Adjuster for gas engine

A technology for gas engines and regulators, which is applied to combustion engines, internal combustion piston engines, engine components, etc., and can solve problems such as difficult small general-purpose engines and difficult effective application of engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

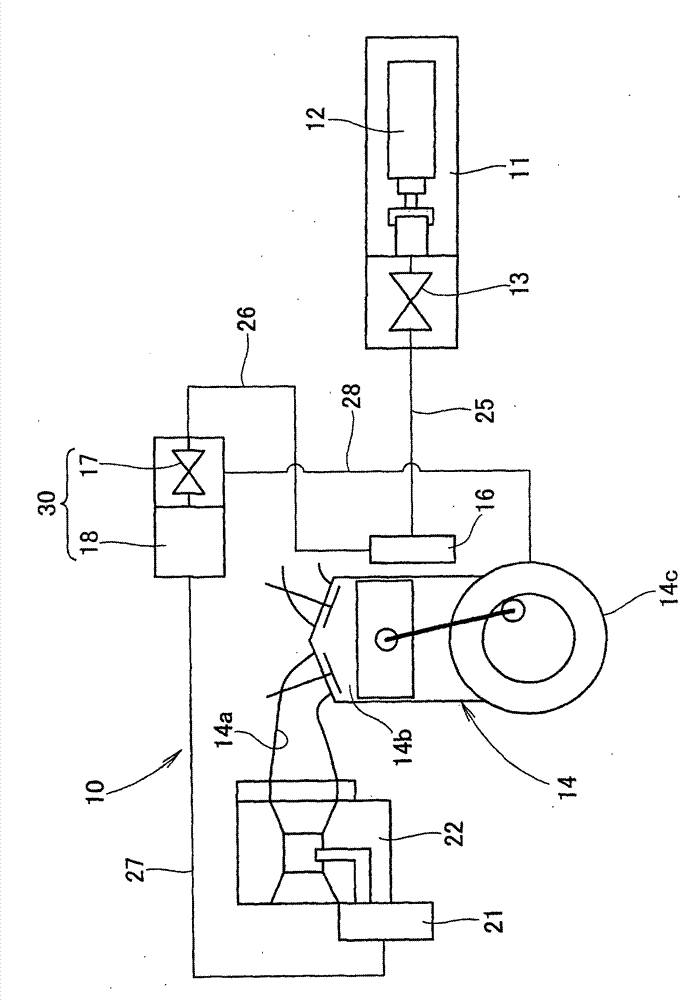

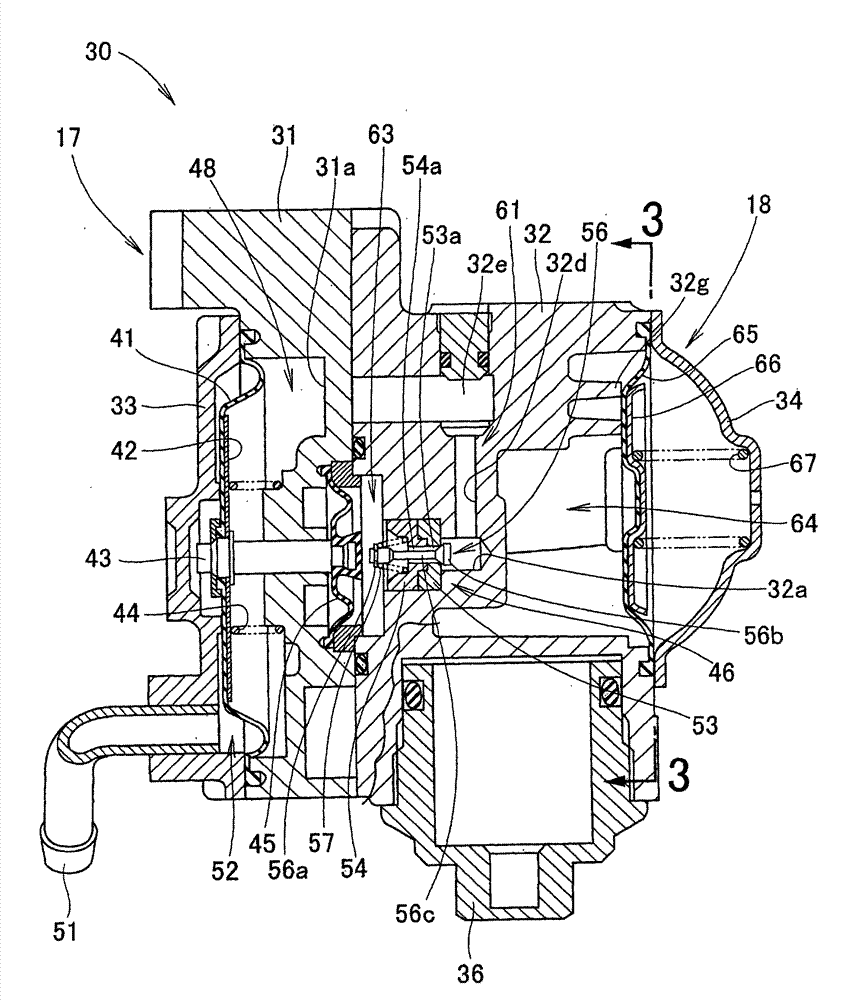

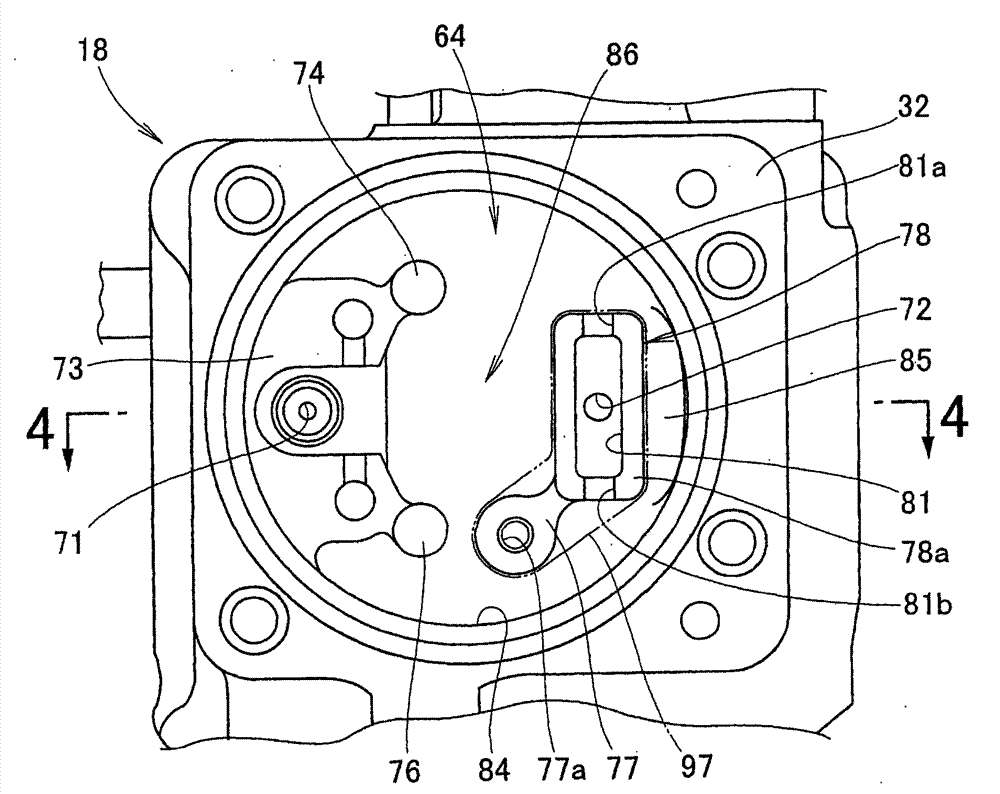

[0027] now refer to figure 1 , the fuel supply device 10 includes: a small cylinder 12 filled with, for example, liquefied butane gas as a liquefied gas fuel, and accommodated in a cylinder housing 11; a manually operated cock 13, which is fixedly arranged in the cylinder housing 11 for Switching between outflow of liquefied gas fuel from the cylinder and interruption of fuel flow; evaporator 16 for converting liquefied gas fuel (liquefied butane) into vaporized fuel (butane gas) using heat generated in gas engine 14 ); the shut-off valve 17, which is used to allow the gasified fuel to circulate at the evaporator 16 when the gas engine is running, and is used to prevent the flow of the gasified fuel when the engine is stopped; the primary regulator 18, which is connected with A stop valve 17 is integrally formed for depressurizing the gasified fuel to a predetermined pressure; and a secondary regulator 21 for further decompressing the gasified fuel depressurized by the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com