Traction limiting device used for jacking counter-slope of bridge

A technology of limiting device and jacking, which is applied in the direction of lifting device, bridge, bridge maintenance, etc., can solve the problems of whether the beam gap adjustment is large, broken, and unable to better meet the bridge jacking project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

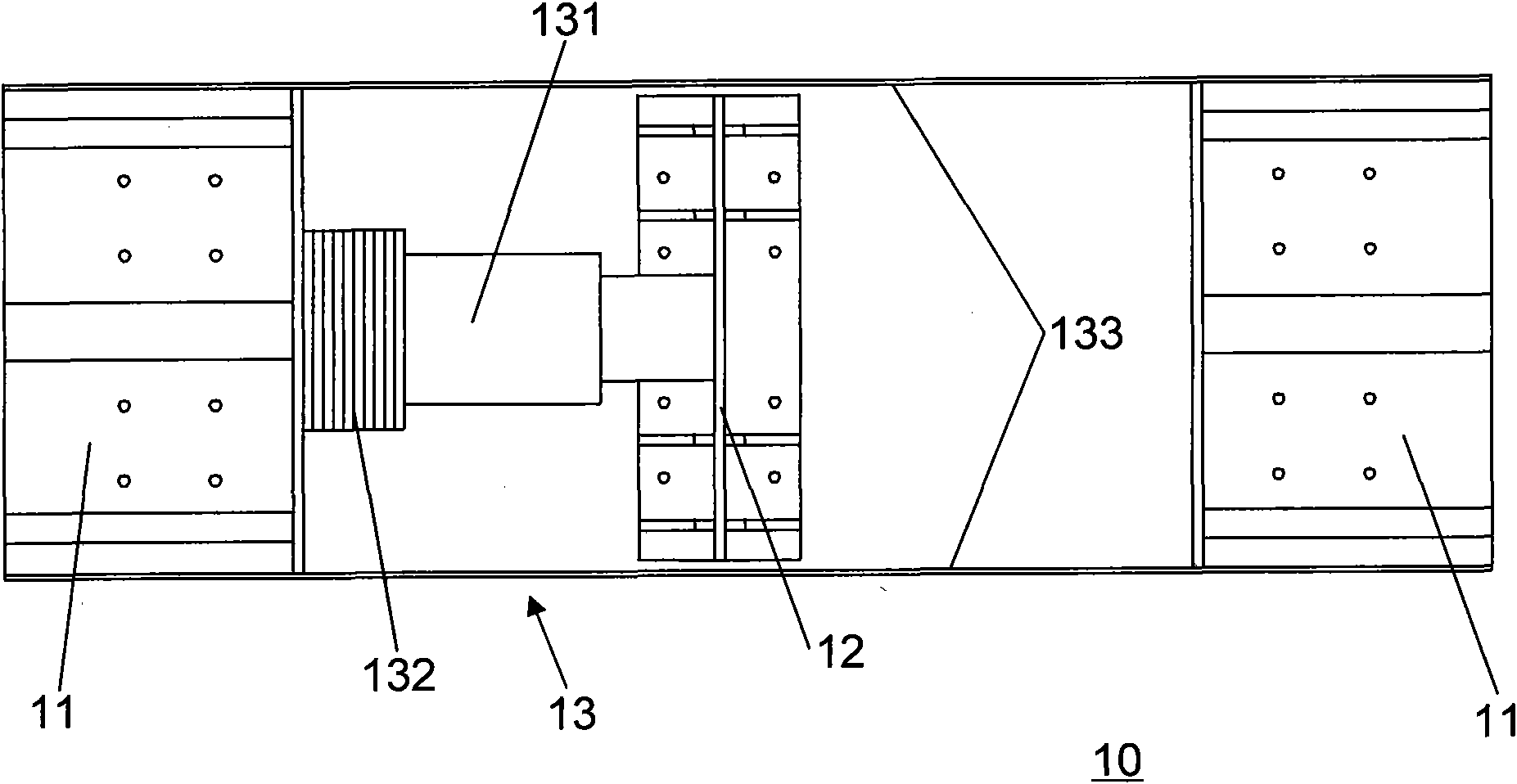

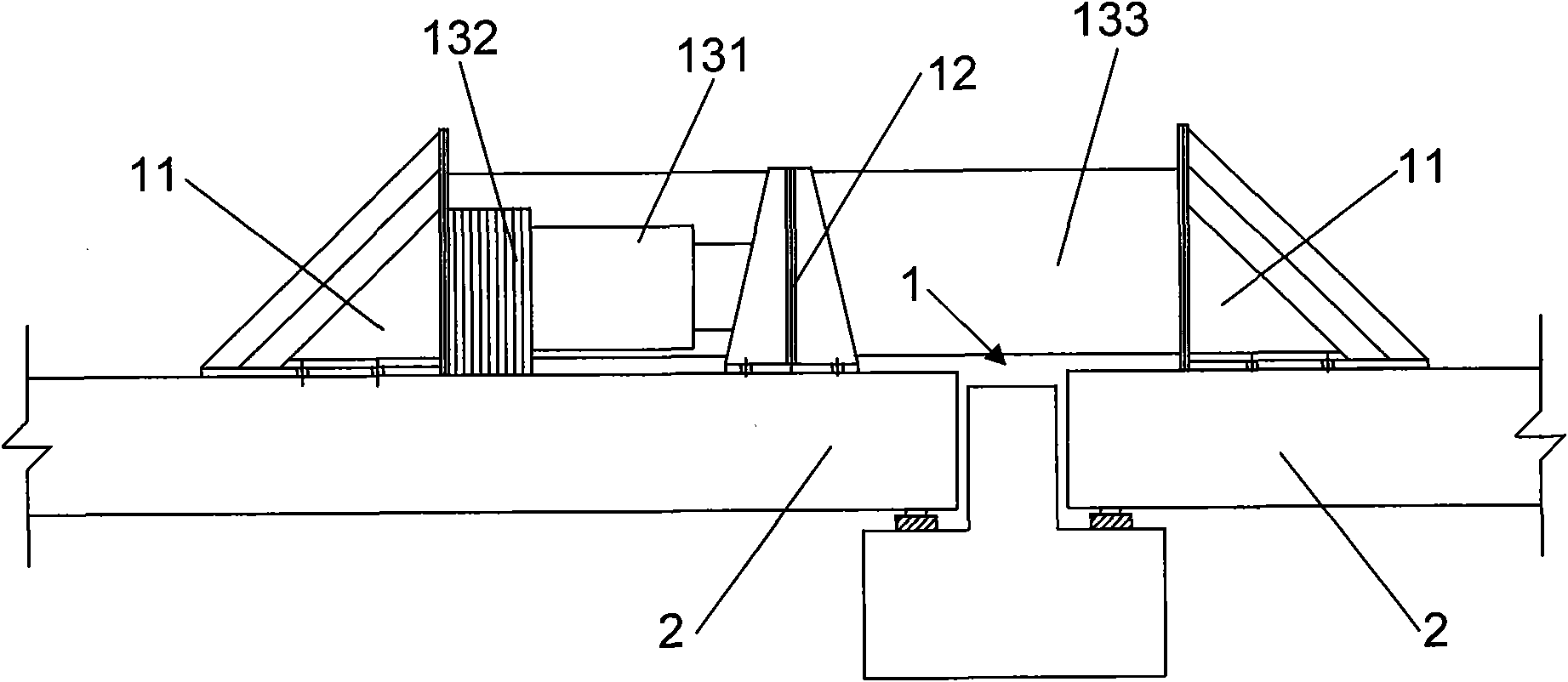

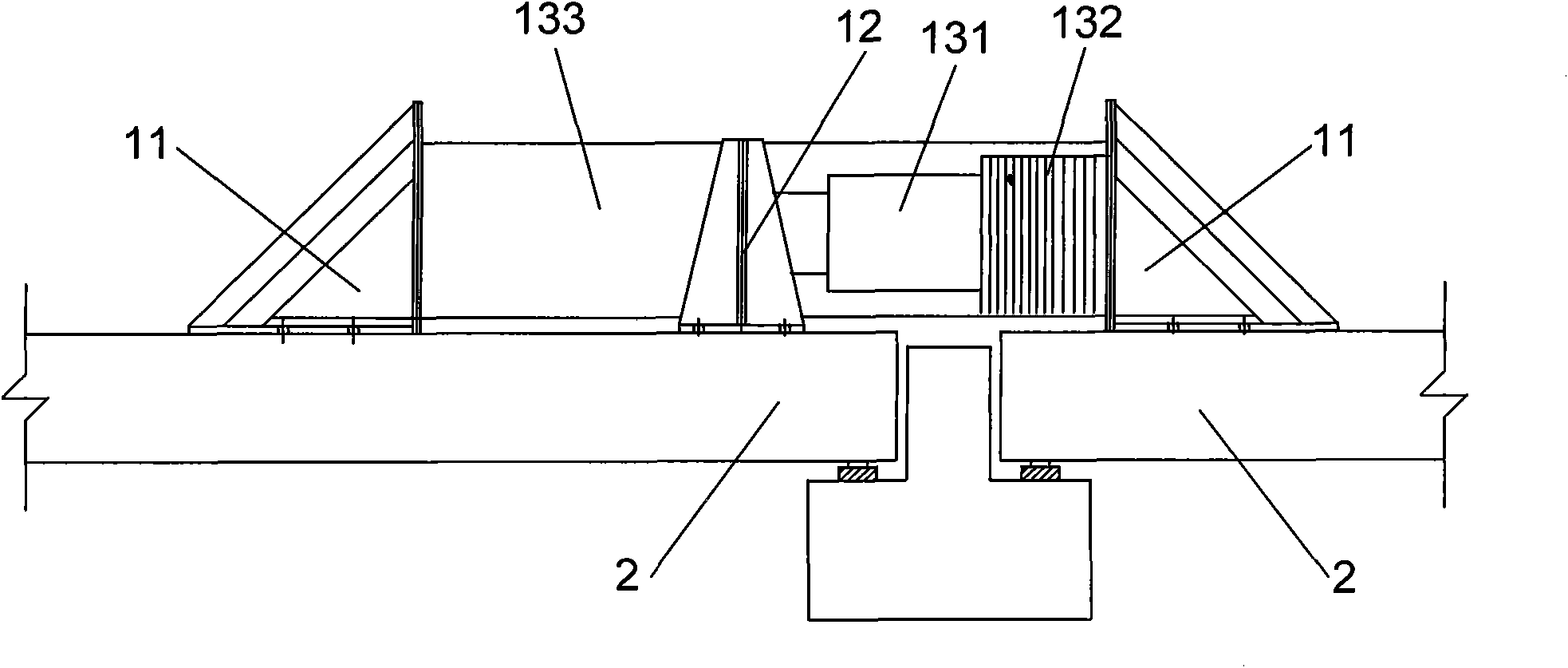

[0014] Please combine Figure 1 ~ Figure 3 As shown, the pulling limiting device 10 for bridge reverse slope jacking of the present invention is located on both sides of the beam gap 1 of the bridge deck, including a pair of reaction force brackets 11, a top plate 12 and a pulling member 13, two The reaction force brackets 11 are respectively placed on the bridge deck on both sides of the beam gap 1, the right side reaction force bracket 11 is fixed to the bridge deck, while the left side reaction force bracket 11 is not fixed to the bridge deck; Between the brackets 11, it is fixed on the same side bridge surface (left side) of the reaction force support 11 that is not fixed with the bridge deck; The above-mentioned pulling part 13 includes a screw jack 131, a backing plate 132 and a pulling plate 133. The screw jack 131 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com