Reinforced nanofiber porous membrane and preparation method thereof

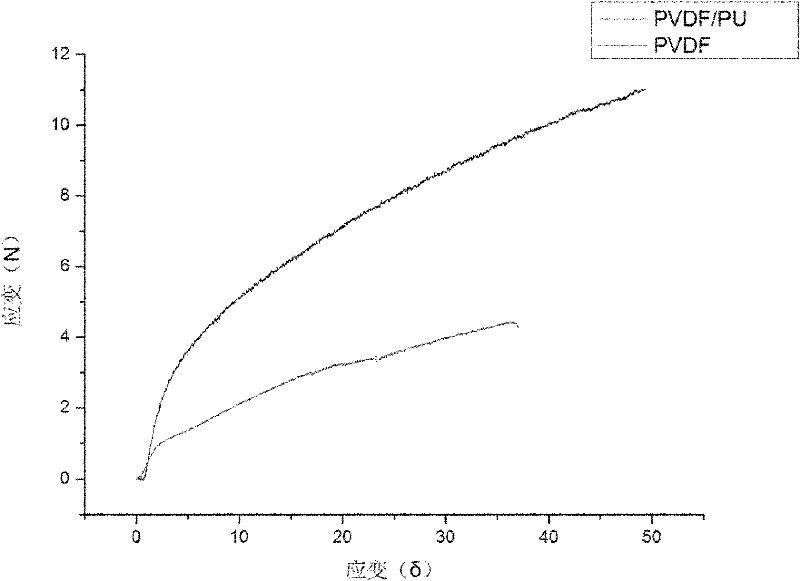

A reinforced, porous membrane technology, applied in the direction of fiber type, fiber treatment, electrical components, etc., can solve the problems of poor mechanical properties of nanofiber porous membranes, decreased battery self-shutdown performance, and failure to reach battery strength, etc., to improve mechanical performance. performance, improved ion permeability, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

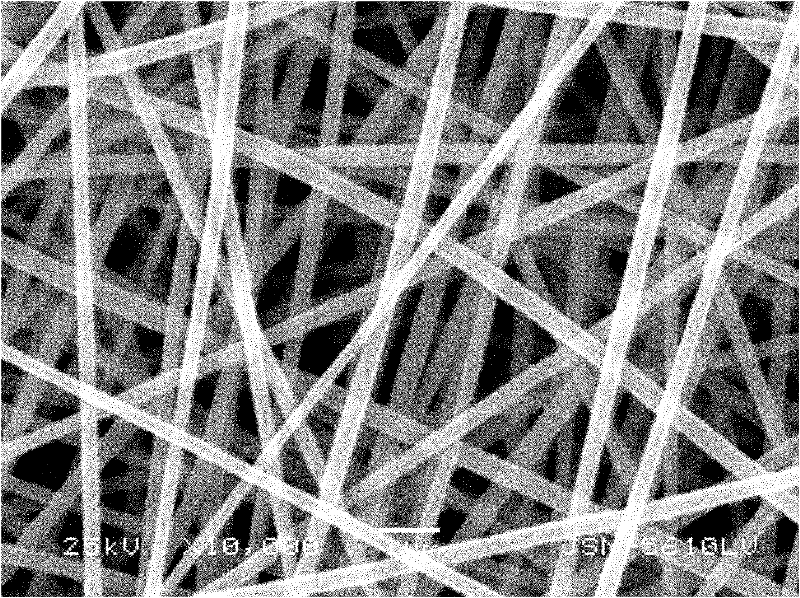

[0038] 1. Preparation of PVDF fiber membrane

[0039] Dissolve polyvinylidene fluoride (PVDF) in a mixed solvent of N, N-dimethylformamide (DMF) and acetone with a mass ratio of 5:5, and prepare a solution with a concentration of 12 wt% at 50-60°C Heat and stir for 10-20 minutes to achieve full dissolution. Inject the solution into a syringe pump with a 8# flat needle. The needle is connected to the high-voltage output end. At the other end 15cm away from the syringe pump is a metal roller electrode grounded to the high-voltage power supply as a collection device. Adjust the injection speed of the injection pump to 0.3ml / h, and slowly increase the voltage to 15kv. The above-mentioned solution is sprayed from the needle of the syringe pump under the action of high pressure, and collected in the form of a non-woven membrane on a metal collecting device. The obtained non-woven membrane is placed in a vacuum drying oven and operated at room temperature and reduced pressure for 12 ho...

Embodiment 2

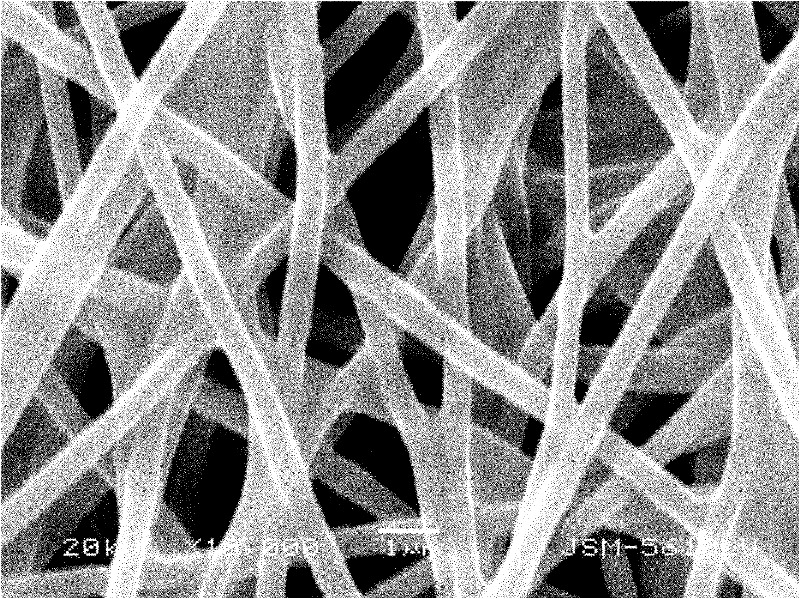

[0050] 1. Preparation of PVDF-HFP fiber membrane

[0051] Dissolve polyvinylidene fluoride-hexachloropropylene (PVDF-HFP) in a mixed solvent of N,N-dimethylformamide (DMF) and acetone with a mass ratio of 8:2 to prepare a solution with a concentration of 16% by weight. Heat and stir at 50°C for 20 minutes to achieve full dissolution. Inject the solution into a syringe pump with an 8# flat needle. The needle is connected to the high-voltage output end. At the other end 15cm away from the syringe pump is a metal roller electrode grounded to the high-voltage power supply as a collection device. Adjust the injection speed of the syringe pump to 0.47ml / h, and slowly increase the voltage to 15kv. The above-mentioned solution is sprayed out from the needle of the syringe pump under the action of high pressure, and collected on the metal collecting device in the form of a non-woven membrane. The obtained non-woven membrane is placed in a vacuum drying oven and operated at room temperatu...

Embodiment 3

[0062] 1. Preparation of PMMA nanofiber porous membrane

[0063] Dissolve polymethyl methacrylate (PMMA) in a mixed solvent with a mass ratio of N, N-dimethylformamide (DMF) and toluene = 3:2, prepare a solution with a concentration of 20 wt%, and stir at room temperature 24h to achieve full dissolution. Inject the solution into a syringe pump with an 8# flat needle. The needle is connected to the high-voltage output end. The other end 18cm from the syringe pump is a metal roller electrode grounded to the high-voltage power supply as a collection device. Adjust the injection speed of the syringe pump to 0.2ml / h, and slowly increase the voltage to 15kv. Under the action of high pressure, the polymer solution is sprayed from the needle of the syringe pump, and the non-woven membrane is collected on the metal collecting device. The obtained non-woven membrane is placed in a vacuum drying oven and operated at room temperature and reduced pressure for 16 hours. After there is no res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap