Ball bearing assembly for satellite deployment mechanism

A technology for deploying mechanisms and spherical bearings, applied to bearing components, shafts and bearings, sliding contact bearings, etc., can solve problems such as no explanation or report, no data collected, etc., and achieve the effect of improving functional reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

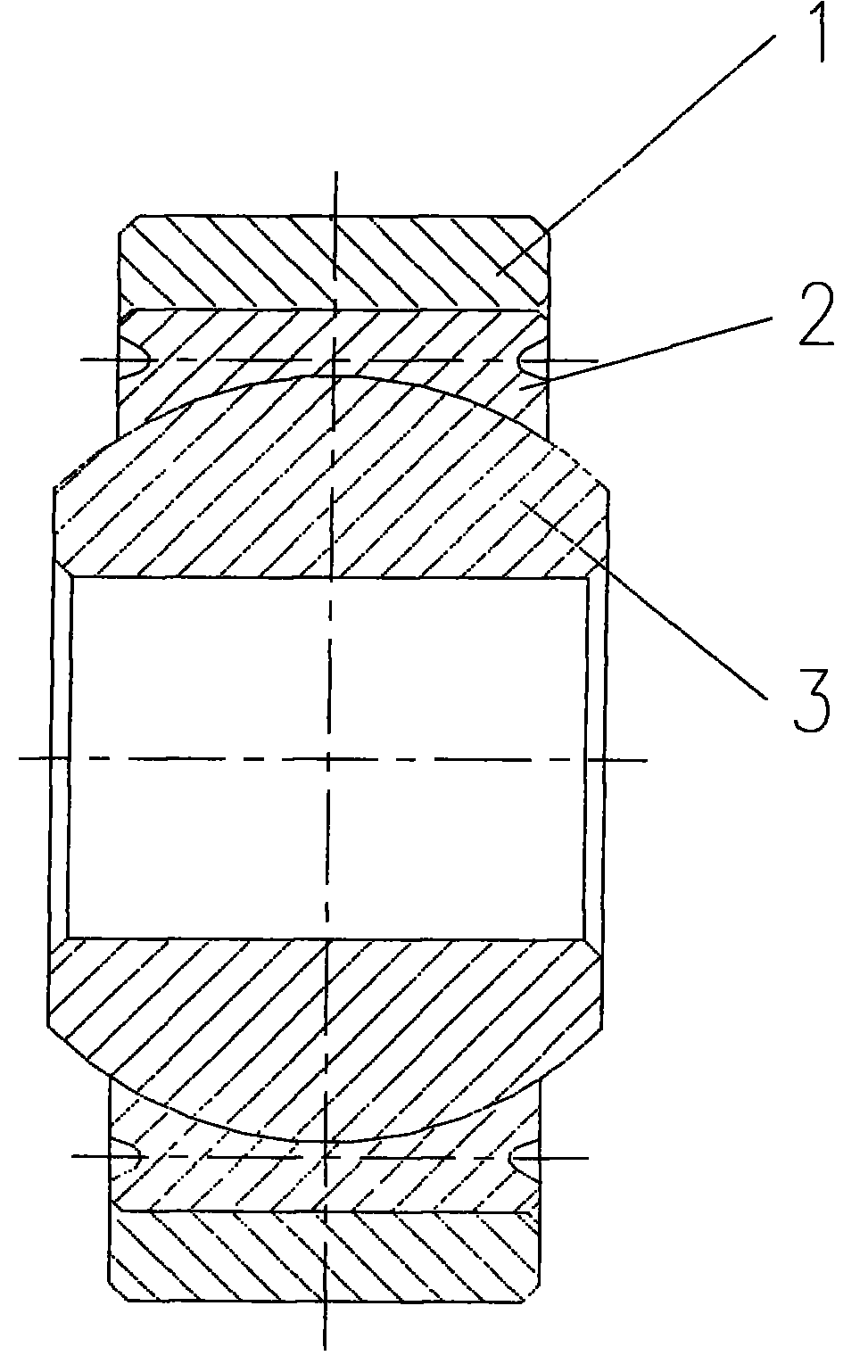

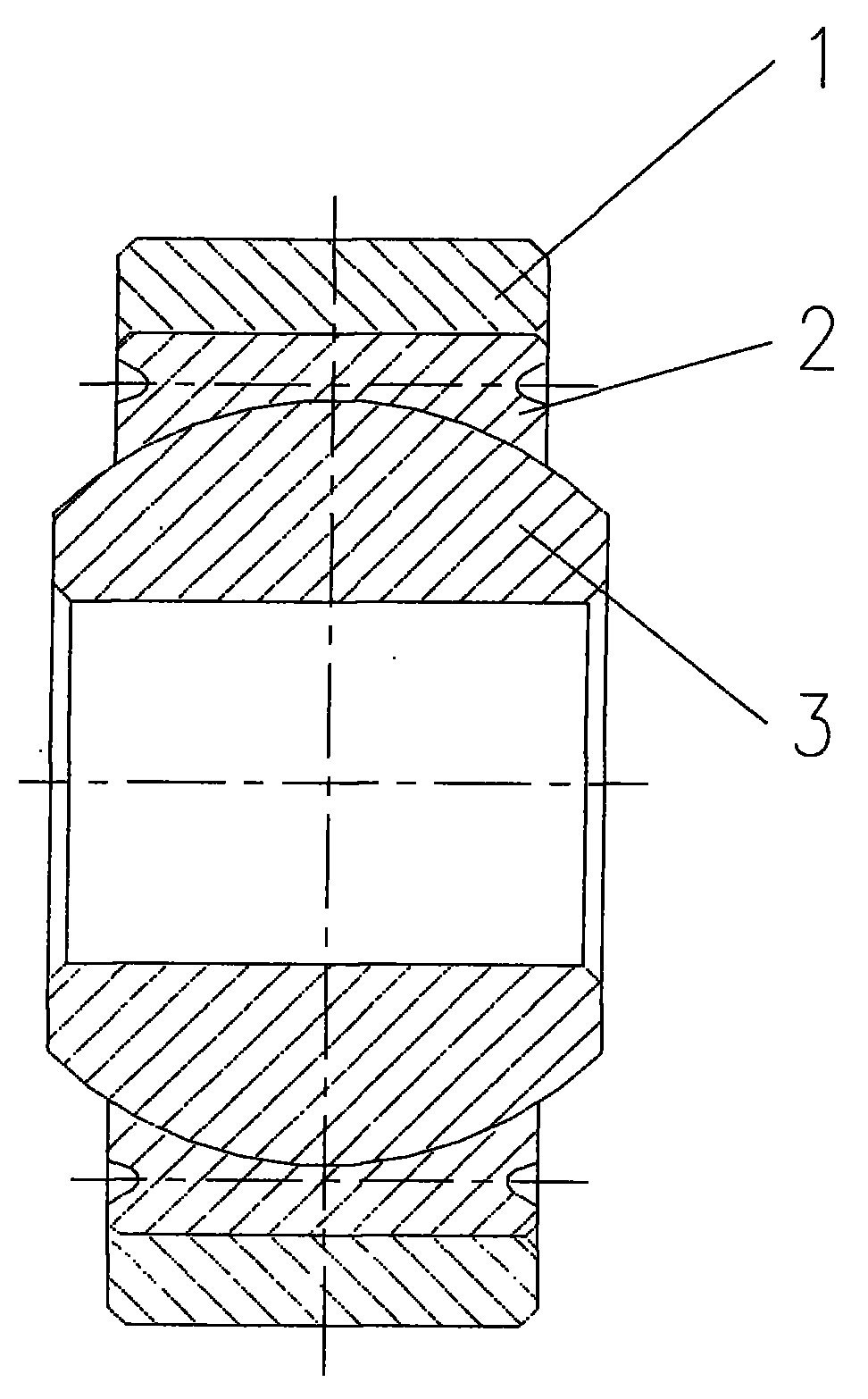

[0015] Accompanying drawing is the structure schematic diagram of the spherical bearing assembly of the satellite deployment mechanism of the present invention, as figure 1 As shown, the device includes:

[0016] Outer ring 1, whose outer surface is coated with high-vacuum solid lubricating film, is connected with the male hinge of the expansion mechanism; middle ring 2; spherical inner ring 3, whose outer surface is coated with high-vacuum solid lubricating film, and is connected with the female hinge of the expansion mechanism. When the unfolding mechanism moves, the outer ring 1 and the middle ring 2 or the middle ring 2 and the spherical inner ring 3 rotate relative to each other.

[0017] The outer ring adopts a ring structure, with an outer diameter of Φ17.984mm and an inner diameter of Φ15mm. The material is made of stainless bearing steel 9Cr1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com