Bead core rack

A bead core and bead apex technology, which is applied in the field of bead core support, can solve the problems of reducing tire uniformity, bead core drop, bead core misalignment or distortion, etc., and achieves suppression of drop and tire uniformity The effect of reducing, suppressing misalignment and distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

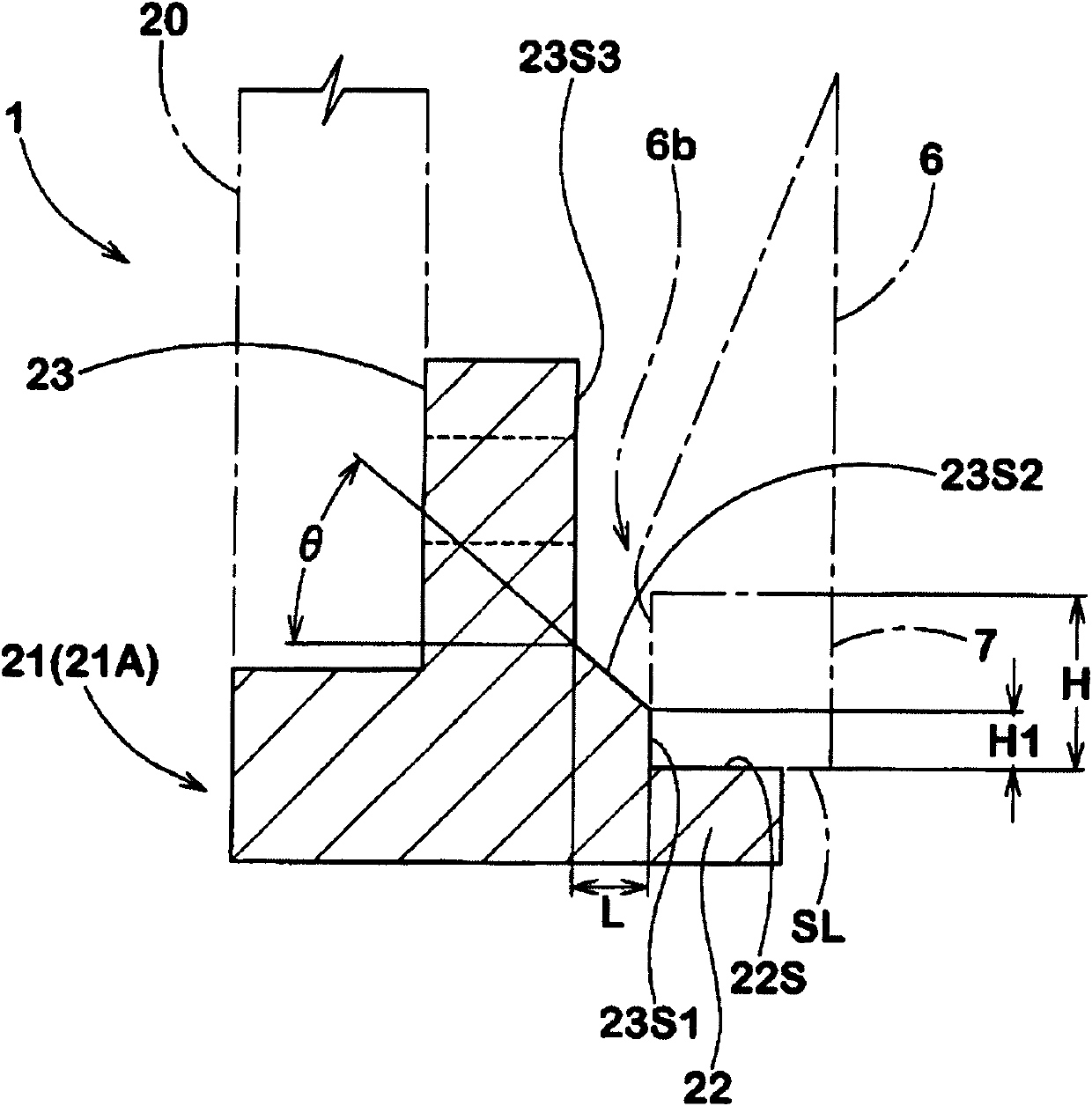

[0048] Next, embodiments of the present invention will be described in detail.

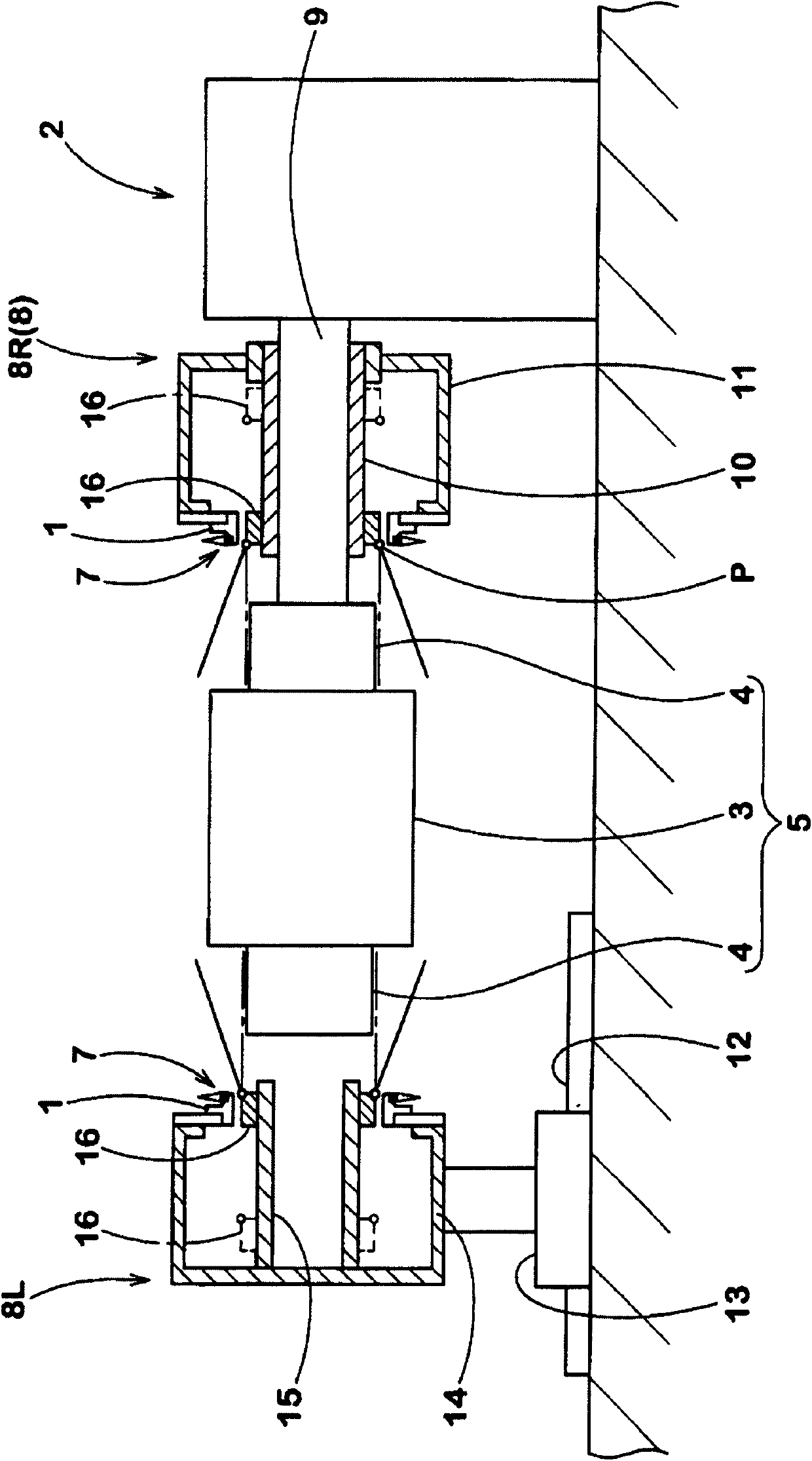

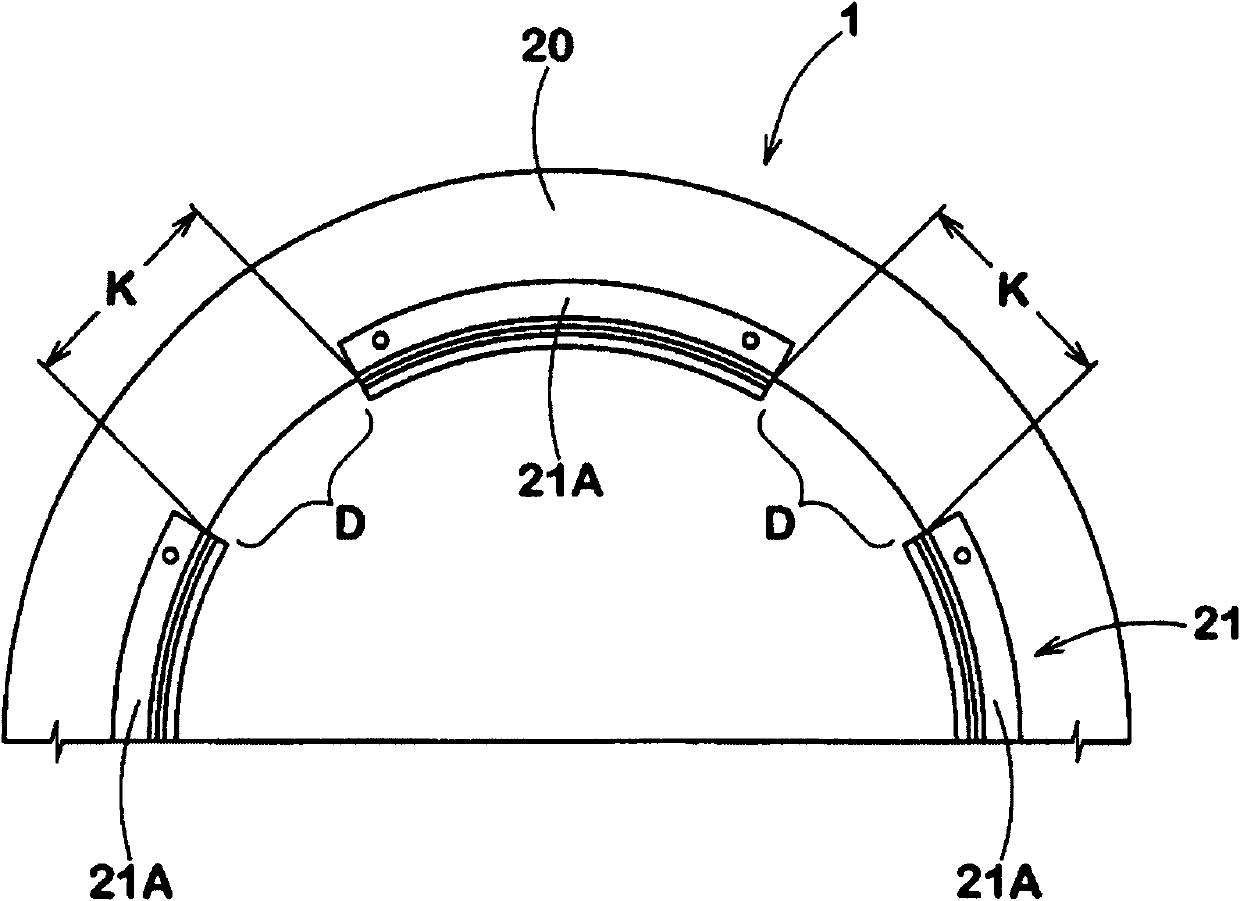

[0049] figure 1 It is a side view showing an example of a green tire building apparatus 2 using the bead core holder 1 of the present invention.

[0050] exist figure 1 Among them, the green tire building device 2 has: a building machine 5, which arranges the drum sub-section 4 with reverse capsule on both sides of the cylindrical drum 3 that can be reduced in diameter; a bead core positioner 8, which There is a bead core holder 1 which places a bead core 7 with bead apex 6 attached on the side of said drum 3 .

[0051] As the molding machine 5, a conventionally known configuration can be used.

[0052] In addition, the bead core positioner 8 is composed of bead core positioners 8R and 8L disposed on one side and the other side of the molding machine 5, and the bead core positioner 8R on one side is supported on the On the support shaft part 9 of the molding machine 5. In this example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com