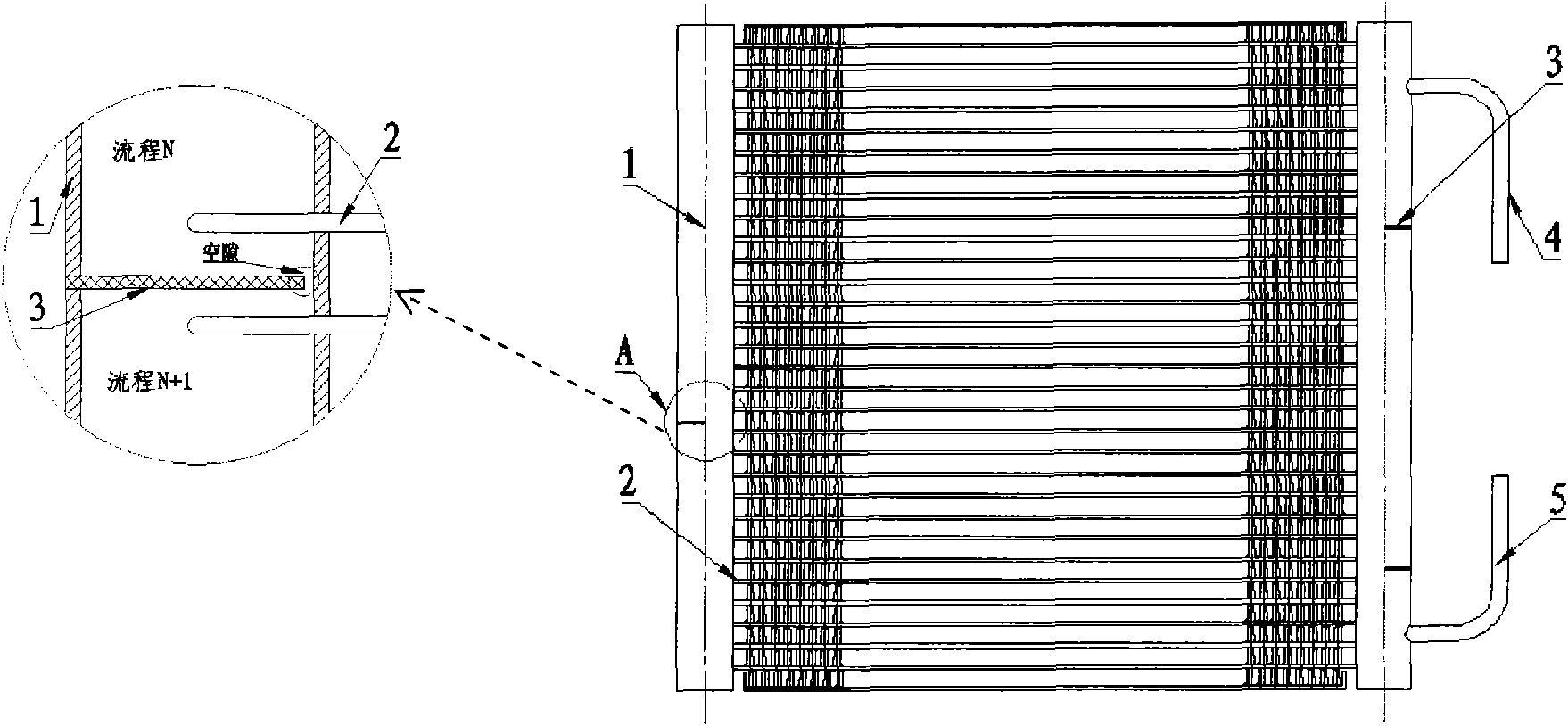

Header pipe baffle plate capable of preventing inner leakage

A technology of headers and baffles, which is applied in the field of parts and components, and can solve problems such as detecting whether there is a gap between the headers and baffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

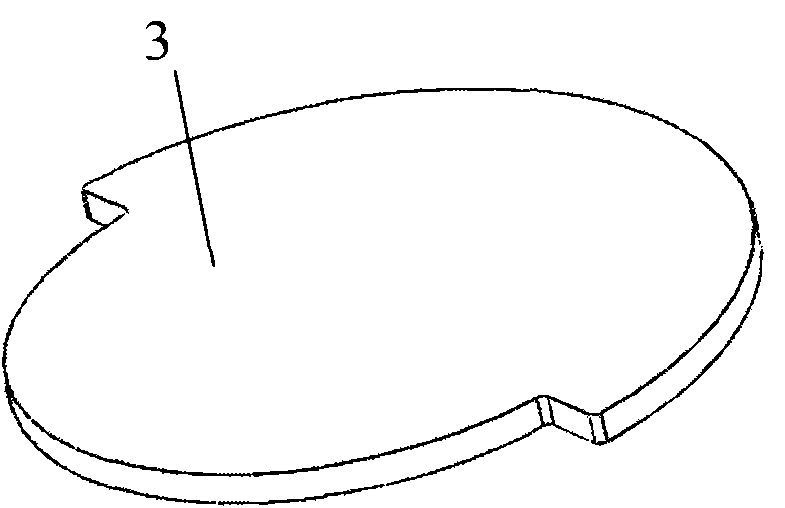

[0021] Such as image 3 As shown, the anti-internal leakage header separator is characterized in that it includes a single-layer separator 6, and the circumferential side of the single-layer separator 6 is provided with a groove 7.

[0022] The section of the groove 7 is triangular, rectangular, square or semicircular.

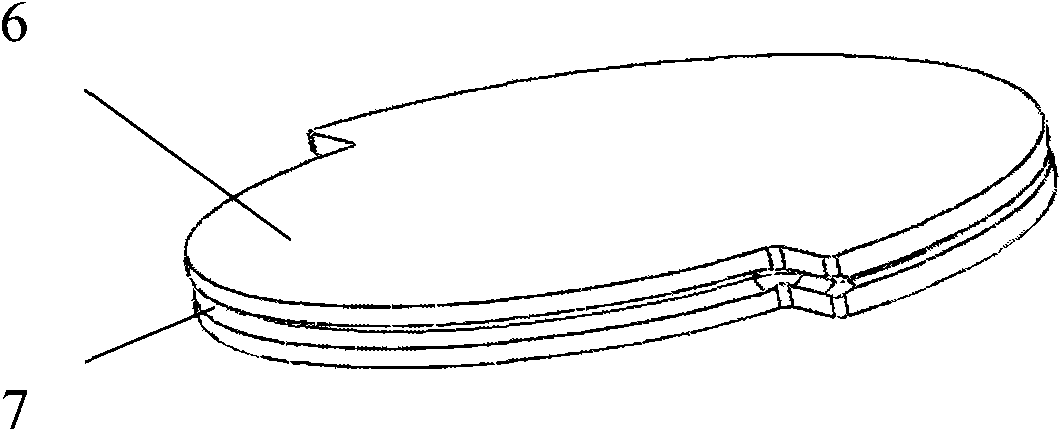

[0023] Such as Figure 4 Figure 5 As shown, the anti-internal leakage header partition is characterized in that: it comprises two partition plates 8, wherein a single side of one partition plate 8 is provided with a plurality of equal-height bosses 9, and the two partitions The dividing plate 8 sandwiches the boss 9 so that there is a gap between the two dividing plates 8 .

[0024] The boss 9 is a circular platform, a strip platform or a rectangular platform.

[0025] Such as Image 6 As shown, it comprises two dividing plates 8, wherein one or two dividing plates 8 have a conical platform 10 on one side, and the two dividing plates 8 clamp the conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com