Clonidine hydrochloride sustained release micropill preparation

A technology of clonidine hydrochloride and sustained-release pellets, which can be used in cardiovascular system diseases, block delivery, drug combination, etc. The incidence of reaction, the effect of high and stable blood concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

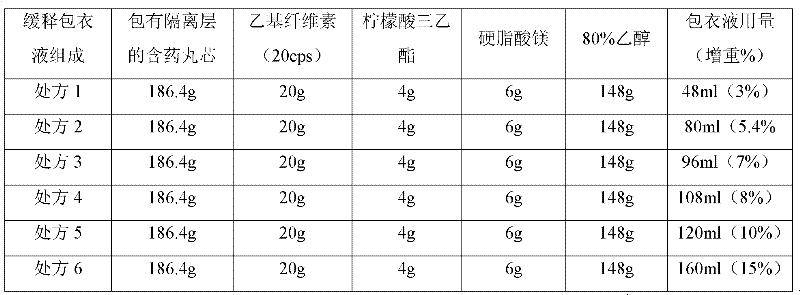

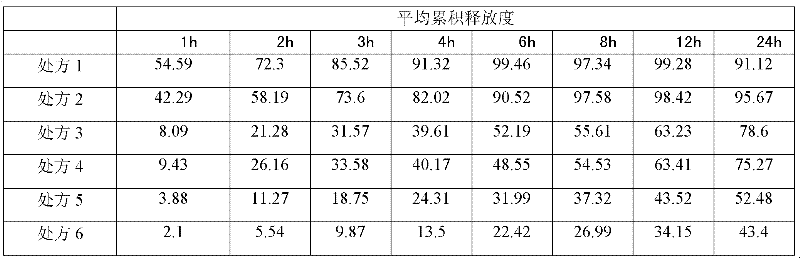

Examples

Embodiment 1

[0046] (1) Preparation of pill-containing core (A)

[0047] Clonidine hydrochloride

4.0g

Blank pellet core (sucrose type)

1600g

Opadry (CLEAN)

40.0g

purified water

760.0g

[0048] Preparation Process:

[0049] Weigh Opadry (CLEAN), add it to purified water and stir to dissolve, pass a 100-mesh sieve just before use, then add the prescription amount of clonidine hydrochloride raw material, stir and dissolve, to obtain a coating liquid. Weigh the blank pellets and add them to the fluidized bed coating machine (WBF-5G, Chongqing Yingge Granulation Coating Technology Co., Ltd.), and use the low spray coating system (Wurster system) for coating. The coating parameters of the equipment are :Inlet air volume 250m 3 / hr, inlet air temperature 50℃, atomization pressure 2kg / cm 2 , The flow rate of the coating liquid is 7rpm. After the coating liquid is sprayed, it is fluidized and dried for 10 minutes and then discharged to obtain a pill-containing core.

[0050] (2) Isol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap