Method for producing a target substance using a simulated moving bed chromatography separation system

A technology for simulating a moving bed and a target substance, which is applied in the field of manufacturing target substances, and can solve the problems of increasing the circulating flow of the incapable eluent and increasing the pressure loss, and achieve the effect of suppressing the decline of the separation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

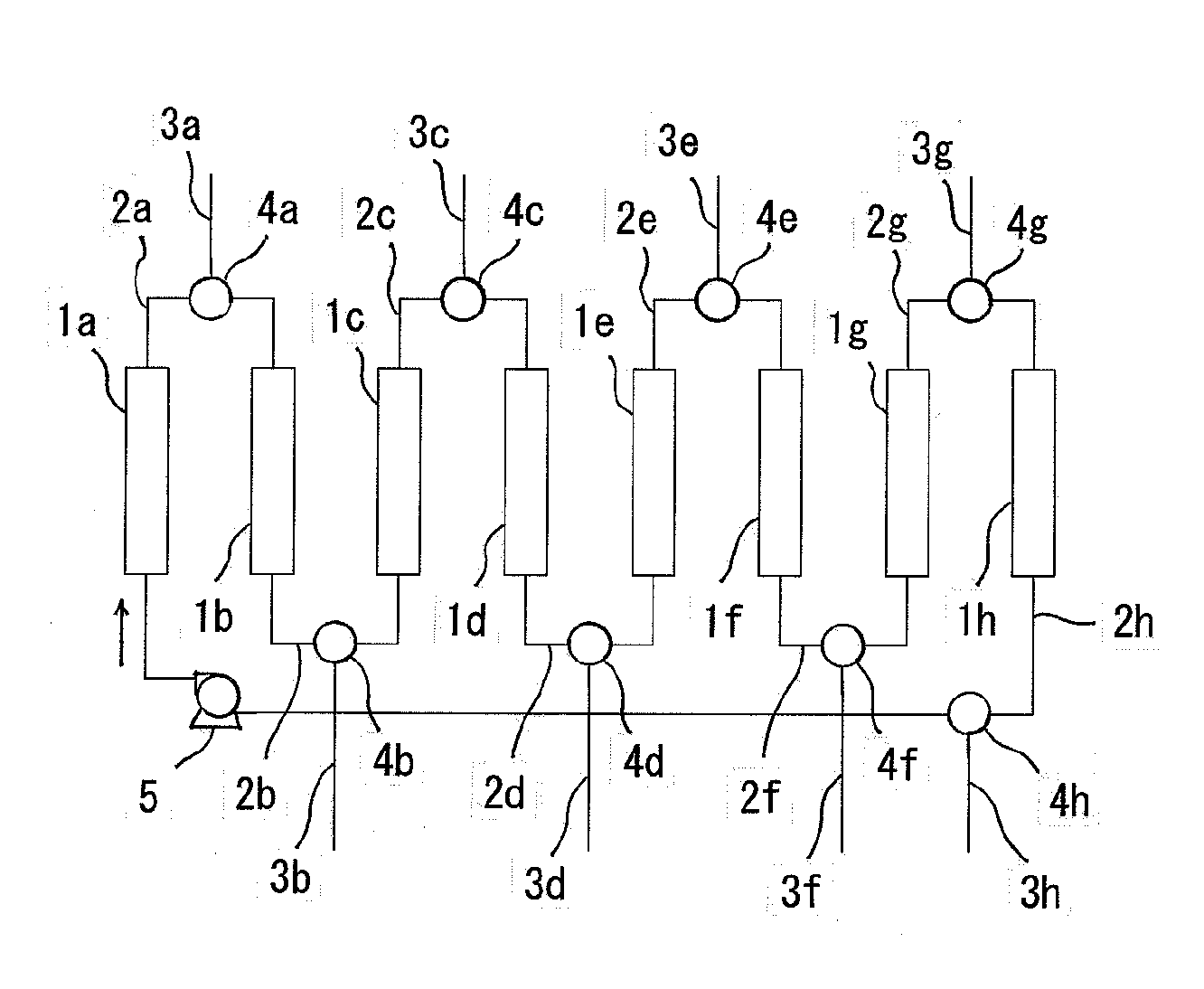

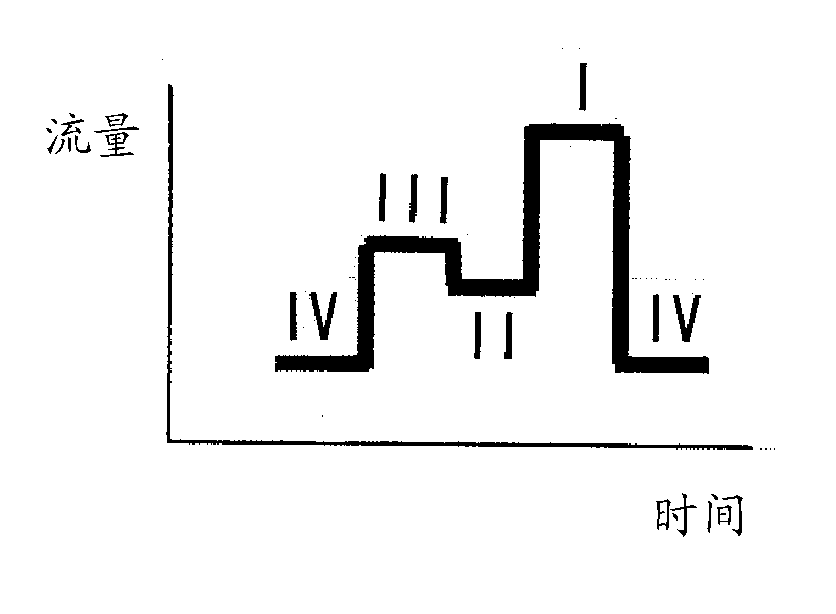

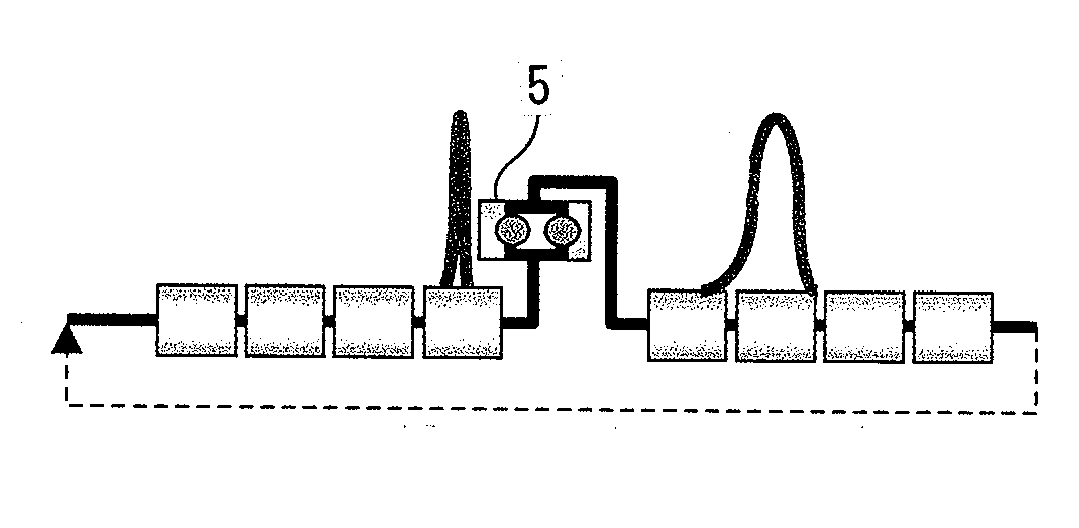

[0050] The present invention is a method for isolating a production target substance from a sample, that is, in the method for separating a production target substance from a sample using an SMBC separation device, the first SMBC separation device that satisfies the first condition can be used to separate the production target substance in the sample. The sample of the target substance is used in a second SMBC separation device satisfying the second condition to separate and manufacture the target substance from the sample.

[0051] As the above-mentioned SMBC separation device satisfying the first and second conditions, a known SMBC separation device can be used. Such an SMBC separation device includes a device as described in Japanese Patent Application Laid-Open No. 2006-84457, which includes: an annular flow path connected to an arbitrary connection flow path, and a first section for supplying an eluent to the annular flow path. One flow path is connected to any connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com