Welding tool capable of increasing qualification rate of chain wheel welding and welding technology using the same

A welding tooling and qualification rate technology, applied in the field of welding process and welding tooling, can solve the problem of low deformation qualification rate of double-row sprockets, and achieve the effects of stable welding process, improved qualification rate, and control of terminal jump and variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

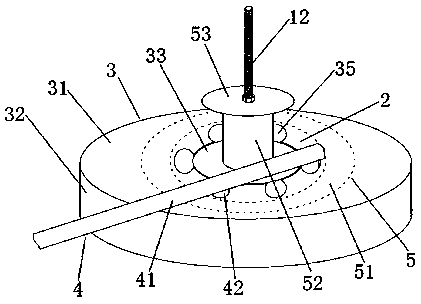

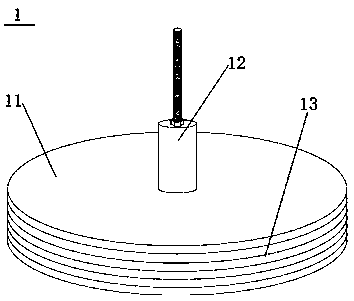

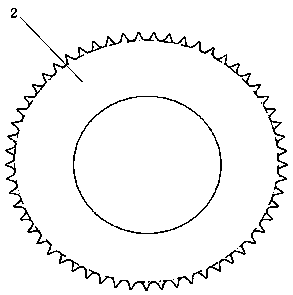

[0028] Please refer to Figure 1 to Figure 6 , the present invention provides a kind of welding frock that improves the qualified rate of sprocket welding, and the welding frock is applied to double-row sprocket 5, such as Image 6 As shown, the double sprocket 5 includes a large chain sheet 51, a wheel hub 52 and a small chain sheet 53; as Figure 1-Figure 4 As shown, the welding tool includes a positioning base 1, a splash guard 2 and a locking pressure plate 3; the positioning base 1 includes a chassis 11 and a positioning rod 12 vertically fixed in the center of the chassis 11, and the side of the chassis 11 is provided with external threads 13, double-row The wheel hub 52 of sprocket wheel 5 is enclosed within on the positioning bar 12, and big chain piece 51 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com