Single-layer projected capacitive touch panel and manufacturing method thereof

A technology of projected capacitance and touch panel, which is applied in the direction of electrical digital data processing, instrumentation, input/output process of data processing, etc., and can solve the problems of low light transmittance and production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

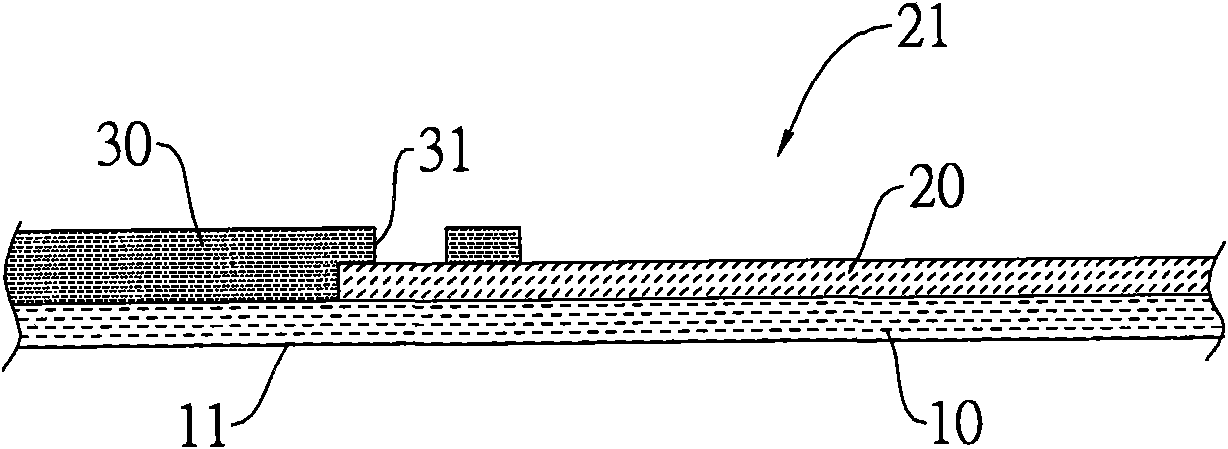

[0060] see Figure 1A to Figure 1H As shown, a preferred embodiment of the single-layer projected capacitive touch panel of the present invention is manufactured by the following steps:

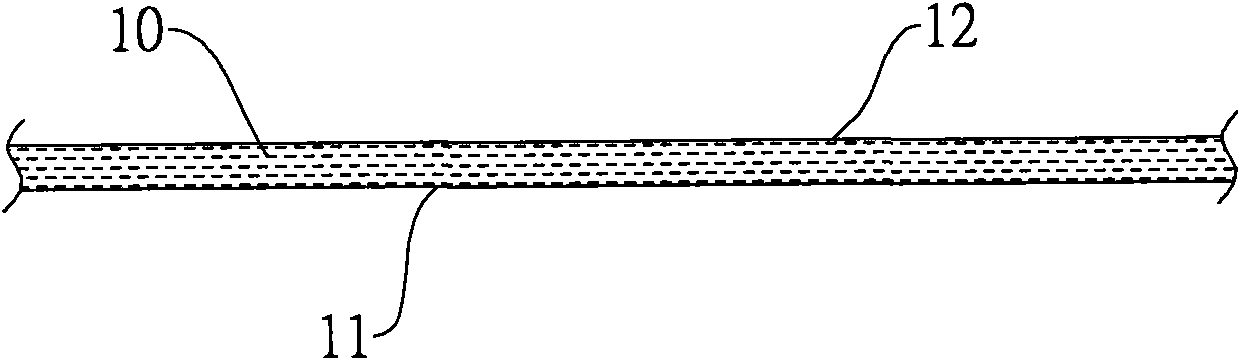

[0061] Prepare a mother glass plate, which can be divided into a plurality of glass cover plates 10 of the single-layer projected capacitive touch panel of the present invention (eg Figure 1A and figure 2 As shown), each glass cover plate 10 has an action surface 11 and a circuit surface 12;

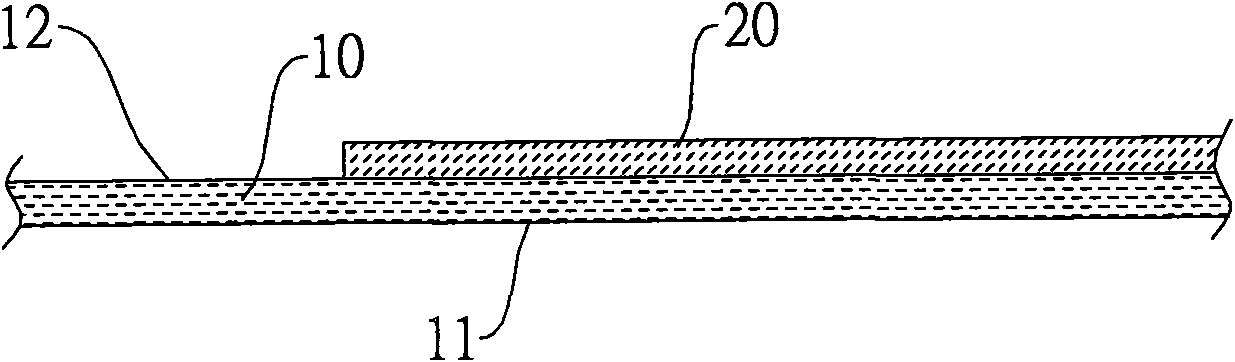

[0062] Form a touch sensing circuit layer 20, such as Figure 1B As shown, a corresponding touch sensing circuit layer 20 is partially formed on the circuit surface 12 of each glass cover plate 10 of the glass mother board, as shown in FIG. figure 2 Shown is the central area of the circuit surface 12 of each glass cover plate 10, and each touch sensing circuit layer 20 is a single-layer touch sensing circuit, such as a single-layer indium tin oxide (Indium tinoxide, ITO for short) circuit compo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap