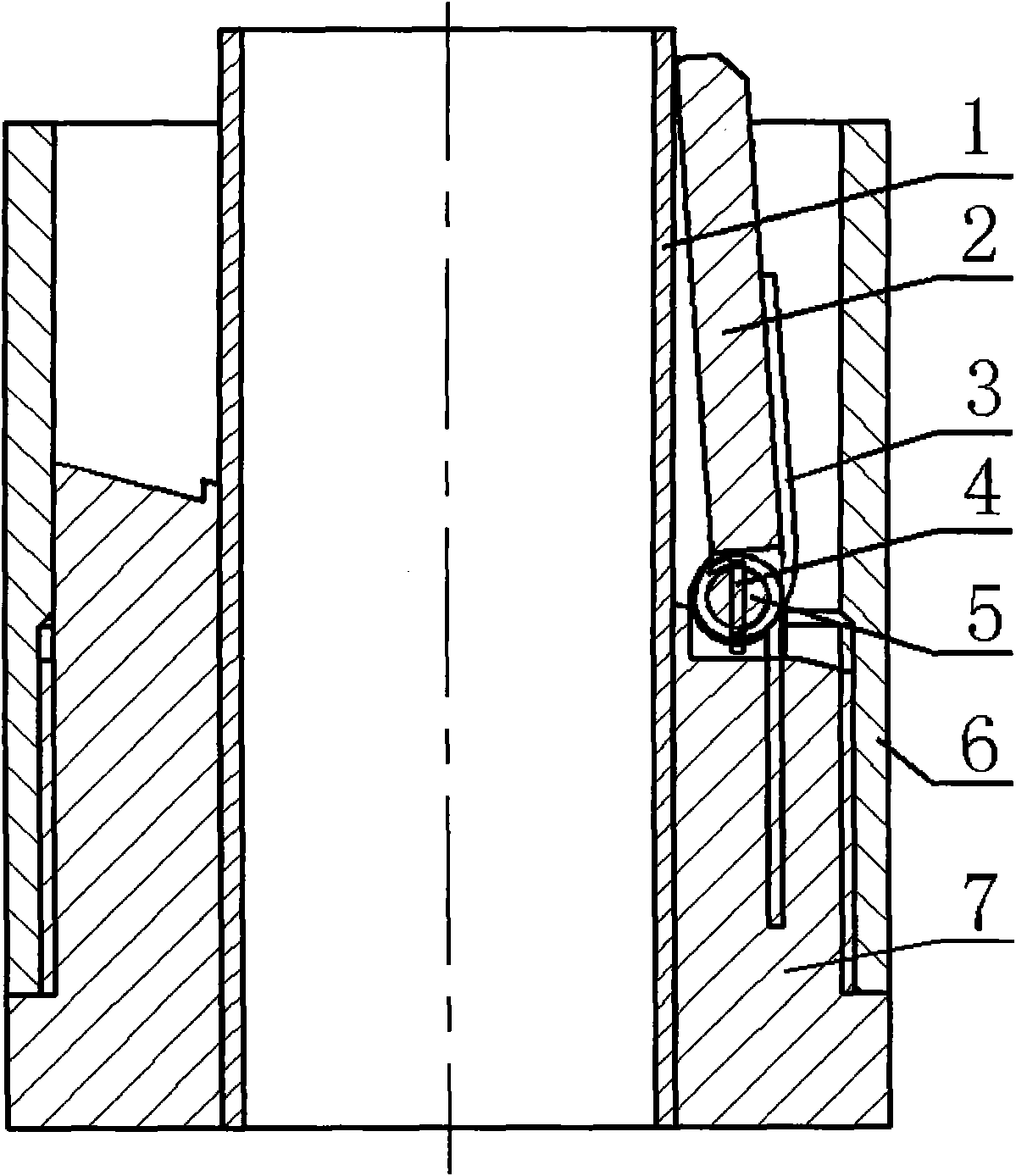

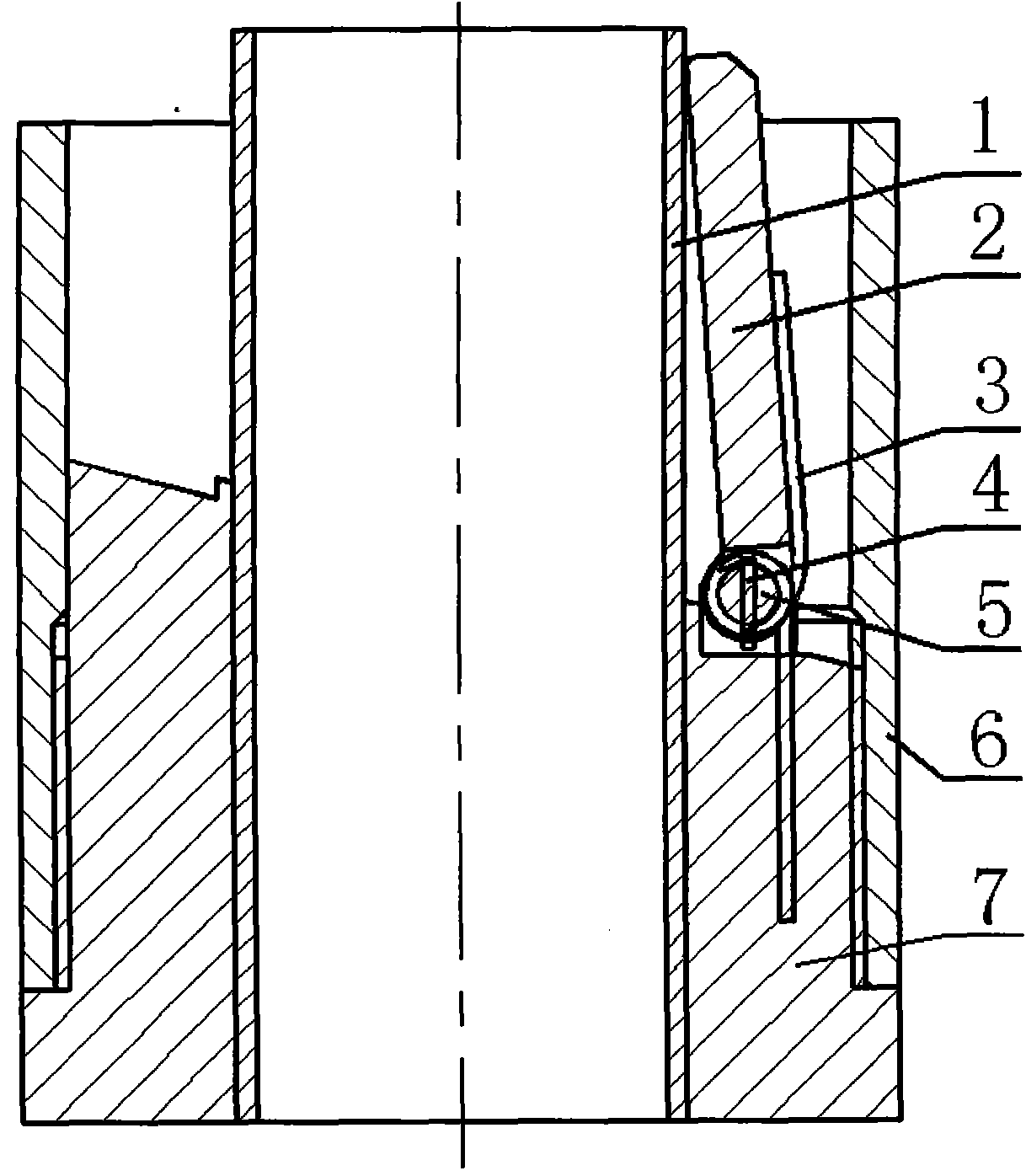

[0008] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0009] When adopting the present invention to perform coring operations, the plate valve seat 7 is threadedly connected to the outer cylinder 6, the rotation axis of the plate valve 2 coincides with the center line of the torsion spring 3, and is connected to the plate valve seat 7 through the pin 5, one end of the pin 5 Secure with positioning pin 4. The torsion spring 3 is made as a double-sided elastic type, so that the plate valve 2 is evenly stressed. The free ends of the torsion spring 3 on both sides are inserted into the reserved deep hole of the plate valve seat 7, and the middle extension section is in contact with the upper end surface of the plate valve 2. When the plate valve 2 is opened, the torsion spring 3 generates elastic force, and when the plate valve 2 is closed, the elastic force acts on the upper end surface of the plate valve 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com