Cutter frame for machining large end of loose joint

A technology for processing knives and tool holders, which is applied in the field of tool holders, can solve problems such as slow processing speed and poor product sealing function, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

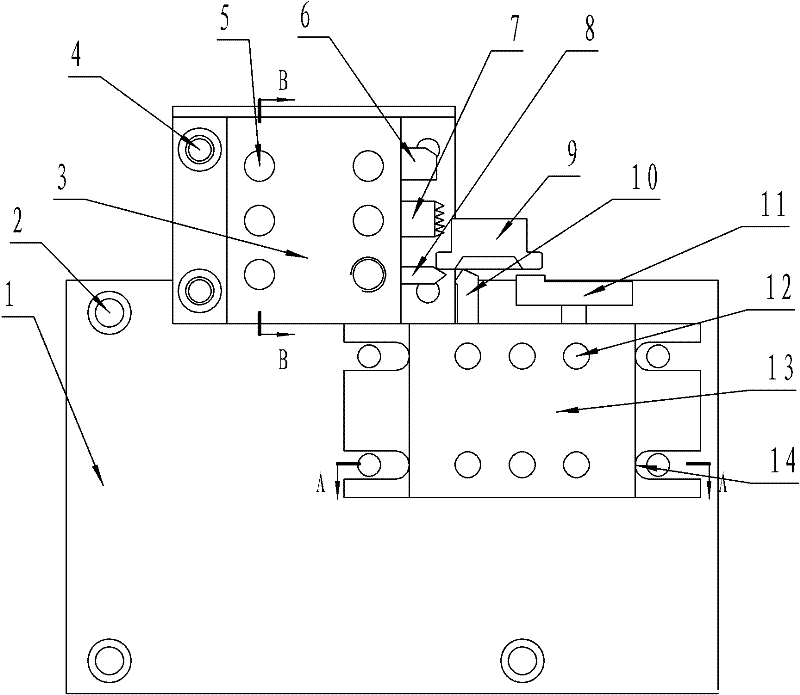

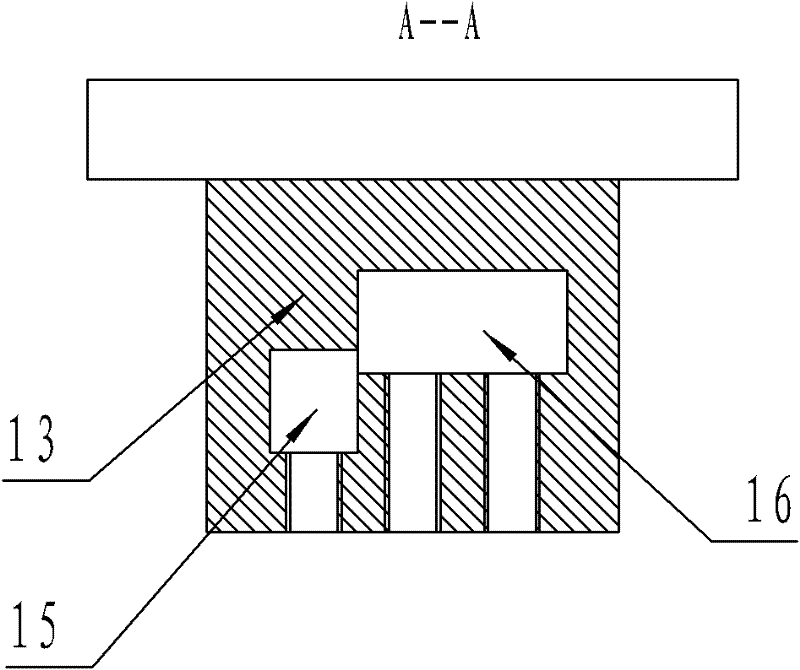

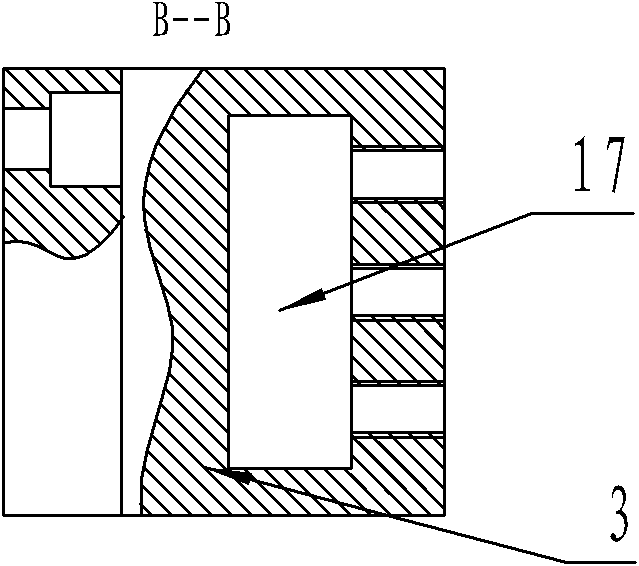

[0014] Embodiment 1, a kind of tool rest of processing live joint big head, its structure is: as figure 1 The convex tool holder bottom plate 1 shown in the figure is equipped with a mutually vertical outer circle processing tool mounting frame 3 and an end surface processing tool mounting frame 13, and the outer circle processing tool mounting frame is fixed on the protrusion of the tool frame bottom plate by the mounting frame fixing bolt 4 , The end face processing tool mounting frame is fixed on the lower right side of the outer circle processing tool mounting frame, and the end face processing tool mounting frame base two ends are provided with mounting frame positioning grooves 14, and fixing bolts are housed in the grooves.

[0015] There is an outer circle machining tool mounting hole 17 in the middle of the outer circle processing tool mounting frame, and a tool fixing bolt 5 is arranged on the top, and a 45 degree partial knife mounting hole 15 and an end face knife m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com