Battery can and alkaline battery

一种电池罐、电极的技术,应用在碱性电池领域,能够解决碱性电池制造成本增加、零部件数量增加等问题,达到提高耐液体泄漏性能、增加制造成本、降低气体发生量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

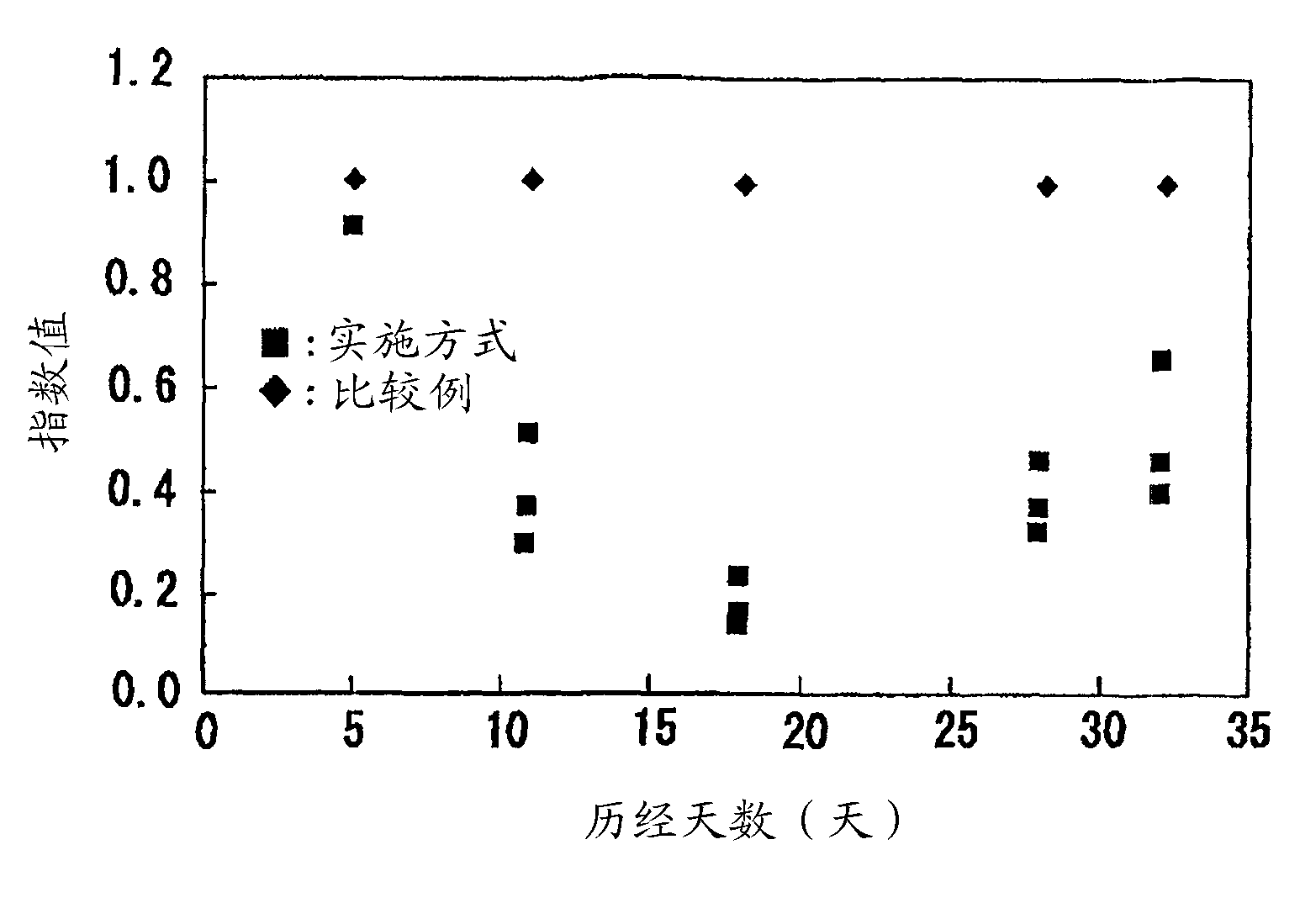

Examples

Embodiment Construction

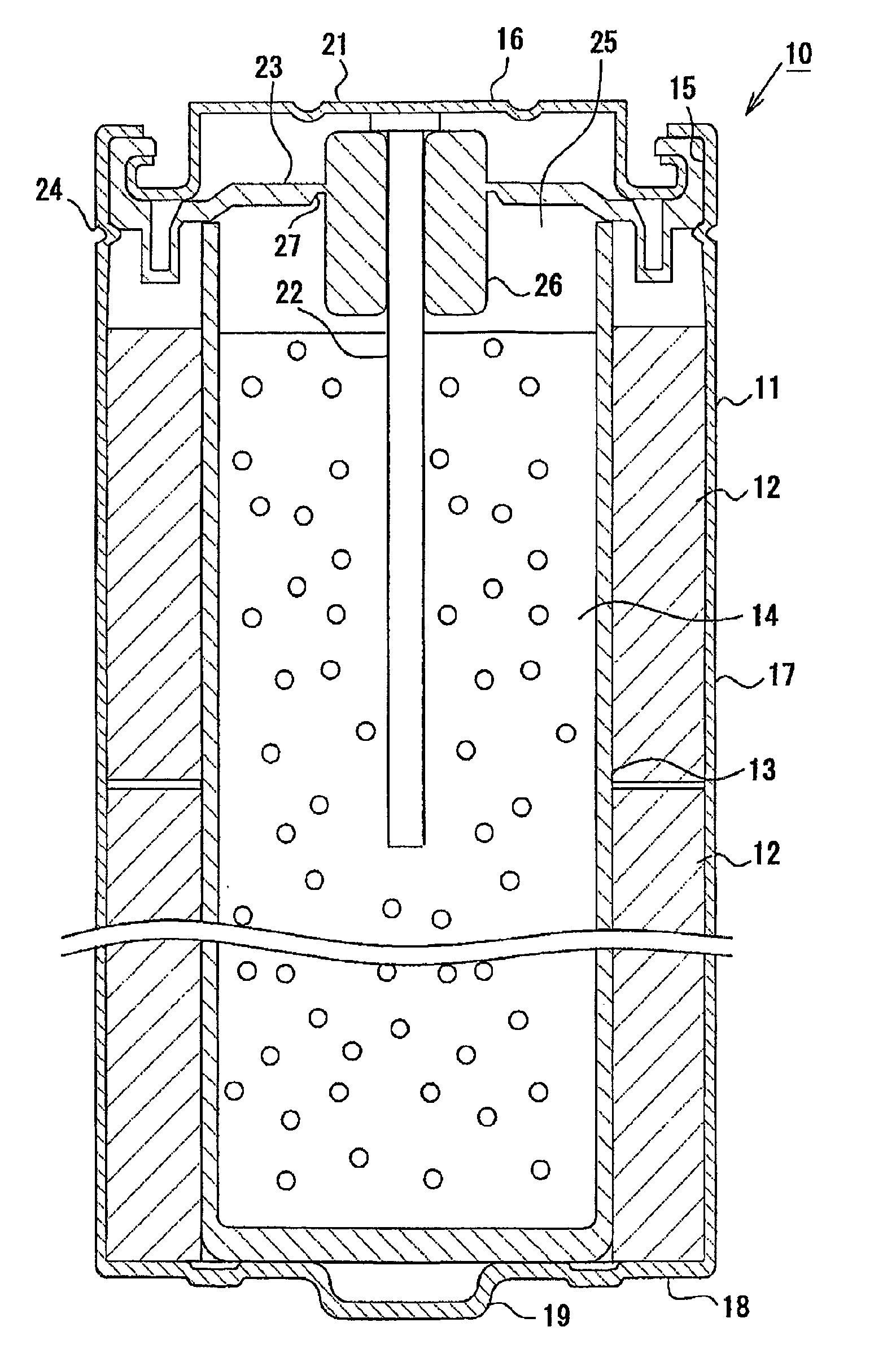

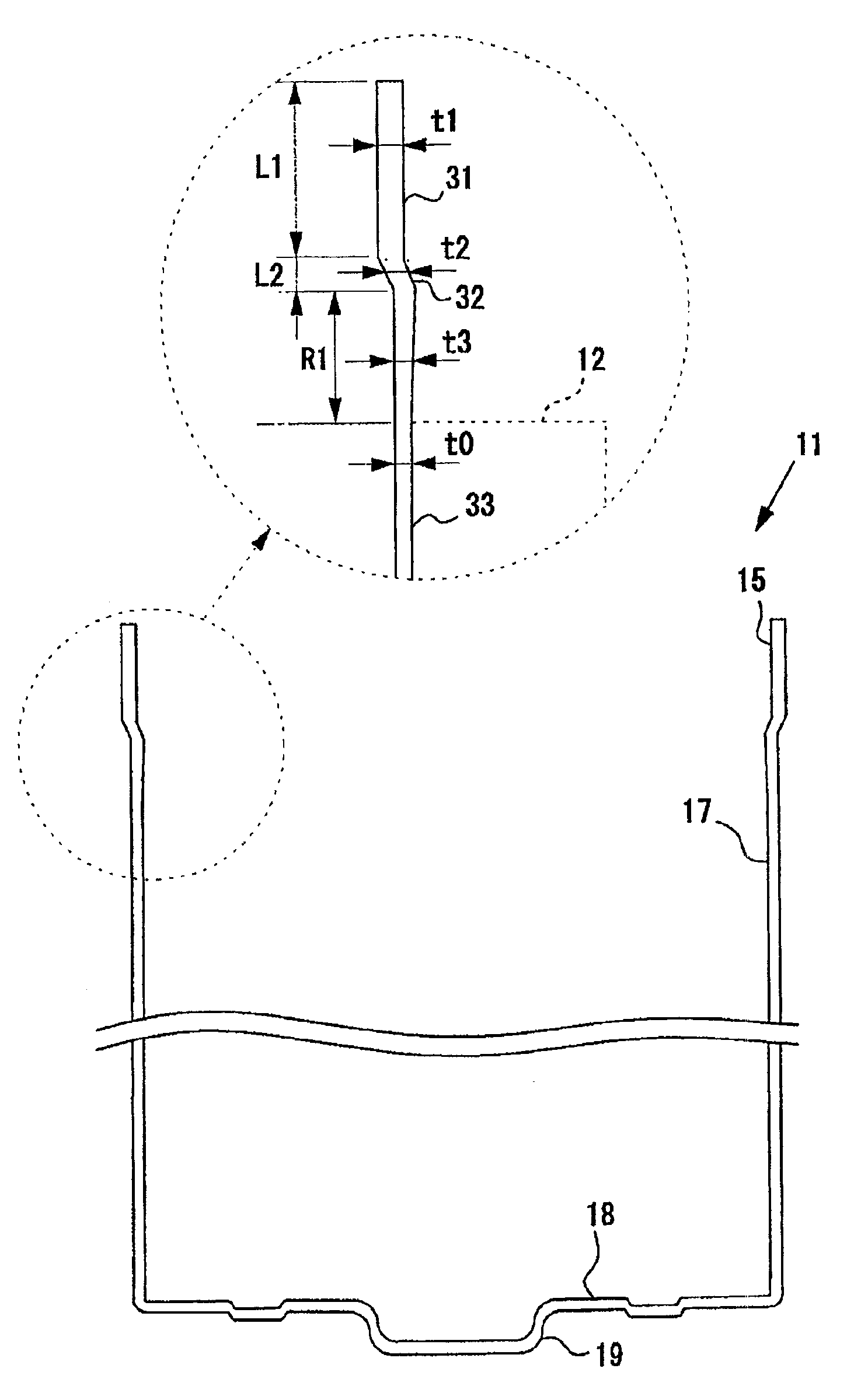

[0032] One embodiment of the invention will be described in detail below based on the drawings. figure 1 It is a cross-sectional view showing a schematic configuration of the alkaline battery 10 of the present embodiment. In addition, the alkaline battery 10 of this embodiment is an LR03 type (size 7) battery.

[0033] Such as figure 1 As shown, the alkaline battery 10 has a bottomed cylindrical positive electrode can 11 (battery can), an annular positive electrode mixture 12 (electrode mixture) embedded along the inner surface of the positive electrode can 11, inserted into the positive electrode mixture 12 The inner bottomed cylindrical separator 13, the gel-like negative electrode mixture 14 arranged in the center of the positive electrode can 11, the hollow part of the separator 13, and the current collector attached to the opening 15 of the positive electrode can 11 16.

[0034] The positive electrode can 11 is a press-worked product made of nickel-plated steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com