Vehicle roof system

A roof and roof panel technology, which is applied to the roof, vehicle parts, transportation and packaging, etc., can solve the problems of increasing manufacturing costs, limiting passengers' vision, and increasing the front and rear dimensions of the front frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

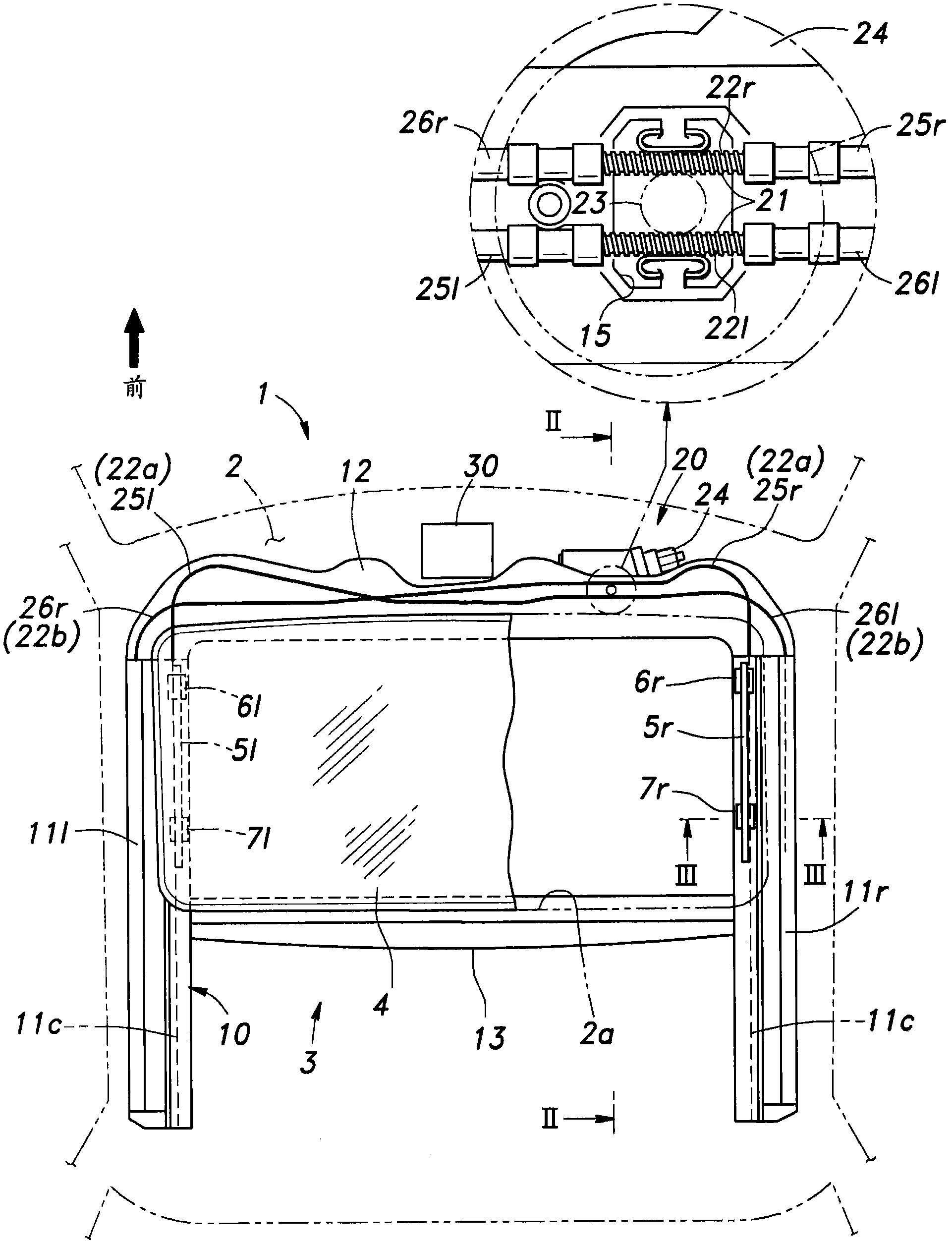

[0026] figure 1 is a transparent top view showing a roof system embodying the present invention. The illustrated roof 1 includes a fixed roof 2 and a sunroof system 3, the fixed roof 2 occupies most of the roof 1 and forms a rectangular window 2a at its front, the sunroof system 3 can selectively close and open the roof window 2a .

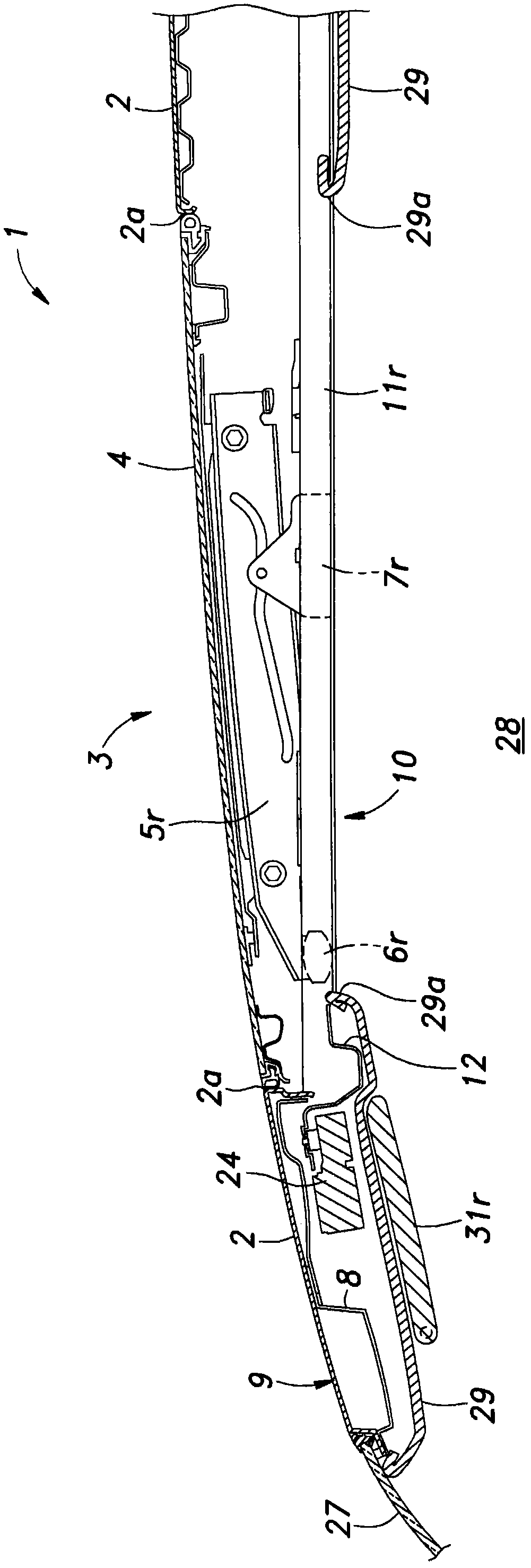

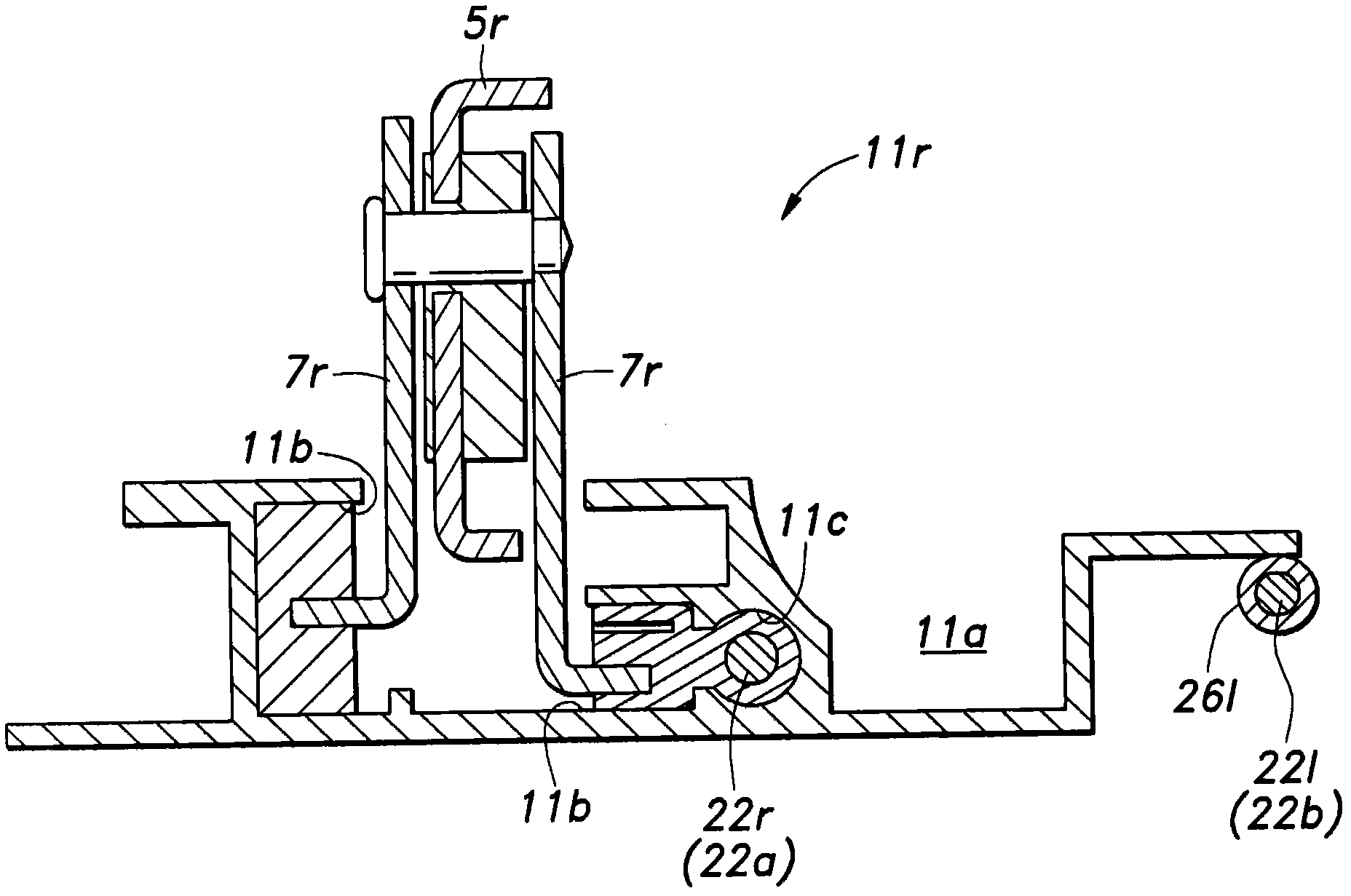

[0027] The majority of the roof system is symmetrical with respect to the central longitudinal plane of the body, and only one of the two symmetrical parts will be discussed below where appropriate, since the two symmetrical parts are substantially identical to each other. In some places, these symmetrical parts are indicated by a number with a suffix r or l to indicate which side of the body the part in question is located on. Elsewhere, these parts are generally indicated by the corresponding numeral without a suffix.

[0028] The sunroof system 3 includes a sunroof frame 10 fixedly fastened to the roof panel 2 and surrounding the roof window...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap