Compressed trasmission belt

一种传动带、挤压式的技术,应用在V形带、皮带/链条/齿轮、机械设备等方向,能够解决摩擦力不稳定、刚性低、载荷分布易变得不均匀等问题,达到提高动力传递效率、抑制接触载荷的增大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

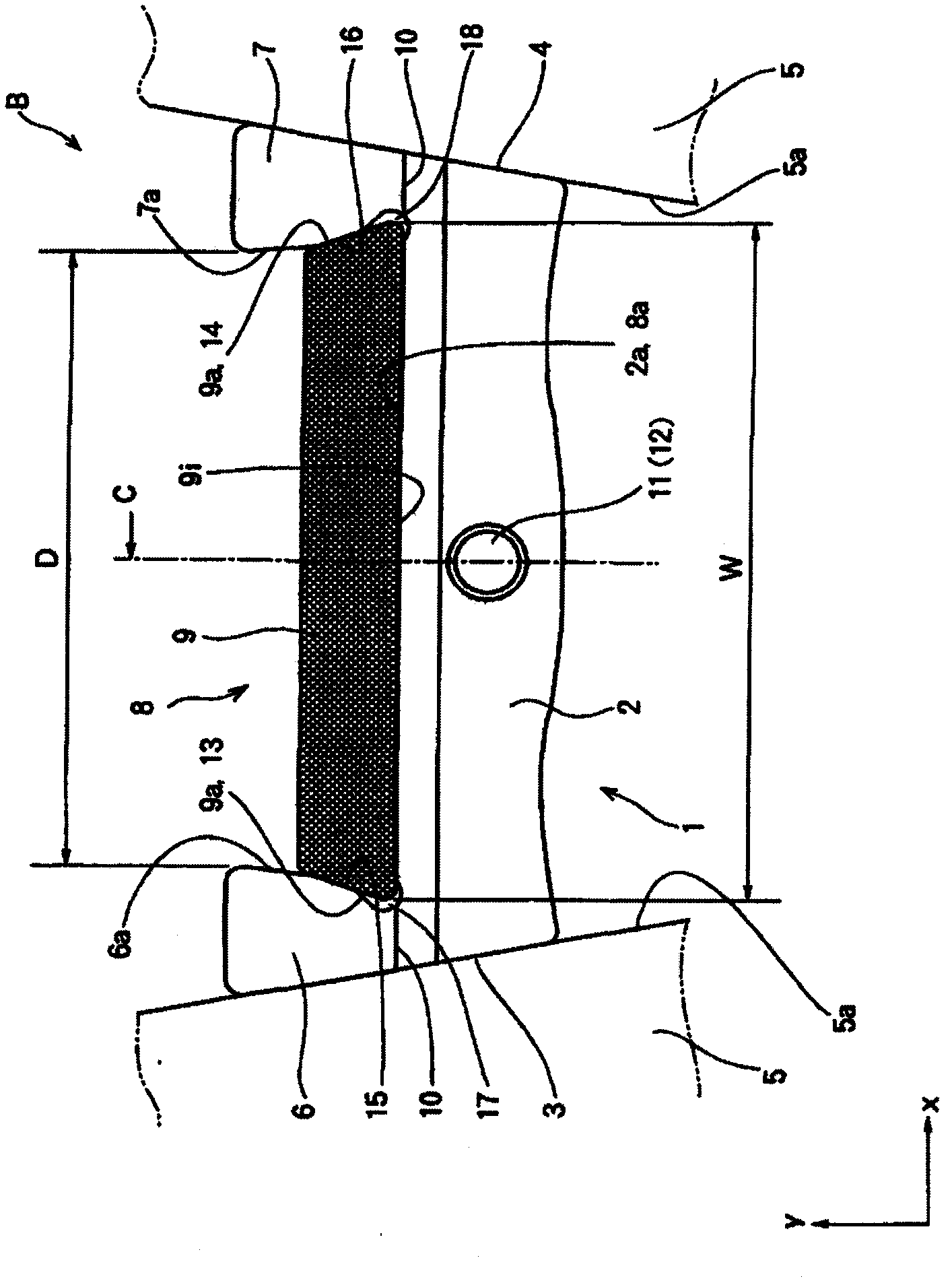

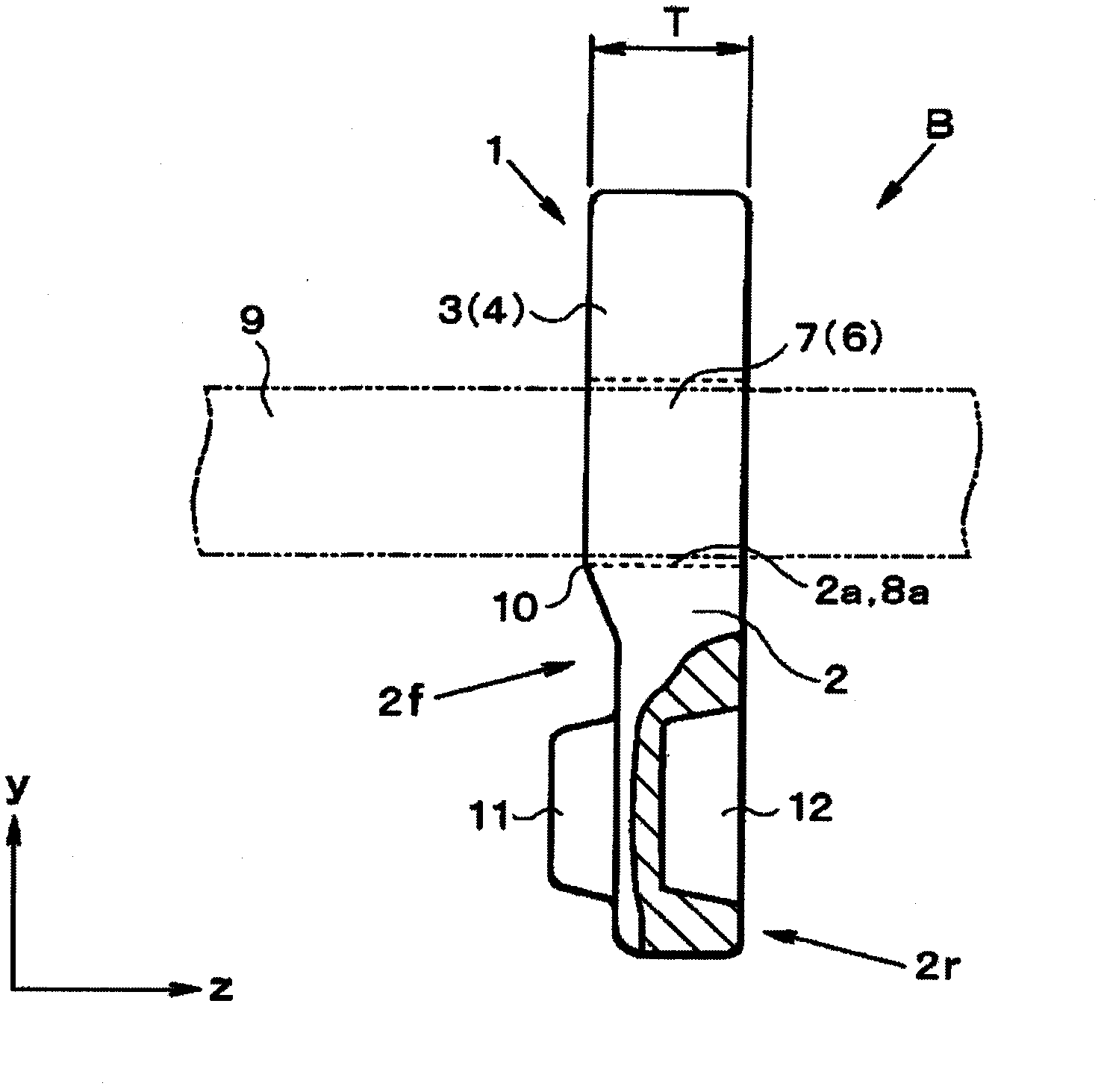

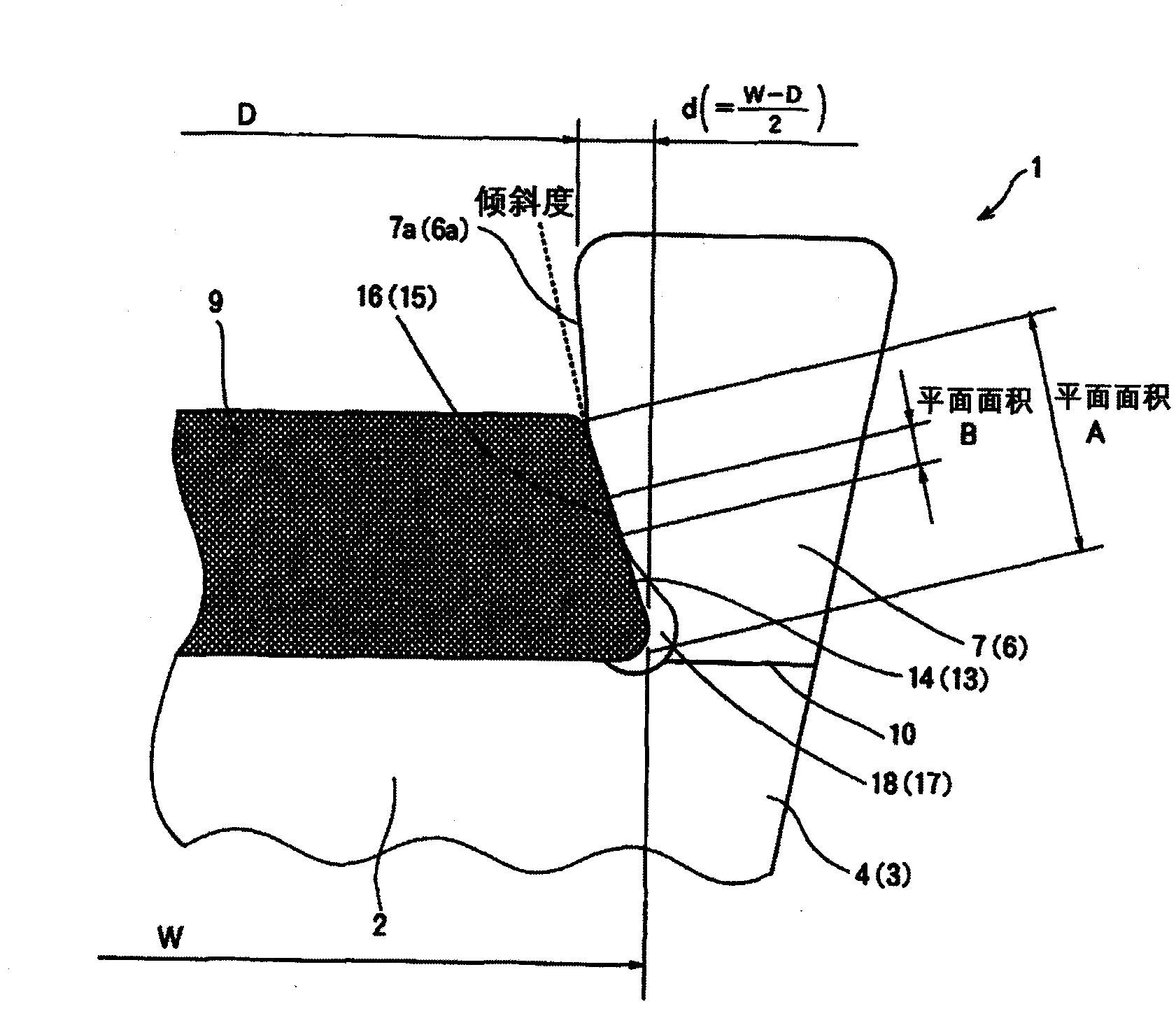

[0030] Next, the present invention will be specifically described with reference to the drawings. First, according to figure 1 , figure 2 The structure of the extrusion belt according to the present invention will be described. exist figure 1 , figure 2 shows an example in which the extruded belt B is, for example, wound around the drive side (input shaft) pulley and the driven side (output shaft) pulley of the belt type continuously variable transmission so that A belt that transmits power between the pulleys. Furthermore, the member 1 in the present invention is constituted by, for example, a metal plate-like member. On the body (base) portion 2 of the member 1, the belt width direction ( figure 1 The left and right side surfaces 3, 4 in the x-axis direction) are formed as tapered inclined surfaces. The tapered side surfaces 3 and 4 are in frictional contact with the belt winding groove (V-shaped groove) 5 a of the pulley 5 to transmit torque.

[0031] On the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com