Air inlet manifold for supercharged gasoline engine

A gasoline engine, intake manifold technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing the cost and weight of the whole machine, failure, high low-frequency vibration acceleration, etc., and reduce the local surface height. Frequency vibration speed level, increase the cost and weight of the whole machine, reduce the effect of local vibration acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

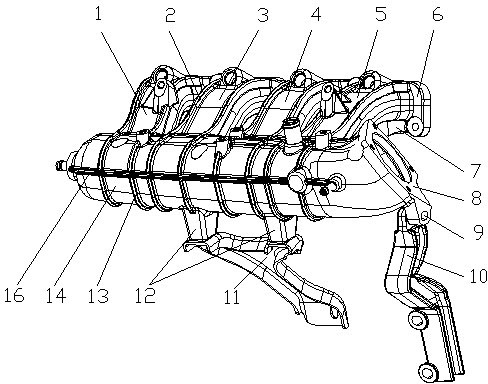

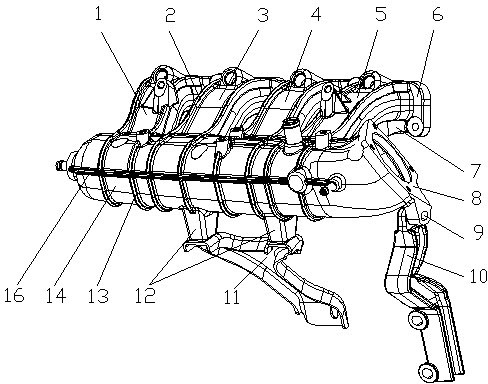

[0012] Below, the present invention will be further described in conjunction with accompanying drawing and example:

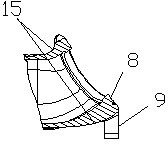

[0013] see figure 1 The shown intake manifold of a turbocharged gasoline engine includes a pressure stabilizing chamber 14 made of aluminum alloy material, an air inlet flange 8 arranged at one end of the stabilizing chamber, and a first air passage communicated with the stabilizing chamber 1. The second air passage 3, the third air passage 4 and the fourth air passage 5, and the cylinder head connecting flange 6 arranged at the mouth of the first air passage, the second air passage, the third air passage and the fourth air passage;

[0014] The bottom of the pressure stabilizing chamber 14 is provided with two first bracket mounting straps 12, and the bottom of the air inlet flange 8 is provided with a second bracket mounting strap 9; the first bracket mounting straps 12 and the second bracket The mounting bracket 9 is connected to the cylinder body through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com