Tensioner

A technology of tensioning device and plunger, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems that the tensioning device cannot ensure oil, the number of parts is large, and the structure is complicated, and the structure is simple, The number of parts is simple and the effect of maintaining the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

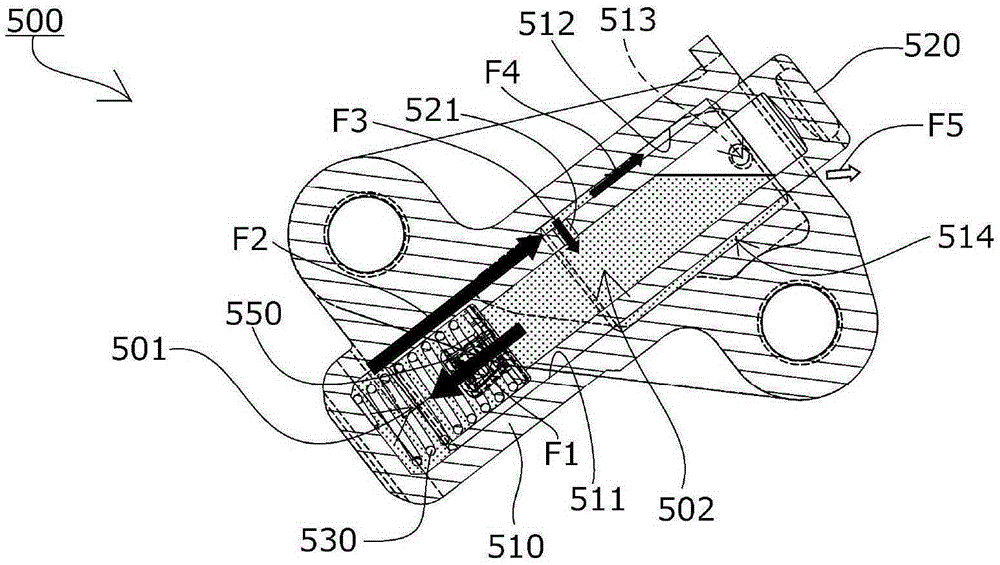

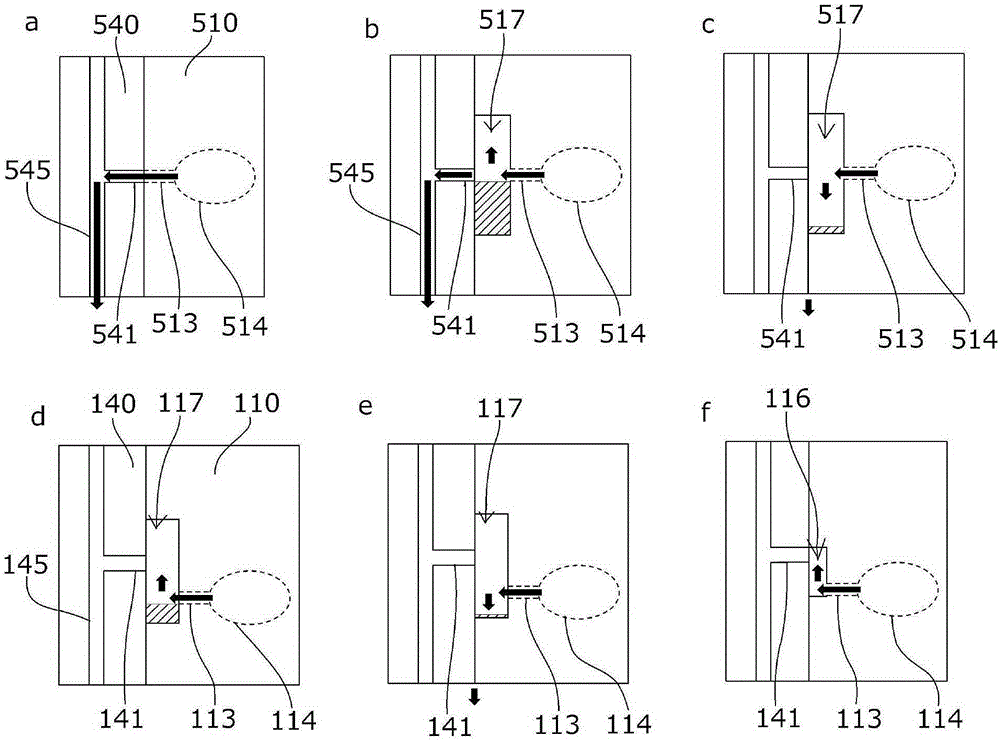

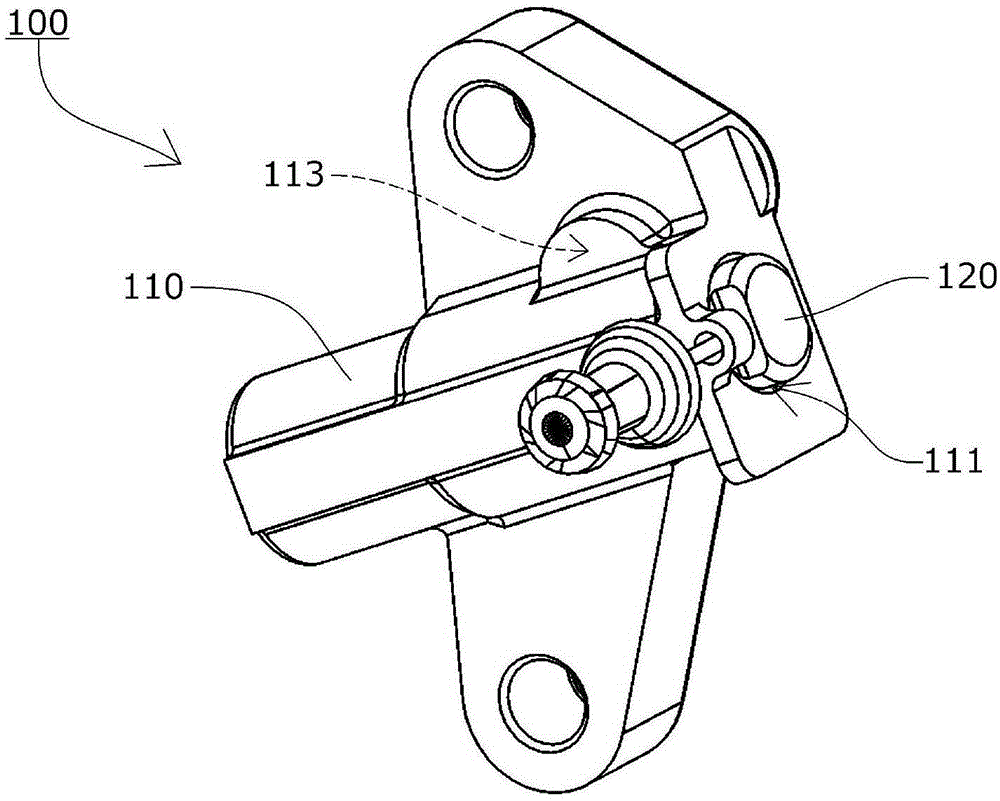

[0059] Such as image 3 , Figure 4 As shown, the tensioner 100 according to one embodiment of the present invention includes: a tensioner body 110 having a cylindrical plunger receiving hole 111 with one side open; a cylindrical plunger 120 slidably inserted into the In the plunger receiving hole 111; and the urging unit, that is, a coil spring, is freely accommodated in the pressure oil chamber formed between the plunger receiving hole 111 and the rear end side of the plunger 120, and faces the plunger in the protruding direction. apply force.

[0060] The inside of the tensioner main body 110 and the structure of the plunger 120 are the same as those of the aforementioned tensioner 500 except for the position of the main body supply hole 113 .

[0061] The main body supply hole 113 is provided more upward than the region where the plunger receiving hole 111 is projected on the wall surface in the horizontal direction, and is provided so as to communicate with an internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com